SOFTLINK WB169-SI2 User manual

Contents

1 Introduction 1

1.1 Wireless M-BUS Communication Protocol ................................ 1

1.2 Module usage ................................................. 1

1.3 External synchronization, tariff switching and alarm functions ...................... 2

1.4 Bi-directional communication mode ..................................... 2

1.5 Hardware features and power supplying .................................. 3

1.6 Variants and ordering codes ......................................... 3

2 Technical parameters overview 4

3 Configuration of the WB169-SI2 module 5

3.1 Setting of WB169-SI2 module parameters by configuration cable .................... 5

3.1.1 List of module configuration parameters .............................. 5

3.1.2 Displaying the List of configuration commands (”HELP”) .................... 6

3.1.3 ”System commands” group for general diagnostics ........................ 7

3.1.4 Commands for writing of configuration and reset ......................... 7

3.1.5 ”WMBUS” group commands for setting of messages ....................... 8

3.1.6 ”Inputs” group parameters ..................................... 11

3.1.7 Description and setting of ”Leak” alarm function ......................... 15

3.1.8 Description and setting of ”Burst” alarm function ........................ 16

3.1.9 Setting of sensor inputs ....................................... 17

3.1.10 Description and setting of ”Tariff switching” function ...................... 19

3.1.11 ”Modem commands” group for RF-subsystem diagnostics .................... 20

3.1.12 Commands of ”Utils” group for setting of module common functions .............. 20

3.1.13 Overview of module configuration parameters ........................... 22

3.2 Setting of parameters by using of optical ”USB-IRDA” converter .................... 24

3.3 Structure of module data messages ..................................... 28

3.3.1 Iinformation message ......................................... 28

3.3.2 Alarm message ............................................ 30

4 Operational conditions 32

4.0.1 Risk of mechanical and/or electric damage ............................. 32

4.0.2 Risk of premature battery discharge ................................ 32

4.0.3 Risk of damage by excessive humidity ............................... 32

4.1 The condition of modules on delivery .................................... 33

4.2 Modules storage ............................................... 33

4.3 Safety precautions .............................................. 33

4.4 Environmental protection and recycling .................................. 33

4.5 WB169-SI2 module installation ....................................... 33

4.6 Module and meter replacement ....................................... 35

4.7 Module dismantling ............................................. 36

4.8 Functional check of the module ....................................... 36

4.9 Operation of the WB169-SI2 module .................................... 37

4.10 Using of WB169-SI2 module for remote monitoring of sensors ...................... 37

5 Troubleshooting 39

5.1 Possible causes of module failures ...................................... 39

5.1.1 Power supplying failures ....................................... 39

5.1.2 System failures ............................................ 39

5.1.3 Transmitter and receiver failures .................................. 39

5.1.4 Failures of communication with meters ............................... 40

5.2 Troubleshooting procedure .......................................... 41

6 Additional information 41

WB169-SI2 i

List of Tables

1 Overview of WB169-SI2 module technical parameters .......................... 4

2 Overview of WB169-SI2 module configuration parameters ........................ 23

3 Structure of Wireless M-BUS message header of the WB169-SI2 module ................ 28

4 Description of variables of WB169-SI2 module info-message data block ................. 29

List of Figures

1 Principle of data transfer from the WB169-SI2 module .......................... 2

2 Appearance of the WB169-SI2 module ................................... 3

3 Setting of VIF and its effect on decoding of message ........................... 14

4”Leak” alarm function principle ....................................... 15

5”Burst” alarm function principle ...................................... 17

6 Conversion table between ”LIMIT” value and corresponding minute flow ................ 17

7”Tariff switching” function principle .................................... 19

8 Table for selection of info-message content (”mask”) ........................... 21

9 WB169-SI2 module configuration table ................................... 24

10 Basic forms of WB169-SI2 module in ”SOFTLINK Configurator” application ............. 27

11 Input/output setting form and form for setting of encryption ...................... 28

12 View of WB169-SI2 module information message received by WMBUSAN4 analyzer ......... 29

13 Encrypted and decrypted message of the WB169-SI2 module ...................... 30

14 Structure of WB169-SI2 module message with both inputs in alarm mode ............... 30

15 Structure of alarm message about the change of sensor status on the port of WB169-SI2 module . . 31

16 Structure of alarm message about the reset of WB169-SI2 module ................... 31

17 Structure of WB169-SI2 module alarm message about the ”Leak” type of alarm ............ 31

18 Set of WB169-SI2 module components with stick antenna ........................ 33

19 Detail of WB169-SI2 module PCB ..................................... 34

20 Example of ”Radar” application table ................................... 37

21 Types of sensor outputs convenient for WB169-SI2 module ....................... 38

22 Principle of ”electronic seal” sensor ..................................... 38

23 Using of position sensor for door monitoring ............................... 38

WB169-SI2 ii

1 Introduction

This document describes features, parameters and setting possibilities of the WB169-SI2 module, which is used for

reading of either consumption meters with pulse output (water meters, electrometers, gas-meters. . . ), or two-state

sensors (e.g. door contacts, flood detectors, fire detectors, electronic seals...etc.) and for radio-broadcasting of the

data from connected meters/sensors to the superior remote reading system in form of Wireless M-BUS standard

messages. The WB169-SI2 module works either in unidirectional communication mode N1, or in the bidirectional

N2 mode. In both modes the module regularly broadcasts information messages of ”User Data” type intended for

superior ”master” device. In bidirectional N2 mode it is possible to use a back channel from master device, that

can be used for transfer of ”Request” type of messages with remote configuration demands. In ”alarm mode” the

module sends ”Alarm from meter” type of messages based on the sensor status changes. These messages are sent

immediately, out of regular broadcasting interval.

