ITV2-PR-TFM132

Installation and Maintenance Manual

Electro-Pneumatic Regulator (for PROFIBUS DP)

ITV10*0-PR****-Q,

ITV20*0-PR****-Q,

ITV30*0-PR****-Q

1 Safety Instructions

This manual contains essential information for the protection of users and

others from possible injury and/or equipment damage.

• Read this manual before using the product, to ensure correct handling,

and read the manuals of related apparatus before use.

• Keep this manual in a safe place for future reference.

• These instructions indicate the level of potential hazard by label of

“Caution”, “Warning” or “Danger”, followed by important safety

information which must be carefully followed.

• To ensure safety of personnel and equipment the safety instructions in

this manual and the product catalogue must be observed, along with

other relevant safety practices.

Caution Indicates a hazard with a low level of risk, which if

not avoided, could result in minor or moderate

injury.

Warning Indicates a hazard with a medium level of risk,

which if not avoided, could result in death or

serious injury.

Danger Indicates a hazard with a high level of risk, which if

not avoided, will result in death or serious injury.

• Electromagnetic compatibility:

This product is class A equipment intended for use in an industrial

environment. There may be potential difficulties in ensuring

electromagnetic compatibility in other environments due to conducted as

well as radiated disturbances.

• The compatibility of pneumatic equipment is the responsibility of

the person who designs the pneumatic system or decides its

specifications.

Since the products specified here can be used in various operating

conditions, their compatibility with the specific pneumatic system must

be based on specifications or after analysis and/or tests to meet specific

requirements.

• Only trained personnel should operate pneumatically operated

machinery and equipment.

Compressed air can be dangerous if an operator is unfamiliar with it.

Assembly, handling or repair of pneumatic systems should be performed

by trained and experienced personnel.

• Do not service machinery/equipment or attempt to remove

components until safety is confirmed.

• Inspection and maintenance of machinery/equipment should only be

performed after confirmation of safe locked-out control positions.

• When equipment is to be removed, confirm the safety process as

mentioned above. Switch off air and electrical supplies and exhaust all

residual compressed air in the system.

• Before machinery/equipment is re-started, ensure all safety measures

to prevent sudden movement of cylinders etc. (Supply air into the

system gradually to create back pressure, i.e. incorporate a soft-start

valve).

• Do not use this product outside of the specifications. Contact SMC

if it is to be used in any of the following conditions:

• Conditions and environments beyond the given specifications, or if the

product is to be used outdoors.

• Installations in conjunction with atomic energy, railway, air navigation,

vehicles, medical equipment, food and beverage, recreation equipment,

emergency stop circuits, press applications, or safety equipment.

• An application, which has the possibility of having negative effects on

people, property, or animals, requiring special safety analysis.

• Ensure that the air supply system is filtered to 5 microns.

