SKYLUX Climalux 36179 User manual

CANOPY

Climalux®

Mounting instructions

EN

Art.N° 36179

E_MH_Mounting_instructions_Skylux_Climalux 01/11/2017

2/36

CONTENTS p. 2

OVERVIEW CLIMALUX PROFILES AND PARTS p. 3 - 4

GENERAL INSTALLATION TIPS p. 5 - 11

MEASURING YOUR CLIMALUX PITCHED ROOF p. 6 - 7

PREPARATION p. 8

GENERAL TIPS AND MAINTENANCE INSTRUCTIONS p. 9 - 10

PLAN OF CLIMALUX CONSERVATORY ROOF p. 11

SPECIFIC INSTALLATION TIPS FOR THE CLIMALUX SYSTEM p. 12 - 29

POSTS p. 13

GUTTER p. 14 - 16

GUTTER RAFTER FOR ROOF WITH OVERHANG p. 17 - 18

WALL PROFILE p. 19

RAFTERS AND SIDE RAFTERS p. 20 - 22

SPACERS p. 23

GLAZING p. 24

FINISH p. 25 - 29

ANNEX p. 30 - 35

LOAD GRAPHS p. 31 - 33

LOAD GRAPHS FOR RAFTERS p. 31

LOAD GRAPHS FOR GUTTER PROFILES p. 32 - 33

SPECIFIC INSTALLATION TIPS FOR LED LIGHTING p. 34

GLAZING THICKNESS TABLE p. 35

Table of contents

01/11/2017 3/36

E_MH_Mounting_instructions_Skylux_Climalux

Overview of Climalux profiles and parts

MX WALL PROFILE

GX GUTTER

GLX ORNAMENTAL PROFILE FOR GUTTER

GIX CONNECTING PIECE FOR GX

GDGL LED PROFILE FOR GDG

GR RAISED PROFILE FOR GUTTER GX

GDX GUTTER SUPPORT FOR OVERHANG

GDCX CLIP PROFILE FOR CROSS-BEAM GDX

DX RAFTER

L16P SIDE PROFILE 16 MM

CL16 CLIP ALU 16 MM

CLLX SIDE CLIP 16 MM

CLSB BASE SCREWABLE CLIP

FROM 7 UP TO 16 MM

CLST TOP SCREWABLE CLIP

CLSL TOP SCREWABLE SIDECLIP

PX POST 110/141 FOR GUTTER GX

PGDX POST 110/110 FOR CROSS-BEAM GDX

C1CX

COEXRUBBER FOR WALL TOP

WHITE/BLACK

COEXRUBBER FOR WALL TOP

GREY/BLACK

C2CX

COEXRUBBER WHITE/BLACK FOR

TP-TPG-TPGL

COEXRUBBER GREY/BLACK FOR

TP-TPG-TPGL

C3 RUBBER FOR SHEET SPACER GREY

CY10 RUBBER GREY FOR CL16 AND CLSB

C8 RUBBER GREY FOR CL16 AND CLSB

WALL

GUTTER

RAFTERS

POSTS

RUBBERS

E_MH_Mounting_instructions_Skylux_Climalux 01/11/2017

4/36

Overview of Climalux profiles and parts

AX SHEET SPACER

U16P REINFORCED PVC END PROFILE

16 MM WHITE

U16A ALU END PROFILE 16 MM

U16 PRE DRILLED ALU END PROFILE 16 MM

L432 L-OBTURATOR PROFILE

BT16 CLOSED SYNTHETIC TAPE FOR 10 AND

16 MM SHEETS WITH GARANTEE

BB16 PERFORATED SYNTHETIC TAPE FOR

16 MM SHEETS WITH GARANTEE

S16X STOP FOR DX

GSX END PIECE GUTTER FOR GX

GLSX END PIECE GUTTER FOR GX + GLX

GRSX END PIECE GUTTER FOR GX + GR

LOGO LOGO CLIMALUX FOR END PIECE

GUTTER

GDSX END PIECE FOR CROSS-BEAM GDX

MSX END PIECE WALL PROFILE FOR MX

909 CONNECTING PINS

LGDX FIXING PROFILE “L” FOR CROSS-BEAM

GDX

PV BASE-PLATE FOR POST PART 110/50

PU U TOP-BOTTOM FOR POST PX 110/141

PUX U TOP-BOTTOM FOR POST PGDX

110/110

BMR STAINL SCREW, NUT AND RING

SPRING M8

GC WATER OUTLET + SWIVEL

DIAM 80 MM GREY

UGS

WUGS

UNIVERSAL OUTLET +

OUTLET GUTTER SPOUT

ZSB/G

ZSC

STAINL. STEEL SCREW 5,5 x 32 MM

TX 25

STAINL. STEEL SCREW 5,5 x 32 MM

TX 25 WITH BUTYL SEALING

6,3 x 25 SELFDRILLING SCREW 6,3 x 25 mm

CLIMALUX

TX25

10

ACCESSORIES

01/11/2017 5/36

E_MH_Mounting_instructions_Skylux_Climalux

General installation tips

Please read this manual carefully.

The installation must be carried out by people with sucient technical knowledge and experience in the area of

conservatory installations. The installer must take the required safety measures into account during the installation

such as the use of scaolding and personal protection equipment - safety shoes, helmet (i.e. hard hat), gloves,

safety goggles, etc. - to ensure the work is carried out in a safe environment. During installation, please make sure

that the necessary precautions have been taken to ensure the stability of the unfinished construction.

Fixing material

The selection of required fixing material is to be made in function of the foundation or the walls. Check whether

the foundation and the walls on which the structure is to be anchored have a sucient load-bearing capacity. The

installer is responsible for the assessment of the appropriate fixing materials for the load and foundation on which

the structure is to be fixed. Please contact your fixing material supplier or specialised engineering consultants in

case of doubts. Skylux cannot be held responsible for the installation or the fixing materials used.

Seal installation

A distinction is made between push-in seals and slide seals.

The seal of a push-in seal is pushed into the profiles. The C2CX, C8 and CY10 seals are push-in seals.

The slide seals C1CX & C3 are slid into the profiles.

The seals C1CX and C2CX are equipped with an anti-stretch wire that prevents the seal from being stretched

during installation. This technology ensures that the seal cannot shrink after installation.

Avoid the use of silicone and detergent when installing the seals. Plastic sheets can be damaged by these products.

Plastic sheets can result in settlement noise due to temperature fluctuations. This will not aect the guarantee and

will not be accepted as a claim.

Terms, conditions and guarantee

The guarantee is void when the installation instructions provided below are not followed. Not following the

instructions and/or using other parts may have an adverse eect on the safety and life cycle of the product.

Variations are not permitted without written permission of the manufacturer. Our installation instructions manual

and film are based on the latest level of our knowledge and technics. We cannot be held responsible for possible

incomplete information. Always check if our product is suited for your application. As the manipulation and the

mounting of the product are done beyond our control, can Skylux not be held responsible for possible damages.

The installer must take the specified span values in relation to the glazing and load (snow and wind) according

to the applicable standards into account. The load graphs that you will find in this manual on page 31-33 are

only indicative. Contact the manufacturer, architect or engineering consultant for conservatory roofs outside

the normal range. The manufacturer reserves the right to change this manual without prior verbal or written

notification.

Skylux reserves the right to change this manual without prior notification. Changing the installation requirements

or the product will not mean a right to any compensation or exchange of parts.

The latest version of this manual can be consulted by visiting www.skylux.be.

Climafast

The Climafast calculation application is oered by Skylux for free and is at disposal of the professionals. You

will receive information on how to log on and download the Excel version of the application upon request. With

Climafast, you can determine the price of your Climalux roof. An overview of profiles, lengths, parts, allowed

loads, etc, is provided for each project. The aim of this application is to inform the user.

Skylux reserves the right to change the Climafast application without prior notification. The results of the

application are indicative and do not give right to any compensation. The latest version of the calculation

application can always be downloaded from www.skylux.be.