1.1 Wireless M-BUS Communication Protocol

Wireless M-BUS is the communications protocol described by international standards EN 13757-4 (physical and

link layer) and EN 13757-3 (application layer), which is intended primarily for radio transmission of remote reading

values from consumption meters and sensors. Protocol Wireless M-BUS (hereinafter ”WMBUS”) is based on a

standard M-BUS definition (uses the same application layer as M-BUS standard), but is adapted for data transfer

via radio signals.

Communications via WMBUS protocol works in Master-Slave mode, where ”Master” is a collecting data device,

”Slave“ is a providing data device. Slave device could be integrated or external radio module transmitting data

from the meter/sensor. The communications protocol WMBUS defines several communication modes (simplex or

duplex). If working in simplex mode a ”Slave” device only transmits messages to ”Master” that these messages

receives. If working in ”bidirectional” mode, it is possible to use a back channel from ”Master” device to ”Slave”

device for ”Request” type of messages, that can contain e.g. request for the change of slave’s configuration.

Wireless M-BUS communications protocol partially supports repeating of the messages. If receiving from some

”Slave” device is not possible because of the low level of radio signal, the messages can be re-transmitted (repeated)

by appointed element of the radio network (repeater or slave with such functionality). Each repeated message is

marked as ”repeated message” so as not to be repeated again.

1.2 Module usage

The WB169-SI2 module can be used either for remote reading of two consumption meters with pulse output, or for

transfer of alarm messages from two two-state sensors. It is possible to combine both type of usage.

When using for remote reading of consumption meters (water meters, gas-meters, electro-meters...), up to

two meters with standard pulse (”SI”) output can be connected to the module. The meters can be of different kind,

with different quantities and units and with different conversion rates. The module continuously registers incoming

pulses (generated by meters) into its internal counters, with using of preconfigured multipliers/divisors converts

current status of each counter into the required output units (m3, kWh, MJ...) and broadcasts info-messages with

current statuses of all connected meters as Wireless M-BUS ”User Data” messages.

When using for remote monitoring of sensor statuses (door contacts, flood detectors, fire detectors, electronic

seals..), up to two two-state sensors with ”off/on” (”0/1”) outputs can be connected to the module. The sensors

can be of different kind, with different type of output and different logic of signaling. The module continuously

monitors status of each sensor and records all its changes. If the counter is switched into alarm mode, the module

immediately transmits alarm messages according to preselected rule. The module regularly broadcasts in each

info-message the number of ”0-to-1” transitions, as well as current sensor status (”0” or ”1”). If the counter is

switched into the alarm mode, the module sends ”Alarm from meter” message immediately at the change of sensor

status.

Each regular information message contains module identification, values of both counters, actual statuses of

all connected sensors in alarm mode and operational entries from embedded sensors (battery voltage, processor

temperature). Each alarm message contains only module identification and information about the actual status

of that port, on which the status was changed. Detailed information about the content and format of information

and alarm messages can be found in paragraph 3.3.

Information and alarm messages are transmitted either in open mode (without encryption), or encrypted by AES-

128 encryption key. The messages are transmitted on the 169.4 MHz frequency with data rate from 2.4 kbps to

19.2 kbps (according to used frequency channel). Messages can be received either by WB169-RFE communication

WB169-SI2 1

gateway (WMBUS Ethernet GateWay produced by SOFTLINK), or any other ”Master” device that complies with

the Wireless M-BUS EN 13757-3 / EN 13757-4 standard for 169 MHz frequency band. Principle of data transfer

from the WB169-SI2 module for both kinds of solutions is depicted in the figure 1.

Figure 1: Principle of data transfer from the WB169-SI2 module

1.3 External synchronization, tariff switching and alarm functions

TheWB169-SI2 module can be used in a wide variety of applications within different industries. The external

synchronization function is intended especially for measurement of electrical energy and gas. When using this

function, broadcasting of the module is synchronized from external source of synchronization pulses. It can be used

for measuring of energy consumption in standardized 15-minutes intervals synchronized with parallel measurement

of superior energy/gas distributor. Detailed description of this function can be found in paragraph 3.1.5 ”WMBUS’

group commands for setting of messages”.

The tariff switching function, that is also intended for energy measurement, enables distribution of input pulses

between two internal counters (”high tariff” and ”low tariff”) on the base of external control voltage of daily load

diagram system (also known as ”DSM” - demand side management). Detailed description of this function can be

found in paragraph 3.1.10 ”Description and setting of ”Tariff switching” function”.

The WB169-SI2 module enables also monitoring of operational parameters of objects by reading of sensor statuses.

Typical example of this usage is monitoring of opening/closing of overhead doors of halls, where the module can

provide information about current status of each door and measure number of open/close cycles of the doors.

Another example is monitoring of current statuses of circuit breakers or closing valves or monitoring of safety-

loops (”electronic seals”). Detailed description of special settings for sensor monitoring purposes can be found in

paragraph 3.1.9 ”Setting of sensor inputs”.

The special alarm functions ”Leak” and ”Burst” are intended for measuring of water and gas. The ”Leak”

function serves for detection of permanent minor leaks in water/gas distribution systems. The ”Burst” function

serves for detection of breakdowns in water/gas distribution systems, when some kind of accident (e.g. broken pipe)

causes huge overconsumption. Each of these functions can be configured for any port of the module. Corresponding

”Leak” and ”Burst” alarm messages are transmitted immediately after detection of the alarm status. Coding of

these alarm messages complies with M-Bus standard. Detailed description of alarm messages can be found in

paragraph refsection:struktura-zpravy ”Structure of module data messages”.

