SKYLUX Cintralux Alu EP 10/10 User manual

BARREL VAULTS

Cintralux Alu EP 10/10

Mounting instructions

EN

Art.N° 43984

E_MH_Mounting_instructions_Skylux_Cintralux_Alu_EP10-10 01/09/2020

2/18

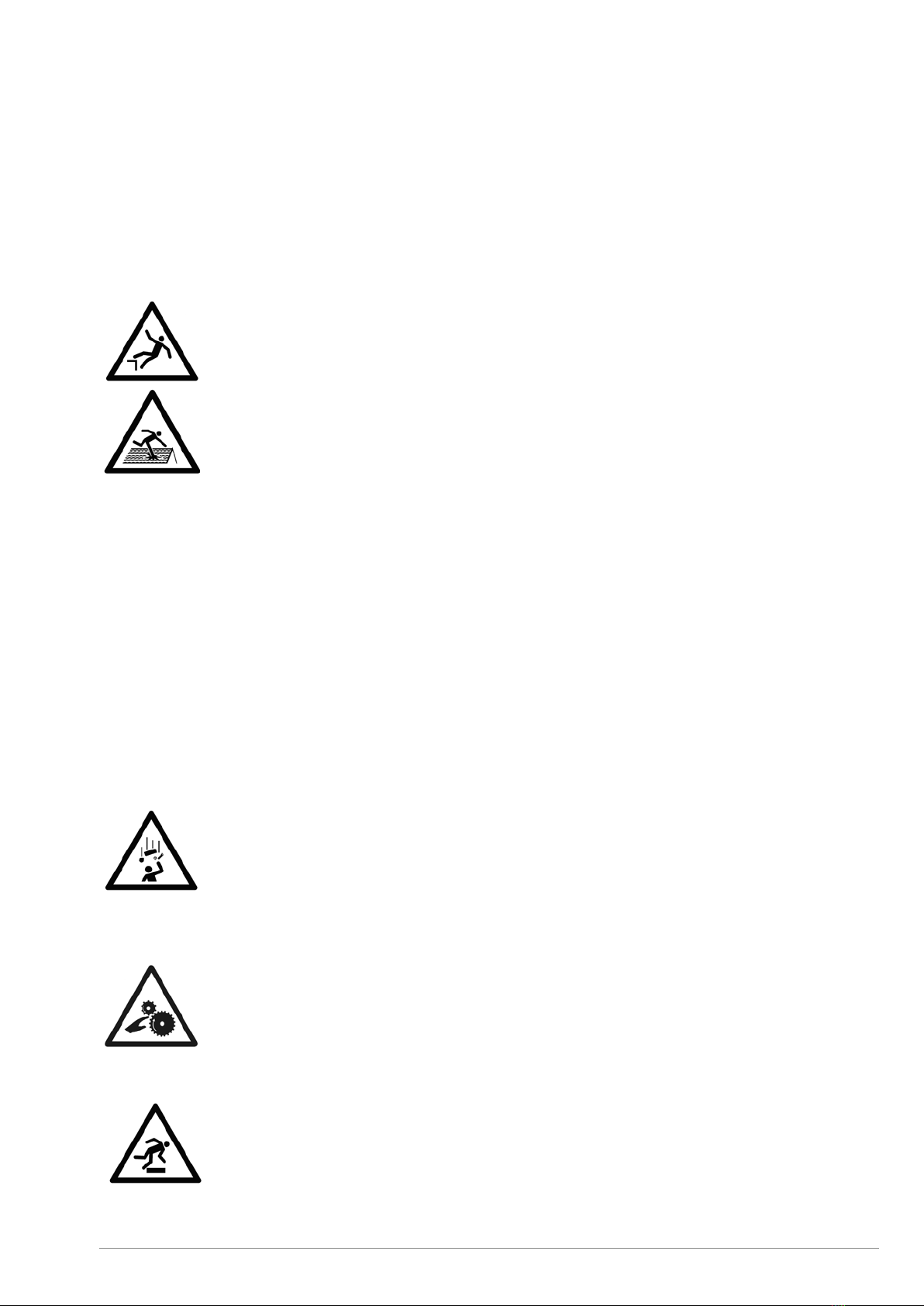

Safety

Take the necessary and required safety precautions, such as safety nets and lifelines when installing from the

outside, safety goggles, gloves, hard hat, etc.

Do not step on the glass.

Falling from height

• When using ladders to go on the roof:

- Ladder in good condition?

- Set up correctly at an angle of 75°?

- Secured below and on top against moving?

- Don’t take heavy material with you on the ladder (3-point contact rule)! If possible,

use a crane to lift the material.

• Do not lift material over the roof edge; use a crane to put the material on the roof.

• Roof zone: make sure the part of the roof where the skylight/barrel vault will be installed is

safe enough, e.g. secure the edge (support system in the roof gutter that supports against the

outer wall of the building, with suitable A B C category depending on the roof pitch) or use a

scaffold so no one can fall off the roof. If the roof is not safe enough, always use a harness with

lifeline (adapted to the fall height), attached to a suitable attachment point.

•Make sure the roof is stable and does not have dangerous openings or insufficient secure parts

(e.g. corrugated sheets, …). Take the necessary measures if this is not the case: strengthen,

use suitable safety nets below the danger zones, …

• Before making the roof opening for the skylight/barrel vault: make sure there are safety nets

conform to the current legislation. The nets must be attached firmly and sufficiently to the

building.

•When using an aerial work platform: always wear and secure your harness (mandatory)! Leaving

the cage is forbidden.

• Never walk backwards on a roof, always walk forwards.

• Make sure there’s enough light in the working zone.

Low-hanging obstacles and falling loads

• Forbidden to walk under or within a radius of 1 m of a hanging or lifted load.

