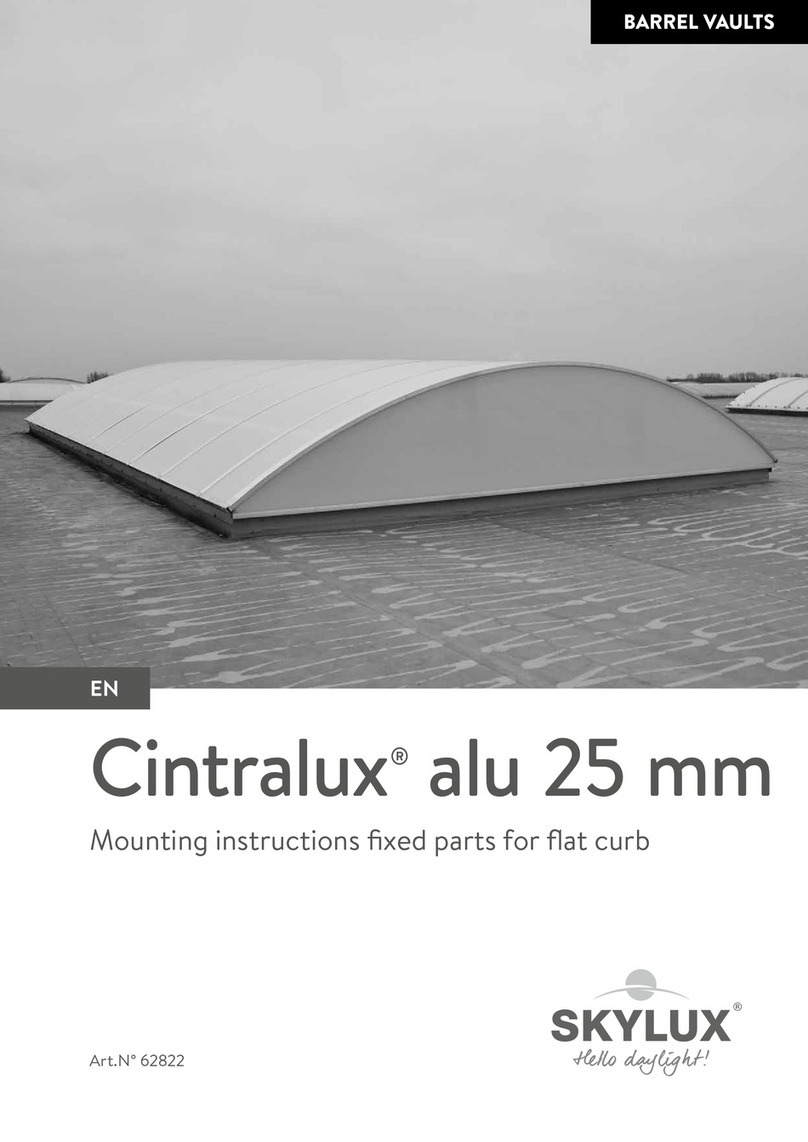

SKYLUX ClimaCar User manual

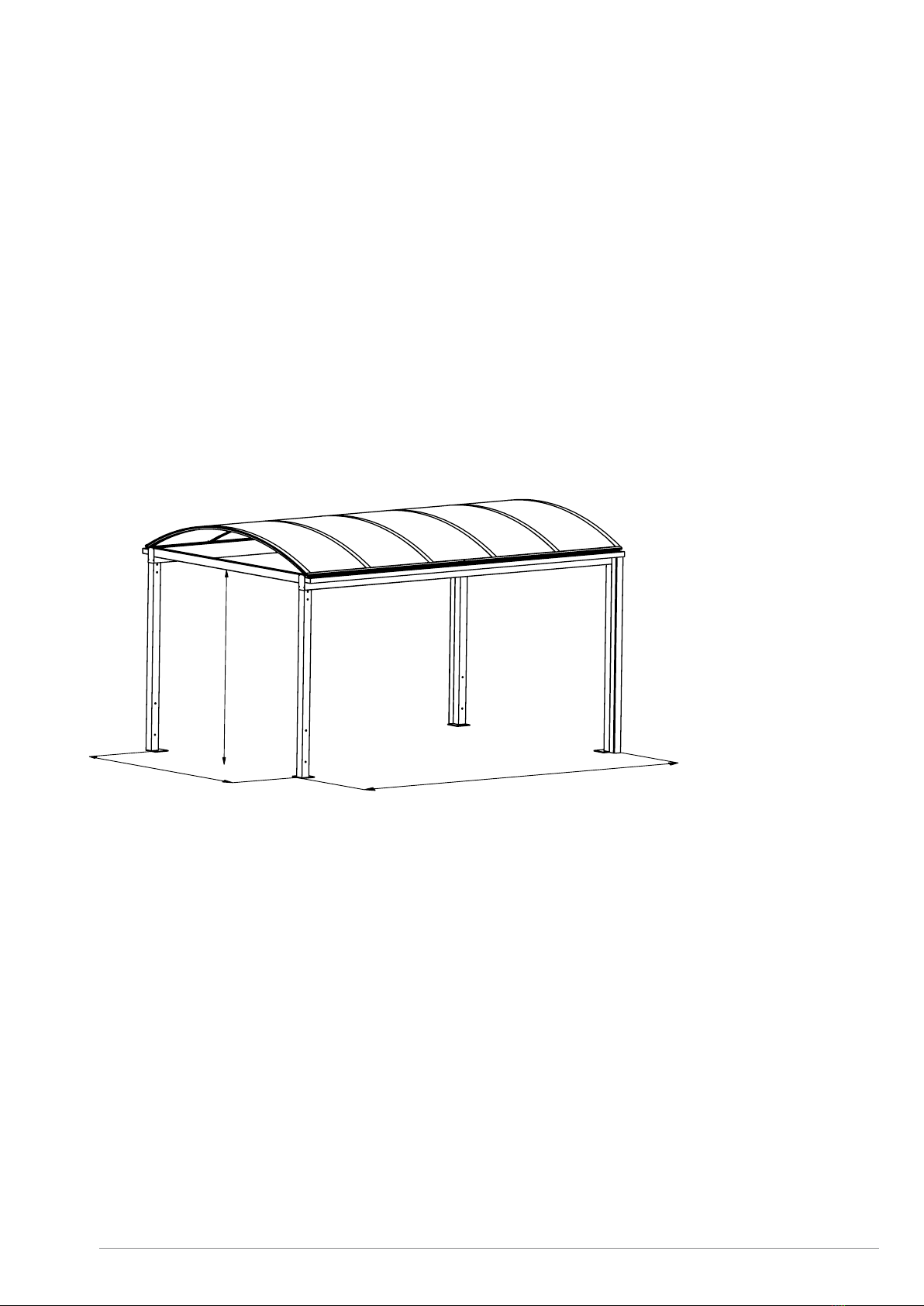

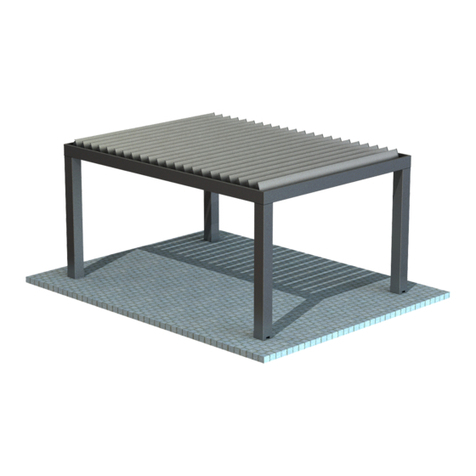

CARPORT

ClimaCar

®

Mounting instructions

EN

Art.N° 49579

E_MH_Mounting_instructions_Skylux_ClimaCar 01/04/2019

2/32

CONTENT p. 2

OVERVIEW CLIMACAR PROFILES AND PARTS p. 3 - 4

GENERAL INSTALLATION TIPS p. 5

DIMENSIONS p. 6 - 7

PREPARATION p. 8 - 9

EXAMPLE DRAWING CLIMACAR p. 10

POSTS WITH POST SUPPORT p. 11 - 12

POSTS IN CONCRETE p. 13 - 14

SUPPORTS p. 15- 16

RECTANGULAR PROFILES 72 X 110 p. 17

RECTANGULAR PROFILES 35 X 35 p. 18

INSTALLATION SUBSTRUCTURE p. 19 - 21

INSTALLATION GUTTERS G120A p. 22

INSTALLATION SUPERSTRUCTURE p. 23 - 27

FINISH p. 28 - 29

Table of contents

01/04/2019 3/32

E_MH_Mounting_instructions_Skylux_ClimaCar

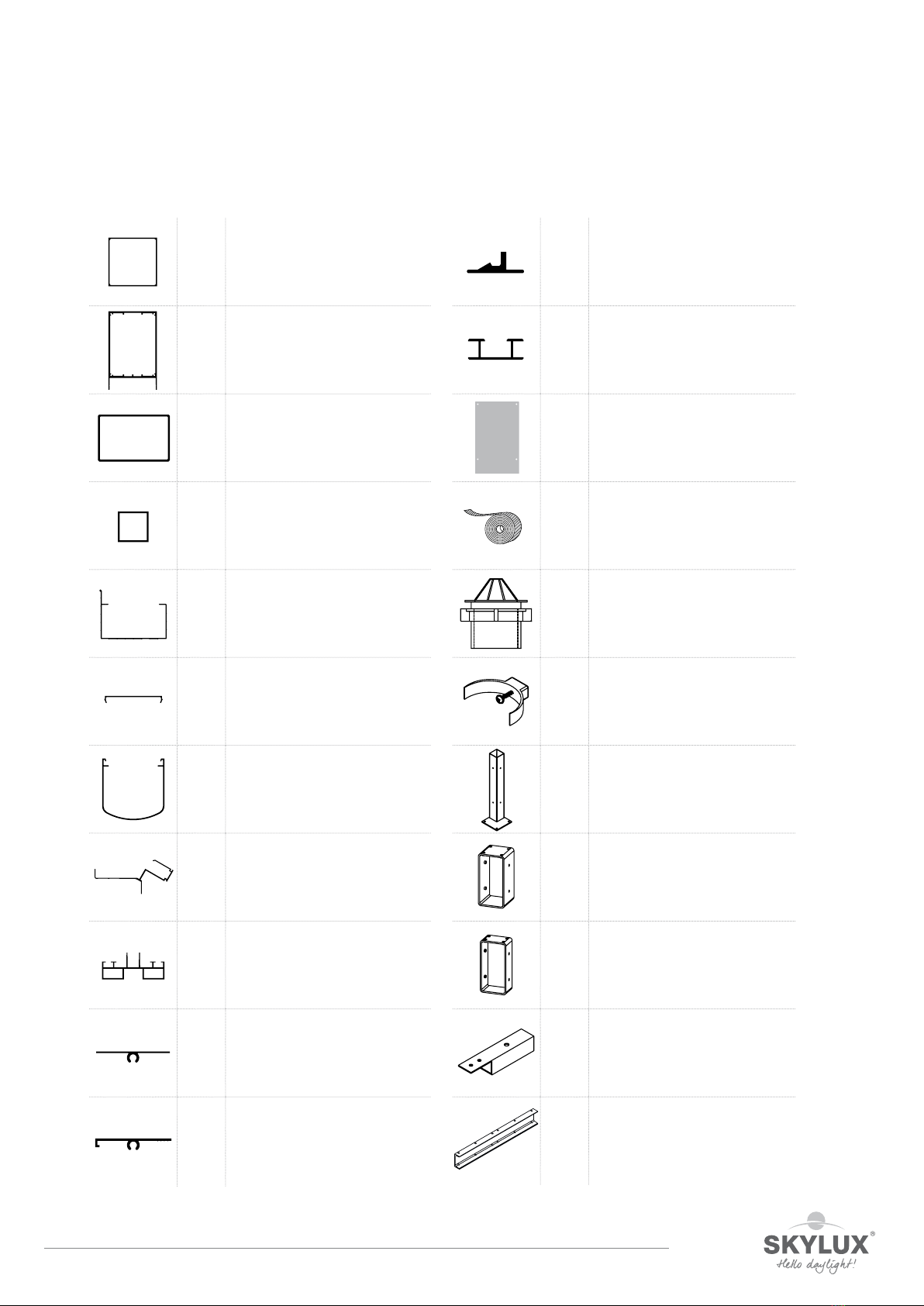

Overview ClimaCar profiles and parts

PGDX POST 110/110

GDX SUPPORT

P72 RECTANGULAR PROFILE 72 x 110

LP08 RECTANGULAR PROFILE 35 x 35

G120A GUTTER

PCB72 POST CLIP BASE (OPTIONAL)

PC72 POST CLIP (OPTIONAL))

LP836 BASE PROFILE

LP533 LOWER ARCH

LP502 LOWER ARCH

LP512 LATERAL UPPER ARCH

LP505 DRAFT STIP

GDGL RIDGE CONNECTION PROFILE

GDSX END PLATE FOR SUPPORT GDX

TAPE SYNTHETIC TAPE ALU

GC OUTLET + SWIVEL ø 80 MM

412 BRACKET FOR DRAINPIPE

PS

POST SUPPORT

C110

BRACKET FOR PGDX

C72

BRACKET FOR P72

GT35

BRACKET FOR LP08

