Explanation of signal

words for safety

NOTE

Emphasizes useful hints and

recommendations as well as

information to prevent property damage

and ensure efficient trouble-free

operation.

CAUTION

Indicates a dangerous situation that can

lead to light personal injury if

precautionary measures are ignored.

WARNING

Indicates a dangerous situation that

could lead to death or serious injury if

precautionary measures are ignored.

DANGER

Indicates a dangerous situation that will

lead to death or serious injury if

precautionary measures are ignored.

Safety

Read and carefully observe these installation

instructions before installing/operating/

troubleshooting assembly. Assembly must

be installed, maintained and repaired exclu-

sively by persons familiar with instructions.

Install assembly only after safety instruc-

tions and this guide have been read and are

completely understood.

Adequate personal protection must be

used to prevent splashing of material on skin

or in eyes.

Always disconnect power source (electri-

city, air or hydraulic) from pump when it is

not being used.

Equipment generates very high grease

pressure. Extreme caution should be used

when operating this equipment as material

leaks from loose or ruptured components

can inject fluid through skin and into body. If

any fluid appears to penetrate skin, seek

attention from a doctor immediately.

Do not treat injury as a simple cut. Tell

attending doctor exactly what type of fluid

was injected.

Any other use not in accordance with

instructions will result in loss of claim for

warranty or liability.

• Do not misuse, over-pressurize, modify

parts, use incompatible chemicals, fluids,

or use worn and/or damaged parts.

• Incorrect use may result in damage

to equipment caused by over or

under lurication.

• Do not exceed stated maximum

working pressure of pump or of lowest

rated component in your system.

• Always read and follow fluid manufactur-

er’s recommendations regarding fluid

compatibility, and use of protective

clothing and equipment.

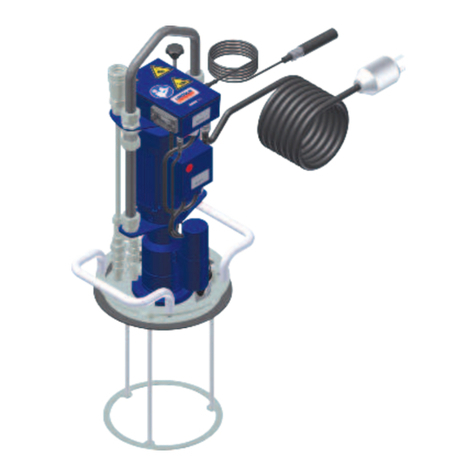

• Pump should be mounted vertically

upright only.

• Install components of PS pump so

operator can always see low–level position

of pump reservoir.

• Each time reservoir has been refilled,

make sure pump is pumping lubricant.

• Failure to comply may result in personal

injury and/or damage to equipment.

Exclusion of liability

Manufacturer of PS pump will not accept

any liability for damages caused by:

• Lack of lubricant due to irregular refilling

of pump.

• Use of contaminated lubricants.

• Use of greases that are not or only

conditionally pumpable by PS pump.

• Inadequate disposal of used or contami-

nated lubricants and components that

have been in touch with lubricant.

• Unauthorized modification of system

components.

• Use of unapproved parts.

• Operation without adhering to minimum

pause time and respectively maximum

lubrication time († Table , page ).

Regulations for

prevention of

accidents

To prevent accidents, observe all city, state

and federal safety regulations of country

where product will be used.