• Demarcate the danger zone below the skylight/barrel vault, in the building as well as on the

outside near the outer walls (in case material slides off the roof). If the zone is demarcated,

people cannot be hit by any falling loads. It’s prohibited to enter these danger zones during

construction.

Crushing hazard

• All working tools are in good condition, provided with a valid CE label and all necessary safety

regulations. These cannot be removed.

• People who use these working tools are educated for this purpose. Protections are always

present on all working tools. They are in good condition and need to be set correctly.

Tripping/falling

•Safety is key and it begins with order and tidiness. Clean everything immediately, leave nothing

lying around.

• Trash needs to be sorted.

• Be cautious with electric cables (danger of tripping/falling). Never walk backwards!

• Make sure there’s enough light in the working zone.

01/09/2020 3/18

E_MH_Mounting_instructions_Skylux_Cintralux_Alu_EP10-10

Sharp objects

• Make sure your fingers/hands are not pinched and watch out for cuts while handling skylights

or barrel vaults.

• Be careful where you put your hands during the installation.

• Wearing cut-resistant gloves is mandatory.

Ergonomics

• Always lift loads correctly: bend your knees, move your feet instead of forcing your spine, lift

as close to your body as possible.

• Parts of more than 25 kg must be lifted with at least 2 persons.

Personal protective equipment

• Work clothes, safety shoes and helmet are mandatory for everyone.

• Lifeline and harness are mandatory if the edge is not secured enough or if there are no safety nets below the

roof opening. They are also necessary when using an aerial working platform.

• Use gloves when handling skylight or barrel vault parts.

• Safety glasses and hearing protection are mandatory when using saws / grinders.

Always perform a Last Minute Risc Analysis!

If in doubt: STOP! Do not take unnecessary risks. Ask your supervisor if needed.