UPN140

CONNECTION PROFILE

E_MH_Mounting_instructions_Skylux_ClimaCar 01/04/2019

4/32

Overview ClimaCar profiles and parts

PT110

REINFORCEMENT PLATE

G120AS

END PIECE FOR GUTTER

BOLT

M10x30 BOLT M10 X 30 GALVANISED

Washer

M10 WASHER M10 GALVANISED

SCR

5,8x38 SELF-DRILLING SCREW

ZSB

ZSG

SELF-DRILLING SCREW INOX

SELF-DRILLING SCREW LACQUERED

BOUT

M8x60 BOLT M8 X 60 INOX HEXGONAL

BOLT

M8x20 BOLT M8 X 20 INOX SOCKET

BOLT

M10 x

180

BOLT M10 X 180 INOX SOCKET

51197

51819

COUNTERSINK DRILL Ø 16,5 MM

COUNTERSINK DRILL Ø 20,5 MM

Washer

M8 WASHER M8 INOX

NUT

M8 NUT M8 GALVANISED

ZSR ANCHOR BOLT HSA 8/75

UGS

WUGS

UNIVERSAL GUTTER SPOUT +

SWIVEL GUTTER SPOUT

411 DRAINPIPE + SLEEVE ø 80 MM

414 CURVE 87° WITH SLEEVE ø 80 MM

01/04/2019 5/32

E_MH_Mounting_instructions_Skylux_ClimaCar

General installation tips

Please read this manual carefully.

The installation must be carried out by people with sucient technical knowledge and experience in conservatory installation.

The installer must take the required safety measures into account during installation such as the use of scaolding and

personal protective equipment (safety shoes, helmet, gloves, safety goggles, etc.) to ensure the work is carried out in a

safe environment. During installation, the necessary precautions must be taken to ensure the stability of the unfinished

construction.