Detailed description of ”Leak” function can be found in paragraph 3.1.7 ”Description and setting of ”Leak” alarm

function”. Detailed description of ”Burst” function can be found in paragraph 3.1.8 ”Description and setting of

”Burst” alarm function”.

1.4 Bi-directional communication mode

If the WB169-SI2 module is preset for working in bi-directional communication mode N2, it could receive the

”Request” type of messages according to the Wireless M-BUS standard. These messages can be originated by

superior system or by superior ”Master” device and can contain commands for remote configuration of following

parameters:

WB169-SI2 2

- setting of transmitting power;

- setting of info-messages broadcasting period;

- correction of statuses of pulse counters - relatively (”add NN”) or absolutely (”set NN”) ,

Receiving of ”Request” type message take place always during the 500 ms long time window that starts immediately

after transmitting of regular ”User Data” info-message. During this interval the WB169-SI2 module opens its

receiver so as to be able to receive possible ”Request” message. The module confirms receiving of ”Request” by

sending of ”Acknowledgment” type of message.

Management of ”Request” type of messages must be implemented into the central application software or into the

superior ”Master” device. The messages are coded by M-Bus standard principles with short Wireless M-BUS header

with special indication of ”Request” type messages (C-byte =”53”, CI-byte = ”5A”). The message contains one

data block (with appropriate DIFE/VIFE code and required value) for each parameter, that should be remotely

changed. More detailed description of ”Request” type of message can be provided by producer of the module on

request.

1.5 Hardware features and power supplying

The module is enclosed in transparent humidity-proof plastic casing and can be used in interiors as well as in

exteriors. The casing is designed for mounting on the wall or other construction element (beam, pipe...). Module

can be treated with an additional sealing by high-adhesion silicon filling, that can ensure proof against inundation

by water (IP68 grade). If this treatment is required from the manufacturer, it must be ordered separately.

The module can be controlled and configured either by configuration cable, or wirelessly - by infra-red remote

control with using of optical converter. The module is equipped with the circular crater-shaped pit, that supports

magnetic fixing of optical converter with holding on magnet in right position.

The module is power supplied by internal battery with 13 Ah or 5.8 Ah capacity (see ordering options). If using

of 13 Ah battery, the module lifetime for 60 minutes broadcasting period is more than 8 years. If using of 5.8

Ah battery, the lifetime is up to 8 years for 120 minutes broadcasting period. Battery lifetime can be negatively

influenced by shorter broadcasting period or by storing and operation in sites with the temperatures exceeding the

recommended range for module storage and operation. Operation in bi-directional mode (N2) with using of back

channel decreases the battery lifetime by 5 %. External appearance of the WB169-SI2 module is shown in the

Figure 2.

Figure 2: Appearance of the WB169-SI2 module

1.6 Variants and ordering codes

The WB169-SI2 module is delivered in four variants with different capacity of internal battery and with different

degree of protection. There are four ordering codes for delivery of required hardware configuration of the module:

-WB169-SI2-B13 - ordering code for variant with 13 Ah battery and IP65 degree of protection

-WB169-SI2-B13/IP68 - ordering code for variant with 13 Ah battery and IP68 degree of protection

-WB169-SI2-B5 - ordering code for variant with 5.8 Ah battery and IP65 degree of protection;

-WB169-SI2-B5/IP68 - ordering code for variant with 5.8 Ah battery and IP68 degree of protection.

Together with the WB169-SI2 module also some time-tested sensors for industrial use can be ordered directly from

module’s producer (e.g. magnetic position sensor, security loop, flood detector...). Actual list of offered sensors is

available at producer’s e-shop: www.softlink.cz/obchod.

WB169-SI2 3

2 Technical parameters overview

Overview of WB169-SI2 module technical parameters is shown in the Table1below.

Table 1: Overview of WB169-SI2 module technical parameters

RF subsystem parameters

Frequency band * 169.40625 to 169.46875 MHz

Modulation * 2-GFSK, 4-GFSK

Bandwidth * 12.5 or 50 kHz

Transmitting power 500 mW

Sensitivity of back-channel receiver -109 dBm

Communication protocol Wireless M-BUS

Communication mode (by EN 13757-4) N1, N2

Transmission speed * 2400, 4800, or 19200 Baud

Antenna connector SMA female

Antenna characteristic impedance 50 Ω

Configuration interface RS232

Transmission speed 9600 Baud

Operation mode asynchronous

Transmission parameters 8 data bits, 1 stop bit, none parity

Signal level TTL/CMOS

Optical configuration interface

Transmission speed 115 200 Baud

Optical I/F specification complies with IrPHY 1.4 standard

Pulse/sensor inputs

Resistance of released contact more than 10 MΩ

Resistance of short-circuited contact less than 1 kΩ

Maximum frequency of input pulses 10 Hz

Minimum pulse length 40 ms

Range of voltage measurement in analog mode (0 ÷3,6) V

Maximum voltage on the input 3,6 V

Power supplying

3,6 V lithium battery capacity 5.8 or 13 Ah

Weight and dimensions

Length 145 mm

Width 45 mm

Height 100 mm

Weight cca 300 g

Storage and installation conditions

Installation environment (by ˇ

CSN 33 2000-3) normal AA6, AB4, A4

Operation temperature range (-20 ÷40) ◦C

Storage temperature range (0 ÷40) ◦C

Relative humidity ** 95 % (w/o condensation)

Degree of protection ** IP65 or IP68

* in reliance on selected frequency channel - see EN 13757-4, Mode N, Physical link parameters (Table 18).