E_MH_Mounting_instructions_Skylux_Cintralux_Alu_EP10-10 01/09/2020

4/18

SAFETY p. 2

TABLE OF CONTENTS p. 4

OVERVIEW PROFILES AND

SUPPLIES p. 5

SAFETY AND WARNINGS p. 6

PRIOR INSPECTION p. 6

ASSEMBLY SEQUENCE OF FIXED AND

OPENING PARTS p. 8

OUTLINE DRAWING CINTRALUX

ALU EP10/10 FIXED PARTS p. 8

ASSEMBLY SEQUENCE OF FIXED PARTS p. 9

ASSEMBLY CINTRALUX ALU EP10/10

FIXED PARTS p. 9

INSTALLATION OF THE END PROFILE

AND LATERAL PROFILE p. 9

INSTALLATION OF THE LOWER ARCH

PROFILES AND THE INNER SHEETS p. 11

INSTALLATION OF THE INTERMEDIATE

ARCHES p. 12

INSTALLATION OF THE OUTER

SHEETS p. 12

INSTALLATION OF THE UPPER

ARCHES p. 13

TIGHTEN THE BOLTS P. 14

INSTALLATION OF THE OUTER END

SHEETS P. 14

FINISH WITH ALUMINUM STRIPS P. 16

CHECK THE ARCH TENSIONS P. 16

FINISH THE SEAMS OF THE LATERAL

PROFILES P. 17

CONTINUE FINISHING THE OPENING

PARTS, IF ANY P. 17

MAINTENANCE P. 17

SNOW AND WIND LOAD P. 17

DISCLAIMERS P. 17

Table of contents

01/09/2020 5/18

E_MH_Mounting_instructions_Skylux_Cintralux_Alu_EP10-10

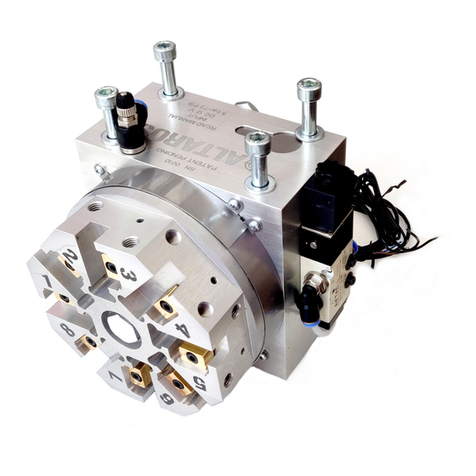

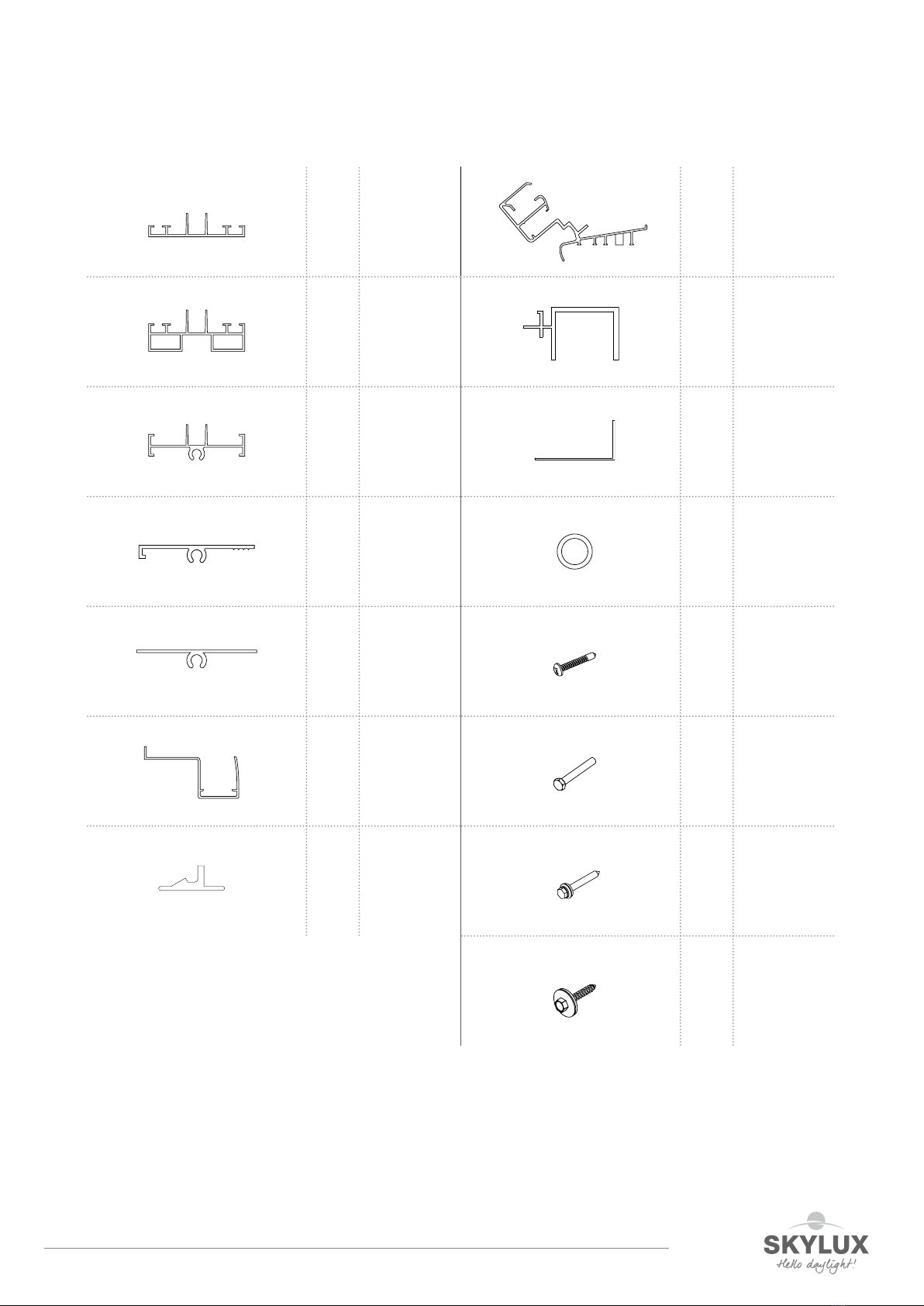

Overview profiles and supplies

LP511 light lower arch

LP533 heavy lower

arch

LP97 intermediate

arch

LP512

lateral arch

(upper arch with

bottom flange)

LP502 upper arch

LP528 lower end

profile

LP505 aluminium draft

strip

LP210- lateral profile

LP623 upper end

profile

LT545 corner profile

PVC tube

Ø 16 x 500 mm

22433

self-drilling

screw

4.2 x 16 mm

15441 hexagonal bolt

M8 x 60

36187

screw with

neoprene seal

Ø 6.5 x 50 mm

wooden curb

36164

self-drilling

hexagonal

collar screw

metal curb

E_MH_Mounting_instructions_Skylux_Cintralux_Alu_EP10-10 01/09/2020

6/18

Safety and warnings

See page 18 in this manual.