Fixing material

The selection of required fixing material is dependent on the foundation or the walls. Check whether the foundation and

the walls on which the structure is to be anchored have a sucient load-bearing capacity. The installer is responsible for the

assessment of the appropriate fixing materials for the load and foundation on which the structure is to be fixed. Please contact

your fixing material supplier or specialised engineering consultants in case of doubts. Skylux cannot be held liable for the

installation or the fixing materials used.

Static (Statik)

All guidelines and parts mentioned in this manual must be used and applied correctly to comply with the Static (Statik).

Polycarbonate plastic sheets

Only use polycarbonate sheets of Skylux. These sheets must always be installed with the UV protected side facing upwards.

This “sun side” is always marked on the protective foil. The sheet ends must be taped with the supplied aluminium-coloured

tape. This avoids dust and dirt from entering the sheets. Polycarbonate is not completely damp proof. Condensation in the

channels may occur (physical phenomenon). Avoid using silicone because it can aect the plastic sheets. Plastic sheets can

produce contraction or expansion sounds due to change in temperature. This does not influence the guarantee and is not

accepted as a damage claim.

Conditions and guarantee

The guarantee is no longer valid if the mounting instructions mentioned in this document are not followed. If these

instructions are not respected and/or if other parts are used, this can lead to detrimental consequences for the safety and

durability of the product. Deviations are not allowed without the written permission of the manufacturer. The mounting

instructions are based on our latest level of knowledge and technique. We cannot be held responsible for possibly insucient

information. Always check if our product is suitable for your application. Since the usage and installation of our product is

carried out beyond our control, Skylux cannot be held responsible for possible damage. The installer must take into account

the presented span lengths depending on the glazing and load (snow load or wind load) in accordance with the valid standards.

For out of range carports you can always contact the manufacturer, architect, or study bureau. Technical changes are

reserved to the manufacturer without preceding oral or written notification. Skylux reserves the right to change the mounting

instructions without preceding notification. Changes in the mounting instructions or product changes do not allow for

compensation or exchange of parts. The latest version of this manual can always be consulted on www.skylux.be.

ClimaCarfast

Skylux provides you the free ClimaCarfast calculation application. You will receive information on how to log on and download

the Excel version of the application upon request. ClimaCarfast calculates the price of your ClimaCar roof. For each project,

you will receive an overview of the profiles, lengths, parts, permitted loads, etc. The application provides information and

indications for the user. Skylux reserves the right to change the ClimaCarfast calculation application without prior notification.

The calculation results are indicative and do not allow for compensation. The latest version of the calculation application can

always be downloaded on www.skylux.be.

E_MH_Mounting_instructions_Skylux_ClimaCar 01/04/2019

6/32

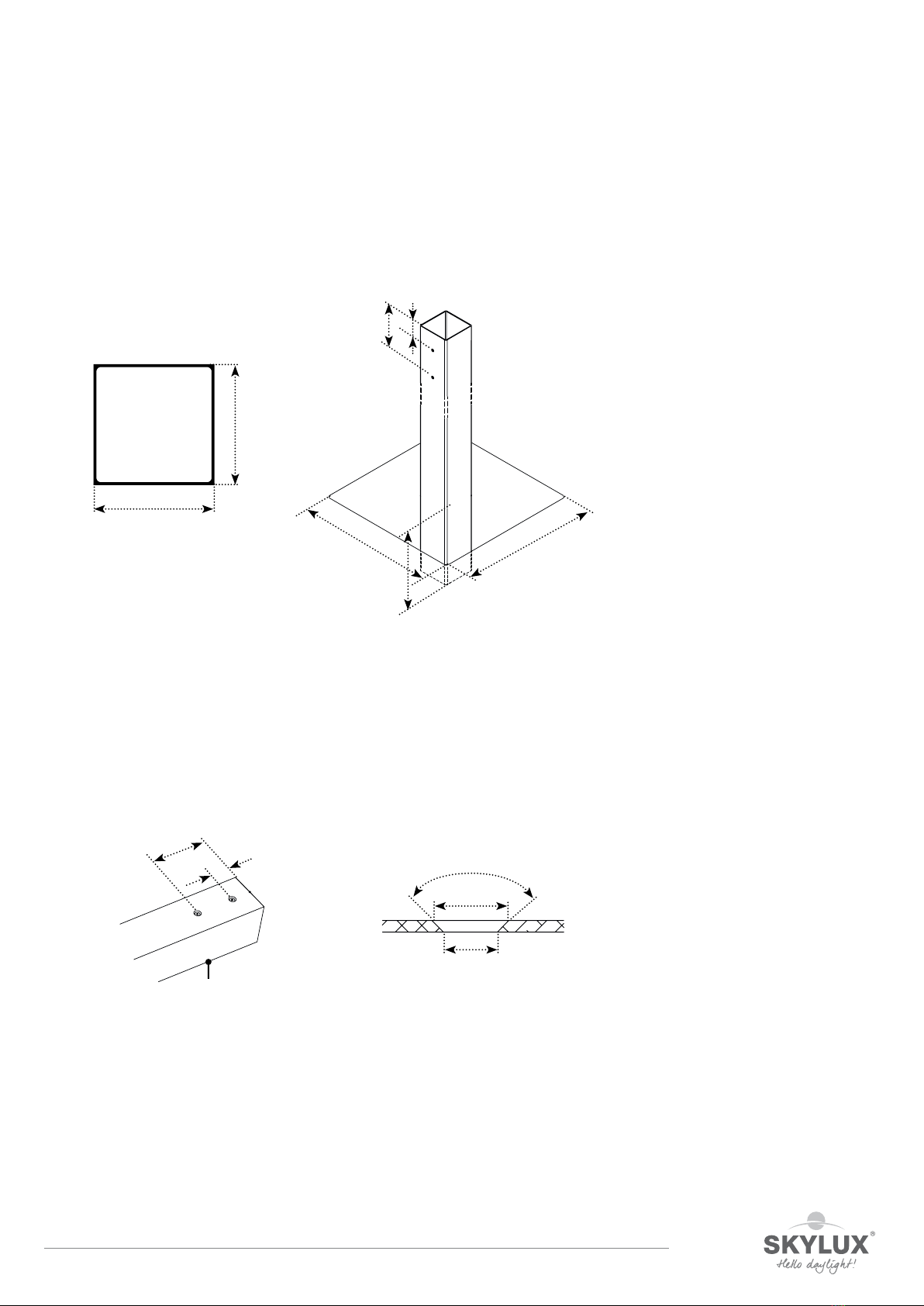

Dimensions

Standard dimensions

Width B: width between the posts (clear width): 3025 of 3500 mm

Depth D: total depth: 5000, 6000, 7000, 8000, …… 45000 mm (per metre)

