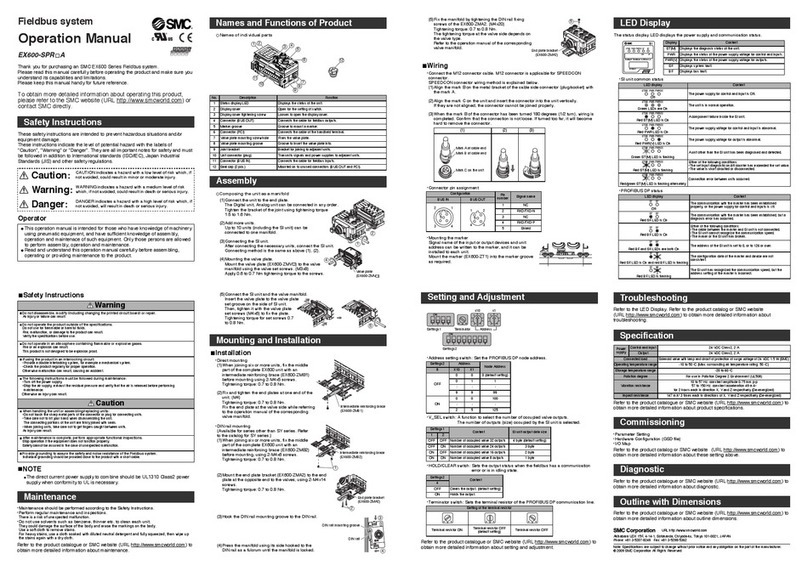

1

No.

2

6

3

4

Connector (PCI) Connector for Handheld Terminal.

Valve plate mounting

hole Holes for fixing the valve plate.

Valve plate mounting

groove Groove for mounting the valve plate.

5

7

8

Joint bracket Bracket for joining to adjacent units.

Unit connector (Plug) Connector for signals and power supplies to

adjacent units.

Connector (BUS IN) Connector for fieldbus inputs.

9

10

11

Seal cap (2 pcs.) Fitted to unused connectors.

(BUS OUT and PCI)

12

NOTE

•The direct current power supply to combine should be U 1310 Class2

power supply when conformity to U is necessary.

•The output rating is U tested as a DC output for General use.

Caution

4 Installation

Assembly

(1)Connect a unit to the end plate.

Digital and Analogue I/O units can be

connected in any order.

Tighten the joint brackets to a torque of

1.5 to 1.6 Nm.

(2)Add more I/O units.

Up to 10 units (including the SI unit) can

be connected to one manifold.

(3)Connecting the SI unit.

After connecting the required I/O units, connect the SI unit.

The method is as above in (1), (2).

(4)Mounting the valve plate.

Mount the valve plate

(EX600

-

ZMV ) to the valve

manifold using the valve set screws.

(M3 x 8)

Apply 0.6 to 0.7 Nm tightening

torque to the screws.

(5)Connect the SI unit to the valve manifold.

Insert the valve plate

into the valve plate

mounting groove on the

side of the SI unit.

Fix using the valve

plate screws (M4 x 6)

supplied, to a torque of 0.7 to 0.8 Nm.

Installation

Direct mounting

(1)When joining six or more

units, fix the middle part of

the complete EX600 unit

with an intermediate

reinforcing brace

(EX600

-

ZMB1) before

mounting, using 2

-

M4 x 5

screws.

Tightening torque:

0.7 to 0.8 Nm.

(2)Mount and tighten the end plate and the solenoid valve at one end

of the unit. (M4)

Tightening torque: 0.7 to 0.8 Nm.

The tightening torque at the manifold solenoid valve side depends

on the valve type. Refer to the operation manual of the

corresponding valve manifold.

(2)Mount the end plate bracket

(EX600

-

ZMA2) to the end plate,

using 2

-

M4 x 14 screws.

Tightening torque: 0.7 to 0.8 Nm.

(3)Hook the DIN rail mounting

groove on to the DIN rail.

DIN rail mounting

(Not available for SY series valves. Refer to the SY catalogue.)

(1)When joining six or more

units, fix the middle part of

the complete EX600 unit

with an intermediate

reinforcing brace

(EX600

-

ZMB2) before

mounting, using 2

-

M4 x 6

screws.

