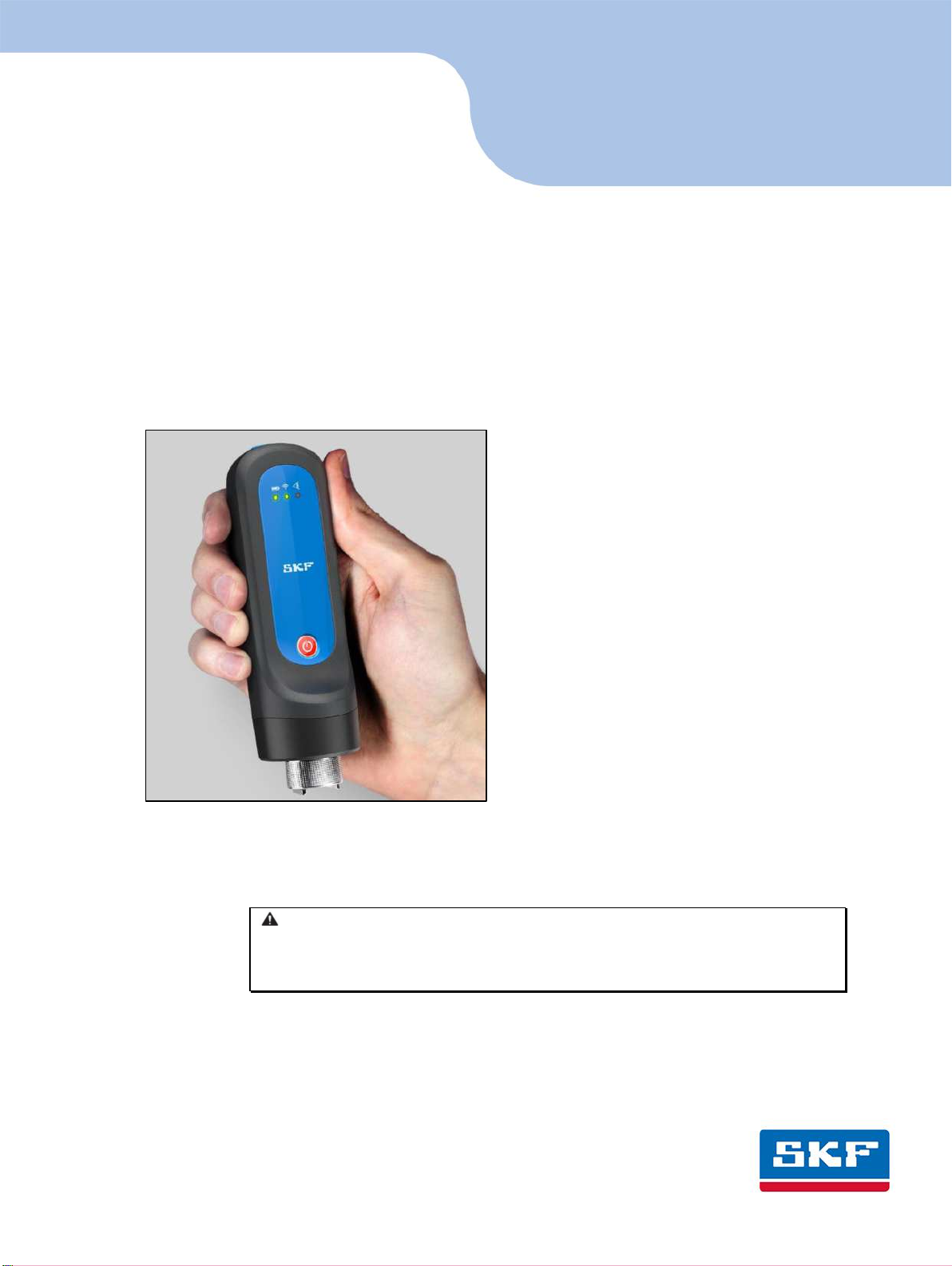

QuickCollect CMDT 391 / CMDT 391-Ex 1 - 1

User Manual –Revision B

1

Introduction

Safety Messages

WARNING! Your safety is extremely important. Read and follow all warnings in

this document before handling and operating the equipment. Failure to observe

the safety warnings may result in personal injury and/or damage to the

equipment and data loss.

WARNING! - Warning messages are used to highlight an operating procedure, practice,

condition or statement that must be strictly observed to prevent equipment damage or

destruction, or corruption to or loss of data.

IMPORTANT: Important messages means that there is a risk of product or property

damage if the instruction is not heeded.

Personnel Safety

Dress properly. Do not wear loose clothing or jewellery. Keep hair, clothing and gloves

away from moving parts.

Do not overreach, always maintain proper footing and balance when placing or

retrieving the sensor.

Use safety equipment. Always wear eye protection. Non-slip safety shoes, hard hat and

hearing protection must be used in the appropriate settings.

Do not repair or adjust energised equipment alone, under any circumstances. Someone

capable of providing first aid must always be present for your safety.

Persons working on or near high-voltage equipment should be familiar with approved

industrial first-aid methods.

Never open or work on energised electrical systems unless authorised by a responsible

authority. Energised electrical systems are dangerous and electric shocks from energised

systems can be fatal. Always ensure that the necessary permission or permit to work has

been obtained before commencing any work.

Always obtain first aid or medical attention immediately after sustaining an injury. Never

neglect an injury, no matter how superficial it initially seems.

Device Safety

If the sensor has been dropped, check for damage before using. Sensors must only be

serviced by qualified SKF repair personnel.

Use only accessories recommended or provided by SKF or the manufacturer. The

magnet must only be attached by hand, no mechanical advantage is to be used. Be

aware that the use of excessive torque when attaching the magnet can damage the

sensor. The recommended torque is 2.9 Nm.