Height H: height under cross beam (clear height): max 3230 mm

B

H

D

01/04/2019 7/32

E_MH_Mounting_instructions_Skylux_ClimaCar

Bg = B + 467

H

Ht = H + 535/595

Bp = B+220

B = 3025/3500

H - 80

D = min 5000, ... max 45000

D - 220

Ht = H + 535/595

Derived dimensions

BBp Bg

3025 3245 3492

3500 3720 3967

Bp: posts included

Bg: gutters included

B 3025 3500

Ht H + 535 H + 595

Ht: total height

E_MH_Mounting_instructions_Skylux_ClimaCar 01/04/2019

8/32

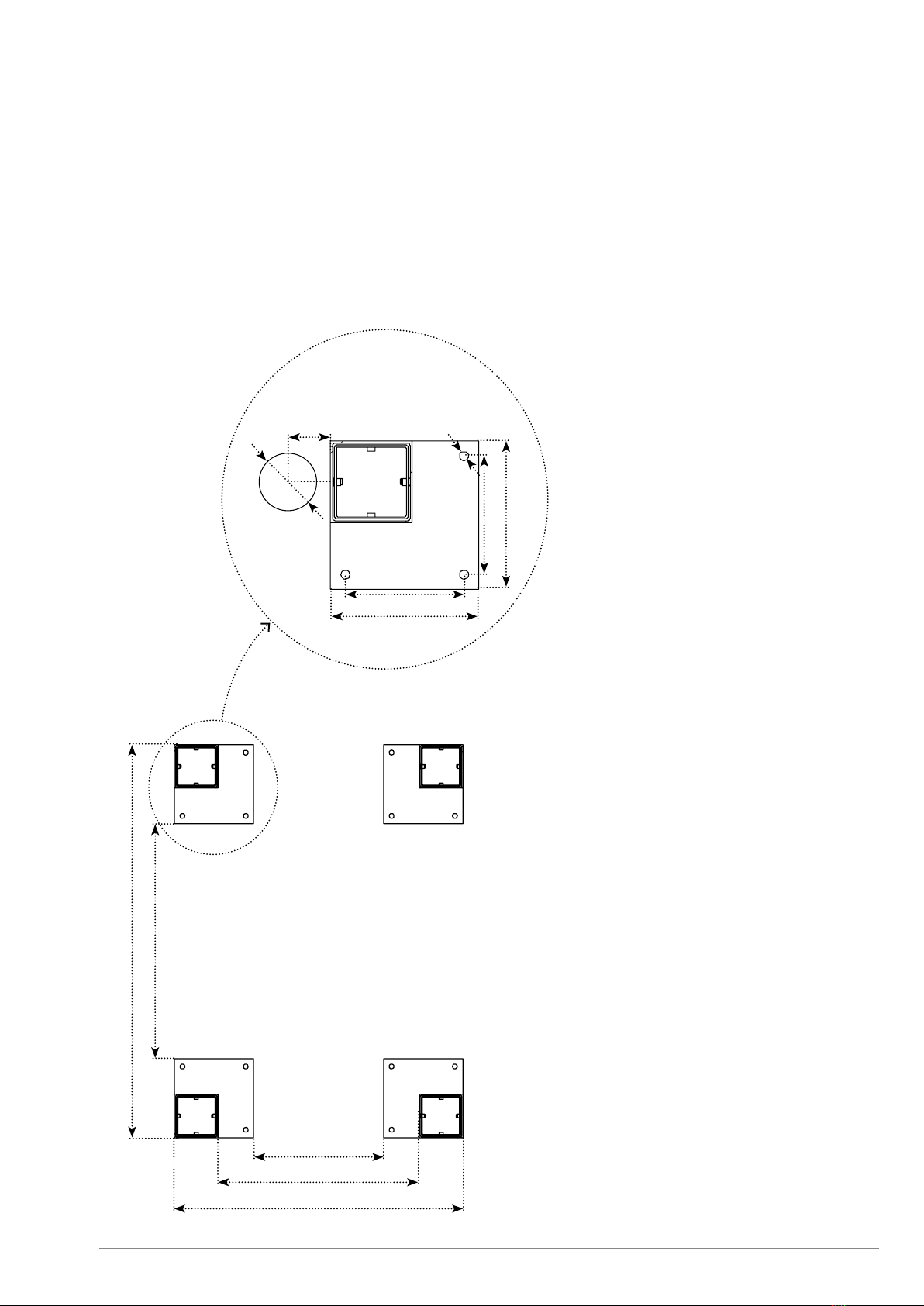

Preparation

1. Installation of the posts on a load-bearing surface

Make sure the surface (foundation) is strong and solid enough for the 4 (corner) posts. The substructure must be

levelled. The gutters are optional. The water drainage can be installed on the front or on the back on the outer side

against the post. Rain water drainage can be provided in the foundation by means of drainpipes.

B - 180

D - 400

D

B + 220

B

160

200

160

200

ø12

60

ø80

01/04/2019 9/32

E_MH_Mounting_instructions_Skylux_ClimaCar

2. Setting posts in concrete

Provide foundation holes of min. 600 x 600 x 800 mm (width x length x height) for the (corner) posts. The

substructure must be perfectly levelled. The gutters are optional. The water drainage can be installed on the front

or on the back on the outer side against the post. Rain water drainage can be provided in the foundation by means

of drainpipes.

