- 4 -

Specific Product Precautions

1. Note the weight of the stainless steel products.

Since the weight of stainless steel cylinders is approximately 1.5

to 3 times heavier than the standard products (with aluminum

body), be careful when calculating weight estimates. Also, when

mounting the cylinder on equipment where vibration is expected,

avoid using single side brackets such as the flange type, and use

double side brackets such as the foot type instead.

Caution

1.Adjust the speed control for the environment in which

it will be used.

Speed adjustment may be changed

environment.

2.

Dust may accumulate on this product’s mounting

screws and brackets in some operating conditions.

Measures must be applied depending on the operating conditions

when mounting.

1.Fully consider the compatibility of stainless steel.

The corrosion resistance of stainless steel is not effective against

all media and corrosive environments. Corrosion proceeds rapidly

with strong hydrochloric acid, hydrofluoric acid,

temperature ammonium gas, etc. Therefore its compatibility to the

environment must be considered carefully.

2.Do not operate cylinders with auto switches in

environments where oil and chemicals are used.

Please contact SMC when operating in environments with

coolants, cleaning solvents, various oils or chemicals, as it may

cause adverse effects (faulty insulation, malfunction due to

swelling of the potting resin, and hardening of lead wires, etc) to

auto switches even in a short period of time. Even with the fluoro

rubber seal specification, the auto switch related parts (switch

body, mounting bracket, and built-in magnet) are identical to the

standard specifications. Therefore, consult with SMC regarding

the cylinder’s compatibility (such as chemical resistance) with an

environment (chemicals, etc.) before operating.

3. Do not immerse the cylinder in water or chemicals.

When the cylinder is operated in a condition with water pressure,

1.Generally, use nitrile rubber (NBR) seals with liquids

that do not contain chlorine and sulfur, and use fluoro

rubber (FKM) seals with liquids that contain chlorine

and sulfur.

However, depending on the type and the brand of liquid (such as

cleaning solvent) that splashes on the cylinder, the operating life

of seals may be reduced dramatically. In cases where special

additives are used, or where liquid caused trouble with the current

nitrile or fluoro rubber seals in the past, request an investigation

or set up a test period for the use of the seals。

2.

Even the fluoro rubber specification may not be

applicable depending on the type of chemicals and the

operating temperature. Therefore, be sure to verify the

seal's applicability before use.

the fluid leaks into the cylinder in the early stages. In the worst

case, the fluid may back flow inside the piping and damage the

solenoid valve.

Caution

1.

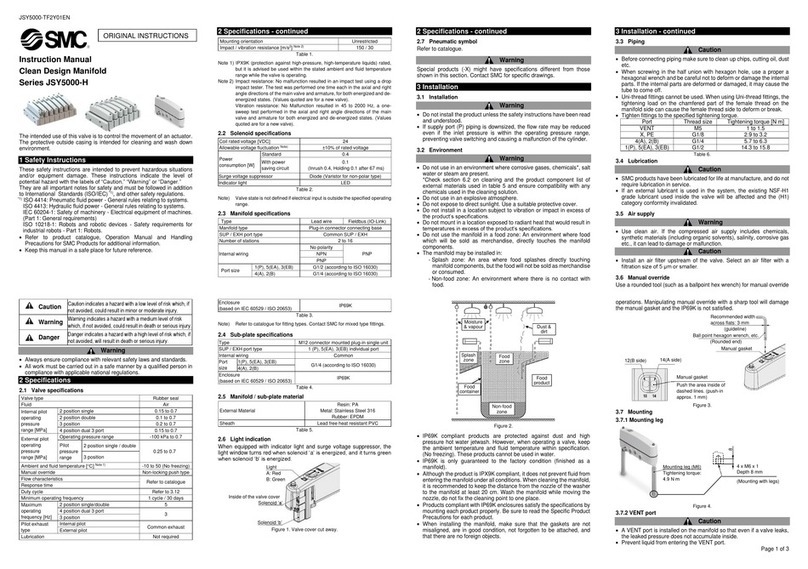

Avoid installing and using a cylinder inside a food

zone.

<Not installable>

Food zone・・・・・・・・・・An environment where food which will be

sold as merchandize, directly touches the

cylinder’s components.

<Installable>

Splash zone・・・・・・・An environment where food which will not

be sold as merchandize, directly touches

the cylinder’s components

Non-food zone・・・・・・An environment where there is no

1.Do not rotate the cover.

If a cover is rotated when installing a cylinder or screwing a

fitting into the port, it is likely to damage the junction part with

cover.

2. When using pins, apply grease, etc., in order to

prevent them from degrading of shape and rusting.

2. When cleaning solvent or chemicals splashes on a

cylinder, the service life may be extremely shortened.

Please contact SMC for details.

1.For details about operating precautions, refer to for the

CG1 series.

1.If cleaning the rot

ating part, grease may leak out,

which shortens product service life. Thus, cleaning

must be as infrequent as possible.

2.If excess water gets into mounting holes, unwanted

bacteria may reproduce. Plug them with plug bolts or

external covers to avoid this.

3.When cleaning cylinders with steam, do it as quickly

as possible, keeping the cylinder’s temperature range

in mind.

4. When cleaning cylinders with a brush, etc., do not

apply excessive force to the weaker parts, such as

auto switch lead wire, etc.