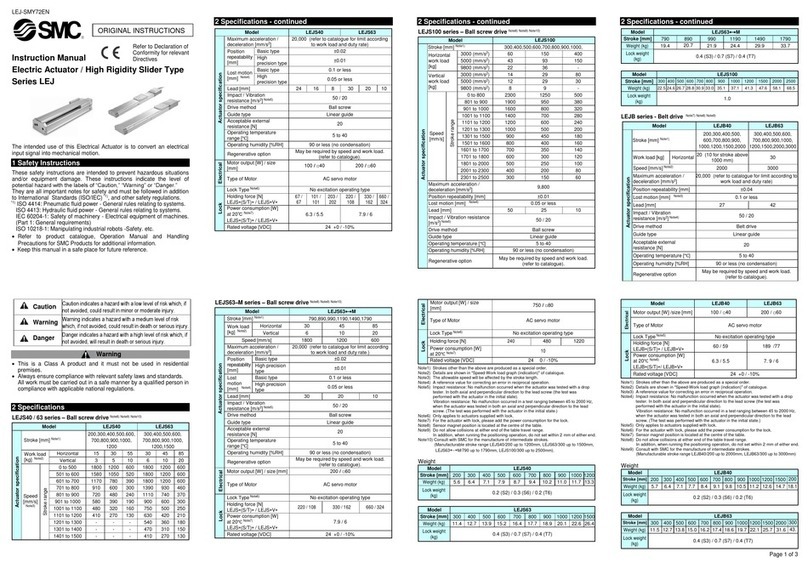

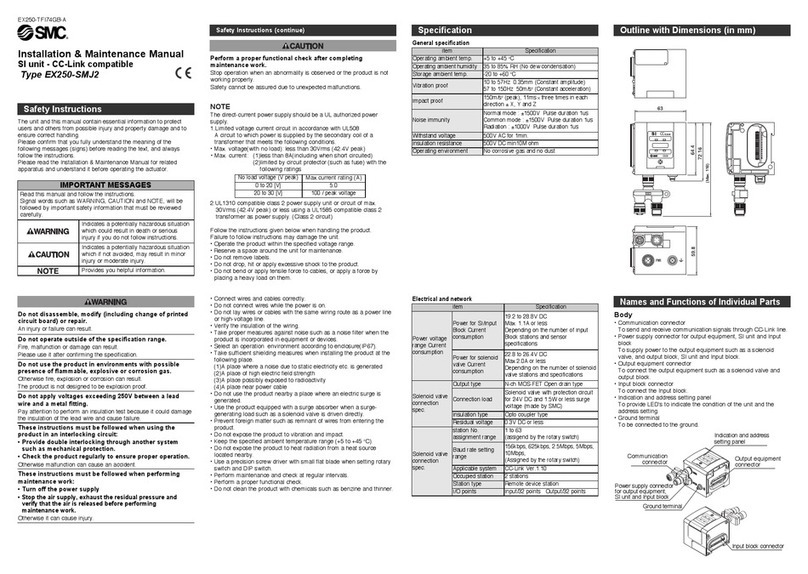

2 Specifications

Model ITV*010 ITV*030 ITV*050 ITV2090

Min.supply pressure (Set pressure) + 0.1 MPa (Set pressure)

–13.3 kPa

Max.supply pressure 0.2 MPa 1.0 MPa 1.0 MPa -101 kPa

Set pressure range 0.005 ~

0.1 MPa 0.005 ~

0.5 MPa 0.005 ~

0.9 MPa -1.3 ~ -80 kPa

Supply voltage 24 VDC±10%

Current consumption Max. 160 mA

Input/output data 12bit/12bit (data 4095 corresponds to 100%F.S.)

Linearity Max. ±1%F.S.

Hysteresis Max. 0.5%F.S.

Repeatability Max. ±0.5%F.S.

Sensitivity Max. 0.2%F.S.

Temperature characteristics Max. ±0.12%F.S./°C

Operating temperature 0~50°C (without condensation)

Protection structure IP65

Model ITV10*0 ITV20*0 ITV30*0

Size (mm) 50×50×124 50×50×146 66×66×167

Weight (No option) 350 g 450 g 750 g

Table 1.

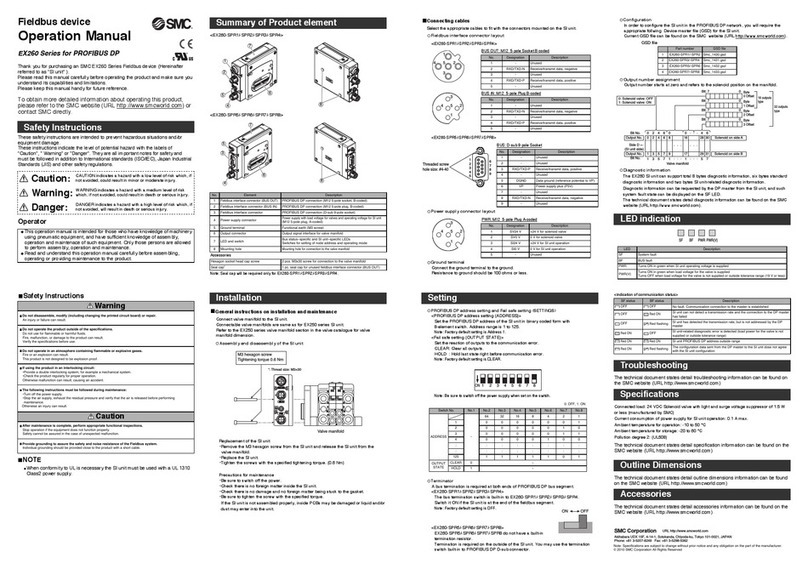

3 Operation Principle

When the input signal increases the supply solenoid valve nturns on and

the exhaust solenoid valve oturns off. Supply pressure is passed to the

pilot valve pthrough the supply solenoid valve. The pilot valve will open

the main valve allowing partial supply pressure to pass to the out port. The

pressure sensor qwill provide output pressure feedback to the control

circuit r. The control circuit will balance the input signal and output

pressure to ensure that the output pressure remains proportional to the

input signal.