60

ø80

600

600

D

D - 220

B + 220

B

E_MH_Mounting_instructions_Skylux_ClimaCar 01/04/2019

10/32

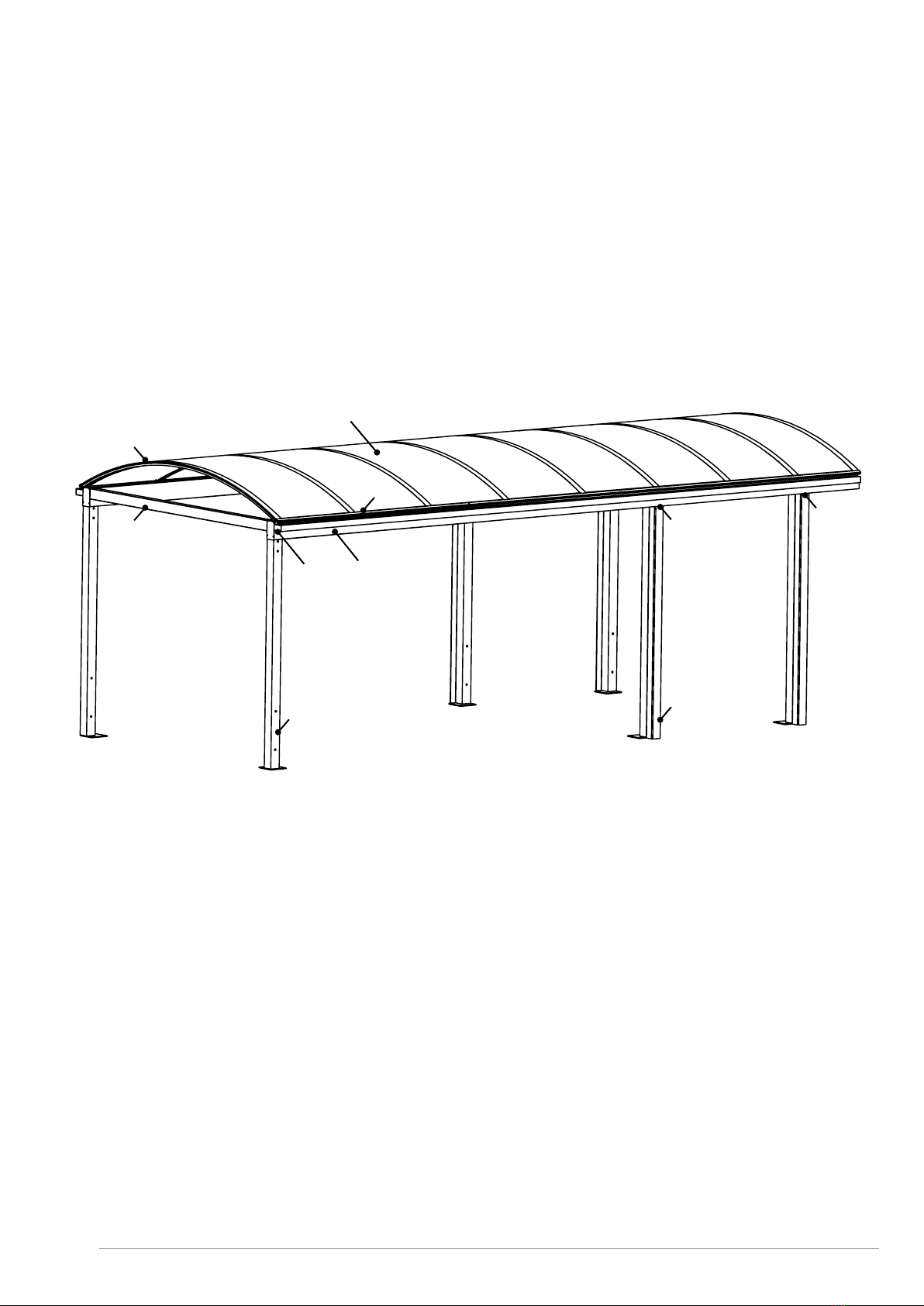

Example drawing ClimaCar

A10 - A11 Posts - Water drainage pg. 11-14, 28

A20 - A21 Supports - Rectangular profiles pg. 15-18

A30 - A31 - A32 Assembly - Gutter pg. 19-22

A40 - A41 - A42 Base profile - Arches - Sheets pg. 23-29

A41

A42

A21

A30

A40

A20

A31

A11

A10

A32

01/04/2019 11/32

E_MH_Mounting_instructions_Skylux_ClimaCar

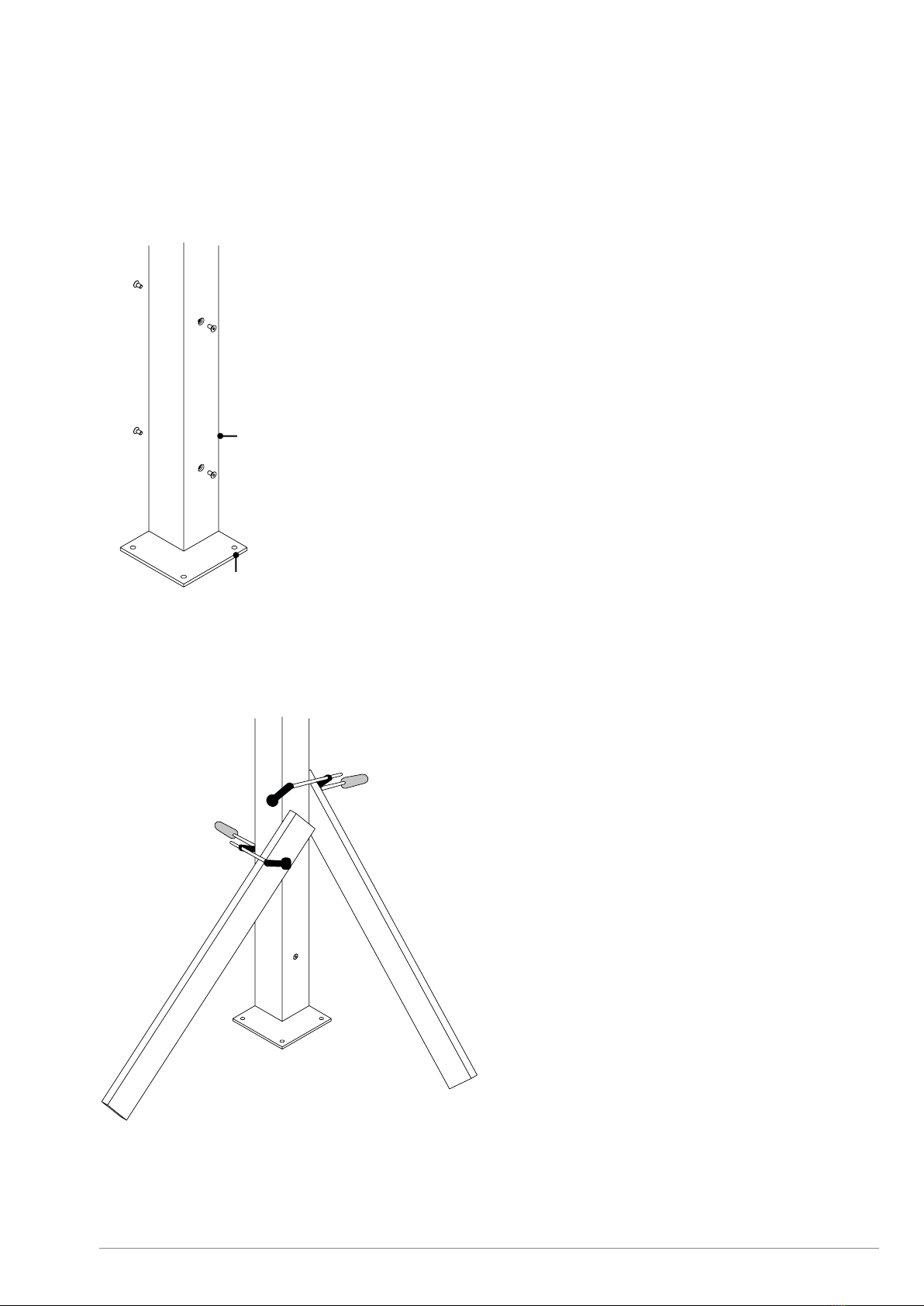

Posts with post support

PGDX 110/110 PS

Preparation posts (4 X)

The post must be sawn to the right length (H– 59 mm).

Drill a central hole (Ø 11) 200 and 600 mm from the bottom in the 2 opposite sides below. Use a countersink 90°

Ø 16,5 mm (art. 51197) to make the hole conical.

Drill a central hole 50 and 150 mm from the top in the 2 opposite sides above. Use a countersink 90°

Ø 16,5 mm (art. 51197) to make the hole conical. The transparent sticker art. 49566 can be used here as a drilling

stencil.

110

110

200

600

ø12

160

200

160

200

200

600

ø11

ø16,50

90°

PGDX

150

50

ø11

ø16,50

90°

PGDX

E_MH_Mounting_instructions_Skylux_ClimaCar 01/04/2019

12/32

Installing the posts with post support

Slide the posts PGDX over the post support PS and use 4 bolts M8 x 20 to attach the posts on the post support.

Do not tighten the bolts yet.

Put the 4 posts on the corners of the ClimaCar with the support plate facing inwards. Be sure to brace these posts

until the construction is completed.