** modules with additional silicon filling are waterproof with IP68 degree of protection.

WB169-SI2 4

3 Configuration of the WB169-SI2 module

Configuration parameters of the WB169-SI2 module can be displayed and changed from the common computer

(PC) by one of these methods:

- with using of ”USB-CMOS” converter and configuration cable connected to the module;

- wirelessly, with using of ”USB-IRDA” or ”BT-IRDA” converter;

-remotely, by using of bi-directional communication system.

Technique of interconnection of the module with configuration computer and general rules of configuration are

described in detail in the chapter 2 of ”Configuration of wacoSystem product family devices”, that can be

downloaded from the producer website:

www.wacosystem.com/support/

www.softlink.cz/en/documents/

The description and meaning of all configuration parameters that can be checked and changed by cable can be

found in the section 3.1 ”Setting of WB169-SI2 parameters via configuration cable”.

Description of interconnection of the converter with PC (”USB-IRDA”) or smartphone (”BT-IRDA”) and general

rules of configuration with using of optical converters are described in the chapter 3 of above mentioned manual

”Configuration of wacoSystem product family devices”. The description and meaning of the parameters that can be

changed by optical converter can be found in the section 3.2 ”Setting of parameters by using of optical converter”.

Principles and short description of communication through the Wireless M-Bus back channel can be found in

paragraph 1.4 ”Bi-directional communication mode”.

3.1 Setting of WB169-SI2 module parameters by configuration cable

3.1.1 List of module configuration parameters

List of all module configuration parameters can be displayed by entering of ”show” command and pressing of

”ENTER” key. The following list of parameters will display in the terminal window:

mon#show

----- Configuration -----

Timezone : 1

MBUS ID : 00100017

MBUS version : 5

MBUS manufacturer : SFT

MBUS medium : 7

MBUS manuf info : SI2N1

MBUS value[0] DIB : 04, VIB 13, multiplier 1, divider 1, mode falling, quick, alr: none

Leak detection periode 24 hour(s), zero periode 90 minutes

Broken pipe min. 50 pulse/10 min. during 30 minutes

MBUS value[1] DIB : 44, VIB 13, multiplier 1, divider 1, mode falling, quick, alr: none

MBUS power : 3 (20 dbm)

MBUS mode : N2

WMBUS channel : 3 - 169,43125 Mhz

Send periode : 60 min

Send mask is 3 : I1, I2

Data will be encrypted by AES

Next send : 30 min.

No. sent : 3 msg(s)

No. recv : 0 msg(s)

Conf. version : 12

SW version 0.01, date Aug 9 2019

mon#

WB169-SI2 5

3.1.2 Displaying the List of configuration commands (”HELP”)

List of all configuration commands can be displayed by entering of ”?” command and pressing of ”ENTER” key.

The following list of commands will display in the terminal window:

Help :

--- System commands ---

deb : Show or set debug level

ta : Show tasks

mb : Show mail boxes

du addr : Dump memory

rb addr : Read byte from addr

rw addr : Read word from addr

rd addr : Read dword from addr

sb addr val : Set byte on addr

sw addr val : Set word on addr

sd addr val : Set dword on addr

port : Show port [a,b,..]

show : Show info

write : Write configuration to flash

cread : Read configuration from flash

clear : Clear configuration and load defaults

--- WMBUS commands --- ---

mid : Show or set MBUS ID (0 - 99999999)

power : Show or set MBUS power (1 - 5)

manuf : Show or set MBUS manufacturer code (AAA)

info : Show or set MBUS info string (0-30 chars)

vers : Show or set MBUS version (0 - 255)

medium : Show or set MBUS medium (0 - 255)

periode : Change periode of send 0 - disable, >0 periode in minutes, <0 from input

mode : Set WMBUS mode 1 - N1, 2 - N2

chan : Set WMBUS channel, type ? for help

ekey : Set encrypt key, point ’.’ no encrypt

--- Inputs ---

val : Show or set counters values[0-1]

mul : Set multiplier of value[0-1]

div : Set divider of value[0-1]

dib : Set DIF and DIFE for value[0-1]

vib : Set VIF and VIFE for value[0-1]

det : Detection 0 - falling, 1 - rising

dmode : 0 - quick, 1 - slow

amode : 0 - disable, 1 - enable

alr : Send alarm : 0 - none, 1 - falling, 2 - rising, 3 - both

leakp : Leak detection periode in hours - 0 disabled

leakz : Leak zero periode in minutes (rounded up to ten minutes)

burstp : Burst min puls in 10 minutes

burstt : Burst check time in minutes (rounded up to ten minutes)

trf : Set tarrif 0 - off, 1 - t1 high, 2 - t1 low

--- Modem commands ---

mr : Modem receive mode 0 - off, 1 - on

mt test time : Set test on modem, 1 - TX carrier, 2 - TX sync, time is in second, default 10

ms : Get modem state

mi : Get modem info

mfreq : Set or get radio frequency correction

cfreq : Set +- frequency correction, 1 = 1Hz

...

WB169-SI2 6

...

--- Utils ---

smask : Send mask bits, 0 - I1, 1 - I2, 2 - temp. 3 - hum. ,default 3 - I1 and I2

tz : Time offset in hours

time : Show or set rtc time, set as BCD : 0x102033 is 10:20:33

date : Show or set rtc date, set as BCD : 0x171231 is 2017-12-31

uptime : Show uptime

sens : Show sensors

sendp : Send nx WMBUS messages

send : Send WMBUS message

reset : Reset device

? : Show this help

Overview of configuration parameters with short description of their meaning can be also found in table 2on the

page 23. The meaning and usage of individual commands are described below.

3.1.3 ”System commands” group for general diagnostics

Commands ””deb”, ”ta”, ”mb”, ”du addr”, ”rw addr”, ”rb addr”, ”rd addr”, ”sw addr”, ”sb addr”,

”sd addr” and ”uptime” are used for troubleshooting and repair of the device in a factory. Manufacturer

strongly recommends not to use these commands during common operation.

Other system commands ”show” (configuration statement) and ”?’ (”Help”) are described in previous part of

section3.1.

By using of ”port” command an actual setting of module ports can be displayed. This command is intended only

for module diagnostics.

3.1.4 Commands for writing of configuration and reset

The module contains two sets of configuration: operating configuration and saved configuration. At the start of the

system the module copies saved configuration to operating configuration, with which continues to work. If the user

changes configuration parameters, it does so only in operating configuration.

If the current operating configuration was not stored to FLASH memory, the module returns to the saved configura-

tion after reset. If the parameter should be changed only temporarily (for example shorten of the broadcasting period

during installation), it is not necessary to save operating configuration in FLASH memory (after the work finishing

module can be returned to normal configuration by its reset). If the parameter should be changed permanently,

there is necessary to save configuration to FLASH memory.

If operating configuration corresponds to the saved set (ie. there are no differences between commands in FLASH

and in the operating set), the module will ”report“ prompt in the format ”mon#”. If operating configuration was

changed so that it no longer matches to the saved set, the module will report prompt in the format ”cfg#”.

Every time the current configuration is saved into FLASH memory the value of the ”Configuration version” param-

eter increases by one and the prompt changes to ”mon#”. The parameter resets to zero by erasing of the FLASH

memory.

Current operating configuration can be displayed by using of ”show” command (see paragraph 3.1.1):

cfg#show

Current operating configuration can be rewrite the to FLASH memory by using of ”write” command:

cfg#write

Writing config ... OK, version 3

Reading of the configuration from FLASH memory can be done by by using of ”cread” command (for older some

modifications the command is ”read”):

cfg#cread

Reading config ... OK, version 3

WB169-SI2 7

The configuration can be erased in Flash memory by using of ”clear” command:

cfg#clear

Clearing configuration ... OK, version

This command deletes all configuration parameters from the FLASH memory, so it is necessary to set them again.

If after erasing all parameters in FLASH memory the module goes to reset, default set of parameters (configured

in the program of the device) is duplicated to FLASH memory. There is only one exception - frequency constant

keeps the actual value also after cleaning of FLASH memory by ”clean” command.

This command is recommended to use only by users with good knowledge of the system or after

consultaion with the manufacturer.

The module reset can be performed by using of ”reset” command.

3.1.5 ”WMBUS” group commands for setting of messages

This group of commands serves for setting of Wireless M-BUS addressing of the WB169-SI2 module and for setting

of broadcasting parameters. There are following command:

mid setting of device fabrication number (”M-BUS ID” – range 0 to 99999999)

manuf setting of manufacturer code (”Manufacturer” - supplement of M-BUS address)

vers setting of ”addressing version” (”Version” - supplement of M-BUS address)

medium setting of media code (”Medium” - supplement of M-BUS address)

info setting device name

periode setting of regular messages broadcasting period

power setting of transmitting power (mW)

mode setting of communication mode (1 - N1 mode, 2 - N2 mode)

chan setting of frequency channel (choice from 7 options)

ekey setting of encryption key (”.” - encryption disabled)

Variable ”M-BUS ID” is a serial number of the device in M-Bus standard identification system. The address is

”read only” type for the WB169-SI2 module and cannot be changed. Assigned serial number of the module can be

displayed by”mid” command (without parameter):

cfg#mid

MBUS ID : 00112233

cfg#

Variable ”Manufacturer” is an international code of device producer according to the M-Bus standard. The code

is ”read only” type for the WB169-SI2 module, its value is ”SFT” (Softlink) and it cannot be changed. Assigned

manufacturer code can be displayed by”manuf” command (without parameter):

cfg#manuf

MBUS manufacturer : SFT

cfg#

Variable ”Version” is number of addressing version according to the M-Bus standard (each type and modification

of the device could have its own line of serial numbers). The code is ”read only” type for the WB169-SI2 module

and cannot be changed. Assigned version number can be displayed by ”vers” command (without parameter):

cfg#vers

MBUS version : 101

cfg#

Variable ”Medium” is an international code of measured medium (water, energy, physical quantity..) according

to the M-Bus standard. The variable is editable and it is factory preset to 07 (”Water”). Current setting of the

medium value can be displayed by ”medium” command (without parameter). Medium parameter can be changed

by entering of required code of medium according to M-Bus standard (range: 0 to 255).

Example of medium code setting to ”02” value (electricity):

WB169-SI2 8

cfg#medium

MBUS medium : 7

cfg#medium2

MBUS medium changed from 7 to 2

cfg#

Note: The full identification of the device in M-Bus standard systems is done by combination of four ID components:

”M-BUS ID”, ”Manufacturer”, ”Version” and ”Medium”. This combination must be unambiguous that means

there cannot exist two M-Bus devices worldwide, that have the same combination of all these parameters. If fixed

configuration of the address components used, producer of the device is responsible for unique setting of ”read

only” address components for each device. If M-Bus address components are configurable, operator of the M-Bus

system can use serial number of connected meter in combining with its type, subtype and manufacturer. Using of

”independent” addressing line is possible only in that case, if the operator of the system owns its M-Bus manufacturer

code and can assure that the identification of all operated devices under his code will be unique

”Info” command can be used for setting of device name that is a part of each broadcasted message (see para-

graph 3.3). The parameter is preset from the factory to ”SI2” value. By using of ”info” command (without

parameter) an actual value of the name can be displayed. The device name can be set by entering of any string of

characters after ”info” command.

Example of displaying, setting and follow-up checking of the device name:

cfg#info

MBUS manuf info : ’ABC’

cfg#info XYZ

Change MBUS manuf info from : ’ABC’ to : ’XYZ’

cfg#info

MBUS manuf info : ’XYZ’

cfg#

Maximum length of the string is 29 characters. The only basic set of characters can be used (without diacritics).

It is not recommended to change this parameter.

”Periode” command serves for setting of broadcasting period of regular info messages. The value of the parameter

is factory preset to 60 minutes. Current value can be checked by ”periode” command (without parameter).

Broadcasting period can be changed by entering of required number of minutes after ”periode” command.

Example of displaying, setting and follow-up checking of broadcasting period:

cfg#periode

Periode is 60 min.

cfg#periode 30

Periode changed from 60 to 30 min.

cfg#periode

Periode is 30 min.

cfg#

The module enables also an external synchronization of its broadcasting from external source of synchro-

nization pulses. For this purpose any of module ports can be assigned as ”synchronizing” by using of ”Periode

-X” command, where ”X” is number of assigned port.

Example of setting of port No. 2 to ”synchronization” mode:

cfg#periode -2

Periode changed from 60 min. to I2

mon#

If using of this setting, the process of transmitting of info message launch after each falling edge of the synchro-

nization pulse is received on the synchronizing port. There is a protective interval of 1 minute implemented in the

system, so the broadcasting period could be at least 1 minute. Requirements for the synchronization pulses are the

same, as for metering pulses.

This feature is important in that case, if the measurement and broadcasting of measured values should be synchronized

with some other process. Typical example is measurement of electrical energy in 15-minutes intervals, that must be

WB169-SI2 9

synchronized with measuring intervals of superior part of the electrical grid. In this case it is necessary to bring

15-minutes synchro-signal (e.g. from electrometer with such kind of output) to the synchronizing port.

WARNING: If there are synchronization pulses with inverse logic connected, it could cause a slight decreasing of

battery lifetime (up to 5 %). ”Inverse logic” means that the input is permanently short-circuited and only during

short time pulses it is released.

Regular broadcasting can be disabled by entering of ”periode” command with ”0” parameter. Example:

cfg#periode 0

Periode changed from 60 min. to disabled

mon#

Group of ”power” (transmitting power), ”chan” (frequency channel), ”mode” (communication mode) and

”ekey” (encryption key) commands is intended for setting of module RF-subsystem parameters.

The command ”Power” is used for adjusting of the module broadcasting power. Factory setting is 100 mW

(average power). Actual value of the power can be displayed by using of the ”power” command without parameter.

Transmitting power can be set-up by entering of the number of power level. There are five levels available:

- value ”1” for transmitting power 14 dBm (25 mW)

- value ”2” for transmitting power 17 dBm (50 mW)

- value ”3” for transmitting power 20 dBm (100 mW)

- value ”4” for transmitting power 24 dBm (250 mW)

- value ”5” for transmitting power 27 dBm (500 mW)

An example of checking, setting and re-checking of transmitting power:

cfg#power

MBUS power : 3 (20 dBm)

cfg#power 5

MBUS power changed from 3 to 5 (27 dbm)

cfg#power

MBUS power : 5 (27 dBm)

cfg#

The command ”Communication mode” is used for selecting of the module’s communication mode. Factory

setting is N1 (unidirectional), or N2 (bidirectional), actual setting can be checked by using of ”mode“ command

without parameter. Change of mode can be done by entering of desired option as a parameter of the command.

Communication modes are defined by the Wireless M-BUS standard, accurate choice of relevant communication

modes of the module is stated in the line ”mode” of ”Help” summary (see the paragraph 3.1).

An example of checking, setting and re-checking of communication mode:

cfg#mode

Mode N1

cfg#mode 2

CC1120 state 0x0f, marcstate 65, fifo tx 0, rx 0

Mode changed from 1 to 2

cfg#mode

Mode N2

cfg#

The command ”Frequency channel” is used for selecting of the module’s radio frequency channel. Frequency

channels for the particular frequency bands are defined by the Wireless M-BUS standard. Actual setting can be

checked by using of ”chan“ command without parameter. Change of channel can be done by entering of desired

option as a parameter of the command. Accurate choice of relevant broacasting communication modes of the module

is stated in a line ”mode” in ”Help” summary (see the paragraph 3.1.2).

An example of checking, setting, saving and re-checking of frequency channel:

WB169-SI2 10

cfg#chan

Help :

1 - chan 1a (169.40625 Mhz), 4.8 kbps

2 - chan 1b (169.41875 Mhz), 4.8 kbps

* 3 - chan 2a (169.43125 Mhz), 2.4 kbps

4 - chan 2b (169.44375 Mhz), 2.4 kbps

5 - chan 3a (169.45625 Mhz), 4.8 kbps

6 - chan 3b (169.46875 Mhz), 4.8 kbps

7 - chan 3g (169.43750 Mhz), 19.2 kbps

cfg#chan 1

Channel changed from 3 to 1 : chan 1a (169.40625 Mhz), 4.8 kbps

CC1120 state 0x0f, marcstate 65, fifo tx 0, rx 0

cfg#chan

Help :

* 1 - chan 1a (169.40625 Mhz), 4.8 kbps

2 - chan 1b (169.41875 Mhz), 4.8 kbps

3 - chan 2a (169.43125 Mhz), 2.4 kbps

...

The command ”Encryption key” is used for setting of the encryption key for an encryption of transmitted

messages by using of AES-128 key. The encryption key of 16 bytes length is entered by using of ”ekey“ command,

followed by the string of 16 bytes that can be entered in a decimal or hexadecimal format (see examples).

