No. VF1000(V200)-TFM121**

Installation and Maintenance Manual

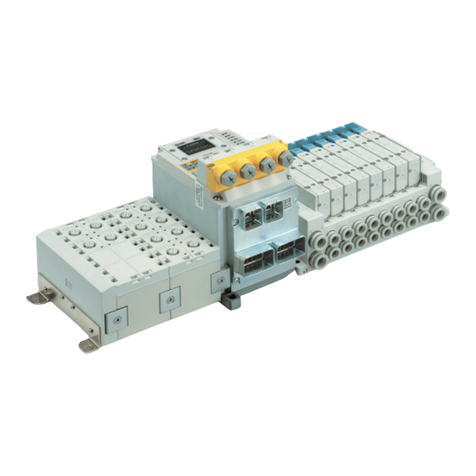

5 port solenoid valve

Series VF1000/3000/5000

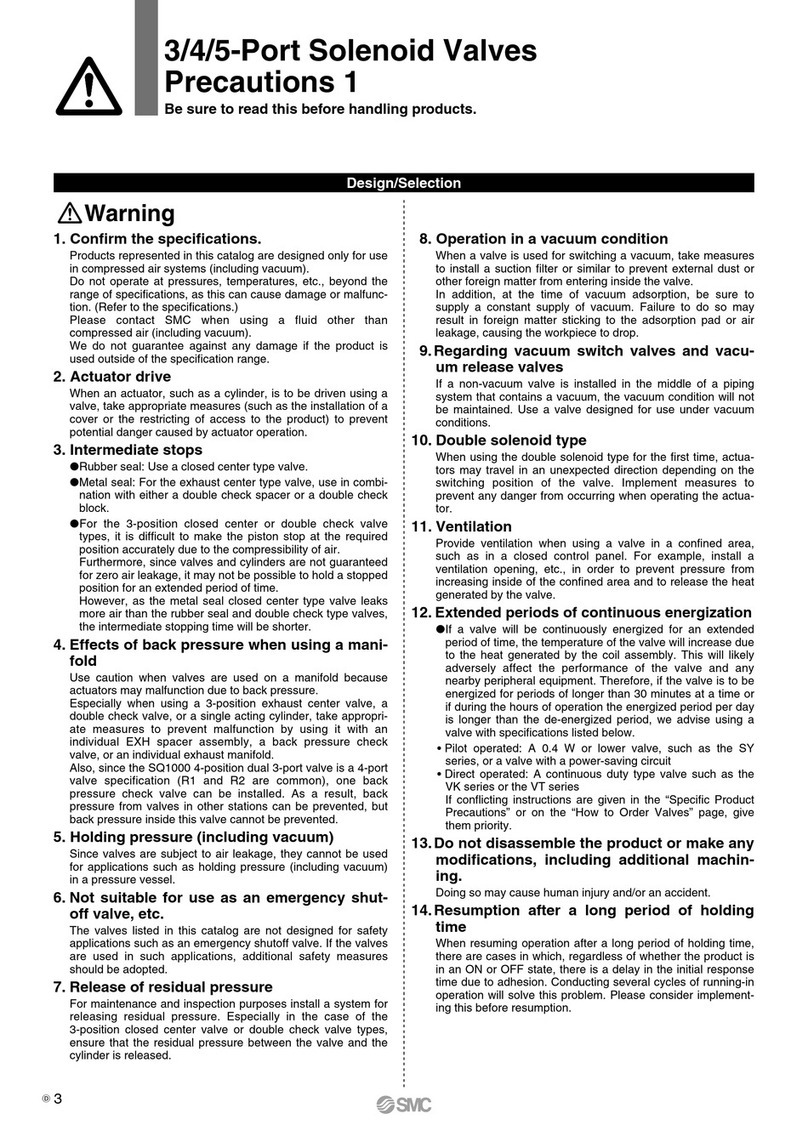

1 Safety Instructions

This manual contains essential information for the protection of users and

others from possible injury and/or equipment damage.

• Read this manual before using the product, to ensure correct handling,

and read the manuals of related apparatus before use.

• Keep this manual in a safe place for future reference.

• These instructions indicate the level of potential hazard by label of

“Caution”, “Warning” or “Danger”, followed by important safety

information which must be carefully followed.

