Snap-On EEWB308B User manual

Other Snap-On Wheel Balancer manuals

Snap-On

Snap-On EEWB332B User manual

Snap-On

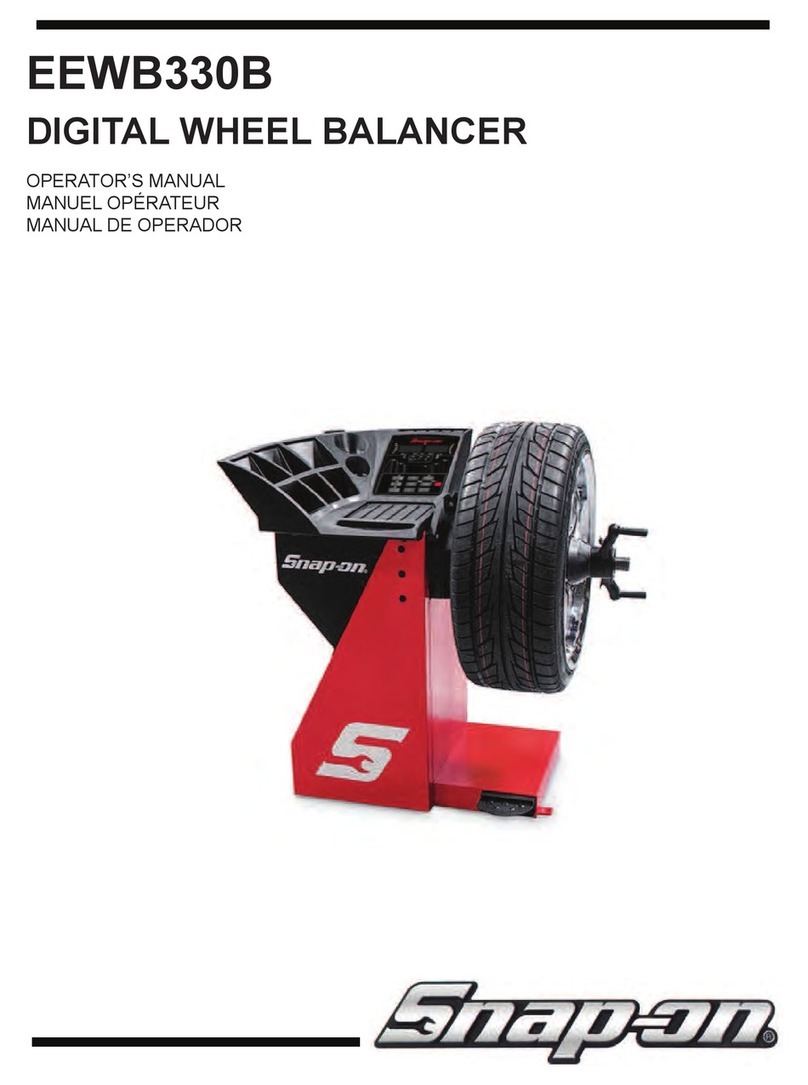

Snap-On EEWB330B User manual

Snap-On

Snap-On WBM250 User manual

Snap-On

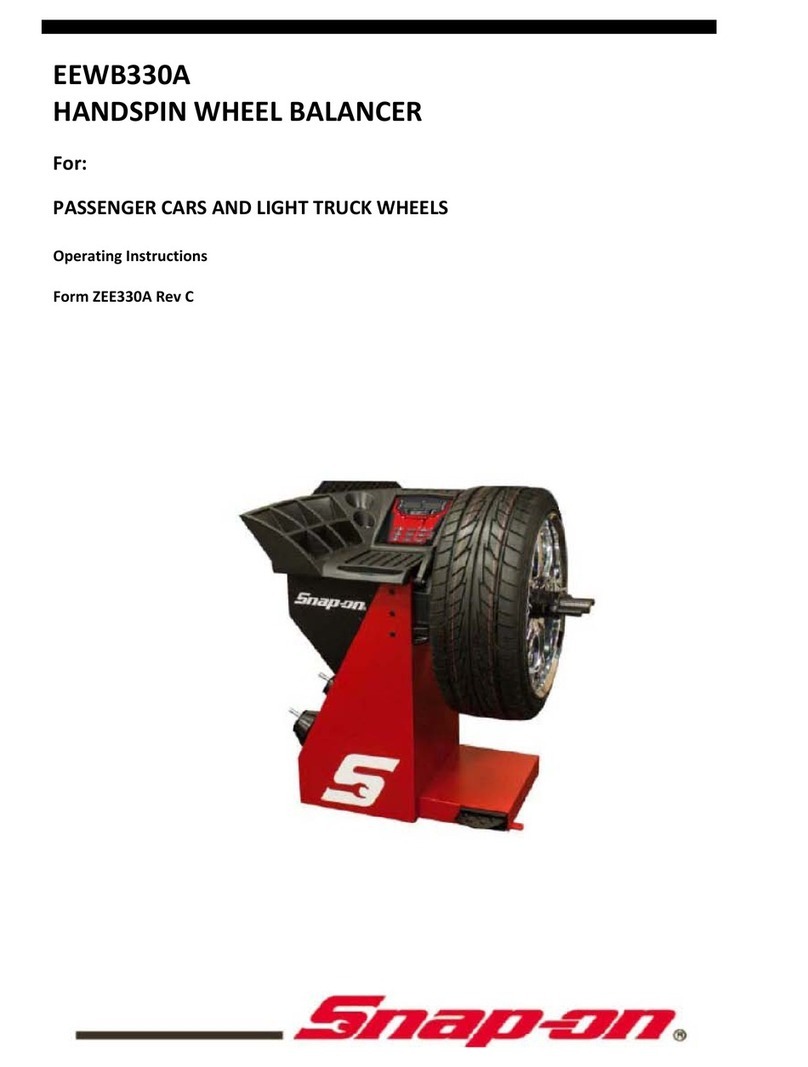

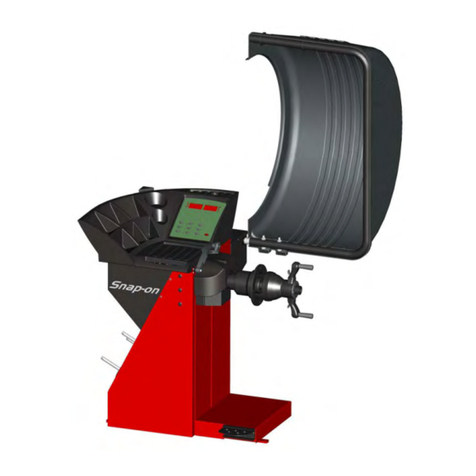

Snap-On EEWB330A User manual

Snap-On

Snap-On Sun SWB 100 User manual

Snap-On

Snap-On SWB 20 User manual

Snap-On

Snap-On Sun SWB 200 User manual

Snap-On

Snap-On Sun SWB 340 User manual

Snap-On

Snap-On EEWB331B User manual

Snap-On

Snap-On EEWB334A User manual

Popular Wheel Balancer manuals by other brands

IDEAL

IDEAL IWA-60-1500-K manual