An example of insertion of the encryption key in hexadecimal format:

cfg#ekey 0x1a 0x2b 0x3c 0x4d 0x5e 0x6f 0xa1 0xb2 0xc3 0xd4 0xe5 0xf6 0x77 0x88 0x99 0xaf

Setting encyption key : 1a 2b 3c 4d 5e 6f a1 b2 c3 d4 e5 f6 77 88 99 af

cfg#

An example of insertion of the encryption key in decimal format:

cfg#ekey42 53 159 188 255 138 241 202 136 21 98 147 235 15 145 136

Setting encyption key : 2a 35 9f bc ff 8a f1 ca 88 15 62 93 eb 0f 91 88

cfg#

If the encryption key is set to the module’s configuration, an information ”Data will be encrypted by AES”

displays in the list of configuration parameters (see chapter 3.1.1)

Encryption can be switched off by setting of ”.” (dot) parameter after the ”ekey“ command:

cfg#ekey.

Encyption disabling

cfg#

In this case an information ”Data will be unencrypted” appears in the list of configuration parameters.

3.1.6 ”Inputs” group parameters

This group of parameters and commands enables setting of internal pulse registers (counters) and setting of output

values of the module.

The WB169-SI2 module is equipped with two inputs (port 1 and 2), that are connected to the corresponding pulse

counters (index 0 and 1). Each counter increases its value up one unit each time it receives pulse from a consumption

meter connected to its port. Below listed commands are used for settings of the initial counter values and constants

(multipliers, divisors) that can be used for adjusting of the output statuses to required values, and also for setting

of auxiliary ”DIF” and ”VIF” M-Bus codes that enable correct decoding of measured values (especially correct

decoding of measuring units).

Each input can be switched to so called ”alarm mode”, in which after each change of input value the counter

only changes its status (goes from ”0” to ”1” or vice versa) and the module transmits the message immediately

with the change of status. Thus the module can read and transfer status information from binary sensors (e.g.

WB169-SI2 11

door contacts, flood detectors..). Detailed description of setting of inputs in alarm mode can be found in the

paragraph 3.1.9 ”Settings of sensor inputs”.

Setting of pulse inputs can be performed with using of following commands:

val[index] initial counter value setting

mul[index] setting of multiplier (output value = status * multiplier)

div[index] setting of divisor (output value = status / divisor)

dib[index] setting of DIF value (= coding method information)

vib[index] setting of VIF value (= measuring unit information)

det[index] setting of trigger edge (0 - falling edge, 1 - rising edge)

dmode[index] setting of pulse input mode (0 - quick pulses, 1 - slow pulses)

amode[index] switching of analog mode (for WB169-SI2 not used)

alr[index] setting of alarm mode (sensor input setting)

alcok[index] specification of alarm mode for ”OK” status (sensor input setting)

alcerr[index] specification of alarm mode for ”Error” status (sensor input setting)

leakp[index] period of leak detection setting (see ”leak” function)

leakz[index] zero interval of leak detection setting (see ”leak” function)

burstp[index] burst alarm limit setting (see ”burst” function)

burstt[index] burst measuring interval setting (see ”burst” function)

trf[index] setting of second port to tariff switching mode (see ”tariff” function)

By using of ”val[index]” command an initial (or actual) value of the counter can be set. After the value is

setup, it increases from this value with each new-coming pulse. Actual counter value can be displayed by using of

”val[index]” command (without parameter). Counter status can be set to required value by using of ”val[index]”

command followed by required whole number (integer).

Example of setting port No 1 (index=0) counter to ”1892” value and follow-up checking of correctness of the

configuration:

cfg#val0 1892

Value[0] changed from 1565252980 to 1892

cfg#val0

Value[0] : 1892 * 1 / 1 -> 1892

cfg#

It is evident from the example, that when checking of current status by ”val[index]” command, the system displays

not only current status value, but also current settings of multiplier and divisor and output value after multiply-

ing/dividing.

By using of ”mul[index]” and ”div[index]” commands a value of multiplier and divisor can be set to the

counter. Default setting of both values is ”1”. If it is necessary to adjust the counter value by some coefficient,

enter convenient combination of multiplier and divisor as shown in example below.

Actual value of multiplier and divisor can be displayed by using of ”val[index]”, ”mul[index]” or ”div[index]”

commands (without parameter) as shown in the example:

cfg#mul0

Multiplier[0] = 1

cfg#div0

Divider[0] = 1

cfg#

Multiplier and divisor setting example:

Watermeter generates measuring pulses after each 50 litres of consumed water. To indicate water consumption in

m3, it is necessary to adjust the original counter value by using of multiplier and divisor as shown in the example:

50 litres = 0.05 m3, so to convert the value to m3, it must be multiplied by 5/100.

It could be done by setting of multiplier to ”5” and divisor to ”100” - see example:

WB169-SI2 12

cfg#mul0 5

Multiplier[0] = 5

cfg#div0 100

Divider[0] = 100

cfg#val0

Value[0] : 2000 * 5 / 100 -> 100

cfg#

From the display of summary shown in the last sequence of commands it is evident that current status value (2000)

will be interpreted as output value 100 (m3). As one unit of the counter represents 50 litres, output value of the

counter is: 2000*50 = 100 000 litres = 100 m3.

By using of ”dib[index]” command a value of DIF code could be set. The DIF code describes character of

the variable, number of ”storage” and format of data field according to the M-Bus standard. Default setting of DIF

parameters of the module counters is as follows:

counter:”0” DIF = 04 00 (instant value, 32-bit integer, storage No ”0”)

counter:”1” DIF = 44 00 (instant value, 32-bit integer, storage No ”1”)

Warning: It is not recommended to make changes of DIF parameter.