E_MH_Mounting_instructions_Skylux_Climalux 01/11/2017

6/36

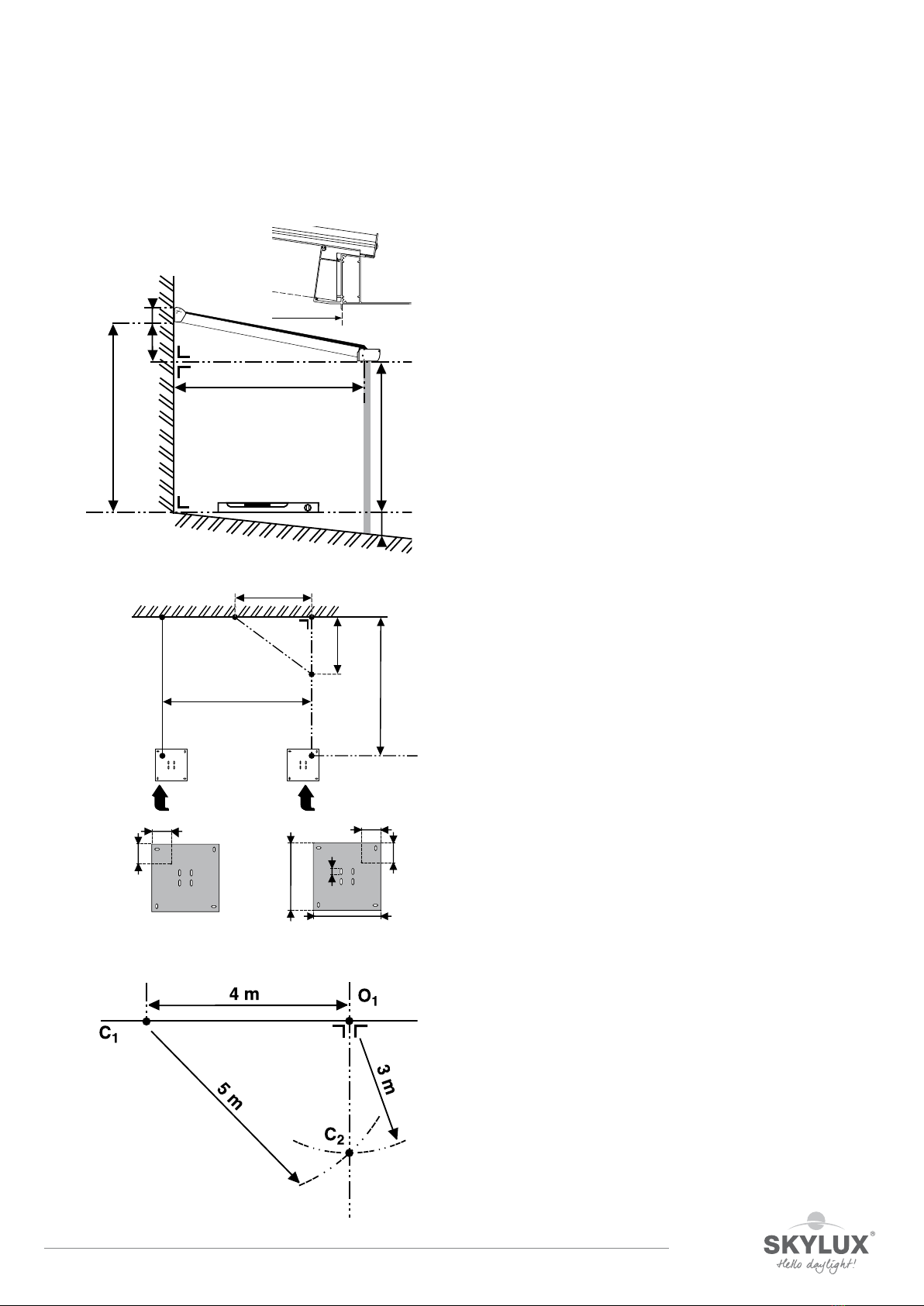

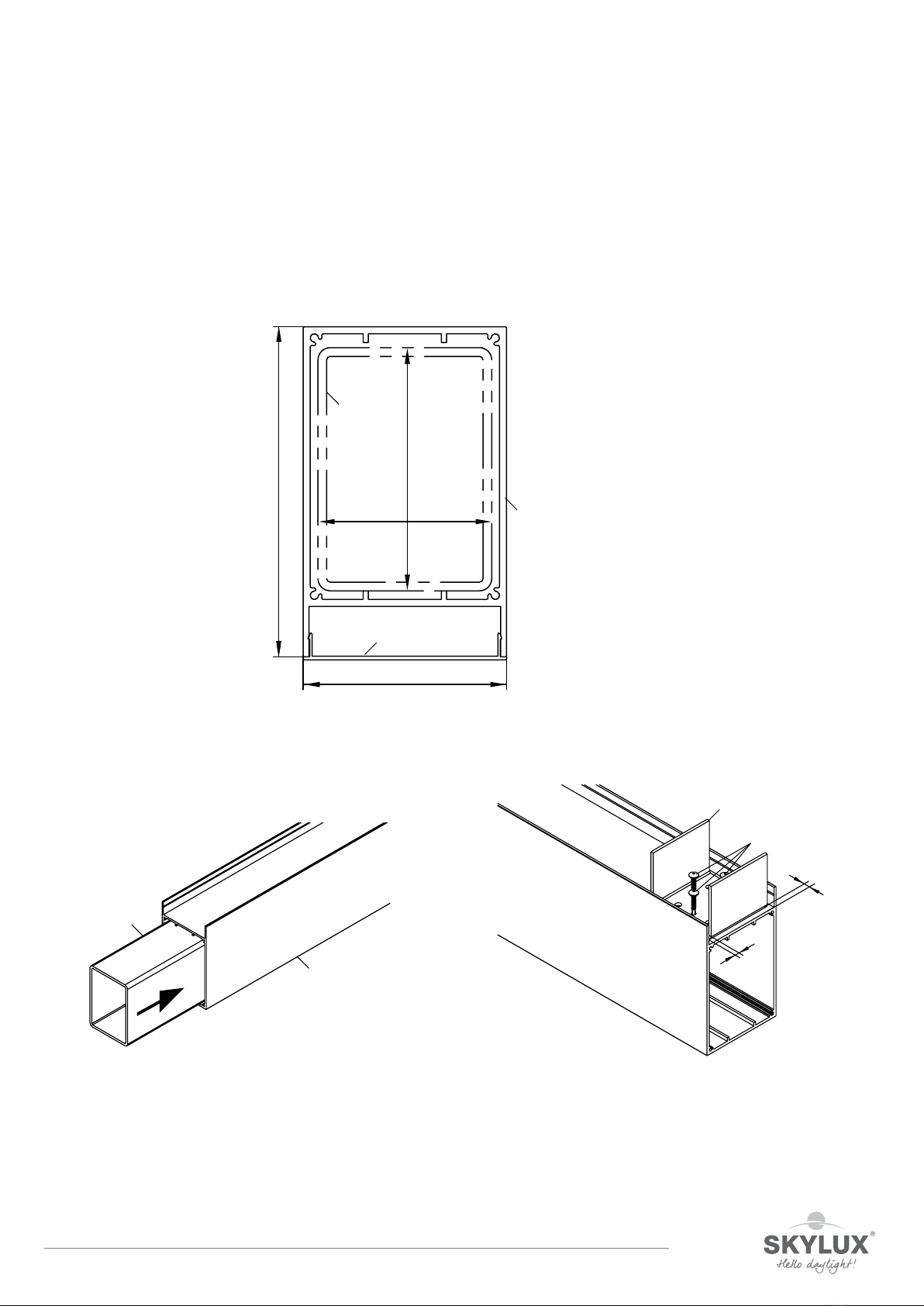

Measuring your Climalux pitched roof

Measurement

Determine the height dierence H.

The height dierence H is the dierence between the bottom side of the wall profile MX and the bottom surface

of the gutter combination. The stop lip for the window is not included in the calculation. The standard roof

inclination is 8°. Other inclinations are possible between min 5° and max 10°.

The height h is always 144 mm.

Determine the depth (fig 2, page 7)

Measure horizontally from the wall to the inner side of the support post to determine the roof depth D. The

additional depth of gutter GX is 160 mm, or of the gutter with ornamental frame GLX is 176 mm for a Climalux.

For a construction with eave, please consult page 22.

Determine the width B (fig 2, page 7)

The width B of the Climalux is the distance between the outer side of the side rafters. If the Climalux is installed

between two walls and a gutter with screwed-on gutter end-pieces is used, you can deduct 5 mm per side from

width B, as the screws for the gutter end piece require additional width and additional clearance is recommended.

These measurements can be used to calculate all other measurements using the Climafast calculation application,

which is available free of charge from Skylux. We strongly recommend the use of the calculation application.

All possible exceptions are taken into account. The correct cutting lengths are provided and only correct

combinations are suggested. The list of measurements for sizing is always provided with the materials.w

160

176

115

150

h = 144

H

D

B

H

D

01/11/2017 7/36

E_MH_Mounting_instructions_Skylux_Climalux

Measuring your Climalux pitched roof

Neem deze handleiding zorgvuldig door.

3

H

HMHG

HN

D

hD

1

O2

B

O1

P1

P2

C2

C1

3 m

4 m

5 m

D

20 mm

300 mm

300 mm

P1

100 mm

95 mm

95 mm

P2

100 mm

2Installing the Climalux post PX and PV base plate.

- Determine point O1.

- Determine O2. The distance O1 - O2= conservatory width “B”.

- Draw a line with chalk using the 3/4/5 rule and determine point

P1. The distance O1- P1is the depth = D

(Refer to item 3 below.)

- Repeat the same calculations for P2.

- Measure the distance (P1- P2), which must be equal to

(O1- O2) as an additional check.

- The base plate can be slid through the slotted holes in order

to position the base plate properly.

- The U for the base plate can be moved 20 mm either way to

allow proper adjustment.

The 3/4/5 rule.

- Determine the auxiliary point C1based on O1at a distance

of 4 metres

- Use a 3 metre string and a piece of chalk to draw a circle from

point O1.

- Use a 5 metre string to draw a circle from point C1.

- The 2 circles intersect at C2.

- Line O1- C2should be at a perfect right angle to your wall

(line C1-O1).

The dierence in height H and depth D for the veranda.

HM= The height from the floor and the bottom side of the

profile measured at the back of the veranda.

HN= The slope of your veranda floor.

HG+ HN= Installation height for the bottom side of gutter GX.

This is also the height for the windows or the length

of the posts.

H = HM- HG

h = 144 mm (wall profile height)

E_MH_Mounting_instructions_Skylux_Climalux 01/11/2017

8/36

Preparation

The Climalux roof can be delivered cut-to-size to reduce the installation time.

Walls

Check that the walls, against which the structure is to be installed, are:

- Suciently load-bearing to anchor the roof.

- Free of obstacles such as water drains, window sills ...

Install a lead slab to ensure a waterproof junction to the walls. Make a slot in the walls against which the

conservatory roof is to be installed. Install a lead slab or zinc flashing.

Height = first joint above Hm + h and max 60 mm above the wall profile.

LED lights (optional)

ClimaLED strips/spots: see p. 34. Please respect in time the specific requirements or modifications during

installation.

Floor

Ensure that the foundation can carry the load. Have an architect determine the required foundation. Implement

measures to remove rainwater from the roof.

Precautions

Protect the finished profiles against scratches and dents during installation.

01/11/2017 9/36

E_MH_Mounting_instructions_Skylux_Climalux

uNearly all silicone products affect

the polymethyl methacrylate or poly-

carbonate sheets. Purchase silicone

types that are safe for polymethyl

methacrylate or polycarbonate pro-

ducts (guarantee certificate).

uThe fumes from this putty may

never evaporate in the slots of the

sheet. The ventilation openings as well

as the sides of the end profiles may

not be closed off. The silicone should

always be allowed to release fumes

freely.

uSome seals contain softening agents

(as used in certain types of rubber,

PVC, polyurethane, etc.) that may

cause small cracks. Use only approved

seals.

uDo not use black or dark-coloured

seals to prevent heat accumulation.

uA lead slab may be placed on the

seals but may not rest against the

sheets.

uSome paints, varnishes and wood

protectors affect the polymethyl

methacrylate or polycarbonate sheets.

Never use lubricants to put the seals

into the profiles.

uNever spray insecticide directly on

to the sheets. Synthetic sheets can be

damaged by these products.

2. SILICONE, SEALS AND

WOOD PROTECTORS

uObserve the safety instructions

that apply to work on roofs.

Polycarbonate sheets: Very

IMPORTANT! The side which is

protected against UV radiation

must always be installed facing

the exterior or the sky. The “sun

side” is indicated on the protec-

tion film.

uThe plastic tape or the provisional

aluminium tape will only ensure the

sheets are free from dust while being

shipped. These should be removed!

Adjusted aluminium tape or end pro-

files must be used.

uThe load-bearing structure must

be strong and stable. (See the regu-

lations that apply to the timber and

metal construction industry.) Cross

supports may be required depending

on the type of sheet used. Only spe-

cific maximum lengths may be used

without a cross support for each

type of sheet taking into account

the loads of 500 N/m2or 750 N/

m2, respectively (see the technical

plastic sheets information sheet).

uPergotop/Pergotop-soft sandwich

panels are only adapted in combina-

tion with Skylux screwable clips.

uHeat accumulation: the top side

of the load-bearing structure that is

turned towards the sheets must be

WHITE reflective.

4. INSTALLATION

Synthetic sheets can expand or shrink

when there are temperature fluctua-

tions. The following tips should be

taken into account:

uEnsure there is 5 mm clearance

lengthwise for each sheet meter and

ensure there is 10 mm clearance

(5 mm on each side) widthwise, for

example, a 3000 mm sheet must

have a clearance lengthwise of 1.5 cm.

uNever block the sheet lengthwise

or widthwise. Always ensure sufficient

clearance.

uNever stick the sheet using silicone

(even when it does not damage syn-

thetic materials). It would prevent the

expansion and shrinkage of the sheets.

uThe sheet is blocked at the bot-

tom end to prevent it from sliding. The

clearance must, therefore, be pro-

vided at the top.

1. CLEARANCE

5 mm 5 mm

uApply white dispersion paint (diluted

in water or paint without solvents) or use

preferably aluminium tape. Attention:

Let the paint dry after painting the

load-bearing structure! Continue with

the installation of the sheets after the

paint has dried. The synthetic sheets may

NEVER be installed directly on to tim-

ber structures.

uDo not place roof tiles directly on

the sheets! Leave a space of at least

10 mm between the sheets and the

roof covering.

uUse a special weather stripping (seal

C6) for sealing the opening between

the plate and the gutter beam. Do not

seal using sealant or fill with PU foam.

uWe formally recommend not add-

ing a ceiling under the acrylic sheets

(PMMA). Any used sun blinds or

other finish under the sheets should

be at least 120 mm from the roofing

sheet. These may not have insulation

properties and should have a reflect-

ing colour. The polycarbonate sheets

(PC) do not require any specific pre-

cautions.

u

WIDTH DISTRIBUTION

OF THE SHEETS:

RECOMMENDED:

standard

sheet width with an adapter for the 2

outer sheets. This is especially impor-

tant for the S5P heat-stop sheet.

NOT RECOMMENDED:

in equal sections with sized sheet

widths. Take the standard sheet width

into account. We formally advise

against sizing multiple-layer sheets.

The closed off sides are

one of the factors that

determine the sheet

strength!

uFollow the installation instructions

provided by the glass manufacturer

when including the installation of

glass!

5. GLASS

uClean the sheets annually using

lukewarm rainwater. Dissolve a little

household soap (neutral) in the water

if required (no detergent!!). Never use

solvents or abrasive products.

uDo not rub dry (may cause

scratches).

uSimply rinse.

3. MAINTENANCE

Space for expansion

uClean the surfaces/profiles min.

1 a year with cold water and a mild

soap. Rinse well with plenty of

water.

Never use solvents or abrasives!