Prior inspection

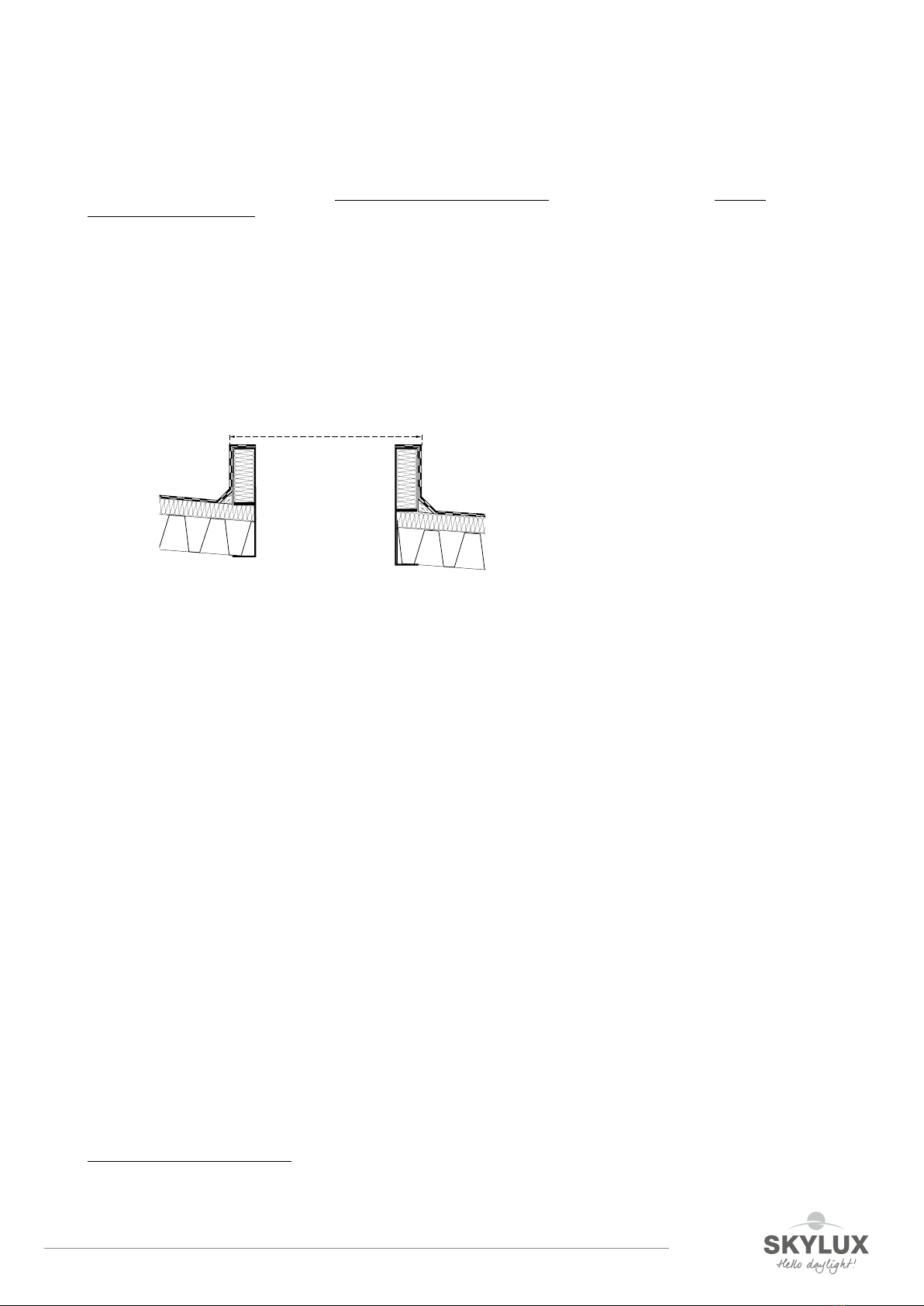

Curb

Before installing the barrel vault, the customer must provide a solid timber or metal curb that must be non-

deformable (can be reinforced with tie rods if necessary). The maximum roof pitch is 5°. Before starting the

installation, please check if following specifications are met:

• Material: wood / galvanised steel min. 3 mm thick

In case of a concrete curb, you first need to anchor a

wooden bar of at least 44 mm thick into the concrete

with suitable countersunk screws. Cover the wooden bar

with the roof covering too. Strictly respect the determined sizes.

• Min. height (above the finished roof): 150 mm

• Min. finished thickness: 65 mm

• Max. finished thickness: 80 mm

• The upper flange and the curb must be equally thick. The

insulation cannot protrude or be thinner than the upper flange.

• Upper flanges of all 4 sides must be on the same surface!

• The curb construction must be free all-round: none of the curbs

may continue at the angle of the lateral side and the front side.

• Pitch of the upper flange:

- barrel vault crosswise on the roof ridge: perpendicular to the roof surface (follow the roof

pitch)

- barrel vault parallel to the roof ridge, 2 possibilities:

o horizontal: both sides must be equally high and levelled (the lowest side of the curb must rise

higher above the roof surface than the highest side). The upper flange can slightly lean

outwards, max. 2°.

o It’s also possible to follow the roof pitch (up to max. 5°).

• Sturdiness: must be able to resist the horizontal and vertical load. See Eurocodes and our technical file for the

determination of the maximum forces on the curb. If any doubt, please consult your architect or research

bureau.

• Deformation: max. 5 mm in case of maximum horizontal load on the curb. Provide enough tie rods at the top of

the curb. If any doubt, please consult your architect or research bureau.

min. 150

min. 100

min. 65

max. 80

min. 3min. 300

max. 5°

01/09/2020 7/18

E_MH_Mounting_instructions_Skylux_Cintralux_Alu_EP10-10

Sizes

Since the barrel vault is made to size, the overall length and widht of the curb (roofing included) must be equal to

the ordered size dimensions of the barrel vault. Look for the narrowest and widest spaces* and measure the min.

and max. overall width:

Permissible tolerances regarding the ordered size:

Width: min: -2 cm

max: +1 cm

Length: ± 0,05%

(about 5 cm in a length of 100 m)

The length of the barrel vault

can be shortened at site,

but we advise not to do this.

• Check the straightness* (±1cm/5m), parallelism* (±1 cm/5m) and perpendicularity (±1°).

* Tighten a rope on both sides of the curb (or use lasers). Look for the average position of

the curb edge to tighten the rope. This rope will also be used to install the lateral profiles

nicely in line

Glazing and arches

The glass sheets are only clamped to allow expansion and contraction in function of temperature fluctuations.

The system is conceived in a way that silicone and rubber sealings between the aluminium and the glazing are

unnecessary (and even forbidden).

All profiles and glass sheets (except the end sheets and the end sheet divisions) are cut to size, pre-curved, pre-

drilled and provided with screw thread.

Respect the exposed UV protected top side of the sheets (glazing).

Always apply the bolts by hand before using a screwing machine to have two full rotations in the arch

profiles provided with screw thread. Otherwise you risk damaging the screw thread.

Do not forget to remove the protective film from the sheets (glazing) after installation.

Sealing

When using roof covering, apply it correctly until it covers the curb. The curb must be covered entirely up until the

daylight size. If the barrel vault is not detached and it borders 1 or several walls, the connection must be vertically

and smooth. This is possible e.g. by using a lead flashing. Please clean, remove sawdust, irregularities, … before the

installation.

Control of the upstand

Check previously the agreed correct sizes of the upstand (overall size – roofing included). Check if the upstands

are parallel with each other. Check the right angles and make sure the top side is smooth and equal. Clean it if

necessary before installation and remove sawing pieces, irregularities, etc.

The installation cannot be started if one of these conditions has not been respected! If you do start installation,

this can lead to negative consequences on several parameters (stability, air and water tightness, …). In this case,

the guarantee will no longer be valid.

A

max + 1 cm

min - 2 cm

E_MH_Mounting_instructions_Skylux_Cintralux_Alu_EP10-10 01/09/2020

8/18

Assembly sequence fixed and opening parts

1 Install the end profiles and lateral profiles. See first step

in this manual (see further).