Tightening torque

0.7 to 0.8 Nm.

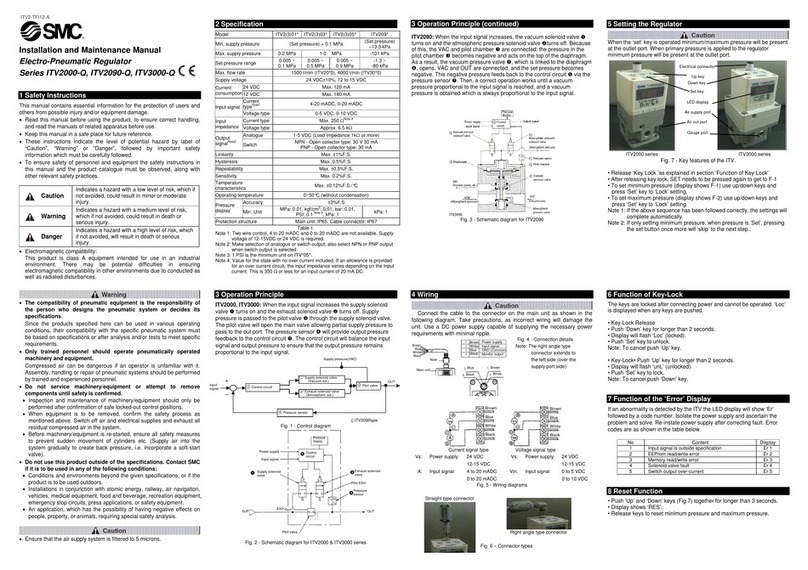

Installation & Maintenance Manual

Fieldbus system (SI unit)

Type EX600-SPN1 / EX600-SPN2

EX600-TFR01

1 Safety Instructions

1 Safety Instructions (continued)

This manual contains essential information for the protection of users

and others from possible injury and/or equipment damage.

•Read this manual before using the product, to ensure correct handling,

and read the manuals of related apparatus before use.

•Keep this manual in a safe place for future reference.

•These instructions indicate the level of potential hazard by label of

"Caution", "Warning" or "Danger", followed by important safety

information which must be carefully followed.

•To ensure safety of personnel and equipment the safety instructions in

this manual and the product catalogue must be observed, along with

other relevant safety practices.

CAUTION indicates a hazard with a low level of risk

which, if not avoided, could result in minor or

moderate injury.

Caution

Warning

Danger

WARNING indicates a hazard with a medium level

of risk which, if not avoided, could result in death or

serious injury.

DANGER indicates a hazard with a high level of risk

which, if not avoided, will result in death or serious

injury.

This product is class A equipment that is intended for use in an industrial

environment.

There may be potential difficulties in ensuring electromagnetic

compatibility in other environments due to conducted as well as radiated

disturbances.

•Do not disassemble, modify (including changing the printed circuit

board) or repair.

An injury or failure can result.

•Do not operate or set with wet hands.

This may lead to an electric shock.

•Do not operate the product outside of the specifications.

Do not use for flammable or harmful fluids.

Fire, malfunction, or damage to the product can result.

Verify the specifications before use.

•Do not operate in an atmosphere containing flammable or

explosive gases.

Fire or an explosion can result.

This product is not designed to be explosion proof.

•If using the product in an interlocking circuit:

•Provide a double interlocking system, for example a mechanical

system

•Check the product regularly for proper operation

Otherwise malfunction can result, causing an accident.

•The following instructions must be followed during maintenance:

•Turn OFF the power supply

•Stop the air supply, exhaust the residual pressure and verify that the air

is released before performing maintenance

Otherwise an injury can result.

Warning

•When handling, assembling or replacing the units:

•Avoid touching any sharp metal parts of the connectors for connecting

units.

•When assembling units, take care not to get any fingers caught between

units. Injury can result.

•When disassembling units, take care to avoid excessive force.

The connection parts of the unit are firmly joined with seals and injury can

result.

•After maintenance is complete, perform appropriate functional

inspections.

Stop operation if the equipment does not function properly.

Safety cannot be assured in the case of unexpected malfunction.

•rovide grounding to assure the safety and noise resistance of the

Fieldbus system.

Individual grounding should be provided close to the product with a short

cable.