A good cleaning is necessary to

avoid the profiles from growing dull

and dirty by the UV light!

General tips and maintenance instructons

The qualitative and technological level of the multiple layer plastic sheet is high. We provide a few important tips for problem-free

installation. Please pay special attention to the following: Space for expansion/silicone and wooden protection/seals.

E_MH_Mounting_instructions_Skylux_Climalux 01/11/2017

10/36

SILICON

E

6. DRAINAGE AND CONDENSATION

uInstall the sheets with inclination or

vertically, never horizontally (unless

interior use).

uMinimum inclination: 10° (18 cm

per meter) or more.

uThe direction of the sheet canals

must always go along with the roof

inclination.

7. SHEET DIRECTION

°°

° °

uType of saw blade:

1. hard metal (for ca 50 m/s)

uMake sure that the bottom NEVER

stands in water (moss and algae).

uCondensation in the canals is not

100% inevitable (physical phenome-

non).

Acrylic and polycarbonate are very

less gas- and dampproof. The charac-

teristics of the material and the gua-

rantee are not diminished because of

this. An appropriate sealing is recom-

mended.

uAlways use a grease pencil to make

notes on the protection film (felt pen

is difficult to remove).

uTo ensure a fest clamping during the

sawing, you should always make sure

that a raised rib is as near as possible

by a sawed edge.

9. SAWING AND DRILLING

uWhen sawing, use a hard metal saw

(widea) with high rotation speed. Saw

slowly and by preference with one

move. Use new or sharpened saw bla-

des. Make sure the sides are always

smooth.

ATTENTION: The basis on which the

sheets are sawn, must be stable and

vibration-free. The sheets must not

move during sawing. The saw blade

must slightly reach out of the sheet.

uRemove all dust and sawing rests

from the canals with pure compressed

air or a powerful vacuum cleaner.

uOnly remove the protection film

after installation to avoid scratches.

uDrilling is strongly advised against.

However, if unavoidable, provide with

grooves (shrinking and dilatation).

°°

°°

°°

2. HSS (not more than 40 m/s)

uAvoid direct sunlight on piled

sheets.

uIf you pile the sheets outside, cover

the sheets with white polyethyl foil.

Always keep the synthetic friendly

tape as sealing on the front sides of

the sheets.

uThe sheets must not be piled direct-

ly on the ground. Use appropriate pal-

let boards.

10. PILING

uNever walk or kneel directly on the

sheets. Always use solid timber boards

underneath. Make sure these boards

are supported by the timber construc-

tion.

uMulti-walled synthetic sheets with

thin walls and a high insulating struc-

ture in the sheet, are sensitive to foot,

knee and other impressions at the

surface. Please take enough precau-

tions during transport and installa-

tion. Impressions in the sheet are not

covered by the guarantee.

12. REMEMBER

uAs we already mentioned several

times, synthetic sheets shrink and

dilate under the influence of tempe-

rature fluctuations. When they move

with regard to the roof construction,

there can be some creak noises. There

is no danger for the sheets if they

have been installed according to the

installation instructions.

u

Screwed clipses cause more creak

noises with synthetic sheets

.

u

If you would like to avoid crack

noises, we advise you to always use

the TP and TPH profiles. The TP can

expand and shrink with the synthetic

sheets or alu sandwich sheets.

14. DILATATION NOISES

Dust and damp may not enter into the

cell structure:

uA combination of BT 16/25/32

at the top and BB 16/25/32 with

U16/25/32P at the bottom, stops

dust of

> 45μm from entering the cell

structure.

uThe underside is provided with a

perforated aluminium filter tape.

To protect the tape, use the U16P/

U25P/U32P or a U profile with per-

forations of Ø 3.5 mm, installed every

20 cm.

uSeal the profile with synthetic

friendly silicone to prevent water infil-

tration maximally.

u

Wet the edge of sheets with no-

drop layer and dry it afterwards before

taping the sheet.

uIf you install sun protection, you

must do this on the upper side of the

sheets: e.g. on the outside.

Attention:

Do not put the sun protection directly

on the sheet!

You can also buy sunproof sheets

(PC: Primalite Clear, Reflex Pearl,

Relax - PMMA: S5P Heatstop) or

install a Skylux conservatory dome.

11. SUN PROTECTION

uThe multi-walled synthetic sheets

resist normal snow load. You can find

the maximum snow load on the tech-

nical files per sheet type and size. In

case of heavy snow fall, we recom-

mend to regularly clear the snow.

The conservatory roof must also be

protected against snow falling from a

higher situated roof.

13. SNOW AND SNOW PILE

uOnly use sheets with identic pro-

duction number per project to avoid

colour differences.

15. FURTHER INSTRUCTIONS

uMulti-walled synthetic sheets may

reflect the sunlight to the inside or

the outside in case of direct sunlight

(following the orientation or the

inclination). This is a normal situation

which does not affect the sheet gua-

rantee.