2 Then, install the reference profiles of the opening parts (see

mounting instructions of the Cintramax opening parts).

3 Finish the fixed part as described further in this manual.

1 or 2 arches are not installed where the opening parts will

come, depending if the opening part consists of 2 modules

(2010 mm) or 3 modules (3082 mm).

4 Last step is finishing the opening parts as described in

the separate manual of the Cintramax opening parts.

Tip: (only in combination with opening parts): make sure the position of the power supply (electric or pneumatic)

corresponds to the position of the opening part.

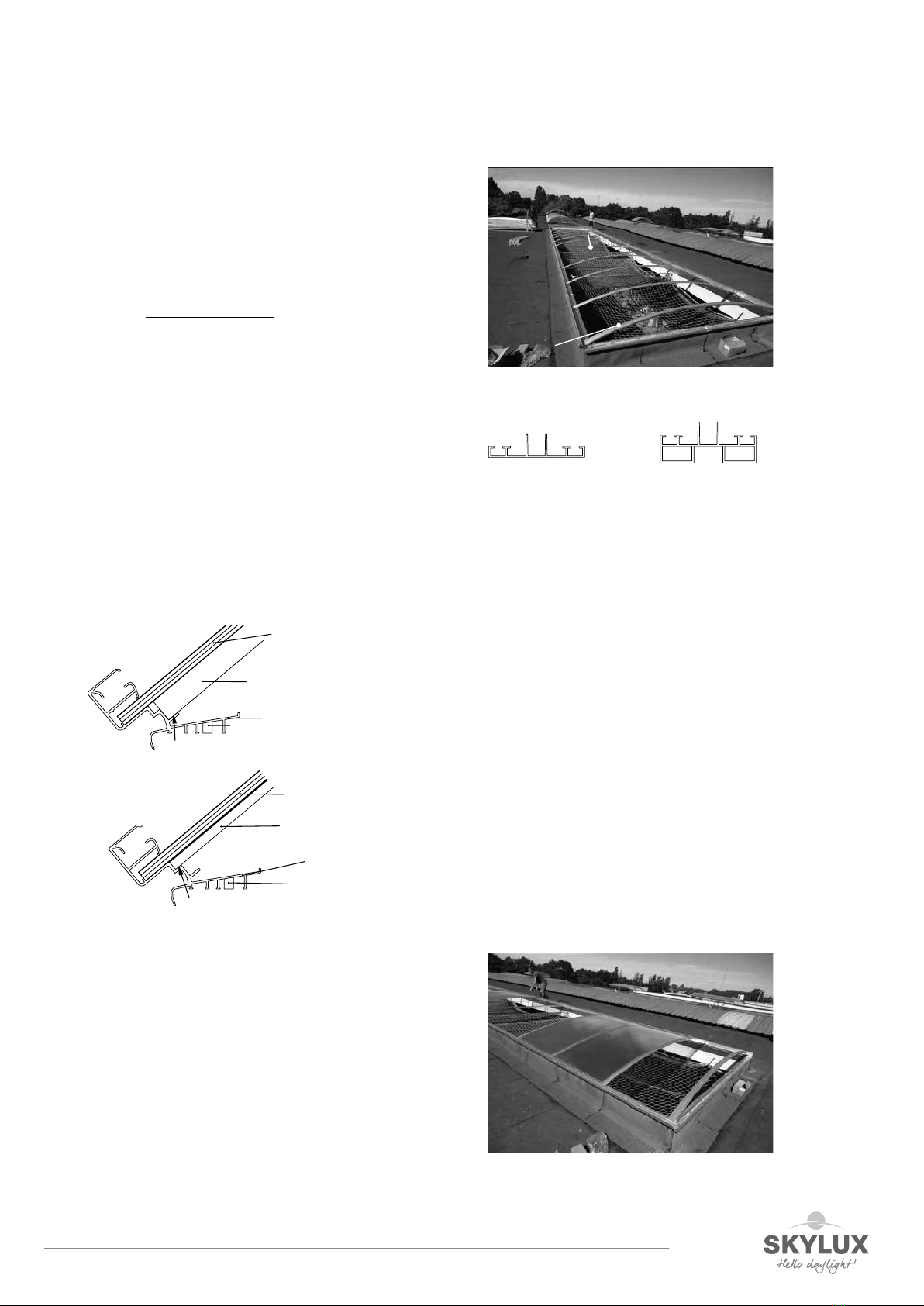

Outline drawing of the fixed parts Cintralux Alu EP10/10

2x10 mm (= EP 10/10):

Illustration: cross section of Cintralux alu EP10/10 structure

1. end profile and lateral profile

3. fixed part

2. reference profile

4. opening part

upper arch

outer sheet

PC multi-walled sheet 10 mm

intermediate arch

inner sheet

PC multi-walled sheet 10 mm lower arch

outer sheet

PC multi-walled sheet 10 mm

inner sheet

PC multi-walled sheet 10 mm

upper arch

outer sheet

PC multi-walled sheet 10 mm

draft strip

bolt M8x60

lateral profile

roofing

(not included in delivery)

intermediate arch

inner sheet

PC multi-walled sheet 10 mm

lower arch

foam

curb excluded

01/09/2020 9/18

E_MH_Mounting_instructions_Skylux_Cintralux_Alu_EP10-10

Assembly sequence for fixed parts

1. Installation of the end profile and lateral profile

2. Installation of the lower arches and inner sheets

3. Installation of the intermediate arch profiles and the spacer profiles

4. Installation of the outer sheets

5. Installation of the upper arch profiles

6. Tighten the bolts

7. Installation of the outer end sheets

8. Finish with aluminium draft strips

9. Check the arch tensions

10. Finish the seams of the lateral profiles

11. Continue finishing the opening parts, if any

Installation of the fixed parts Cintralux EP10/10 mm

1. Installation of end profile and lateral profile

Position the lateral profiles LP210- around the curb according to

the enclosed scheme.

Install the end profile LP528 first and then the lateral

profile LP210-.

(The lateral profiles are to be installed on the ends on top of the

end profiles - the lateral profiles for barrel vaults larger than

4 m long exist of multiple parts and are packaged per

reference, together with the draft strips.)

Make sure the lateral profile just reaches the end sheet.

Fix the end profile on the curb with the supplied screws with

neoprene seal.

Provide a screw every 50 cm, in the provided screw zone. Always use the right screws (metal screws for metal

curb, wood screws for timber, etc.). Tighten the screws so the washer connects perfectly to the profile.

Seal o the corners.

end profile

E_MH_Mounting_instructions_Skylux_Cintralux_Alu_EP10-10 01/09/2020

10/18

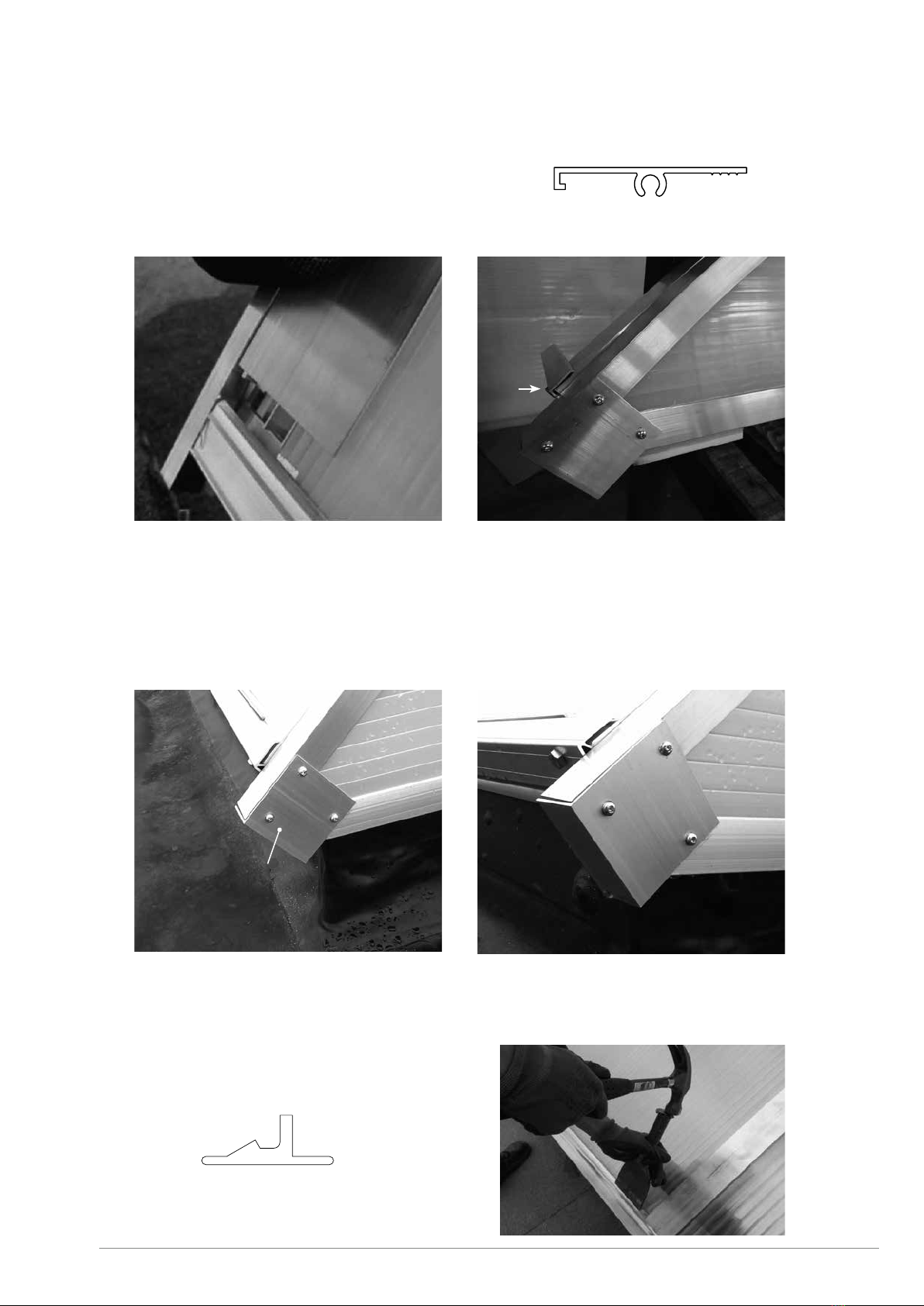

Install all lateral profiles on one side of the curb nicely in line

(use the rope).

We advise you NOT to position the seams of the lateral profiles

opposite of the Cintramax opening parts. Make sure the seams

are next to the opening parts to avoid incorrect alignment of the

opening parts.

Leave a clearance of each time 5 mm (± 2 mm) between the

lateral profiles. Position the lateral profiles evenly on the length

of the curb so all clearances are about the same size. This way,

a small inaccuracy in the curb length can be eliminated.

Tip:

If the curb is a little too long, then the end pieces can be moved

outwards 2 cm each to compensate the dierence.

Tighten the lateral profile on the curb with the supplied screws

with neoprene seal.

Provide a screw every 50 cm in the provided screw zone.