Fig. 1 - Control diagram

Fig. 2 - Schematic diagram

4 Wiring

Connect the cable to the connector on the main unit as shown in the

following diagram. Take precautions, as incorrect wiring will damage the

unit. Use a DC power supply capable of supplying the necessary power

requirements with minimal ripple. When 3 m straight cable connection is

specified, this refers to the power supply cable, the communications cable

should be ordered separately.

Item Pin assignment Wire colour (Note)

1. +24 V Brown

2. N.C. –

3. GND Blue

Connector for

power supply 4. N.C. –

1. N.C. –

2. RXD/TXD_N(A) Green

3. N.C. –

4. RXD/TXD_P(B) Red

Connector for

communication

5. N.C. –

Table 2.

Note: Wire colour when the optional cable is used.

5 LED Display and Communication Protocol

• LED Display

Fig. 3 – Features of the ITV.

ITEM LED ON LED OFF

RUN Power ON (Green) Power OFF

DIA Diagnostic error (Red) Internal operation is normal

BF Profibus communication error (Red) Profibus communication is normal

Table 3.

• Communication Protocol

Item Specification Remark

Communication

protocol PROFIBUS DP For DP-V0

Baud rate (Note) 9.6 k/ 19.2 k/ 45.45 k/

93.75 k/ 187.5 k/ 500 k/ 1.5 M/

3 M/ 6 M/ 12 Mbps

Set by master

GSD-File SMC_1412.GSD

Occupied area

(Input/output data) 1 word / 1 word Lower 2 bits of 7 bytes of

diagnostic area are for diagnostic

information.

Communication

data resolution 12 bit (4096 resolution)

Address setting Switch setting /

Software setting Switching by switch

Terminator Built into the product Switching by switch

Table 4.

Note: Baud rate relates to communication distance

6 Switch Setting

• Selection of address setting mode

Node address of the product can be set by

software mode (SW) or hardware mode (HW).

When software mode is selected, the

communication master sets the node address.

Setting range is 1 to 125.

• Address set switch

In hardware mode use the switches

shown, to set the node address.

• Address setting range is 01 to 99.

x10 x1

6 Switch Setting (continued)

• Setting the terminator

Set Profibus communication line terminator.

With terminator Without Without

(factory setting) terminator terminator

When the product is connected to the Profibus communication line,

ensure the switch is set to “with terminator”.

• Setting the address switch requires the removal of 4 screws in the front

panel of the unit (Fig 3). Take care as the panel hinges to a maximum of

90 degrees.

• After setting an address, always close and fix the panel securely.

Tighten the screws to torque of 0.6 – 0.8 N•m

7 Communication Data Allocation

Set target value

Resolution: 12 bit (100 %F.S.), Occupied byte: 2 Byte

000*

Target value (lower 12 bits)

Target value

(O area) b15 b11 b0

Put 0 in upper 4 bits (Note)

Monitor the output pressure

Resolution: 12 bit (100 %F.S.), Occupied byte: 2 Byte

000*

Output pressure (lower 12 bits)

Output pressure

(I area) b15 b11 b0

Resolution may exceed 12bit depending on control conditions.

Monitors the product error.

7 bytes are occupied for external diagnostic data.

Diagnostic data allocated to byte 7, as shown below.

Byte7 000000BA

Diagnostic (DIA) b7 b0

A. Internal diagnostic error 0: Normal 1: Error

B. Over range error 0: Normal 1: Error

Note: Although 100 %F.S. for target value is 12 bit, communication is

available upto 150 %F.S. (accuracy is guaranteed upto 100 %F.S.)

Over range error is output when 150 %F.S. is exceeded.

Output pressure at this time is controlled by the input data immediately

before the error occurred.

Pressure can be set by sending the input data, in which F.S. consists of

12 bits, to the E/P regulator through the master PLC (target value to

word area).

Setting data 0000h 0FFFh [(a/F.S.) x 4095]HEX

Output pressure 0 % x F.S. (=0) 100 % x F.S. a

fPressure sensor

gControl circuit

cSupply solenoid valve

dExhaust solenoid valve

Supply pressure

OUT

+

–

Input

signal ePilot valve

3

24

5

1

Power supply line

Communication line

BF LED

RUN LED