PS

PGDX

01/04/2019 13/32

E_MH_Mounting_instructions_Skylux_ClimaCar

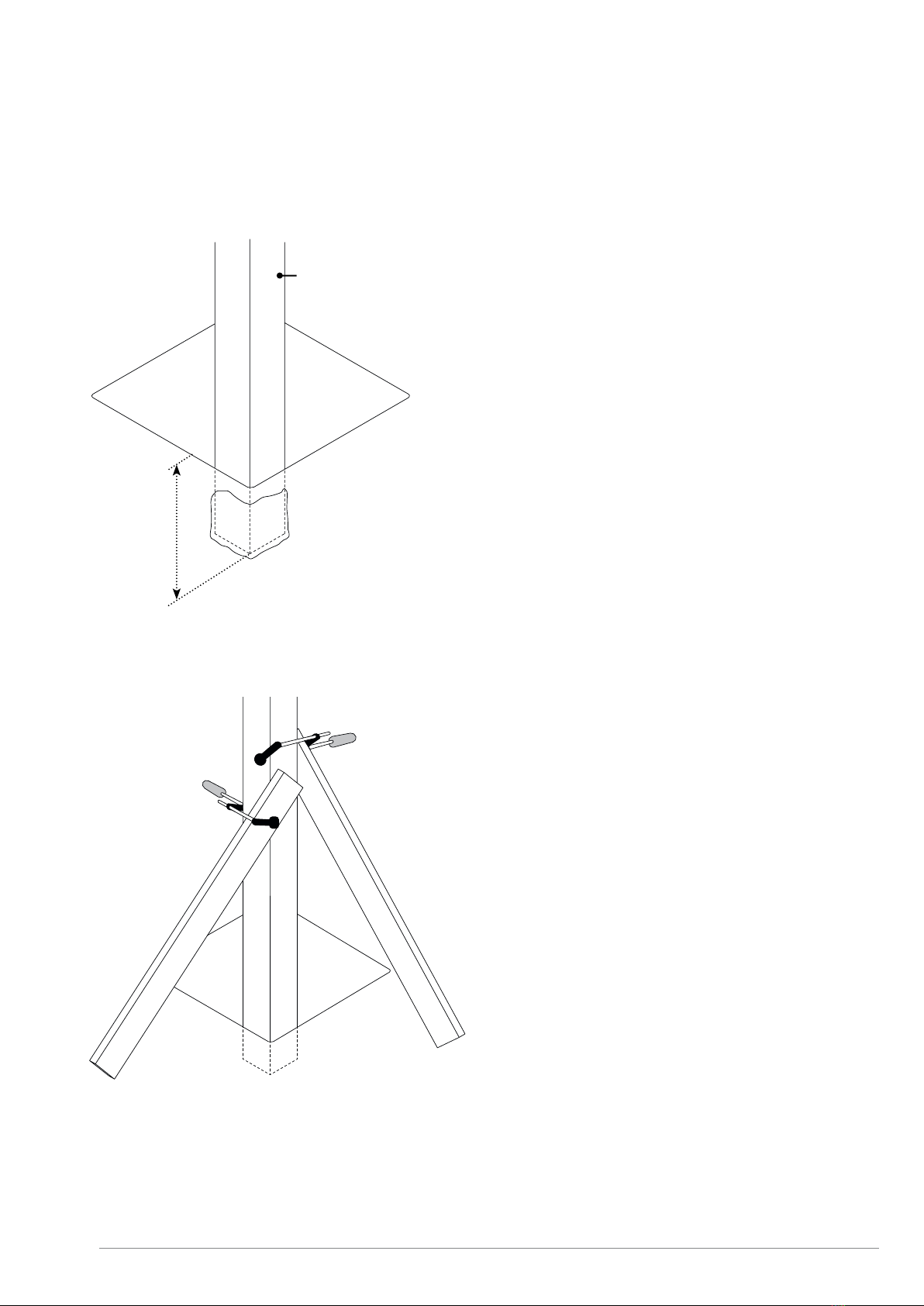

Posts in concrete

PGDX 110/110 PS

Drill a central hole 50 and 150 mm from the top in the 2 opposite sides above. Use a countersink 90° Ø 16,5 mm

(art. 51197) to make the hole conical. The transparent sticker art. 49566 can be used here as a drilling stencil.

110

110

150

50

ø11

ø16,50

90°

PGDX

min. 400

50

600

600

150

E_MH_Mounting_instructions_Skylux_ClimaCar 01/04/2019

14/32

Installing the posts in the foundation

Set all posts in the foundation holes. The post must be at least 40 cm deep. Seal o the opening of the post with

foil to prevent concrete from entering the post. The inside of the post is not protected against the aggressive

eect of concrete.

Install all posts and be sure to brace these posts until the construction is completed.

We advise to brace the subconstruction until it’s completely installed. Afterwards, everything can be levelled and

the foundation holes can be filled with concrete.

PGDX

min. 400

01/04/2019 15/32

E_MH_Mounting_instructions_Skylux_ClimaCar

Supports

GDX C110

Preparation supports (2 x)

Drill holes for the connection profiles 72 x 110

Check the length of the supports. These are sawn to the correct length. Place the support on its side on trestles.

Drill 4 holes of Ø 11 mm in the ends on the side of the support. These holes are necessary to connect the left and

right supports to each other on the ends by means of the 72 x 110 profile. The transparent sticker art. 49564 can

be used here as a drilling stencil.

Preparation supports for posts

Possibility 1: the post is placed on the extremities or on the corner of the carport

Drill 4 holes of Ø 11 mm in the ends on the bottom side.

The transparent sticker art. 49563 can be used here as a drilling stencil.

Place the brackets C110 on the beam and make sure the holes in the bracket

are faced sideways. Put the reinforcement plate PT110 in the support.

Use the bolts M10 x 30 and the washers M10 to secure the brackets.

Do not tighten the bolts yet.

29

117

190

20 20

70

70

20

ø11

70

20

19

34

GDX

C110

GDX

M10 x 30

+ (4x)

E_MH_Mounting_instructions_Skylux_ClimaCar 01/04/2019

16/32

Possibility 2: the post is not placed on the extremities

Drill 4 holes of Ø 11 mm in the bottom side.

DX is the distance between the edge of the gutter support and the central line

of the post. The transparent sticker art. 49563 an be used here as a drilling stencil.

Next, drill 4 holes Ø 11 mm in the top side of the support. Dx is the distance between the edge of the gutter

support and the central line of the post. The transparent sticker art. 49563 an be used here as a drilling stencil.

Use a countersink 90° Ø 20.5 mm (art. 51819) to make the hole conical.

Place the brackets C110 on the beam and make sure the holes in the bracket re faced sideways. Use the bolts M10

x 180 to secure the brackets. Do not tighten the bolts yet.

Possibility 3: the connection of 2 supports is supported by the post

Drill 2 x 2 holes Ø 14 mm in the bottom side at 35 mm from the edge.

Also drill 2 x 2 holes Ø 11 mm at 250 and 465 mm from the edge. Use a countersink 90° Ø 20.5 mm to make the

hole conical.

Afterwards, drill 2 x 2 holes Ø 11 mm in the top side of the support.

Use a countersink 90° Ø 20.5 mm (art. 51819) to make the hole conical. Drill 2 x 2 holes Ø 14 mm at 250 and 465

mm from the edge.

DX

70

70

Ø 14

Dx

70

70

Ø 11 v 20,5

Dx ø11

ø20,50

M10 x 180

(4x)

