Instruction Manual

Model4101-28/5100-28 IRGas SensorModule (7/03) Page:

2.0 System Installation

2.1 Installation

2.1.1 Location of Sensors

There are no absolute rules for determining the quan-

tity and location of gas detection heads to protect any

particular facility. Locate the sensors carefully in all

areas where gas escape may be expected and where it

is desirable to detect the presence of unwanted gas.

Use redundancy where enhanced protection or reli-

ability is required. Light gases such as methane tend

to rise while heavy gases such as propane tend to ac-

cumulate in low areas. Seek advice from experts who

know the characteristics of the gas being detected, air

movementpatternsand the facility.Use commonsense

and refer to various publications that discuss general

guidelines for your industry. See Application Data

SheetADS-001 for further information.

2.1.2 Unpacking

The housing and terminal board are a single assembly

to which the sensor is wired. The control module is a

separateplug-in assembly.Since all modern electronic

equipment can be damaged by static electricity dis-

charge it is important to take precautions. Discharge

static electricity from your body by touching a

grounded metal object before handling the module.

To gain access to the field terminal block remove the

module carefully from the housing by grasping the

centre “pull” knob and pull straight away. Field wir-

ing is connected to the terminal strip located in the

base of the housing.

2

2.1.3 Mounting

The housing should be oriented so that the sensor is

on the under-side of the housing. Use a conduit seal

and conduit loop or trap on the field wiring side to

preventwater or condensation from entering the hous-

ing through the conduit or its threaded connection.

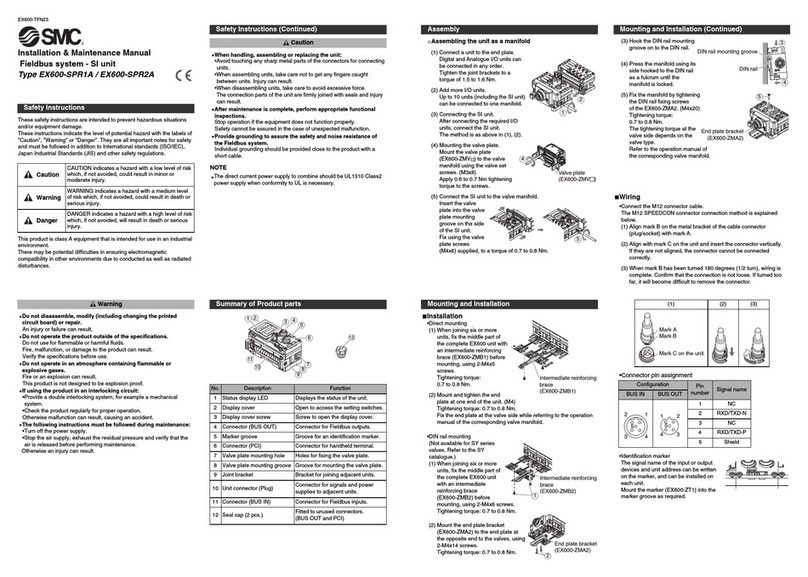

2.2 Wiring -- 4-20 mAversion

2.2.1 Wiring

We recommend using shielded cable. See table be-

low. Refer to applicable wiring codes when installing

andwiring the 4101-28.After the field wiring has been

carefully connected as per Fig 2.1. CHECK THAT

THE CORRECT WIRES ARE CONNECTED TO

THECORRESPONDINGTERMINALSANDTHAT

VOLTAGE LEVELS DO NOT EXCEED THE

SPECIFICATIONS. When the wiring and voltages

have been verified, gently plug-in the control module.

Use gentle hand pressure to align and seat the module

then use firm hand pressure to fully seat the module.

Wire Gauge Maximum Length

16 AWG 2,000 ft.

14 AWG 3,500 ft.

12 AWG 6,000 ft.

10 AWG 9,000 ft.

Recommended Wire / Cable Gauge

Table 1

2.2.2 Jumper Location for Non-Isolated /

Isolated Current Output

The 4101-28 is capable of providing an isolated cur-

rent output. A jumper must be moved to select be-

tween isolated, or non-isolated current output on the

terminal board.

The analog output is precisely controlled by the inter-

nal micro-processor and digital-to-analog converter.

The standard 4 to 20ma signal is proportional to gas

concentration of 0 to 100% LEL. Additional stepped

levels below 4mA provide various diagnostic signals.

2.2.3 Initial LED Status - 4-20 mA

Operation

With power applied, check that the green POWER

LED is ON and the FAULT/ CAL LED is showing a

slow red flash during the first 90 seconds which will

then change to a short green flash every 2 seconds

(confidence blip). During the first 90 seconds the ana-

logoutputwill be at 3.0mA and then change to4.0mA.

Ifafter the 90 secondswarm-up the current isat 2.5mA

orany value other than 4.0mAthen the sensor requires

calibration and the calibration procedure must be ini-

tiated. Observation of the LED status signals and out-

put current levels aid the operator when calibrating

the sensor/transmitter as described below under

CALIBRATION.

Themoduleincludes an alphanumeric displaythat pro-

videsavariety of English languagecommands scrolled

across the display to supplement the LED sequences

and aid the operator. Please refer to the following list

and see Table of Responses