2

SUMMARY

1. Introducon ...................................................................................... 3

1.1 Safety .................................................................................................................... 3

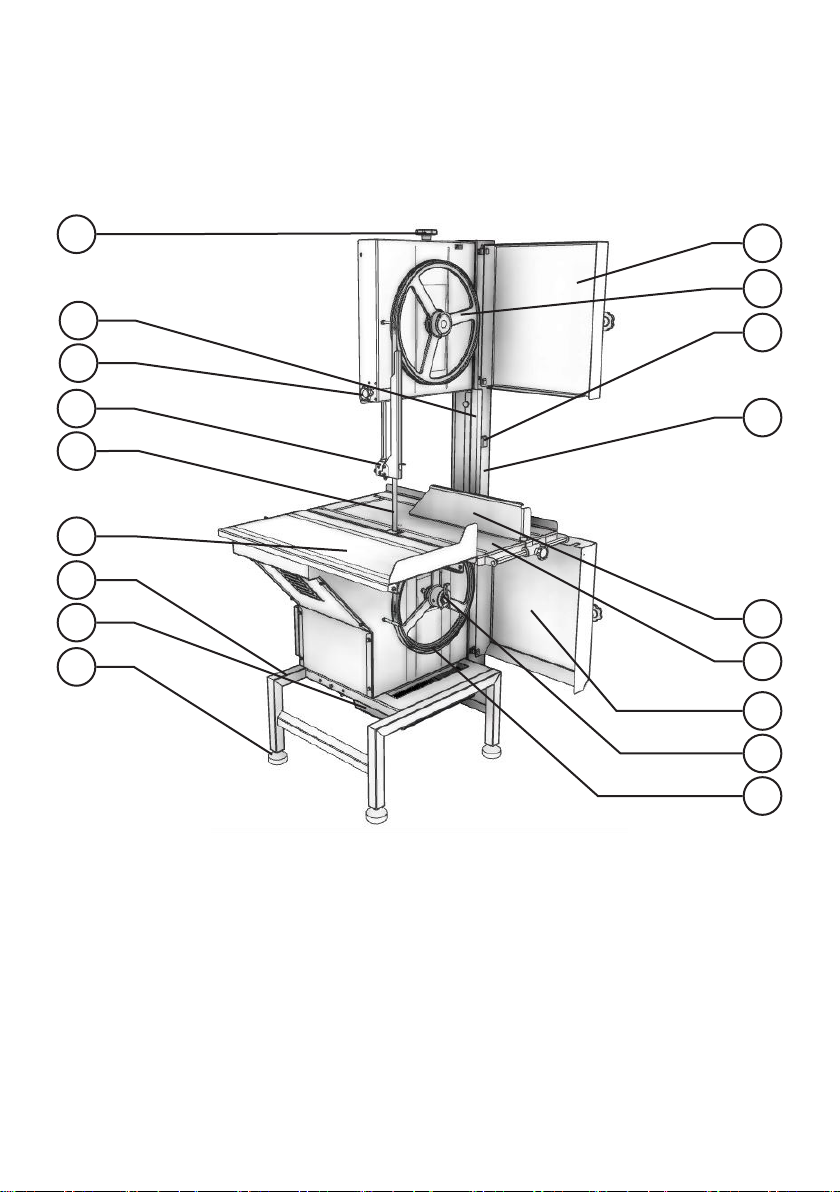

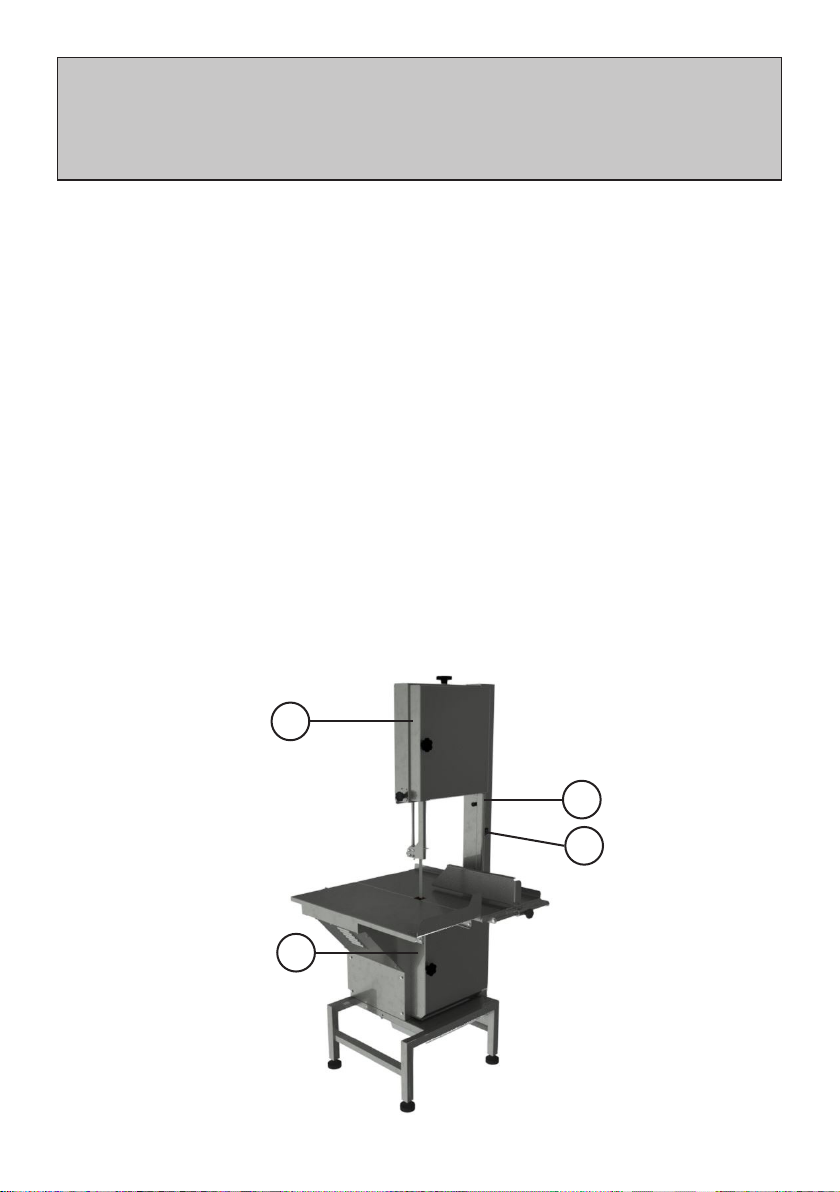

1.2 Main Components ................................................................................................ 5

1.3 Technical Characteriscs ........................................................................................ 6

2. Installaon and pre Operaon .......................................................... 6

2.1 Installaon ............................................................................................................ 6

2.2 Pre Operaon ........................................................................................................ 7

3. Operaon .......................................................................................... 7

3.1 Starng ................................................................................................................. 7

3.2 Operang Process.................................................................................................. 8

3.3 Cleaning And Sanizaon ..................................................................................... 9

3.4 Cauons With Stainles Steel .................................................................................16

4. General Safety Pracces .................................................................. 17

4.1 Basic Operaon Pracces......................................................................................17

4.2 Safety Procedures and Notes Before Switching the Machine On............................18

4.3 Roune Inspecon................................................................................................19

4.4 Operaon .............................................................................................................19

4.5 Aer Finishing The Work ......................................................................................19

4.6 Maintenance ........................................................................................................20

4.7 Warning ...............................................................................................................20

5. Problems Analysis And Soluons ..................................................... 20

5.1 Problems, Causes And Soluons ...........................................................................20

6. Maintenance ................................................................................... 22

7. Electric Diagram .............................................................................. 23