ø11

ø20,50

35

Ø 11 v 20,5

70

Ø 14 Ø 14

250

465

Ø 11 v 20,5

inside carport

35

Ø 14

70

Ø 11 v 20,5 Ø 11 v 20,5

250 465

Ø 14

inside carport

20 20

23,5 23,5

01/04/2019 17/32

E_MH_Mounting_instructions_Skylux_ClimaCar

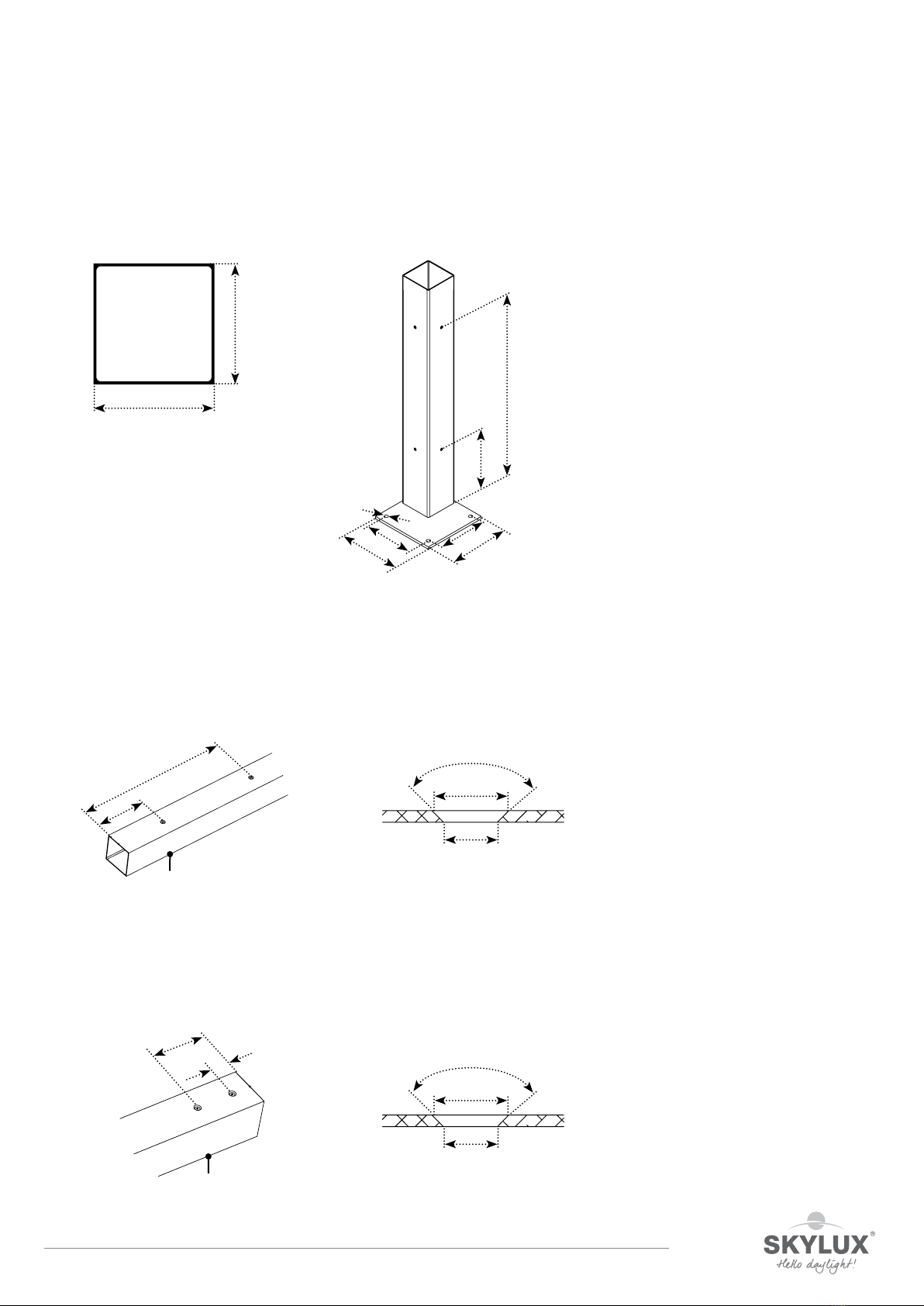

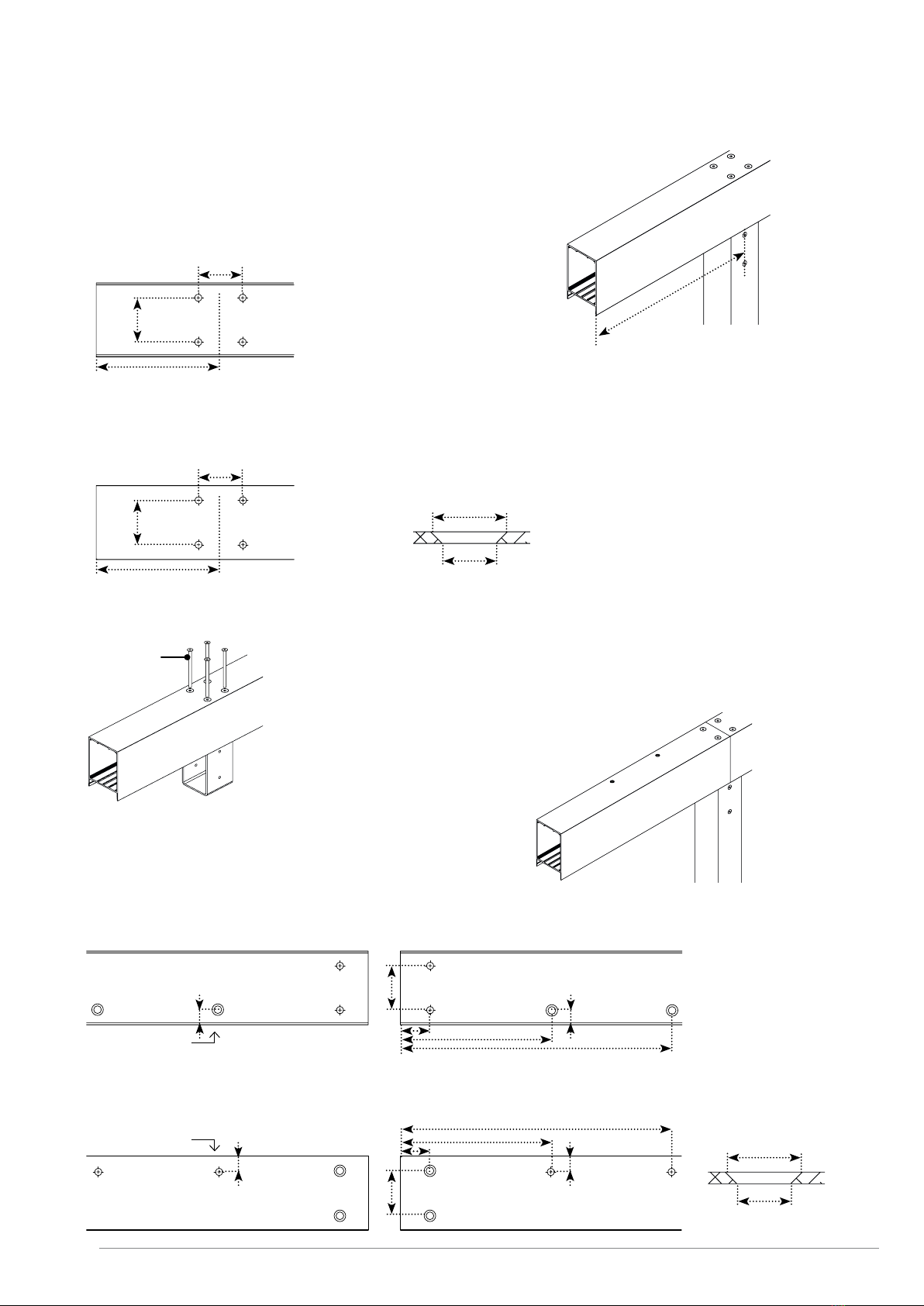

Rectangular profile 72 X 110

P72 C72

Preparation rectangular profile (2 x)

Check the length of the rectangular profiles. These are sawn to a length of 3018 or 3493 mm. Place the profiles

on trestles.

Drill 4 holes of Ø 11 mm in the extremities on the shortest side of the profile. Use a countersink Ø 16.5 mm (art.

51197) to make the holes conical. The transparent sticker art. 49564 can be used here as a drilling stencil.

Slide the brackets C72 into the rectangular profiles and make sure the holes in the bracket are faced outwards.

Use the bolts M8 x 20 to secure the brackets. Do not tighten the bolts yet.