• To ensure safety of personnel and equipment the safety instructions in

this manual and the product catalogue must be observed, along with

other relevant safety practices.

Caution Indicates a hazard with a low level of risk, which if not

avoided, could result in minor or moderate injury.

Warning Indicates a hazard with a medium level of risk, which

if not avoided, could result in death or serious injury.

Danger Indicates a hazard with a high level of risk, which if

not avoided, will result in death or serious injury.

Warning

• The compatibility of pneumatic equipment is the responsibility of the

person who designs the pneumatic system or decides its specifications.

Since the products specified here can be used in various operating

conditions, their compatibility with the specific pneumatic system must

be based on specifications or after analysis and/or tests to meet specific

requirements.

• Only trained personnel should operate pneumatically operated

machinery and equipment.

Compressed air can be dangerous if an operator is unfamiliar with it.

Assembly, handling or repair of pneumatic systems should be performed

by trained and experienced personnel.

• Do not service machinery/equipment or attempt to remove

components until safety is confirmed.

1) Inspection and maintenance of machinery/equipment should only be

performed after confirmation of safe locked-out control positions.

2) When equipment is to be removed, confirm the safety process as

mentioned above. Switch off air and electrical supplies and exhaust all

residual compressed air in the system.

3) Before machinery/equipment is re-started, ensure all safety measures

to prevent sudden movement of cylinders etc. (Supply air into the

system gradually to create back pressure, i.e. incorporate a soft-start

valve).

• Do not use this product outside of the specifications. Contact SMC

if it is to be used in any of the following conditions:

1) Conditions and environments beyond the given specifications, or if

the product is to be used outdoors.

2) Installations in conjunction with atomic energy, railway, air navigation,

vehicles, medical equipment, food and beverage, recreation equipment,

emergency stop circuits, press applications, or safety equipment.

3) An application which has the possibility of having negative effects on

people, property, or animals, requiring special safety analysis.

Caution

• Ensure that the air supply system is filtered to 5 microns.

