7209 Chapman Hwy

Knoxville, TN USA 37920

Tel: +1.865.251.5252

Fax: +1.865.579.4740

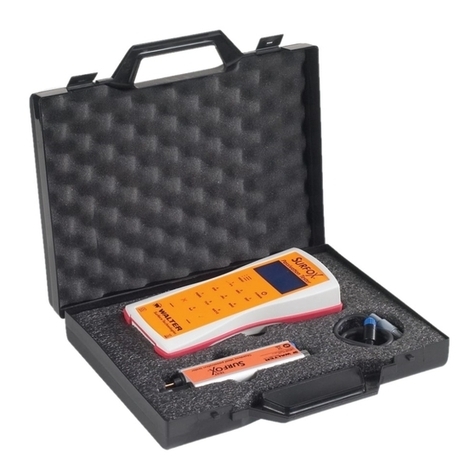

•Cleans connections on backplanes and jumpers

•Superior for FTTh, FTTt, and FTTn

•Effective for the widest range of contaminants

•Easy to use for quick and reliable cleaning

•Rugged and durable, great for all work sites

•Designed for 1st time cleaning of up to 600 cleanings per kit

2.5mm

CleanMachine for ST,SC,FC Fiber Optic End Faces

ST, SC, FC Connection Kit (Part #: XC-AC-CKIT-STSCFC)

Kit Contains:

1 CleanMachine tool for 2.5mm ST,SC, FC end faces

2 CleanWash fiber optic cleaning pen

1 CleanSwab 2.5mm foam swabs

1 Box of CleanStrip foam platen

1.25mm

CleanMachine for LC Fiber Optic End Faces

LC Connection Kit (Part #: XC-AC-CKIT-LC)

Kit Contains:

1 CleanMachine tool for 1.25mm LC end faces 2

CleanWash fiber optic cleaning pen

1 CleanSwab 1.25mm foam swabs

1 Box of CleanStrip foam platen

The XpertClean process is industry proven,

exceeding IEC 61300-3-35, IEC TR62627-01,

and meeting Telcordia GR-2923-CORE and SAE

Aerospace AIR6031.

Dry media can smear oils, not fully remove dry

particulates, and can create a static field that attracts

and holds onto additional debris. Wet cleaning can

oversaturate connectors, drawing up contamination

from around the ferrule as viewed in IEC 61300-3-35.

The result is unreliable cleaning processes that

provide unreliable results. Without XpertClean

additional cleaning passes, replacement jumpers or

connectors will be required.

CleanMachine

XpertClean For Optimal

Fiber Optic Cleaning

•Finger oils

•Mineral oils and grease

•Gels & pulling lubricants

•Dust, dirt & carbon

•Water & salt residue & more

Softing products are designed for optimal cleaning of

connectors using the XpertClean process. The last

thing you want performance degradation due to a

dirty fiber optic end face in the connector, or even

worse, dust on one end face ground into the end face

of the mating connector scratching the surface

causing permanent damage.

Instead, when disconnecting fiber optic connectors

or before connecting fiber optic cables, best practive

is always to clean the end face, save a picture of the

end face using your fiber optic microscope, and then

test the cable.

Features & Benefits

Precautions:

•Be sure to turn off any laser sources before inspecting any fiber connectors, optical

components, or bulkheads.

• Always wear the appropriate safety glasses. Be sure laser safety glasses meet federal and

state regulations and are matched to the lasers used in your environment.

•Never look into a fiber or bulkhead while the system lasers are on, and never connect a fiber

to a fiberscope while the system lasers are on.

•Never touch the end face of the fiber connectors.

https://itnetworks.softing.com/us/xpertclean/

The CleanMachine with XpertClean

process gives first time cleaning for all

common soils: