4EEWB331B

TABLE OF CONTENTS

IMPORTANT SAFETY INSTRUCTIONS.......................................................................................3

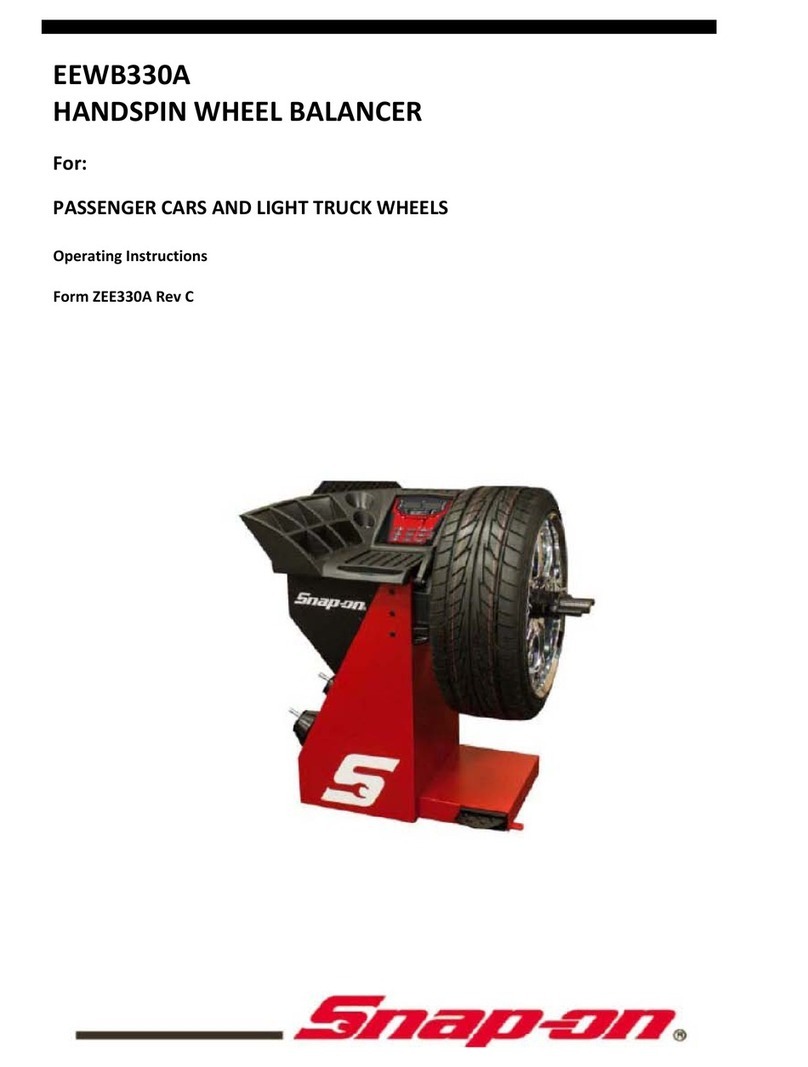

1.0 INTRODUCTION...........................................................................................................................5

1.1 SAFETY NOTICE..........................................................................................................................5

1.2 BALANCER APPLICATION ..........................................................................................................5

1.3 EEWB331B SPECIFICATIONS ...................................................................................................6

1.4 FEATURES ................................................................................................................................... 6

1.5 STANDARD ACCESSORIES........................................................................................................7

1.6 OPTIONAL ACCESSORIES .........................................................................................................7

1.7 DIMENSIONS OF THE MACHINE................................................................................................8

1.8 REQUIRED INSTALLATION AREA...............................................................................................8

1.9 INSTALLATION INSTRUCTIONS .................................................................................................8

2.0 BALANCER INSTALLATION......................................................................................................... 9

2.1 HOOD GUARD INSTALLATION ...................................................................................................9

2.2 ELECTRIC INSTALLATION ..........................................................................................................9

3.0 TERMINOLOGY..........................................................................................................................10

3.1 THE INPUT PANEL..................................................................................................................... 10

4.0 OPERATION OF THE BALANCER.............................................................................................12

4.1 CHECK LIST - INSPECTION...................................................................................................... 12

4.2 WHEEL MOUNTING...................................................................................................................13

4.2.1 STANDARD WHEELS (BACK CONE MOUNT).........................................................................13

4.2.2 CENTERING LIGHT-TRUCK WHEELS .....................................................................................13

4.2.3 WHEEL MOUNTING REQUIRING SPECIAL TOOLING ............................................................14

4.3 MODE SELECTION....................................................................................................................14

4.3.1 WEIGHT PLACEMENT MODES.................................................................................................14

4.3.2 SAPE ARM POSITIONS FOR ALU WEIGHTS PLACEMENT....................................................15

4.4 SELECTING OPERATOR PREFERENCES...............................................................................16

4.4.1 FINE BALANCING MODE .......................................................................................................... 16

4.4.2 OUNCE/GRAMS CONVERSION................................................................................................ 16

4.4.3 RIM DIAMETER IN MILLIMETERS ............................................................................................ 16

4.5 ENTER RIM PARAMETERS ......................................................................................................16

4.5.1 RIM DISTANCE AND DIAMETER (OFFSET) ............................................................................16

4.5.2 MEASURE/ENTER RIM WIDTH (MANUAL) ............................................................................. 16

4.5.3 MANUAL PARAMETER ENTRY .................................................................................................17

4.5.3.1 MANUAL RIM DIAMETER ENTRY............................................................................................. 17

4.5.3.2 MANUAL DISTANCE ENTRY .....................................................................................................17

4.6 Easy Alu FUNCTION...................................................................................................................17

4.6.1 AUTOMATIC RIM DIMENSION READING/SETTING AND ALU MODE ....................................17

4.7 CORRECTION OF THE IMBALANCE ........................................................................................18

5.0 ALU 2P AND 3P BY GAUGE ARM..............................................................................................20

6.0 SPOKE BALANCING MODE ......................................................................................................21

6.1 SPLIT WEIGHT MODE (SWM) ...................................................................................................21

7.0 USER CALIBRATION .................................................................................................................22

8.0 USER FUNCTIONS ....................................................................................................................23

8.1 DATA RECALL ............................................................................................................................23

8.2 WEIGHT UNIT TOGGLE MODE.................................................................................................23

8.3 DIMENSION UNIT TOGGLE MODE........................................................................................... 24

8.4 ANTI-SLIP FUNCTION................................................................................................................24

9.0 OPTIMIZATION/WEIGHT MINIMIZATION. ................................................................................. 25

10.0 TROUBLE SHOOTING ............................................................................................................... 33

10.1 SYSTEM MESSAGES ................................................................................................................34

10.1.1 C CODES.................................................................................................................................... 34

10.1.2 E-CODES.................................................................................................................................... 36

10.1.3 H CODES - WARNING ...............................................................................................................38

11.0 MAINTENANCE .......................................................................................................................... 38