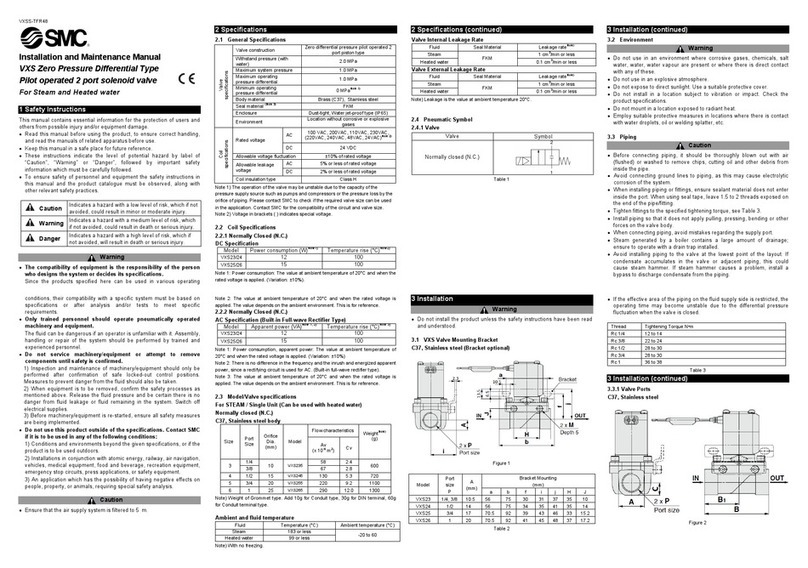

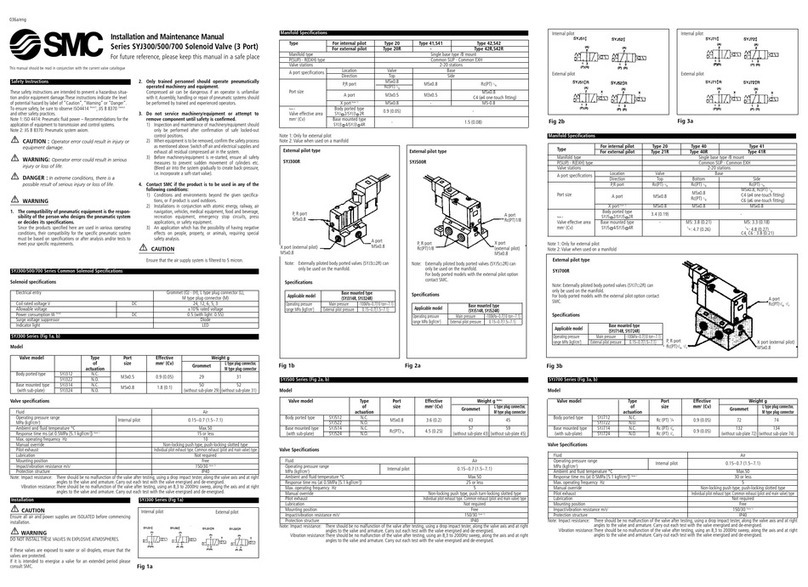

2 Specifications

Refer to the operation manual for this product.

2.1 Specifications

Valve specifications

Fluid Air

2 position single/3 position 0.15 to 0.7 MPa

Standard 2 position double 0.1 to 0.7 MPa

2 position single/3 position 0.15 to 1.0 MPa

Operating

pressure

range High

pressure 2 position double 0.1 to 1.0 MPa 0.2

Ambient and fluid temperature -10 ~ 50 °C (No freezing)

Series VF1000 VF3000 VF5000

2 position single /

2 position double 10 Hz 10 Hz 5 Hz

Maximum operating

frequency

3 position - 3 Hz 3 Hz

Manual override

Non-locking push type, Push turn

locking slotted type, Push turn locking

lever type

Pilot exhaust method

Individual exhaust.

Common exhaust for main valve and

pilot valve (except VF1000 series)

Lubrication Not required

Mounting position Unrestricted

Impact / Vibration resistance 300/50 m/s² (1)

Protection structure Dust proof (G,H,L,M : IP40)

(D,Y,T : IP65*)

Table 1

Note)

Impact resistance: No malfunction occurred when it was tested with a

drop tester in the axial direction and at right angles to the main valve &

armature; in both energised & de-energised states and for every time in

each condition (Values at the initial period.)

Vibration resistance: No malfunction occurred in a one-sweep test

between 45 and 2000 Hz. Tests are performed at both energised and de-

energised states in the axial direction and at right angles to the main valve

& armature. (Valves at the initial period.)

*Based on IEC60529. Compliance to IP65 is limited to the common

exhaust option.

Solenoid Specifications

Grommet (G),(H),

L plug connector (L),

M plug connector (M)

DIN terminal (D),

DIN (EN175301-803)

terminal (Y),

Conduit terminal (T)

Electrical entry

G,H,L,M D,Y,T

DC 24,12 VCoil rated

voltage AC (50/60 Hz) 100,110,200,220,240

Allowable voltage fluctuation ±10% rated voltage1,2,3

Standard 1.5 W

(With indicator light: 1.55 W)

1.5 W

(With indicator light: 1.75 W)

DC Power saving

type

0.55 W

(With indicator light only)

0.75 W

(With indicator light only)

100V

110V [115 V]

200V

220V [230 V]

Power

Consumption

AC

240V

1.55 VA

(With indicator light: 1.7 VA)

Surge voltage suppressor Diode

(Non-polar type is varistor)

Indicator light LED LED

(Neon bulb when AC)

Table 2

1) In common between 110 VAC and 115 VAC, and between 220 VAC and

230 VAC.

2) For 115 VAC and 230 VAC, the allowable voltage is -15% ~ +5% of

rated voltage.

3) S, Z and T type (with power saving circuit), should be used with the

following allowable voltage fluctuation range due to a voltage drop caused

by the internal circuit.

24 VDC: -7% to +10%

12 VDC: -4% to +10%

2 Specifications (continued) 3 Installation (Continued

alves, tighten as follows:

C fitting, etc.

Note r the

) W

2) T

the proper tightening torques shown below.

・m)

2.2 Symbol

Body ported

Single Double

VF1000

VF3000

VF5000

Base mounted

Single Double

VF3000

VF5000

Body ported / Base mounted

Closed centre Exhaust centre Pressure centre

VF3000

VF5000

Figure 1

3 Installation

3.1 Installation

Warning

• Do not install the product unless the safety instructions have been read

and understood.