8. REFLECTION

01/11/2017 11/36

E_MH_Mounting_instructions_Skylux_Climalux

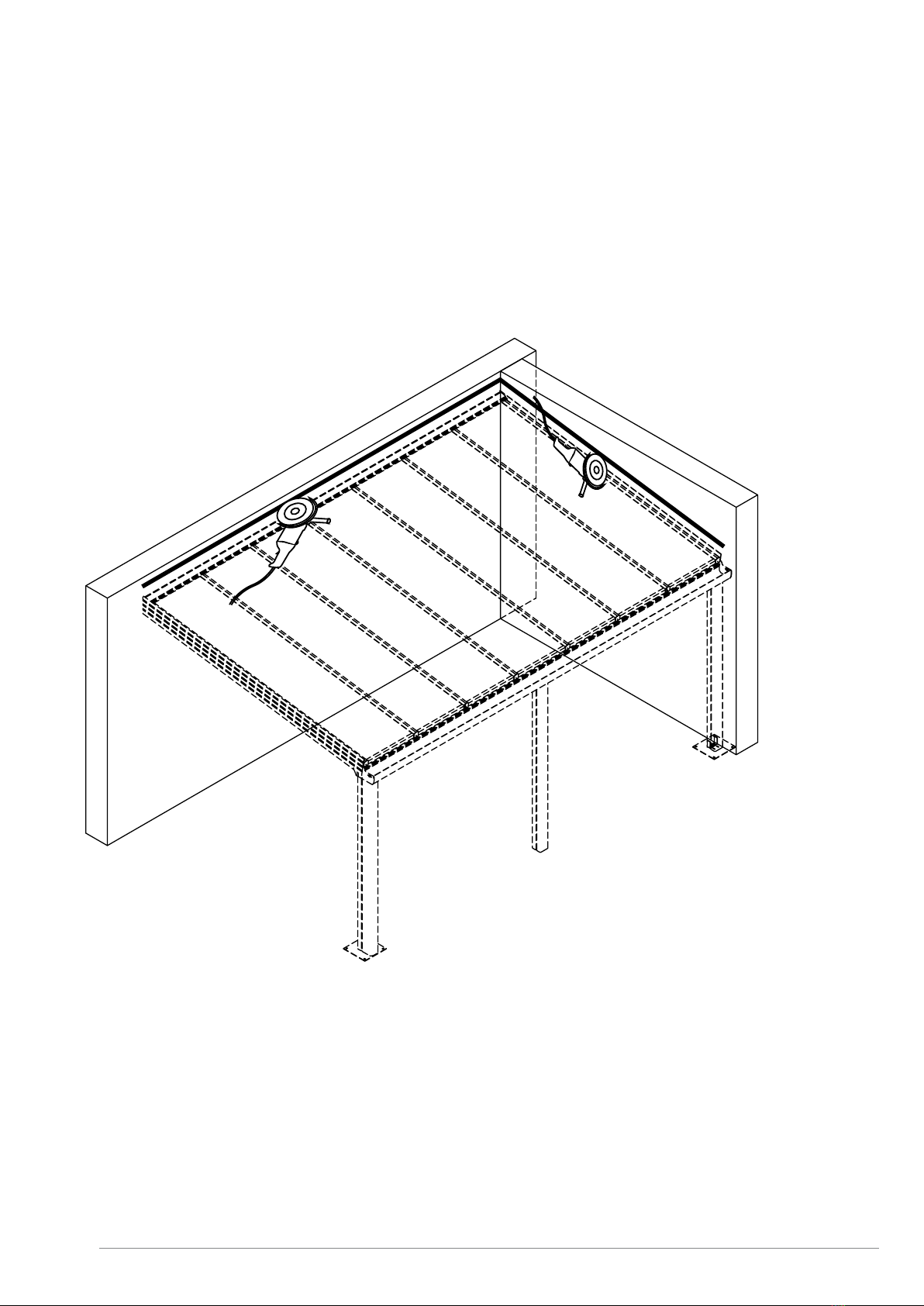

Overview drawing of the conservatory roof

A10 - A11: posts, page 13, 29

A20 - A23: gutters, page 14-18, 29

A30 - A33: wall profiles, page 19, 29

A40 - A42: rafters, side rafters, page 20-28

A10

A11

A20

A21

A22

A23

A40

A41

A42

A30

A31

A32

A33

E_MH_Mounting_instructions_Skylux_Climalux 01/11/2017

12/36

Climalux®

Installation tips

01/11/2017 13/36

E_MH_Mounting_instructions_Skylux_Climalux

Climalux®

Installation tips

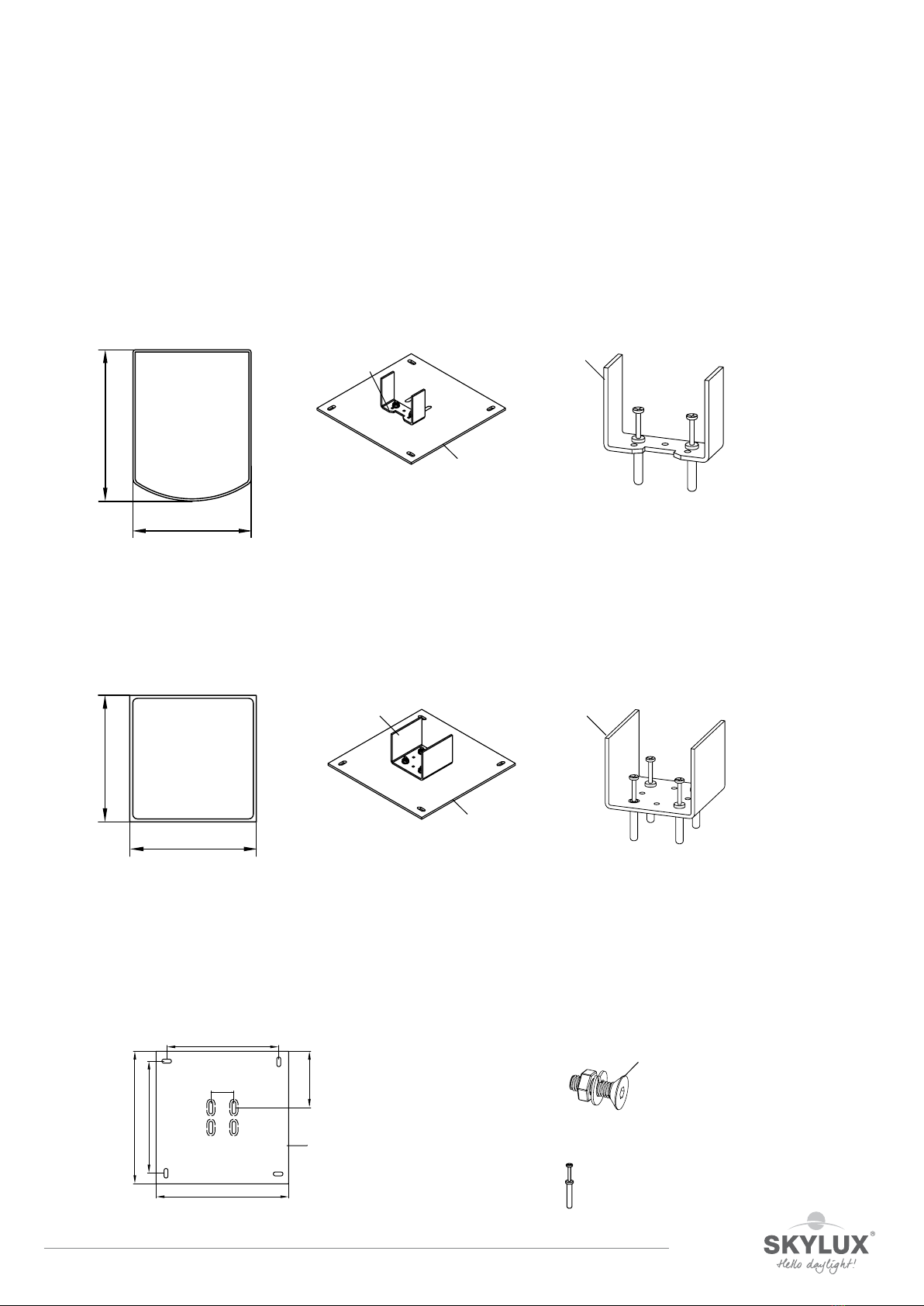

Posts

Determine the length of the posts (HN+ HG) in function of the slope and the position of the wall profile (HM).

Post for gutter GX accessories for corner post accessories for middle post

Base plate PV (optional) and U-shaped bracket U-bracket

Post PX 110/141

Post for gutter rafter GDX

(for roof with overhang)

Post PGDX 110/110 for gutter rafter GDX

Bolt the U-bracket to the PV base plates (fig A) using the BMR screw set (fig B) for the corner posts. Determine

the position of the PV base plates as indicated on page 7 and anchor these on a solid foundation in concrete using

the suitable fixing accessories (not supplied). Position the U-bracket correctly on the base plate and fix it. The

U-bracket for the middle posts can be installed without a base plate directly on a solid basis. Position the posts

over the brackets. Position these perpendicularly (level) and shore these temporarily to ensure they do not fall

over. The top part of all posts must be completely aligned and level.

Fig. A Fig. B

110

141

PU

PV

(optional)

PU

110

110

PUX

PV

PUX

52

300

300

127,5

253,5

253,5

PV

BMR

not supplied

E_MH_Mounting_instructions_Skylux_Climalux 01/11/2017

14/36

Gutter

Multiple gutter combinations are possible.

Use the load graphs on page 31-33 or calculate using the Climafast calculation application:

gutter combination (with reinforcement profile

GX (+ V822)

GX + GLX (+ V822)

GX + GR (+ V822)

Make sure there is a play of 10 mm if the gutter combination is to be installed between two walls. The 5 mm

clearance on each side is required for the installation of the slide ends.

Pre-drilling is required to install the U-brackets if the gutter (rafter) is reinforced with a steel profile. The use of

strong self-drilling screws is recommended.

* The reinforcement profile V822 is not supplied. It can be bought at any local hardware store.

We recommend treating the reinforcement profiles with an anti-corrosion product.