Always use adapted screws (metal screws for metal curb, wood

screws for timber etc.). Tighten the screws so the washer

connects perfectly to the profile.

Carefully seal o the seams below so water from the lateral

profile cannot trickle in.

Seal o the seams on the end profile too.

Now install the lateral profiles on the other side of the curb.

The lateral profiles must be perfectly parallel and attached

to each other at the correct distance, especially with the

opening parts (same daylight size).

Tip:

Use the reference profiles of an opening part to maintain the

right distance.

lateral profile

5 mm

reference profile

01/09/2020 11/18

E_MH_Mounting_instructions_Skylux_Cintralux_Alu_EP10-10

2. Installation of the lower arches and inner sheets

In case there are Cintramax opening parts in the barrel vault:

Install the reference profiles of the opening parts first (see

separate manual for the Cintramax opening parts).

Finish the fixed part afterwards as described further in this

manual.

1 or 2 arches are not installed where the opening parts will

come, depending if the opening part consists of 2 modules

(2010 mm) or 3 modules (3082 mm).

‘light’ or ‘heavy’ lower arches

Now install the lower arches of the fixed part.

Installation of the lower arches depends on the type:

Tip:

Only in combination with opening parts: make sure the position of the power supply (electric or pneumatic)

corresponds to the position of the opening part.

Installation of the lower arches:

The light lower arches are placed on the uppermost edge.

The heavy lower arches are placed on the lowest edge of the lateral profile.

Installation of the inner sheet:

Remove the protective film right before the installation to

avoid scratches. Install the inner multi-walled 10 mm sheets

with the UV side up.

Install the sheet on one side in the lateral profile and bend it

over the lower arch. Push the plate a bit so it can slide into the

matching groove.

Tip:

There’s a small print on the UV side (side that must be faced

outwards/upwards) that can serve as a verification after

removing the protective film.

reference profiles

lower arches

inner sheet

PC multi-walled sheet 10 mm

heavy lower arch

lateral profile

lowest edge of lateral profile

inner sheet

PC multi-walled sheet

light lower arch

lateral profile

foam

foam

uppermost edge of lateral profile

E_MH_Mounting_instructions_Skylux_Cintralux_Alu_EP10-10 01/09/2020

12/18

3. Installation of the intermediate arches

Install the intermediate arch above the lower arch, according to the image.

Insert the M8x60 bolts in the pre-drilled holes in the lateral profile in the

intermediate arch.

Do not tighten the bolts yet.

4. Installation of the outer sheets

The outer wall/outer sheet is installed and slid into the

groove of the lateral profile.

Pay attention to the correct side of the sheets!

intermediate arch

intermediate arch

bolt M8x60

outer sheet

PC multi-walled sheet 10 mm

outer sheet

PC multi-walled sheet 10mm

01/09/2020 13/18

E_MH_Mounting_instructions_Skylux_Cintralux_Alu_EP10-10

5. Installation of the upper arches

Make sure the lower profiles in the middle of the bottom side

of the upper arch profile fit into the notch of the intermediate

arch profile.

Fix the upper arch profiles by hand with the stainless-steel

bolts M6 or M8. Do not tighten yet and make sure you do

not block everything as the aluminium draft strips still must

be installed and the arch profiles must be able to “expand”.

upper arch

lower arch

M8x60 bolts

do not tighten yet!

E_MH_Mounting_instructions_Skylux_Cintralux_Alu_EP10-10 01/09/2020

14/18

6. Tighten the bolts

You can now tighten the bolts to fix the intermediate arches

and the upper arches.

7. Installation of the outer end sheets

Install a PVC tube on both sides between the lower arch and the intermediate arch.

Detailed image of the end pieces, with specific end profiles:

M8x60

bolts

end profile

lateral upper arch

outer sheet

PC multi-walled sheet 10 mm

intermediate arch

inner sheet

PC multi-walled sheet 10 mm lower arch

roofing

(not included in delivery)

curb lowest end profile

multi-walled polycarbonate sheet

32 mm

PVC tube

intermediate arch

PVC tube

PVC tube

PVC tube

01/09/2020 15/18

E_MH_Mounting_instructions_Skylux_Cintralux_Alu_EP10-10

Install the entire 32 mm end sheet in the lowest end

profile and mark the top side of the intermediate

arch on the protective film.

The UV side must face outwards.

Mark until the ends of the lowest end profile for the

correct sheet length.

Take out the sheet from the lowest end profile again.

Saw o the sheet 3 mm BELOW the marked line, in arch form.

Blow away all the saw dust and tape o the sawn edges

with the supplied BB32 tape.

Now reinstall the 32 mm sheet back into the lowest end profile.

marked line

(upper side of the

intermediate arch)

3 mm

saw line

E_MH_Mounting_instructions_Skylux_Cintralux_Alu_EP10-10 01/09/2020

16/18

Tighten the lateral arch (= upper arch with downward flange)

with the uppermost end profile. Use the M8 x 60 mm bolts.

Finish the 4 corners by installing the corner profile

on the lowest and uppermost end profile (on the ends

of the barrel vault):

8. Finish with aluminum strips

Clamp the sheets into the lateral profile by installing the draft

strips below the edge of the lateral profile. Start at one side,

press and tap the strips carefully in their positions.

Do not damage the sheets!

corner profile

01/09/2020 17/18

E_MH_Mounting_instructions_Skylux_Cintralux_Alu_EP10-10

9. Check the arch tensions

Check if the lower and upper arches are equally tightened everywhere on the sheets. Adjust if necessary (it’s not

necessary to tighten very firmly, we even advise against it).

10. Finish the seams of the lateral profiles

Finish the seams of the lateral profiles with the finishing profiles.

Screw the finishing profile on the lateral profile.

11. Continue finishing the opening parts, if any

In case of a combination with Cintramax opening parts, these parts must be finished. See separate manual of the

Cintramax opening parts.

Maintenance

The owner of the building must schedule a yearly maintenance on the Cintramax opening parts and the fixed parts

of the barrel vault. The maintenance should include at least the cleaning of the sheets with water and light and

neutral soap. All attachments must be inspected and loose or damaged parts of the Cintramax must immediately

be fixed or replaced by original parts as described in the ETA Cintralux.

Clean the condensation drain holes (in the lateral profile, etc.) and the inside of the lateral profile at least once a

year.

Snow and wind load

The barrel vaults are resilient to normal wind and snow loads. For specific locations (near the sea or in case of very

tall building > 12 m), reinforcement profiles can be provided with surcharge (only on customer’s request).

Disclaimers

Warnings

Installers: installation must be performed by trained technicians with sucient knowledge of and experience in the

installation of barrel vaults.

Fixing materials: use suitable fixing material depending on the surface and the load. If any doubt, contact the

screw supplier or a specialised engineering firm. We supply fixing material that is suitable for most metal or

wooden surfaces, but this needs to be checked before starting the installation. Skylux is not responsible for the

fixing materials used.

E_MH_Mounting_instructions_Skylux_Cintralux_Alu_EP10-10 01/09/2020

Attention: the CE certification is only valid if the composition, execution and the installation regulations are respected.

Skylux guarantees the CE conformity as described in the documentation and according the plant regulations of the

appliances. Every variance, cancels the CE conformity.

CE according to EN 14963

ONLY USE ORIGINAL PARTS SUPPLIED BY SKYLUX. FAILURE TO USE ORIGINAL PARTS VOIDS THE GUARANTEE.

SKYLUX®IS A REGISTERED BRAND OF SKYLUX

SPINNERIJSTRAAT 100 B8530 STASEGEM

T +32 056 20 00 00 F +32 056 21 95 99

INFO@SKYLUX.BE

WWW.SKYLUX.BE

Compatibility: only use polycarbonate-friendly materials. Avoid using silicone, polyurethane foam, detergents,

paints, varnishes, timber protectants, lubricants, insecticides, etc. A lead flashing may not come into contact with

the multi-layered sheets.

Covering: cover the barrel vault (e.g. heat-deflecting eect) only with a cloth that does not contain softening

agents. It is not recommended to cover acrylic or polycarbonate with a coating or paint. In this case, our guarantee

will no longer apply. It is in your interest that the manufacturer of the coating or paint provides guarantee on

compatibility with acrylic and polycarbonate.

Dust: in the event that there are still certain works to be carried out that entail the release of dust particles (such

as grinding, drilling, plaster work, etc.), then the opening under the barrel vault must be hermetically sealed,

for example with a PVC film. The dust can accumulate on, in, or between the plastic sheets. The grooves of the

multi-layered sheets are sealed o with tape. When sawing multi-layered sheets at the project site, all grooves

must be carefully blown out and sealed o with suitable tape. Before assembly, double check that the grooves are

properly taped and adjust where necessary. Make sure the tape has not been damaged during assembly. There is

no warranty for dust inclusion.

UV side and scratches: always mount the multi-layered sheets with the UV protective side facing up. This ‘sunny

side’ is indicated on the protective film. Remove the protective film just before installation to avoid scratches.

Point load: avoid point load on multi-layered sheets as this can cause permanent imprints. Never lean or walk on

the multi-layered sheets.

Snow accumulation: do not mount barrel vaults in places where snow can slide from a higher structure and fall on

the barrel vault.

Original parts: only use original parts and install them according to the assembly instructions.

Skylux reserves the right to modify this product or these instructions without prior notice. Changes to the

assembly instructions or to the product carry no right to compensation or exchange of parts. The most recent

version of these instructions can be consulted at any time at www.skylux.be.

Safety during assembly

Take the necessary and required safety precautions, such as safety nets in the roof opening(s), fall protection,

protection of the roof edge, safety shoes, safety goggles, gloves, hard hat, etc.

An opening part of a barrel vault (Cintramax CE) has moving parts. It is necessary to open and close the Cintramax

(partially or entirely) during installation. Make sure there are no persons near the near the moving parts.

Pneumatic Cintramax:

can be opened and closed manually, without compressed air.

Attention: once the Cintramax passes the balance point, it opens by itself because of the gas springs.

Make sure there are no persons near the moving parts.

Physical properties multi-layered sheets

Expansion: acrylic and polycarbonate sheets are plastic sheets and will expand and contract in case of temperature

fluctuations. The profile system allows this expansion and contraction. This might cause some noise but will not

influence the stability of the construction.

Condensation: acrylic and polycarbonate sheets are very little permeable to damp, which can cause condensation

in the hollow canals of the sheets. This could mostly happen at the beginning of the installation because there is a

lot of construction liquid that must evaporate. This is a physical phenomenon and disappears after some time. The

condensation has no influence on the characteristics of the plastic sheets or on the guarantee.

Reflection: in some cases, acrylic and polycarbonate sheets can reflect the sunlight to the inside or outside,

depending on orientation and pitch.

Table of contents

Other SKYLUX Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

SCHNIER

SCHNIER 810477 operating manual

Emerson

Emerson Rosemount IK220 quick start guide

Xylem

Xylem Flygt 2860.180 Installation, operation and maintenance manual

Yost Vises

Yost Vises 10904 manual

Hydac

Hydac PTK Series Operating and maintenance instructions

TOYOTA ADVANCED LOGISTICS

TOYOTA ADVANCED LOGISTICS Bastian SOLUTIONS BSBAC 1 HP Installation and maintenance manual