3.2 Environment

Warning

• Do not use in an environment where corrosive gases, chemicals, salt

water or steam are present.

• Do not use in an explosive atmosphere.

• Do not expose to direct sunlight. Use a suitable protective cover.

• Do not install in a location subject to vibration or impact. Check the

product specifications.

• Do not mount in a location exposed to radiant heat.

• If it is used in an atmosphere where there is possible contact with water

droplets, oil, weld spatter, etc., exercise preventative measures.

• When the solenoid valve is mounted in a control panel or its energised

for a long time, make sure that the ambient temperature is within the

specification of the valve.

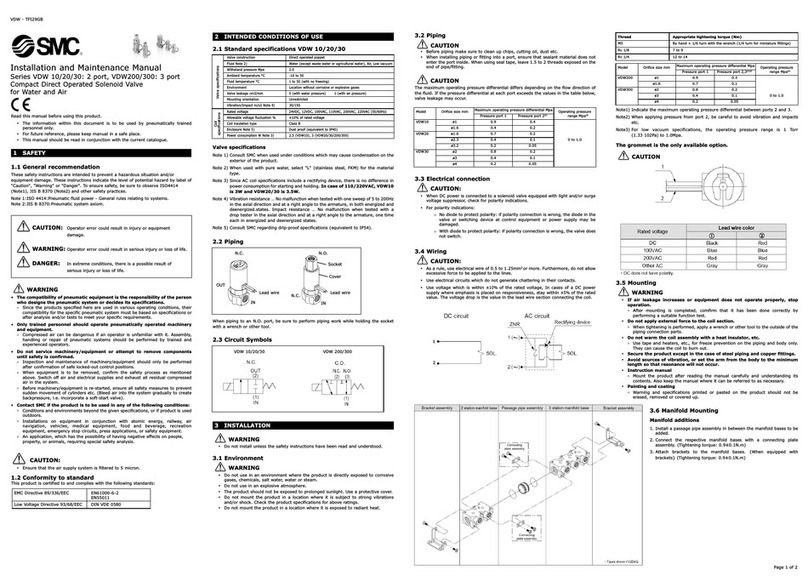

3.3 Piping

Caution

• Before piping make sure to clean up chips, cutting oil, dust etc.

• When installing piping or fittings, ensure sealant material does not enter

inside the port. When using seal tape, leave 1 thread exposed on the

end of the pipe/fitting.

• Tighten fittings according to appropriate tightening torque.

Figure 2

)

3.4 Connection of fittings

When screwing fittings into v

(1) Follow the procedures below when installing an SM

1) M5

After tightening the fitting by hand, use a wrench to tighten the fitting an

additional approximately 1/6 turn. However, if miniature fittings are

used, tighten an additional 1/4 turn with a tightening tool after

tightening by hand.

) If tightened excessively, the thread of the product may break o

gasket may deform. If tightened insufficiently, the thread of the

product may become loose. In either case, air leakage can occur.

hen fittings other than SMC fittings are used, follow the instructions of

(2

the respective fitting manufacturer.

hreads

Fasten with

Connection thread Tightening torque (N

1/8 7 to 9

1/4 12 to 14

3/8 22 to 24

1/2 28 to 30

Table 3

.5 Connection of piping to products

uction manual to avoid mistakes

.6 Precautions on Design <DC>

□With light/surge voltage suppressor (□Z)

3

When piping to a product, refer to its instr

regarding the supply port, etc.

3

・Polar type

oltage suppressor ( S)With surge v Grommet/L,M plug connecter

With light/surge voltage suppressor (□Z) DIN terminal/Conduit terminal

・Non-polar type

suppressor (□R) With light/surge voltage suppressor (□U)

With surge voltage Grommet/L,M plug connecter

With light/surge voltage suppressor (□U) DIN terminal/Conduit terminal

Table 4

• Please connect in accordance with olarity indication. (The non-polar type

•

•

the +,- p

can be used with the connections made either way.)

Please use caution regarding the allowable voltage fluctuation because there is

approximately a 1 V drop for a valve with polarity protection (For details, refer to

the solenoid specifications for the valve.)

When wiring is done at the factory, positive (+) is red and negative (-) is black.