160

115

90,5

211,58

V822

GX

150

176 51,58

90,5

V822

GX

GLX

90,5

160 51,58

211,7

61,5

GX

GR

V822

01/11/2017 15/36

E_MH_Mounting_instructions_Skylux_Climalux

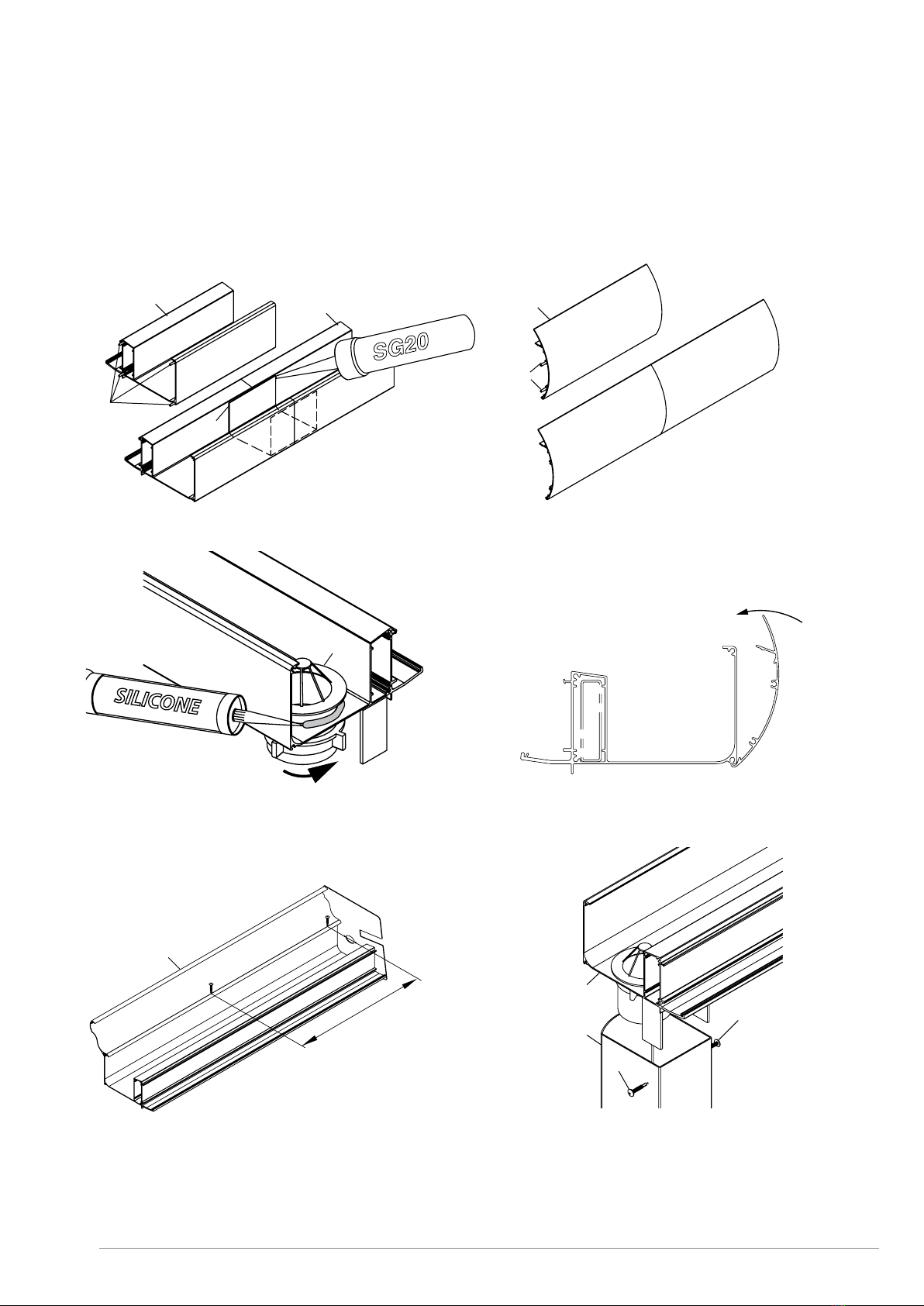

Gutter GX

Assemble the gutter components to prepare for the installation of the gutter

Cut out the opening for the water outlet.

Use a Ø 80 mm circular drill (not supplied).

Slide in the reinforcement profile V822 (optional).

Installation of the U-bracket PU

Use the post caliber for the correct positioning.

* The reinforcement profile V822 is not supplied. It can be bought at any local hardware store.

We recommend treating the reinforcement profiles with an anti-corrosion product.

Ø 80

55

86

GX

GX

V822

4

2

2

4

55

86

PU

ZSB (3x)

E_MH_Mounting_instructions_Skylux_Climalux 01/11/2017

16/36

Gutter

Multiple gutter elements can be connected to each other for gutter lengths > 7 m.

A gutter support must be installed at every gutter connection point.

The gutter profiles can be linked using connection pins 909 and the connector profile GIX. Use silicone SG20 as

sealant.

GLX + 909 (2x)GX + GIX + 909 (4x)

GX GX

909

GIX

GLX

909

A raised profile GR can be installed on the GX gutter. Position

the side gutter slide ends first and subsequently fasten the

GR profile on to the gutter every 500 mm.

500

GR

Install the water outlet in the gutter opening and seal using

silicone.

GC

GX

The ornamental frame GLX is clipsed by a turning movement

on to the gutter. Start at one of the ends.

click

Place the pre-assembled gutter on the posts and fasten the

construction using lacquered screws ZSG. The gutter slide

ends must be pre-installed now if the gutter is installed

between two walls (see page 29).

ZSG

ZSG

GX

PX

01/11/2017 17/36

E_MH_Mounting_instructions_Skylux_Climalux

Gutter rafter for roof with overhang

Components

gutter combination (with reinforced profile)

GDX + GDCX (+ V14105)

Preparation

* The reinforcement profile V14105 is not supplied. It can be bought at any local hardware store.

We recommend treating the reinforcement profiles with an anti-corrosion product.

117

190

100

140

GDX

GDCX

V14105

Installation of the U-bracket PUX.Slide in the reinforcement profile V14105 (optional). Fixing

the reinforcement profile V14105 on to the GDX (top and

bottom) has a favourable influence on the solidness.

V14105

GDX

3,8

7,7

PUX

ZSB (4x)

E_MH_Mounting_instructions_Skylux_Climalux 01/11/2017

18/36

Gutter rafter for roof with overhang

Installation

The construction of the gutter rafter supports the (side)rafters DX (page 22).

Fix the slide ends GDSX with the ZSG

screws.

Fix the gutter rafter on the posts and fasten the

construction with the lacquered screws ZSG.

Multiple gutter elements can be connected to each other

for gutter lengths > 7 m. A gutter support must be installed

at every gutter connection point. The gutter profiles can

be linked using the reinforced profile V14105 and the

connection pins 909. Fasten the gutter rafters GDX on top

and bottom on to the reinforcement profile V14105.

Cut the finishing clips to length and clips it

at the bottom side of the gutter rafter GDX.

PUX GDX

PGDX

ZSG

ZSG

ZSG (4x)

GDSX

GDX

PGDX

909

GDX

GDX

909

GDCX

GDX

CLICK

01/11/2017 19/36

E_MH_Mounting_instructions_Skylux_Climalux

Wall profile

Components

Preparation

Install a lead slab to ensure a waterproof junction to the walls. Make a slot in the walls against which the

conservatory roof is to be installed (page 8). Install a lead slab or zinc flashing.

Drill a hole in the wall profile MX at 250 mm from the ends and subsequently every 500 mm at the top indication

line with a diameter in function of the chosen fixing material. Drill also a hole every 500 mm in the bottom

indication line and start at 30 mm from the edge.

Important: Slight the rubber C1CX in the profile MX before mounting.

Installation

Fix the wall profile using the adapted anchoring. The holes in the bottom wall profile correspond to the height HM

+ 19 mm and HM + 109 mm on the wall.

Finish the top side of the wall profile with silicone and with a lead slab or zinc flashing built-in in the wall.

143,6

30

39,5

19 90

98°

C1CX

MX

500 250

30

500

500

500

500

E_MH_Mounting_instructions_Skylux_Climalux 01/11/2017

20/36

Rafters and side rafters

The rafters are pre-cut at the wall and gutter side. The slot at the wall side corresponds tot the rib of the wall

profile. Check the rafter lengths in function of the glazing + snow and wind load (Use the load graphs on page 31

or calculate using the Climafast calculation application, at disposal for free for professionals).

Components

Rafter

DX + C3 (or CY10)

The rafters DX are pre-cut-to-size.

Preparation

Fix the support seals on both sides of the rafter DX:

C3 for glazing thicknesses 8-11 and 16 mm

CY10 for glazing thicknesses 8 and 9 mm

Fasten the stop profiles S16X on to the gutter side of the

rafters with the supplied ZSG screws.

60

94,5

118

α

DX

gutter wall

C3

(8-11 and 16 mm)

CY10

(8 - 9 mm)

S16X

DX

ZSG

This manual suits for next models

1

Table of contents

Other SKYLUX Tent manuals