E87010-A0095-T003-A4-87DU

Siemens Industry, Inc. 3617 Parkway Ln., Peachtree Corners, GA 30092

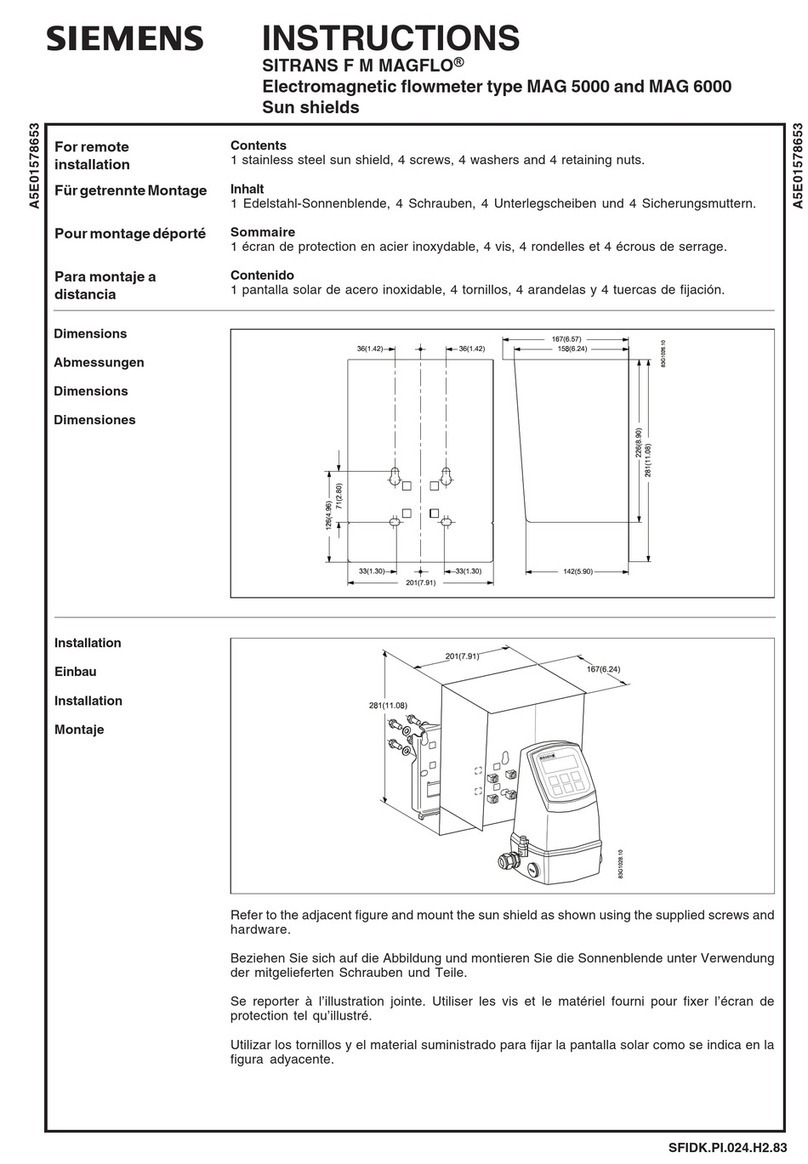

Installation (Figure 1)

1. Remove the enclosure cover from the case.

2. Remove the knockout in the cover.

3. Mount pilot device support bracket assembly with two

mounting screws in location A (Size 1) or B (Size 2 and 3),

tighten screws to 25 lb.-in.

4. For pushbutton 3-wire control, make electrical connections

per Figure 2.

5. For the 2 and 3 position selector switches, make electrical

connections as shown in Figures 3, 4, 5, and 6.

6. Location of auxiliary interlocks may differ from diagrams,

therefore, markings on units should be followed.

7. Affix the appropriate legend label onto the cover next to the

pilot device.

Important! Prior to performing steps 1 through 13 verify that

all power is turned off to the pump control panel.

1. Examine each device on the panel for shipping damage and if

any is noted, notify carrier for claim. Do not apply power to

any damaged device.

2. Operate disconnect switch or circuit breaker with external

handle to verify operation.

3. Manually operate magnetic starter contactor to determine that

moving parts do not bind. Manual operation of the contactor

is performed by pressing on the movable contact assembly as

shown in Figure 1 for Class 87 and Figure 2 for 3RE48.

4. Verify that the supply voltage matches the voltage rating of the

pump panel.

5. Verify that the horsepower rating of the motor does not exceed

the horsepower rating of the pump control panel and the current

rating of the motor is within the adjustable range of the overload

relay. Set the FLA dial on the overload relay to the motor FLA.

Make sure the DIP switches are set to trip class 10 for pumping

applications. Refer to the overload elay instruction sheet

for details.

6. Install in conformance with National Electric Code – NFPA70

in the US or Canadian Electrical Code – CSA C22.1 in Canada,

and any applicable local electric codes.

7. Install the proper size dual element fuses in the disconnect

switch. The disconnect switch and fuse load block will accept

Class H, K, J or R fuses depending on the fuse holder. If the

available fault current of the supply is greater than 10kA, Class

R or J fuses must be used. Verify the available fault current of

supply does not exceed the interrupting rating of the fuses in

stalled and does not exceed the short circuit rating of the

pump panel controller.

8. If the pump controller includes an instantaneous trip breaker,

adjust the trip setting of the breaker according to the instruction

on the door label. Verify the available fault current of the

supply does not exceed the short circuit current rating of the

pump controller.

9. Firmly fasten enclosure to solid mounting surface with customer

supplied fasteners.

10. Install necessary grounding means and wire pump control panel

in accordance with wiring diagram supplied. Conduits installed

in knockouts at the bottom of the enclosure must be located

below all live parts. Conduit hubs or fittings installed on the top

or side walls of the enclosure must have a NEMA 3R rating.

Press Movable

Contact Assembly

here

Press Movable

Contact Assembly

here

Figure 1

Figure 2

11. Check that all wiring is secure and does not interfere with

proper operation of any devices.

12. Check that all wiring connections are tight, including

factory connections.

13. Make a final installation check of steps 1 through 12 and

remove any foreign material from the enclosure.

A5E31166437A-004

Installation of Class 87 and 3RE48 Pump Panels

Hazardous voltage.

Can cause death, serious personal injury, or

property damage.

Disconnect power before working on this equipment.

WARNING