Atlas Equipment

Atlas Equipment WB55 Installation & operation manual

Mondolfo Ferro

Mondolfo Ferro MT 2450 Technical & service manual

Hofmann

Hofmann geodyna 6900-2p Operation manual

CEMB

CEMB K22 Use and maintenance manual

Hofmann

Hofmann POWER CLAMP features Additional instructions

John Bean

John Bean VPI System Operation instructions

PREVOST

PREVOST BAL 250300F operating manual

Aston Global

Aston Global ADP-2000L user manual

MANATEC

MANATEC Fox 3D Smart Mobile PT Service manual

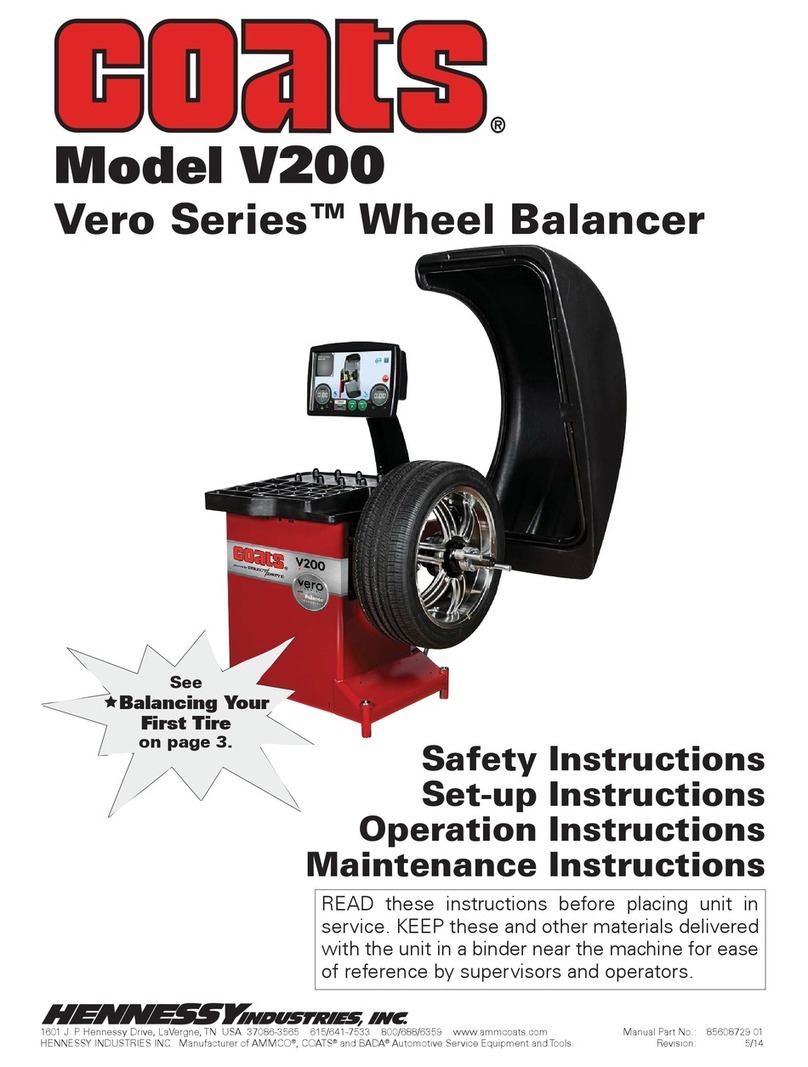

Coats

Coats Vero Series Safety, Setup, Operation & Maintenance Manual

Hunter

Hunter SmartWeight Touch Operation instructions