72

110

150

50

50

150

ø12,30

ø16,50

90°

P72

P72

C72

E_MH_Mounting_instructions_Skylux_ClimaCar 01/04/2019

18/32

Rectangular profile 35 X 35

LP08 GT35

Preparation rectangular profile (1x or 2x)

Check the length of the rectangular profiles. These are sawn to a length of 3018 or 3493 mm and pre-drilled on

the ends (Ø 8.5 mm). Place the profile on trestles.

Length of support max. 5000 max. 7000

Number of profiles 1 x 2x

+ an extra rectangular profile for each connection of 2 supports.

Slide the brackets GT35 into the rectangular profiles until the holes in the bracket match the holes in the profiles.

Use the bolts M8 x 60 + washers M8 and nuts M8 to secure the brackets.

35

35

LP08

GT35

M8 x 60

01/04/2019 19/32

E_MH_Mounting_instructions_Skylux_ClimaCar

Installation substructure

Posts

Check the distances between the posts and brace them suciently (see pg. 8 & 9).

Installation supports (2 x)

Place the supports on the posts. Slide the brackets into the posts. The lowest lips of the support slide over the

posts with a press fit. 4 bolts M8 x 20 are screwed in per post.

Post on the extremities

Post further inside

M8 x 20 (4x)

M8 x 20 (4x)

E_MH_Mounting_instructions_Skylux_ClimaCar 01/04/2019

20/32

Post supports connection

Installation rectangular profiles 72 x 110 (2 x)

The rectangular profiles must be mounted on the ends between the supports.

Use 4 bolts M10 x 30 and washers M10 to attach the rectangular profiles to the supports.

M8 x 20 (4x)

M10 x 30 + (4x)

Slide the brackets C110 into the supporting post and

make sure the holes in the bracket are faced sideways.

Use the bolts M8 x 20 to secure the brackets. Do not

tighten the bolts yet.

Place the support on the half of the post. Turn a bolt M10 x

180 into the outermost hole of the support and secure it in

the bracket C110.

Slide the connection profile UPN140 in the support

until the drill hole matches the opening in the

support. Secure the connection profile with M10 x

180.

lide the second support over the connection profile until it

reaches the first support. Put 2 bolts M10 x 180 in the holes

and tighten them in the bracket C110. Now, enter the 4

remaining bolts on the bottom in the support through the

connection profile UPN140. Provide a washer and nut M10

and tighten them.

M10 x 180

M10 x 180

inside

carport

outside

carport

M10 x 180

inside

carport

outside

carport

This manual suits for next models

1

Table of contents

Other SKYLUX Tent manuals

Popular Tent manuals by other brands

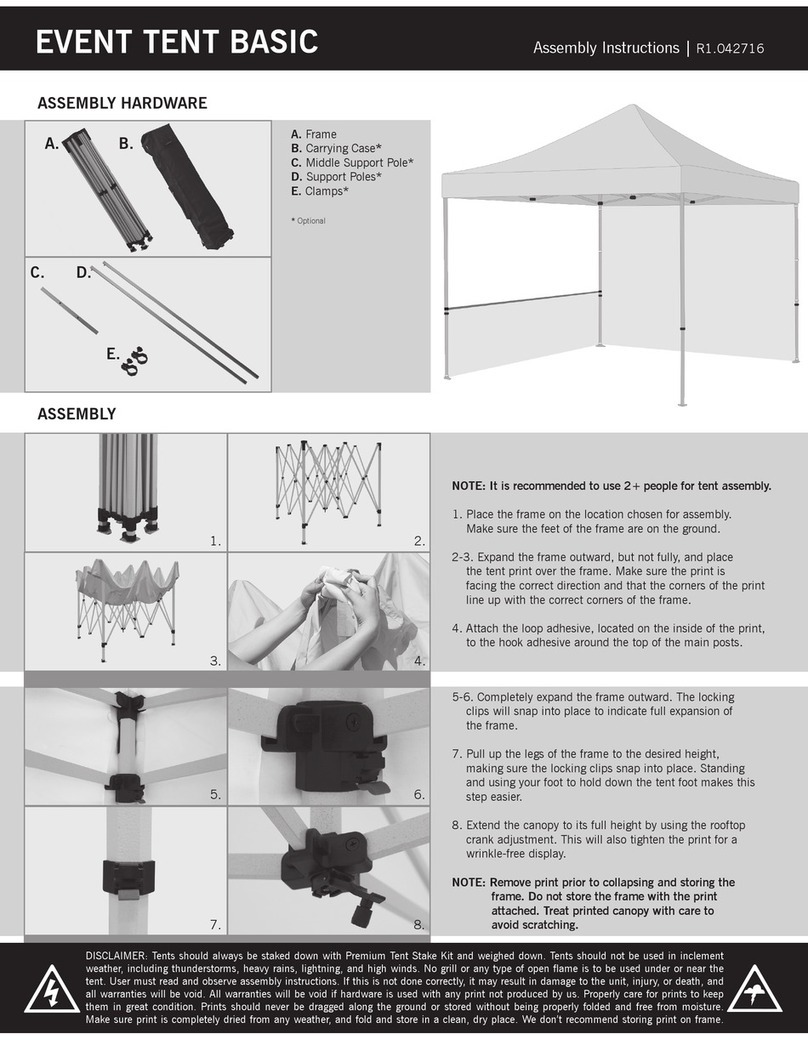

TEX VISIONS

TEX VISIONS EVENT TENT BASIC Assembly instructions

Bestway

Bestway 58460 owner's manual

Outdoor Connection

Outdoor Connection ESCAPE 3 PLUS quick start guide

AC Infinity

AC Infinity CLOUDLAB Series user manual

Isotra

Isotra MIRA 4 MEASUREMENT AND ASSEMBLY MANUAL

Khyam

Khyam Cleveland 6 Erection Instructions

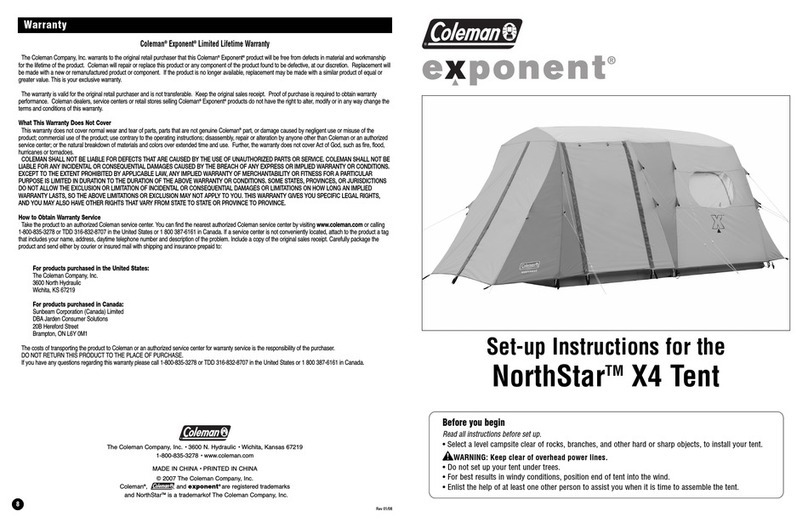

Coleman

Coleman NorthStar X4 Setup instructions

Tentsile

Tentsile UNA owner's manual

Ozark Trail

Ozark Trail WMT14168.1 Assembly instructions

MMI OUTDOOR

MMI OUTDOOR TREK TENTS 283A Setup instructions

skandika outdoor

skandika outdoor PALERMO Setup Instruction

Snugpak

Snugpak JOURNEY TRIO Assembly instructions