By using of ”vib[index]” command a value of VIF code could be set. The VIF code describes the kind of

measured quantity (e.g. volume, temperature, voltage...) and the measuring unit (including multiplier) in which

the value is presented (e.g. m3,◦C, mV, kWh...) according to the M-Bus standard. Default setting of VIF param-

eter of all counters is:

VIF = ”13” (quantity: ”Volume”, measuring unit: 10−3 * m3)

It means that with using of default setting the information message contains value of measured volume in thousandth

of m3, i.e. in litres. If a watermeter is connected to the module with default setting of VIF code, it is necessary

to check out how many litres represent one measuring pulse and setup multiplier and divisor values so as to get

output value in litres. If, as an example, the watermeter generates measuring pulse after each 10 litres of volume,

it is necessary to set multiplier to value ”10”.

If it is needed to get volume in other units than litres (e.g. in m3), or other quantity than volume is measured (e.g.

electrical work in kWh), it is necessary to adjust values of multiplier and divisor to get result in required units as

well as setup correct VIF value to ensure correct presentation of the unit in auxiliary information.

Examples of settings of VIF code

Example of VIF setting in case the water consumption is presented in m3:

Setup values of multiplier and divisor in order to convert output value into ”m3” units (see example of multi-

plier/divisor setting above). Calculate value of VIF code for ”m3” units as follows:

”Codes for Value Information Field (VIF)” table of M-Bus standard designates for ”Volume” quantity ”0001 0nnn”

code, where the result is in 10(nnn −6) m3units. It means that the last three bits of code determine value of unit

multiplier. To get result in litres it is necessary to use multiplier 10(−3) (because 1 liter = 0.001 m3), so that the

value of last three bits must be ’3” (nnn=3). In this case the multiplier is 10(3−6), that is 10(−3) = 0.001). It

means that the correct VIF code for volume in litres is ”0001 0011”, because decadic value nnn=3 converted into

binary code means ”011” value. Conversion of binary ”00010011” value into decadic transcription gives number

”13”, what is default setting of VIF parameter.

To present the measured volume in m3, it is necessary to put multiplier ”1” before ”m3” value. For this case the

value of ”nnn’ must be ”6” (so that the multiplier value is 10(6−6), that is 10(0) = 1). The correct value of VIF

code for volume in m3is ”0001 0110” (because decadic value nnn=6 converted into binary code means ”110” value).

Conversion of binary ”00010110” value into decadic transcription gives number ”16”, what is required setting of

VIF parameter.

Parameter VIF can be setup to ”16” value as follows:

cfg#vib0

VIB[0] : 13

cfg#vib0 0x16

Set VIB[0] : 16

VIB[0] : 16

cfg#

WB169-SI2 13

The same input of VIF parameter could be entered also in decadic form as follows:

cfg#vib0 22

Set VIB[0] : 16

Example of VIF code setting in case the variable is electric work in kWh:

”Codes for Value Information Field (VIF)” table of M-Bus standard designates for ”Energy” quantity ”0000 0nnn”

code, where the result is in 10(nnn −3) Wh units. The last three bits of code determine unit multiplier. To get

result in kWh it is necessary to use multiplier 10(3) (because 1 kWh = 1000 Wh), so that the value of nnn=6 (in this

case the value of multiplier is 10(6−3), that is 10(3) = 1000). It means that the correct VIF code for electric work

in kWh is ”0000 0110”, because decadic value nnn=6 converted into binary code means ”110” value. Conversion of

binary ”00000110” value into decadic transcription gives number ”06”, what is required setting of VIF parameter.

Parameter VIF can be setup to ”06” value as follows:

cfg#vib1 0x06

Set VIB[1] : 06

Above described setting of VIF parameter reflects in decoded message as seen in the figure 3.

Figure 3: Setting of VIF and its effect on decoding of message

In the figure 3can be seen a decoded message of the WB169-SI2 module, where there is the same ”1000” multiplier

value and the same ”1” divisor value set up on both counters.

It is clear from the picture that:

- counter value ”0” with preset ”1 x m3” unit is presented as ”1000 m3”

- counter value ”1” with preset ”1000 x Wh” unit is presented as ”1000 000 Wh”

By using of ”det[index]” command a trigger edge of the counter could be chosen. If it is preset to ”0” option

(default setting) the value of counter will increase with falling edge of incoming pulse (i.e. when the mechanical

contact is short-circuited, or when an electronic pulse generator goes from ”1” to ”0”). If it is preset to ”1” option,

the value of counter will increase with rising edge of incoming pulse (i.e. when the mechanical contact is released,

or when an electronic pulse generator goes from ”0” to ”1”). Actual value of trigger edge setting can be displayed

by using of ”det[index]” command (without parameter).

Example of setting of trigger edge for port No 1 (index=0) to ”1” option (rising edge) and follow-up checking of

trigger edge setting of all ports:

mon#det0 1

Det[0] = 1 - rising

cfg#det

Det[0] = 1 - rising

Det[1] = 0 - falling

Det[2] = 0 - falling

Det[3] = 0 - falling

cfg#

By using of ”dmode[index]” command a smoothening (equalizing) filter of pulse input could be involved or

disconnected. If it is preset to ”0” option (default setting) the equalizing filter is switched off and the input is preset

for detecting of high frequency (quick) pulses. If it is preset to ”1” option, the equalizing filter that can suppress

disturbing pulses on the input is switched on. This setting could be used if there are some parasitic pulses on the

pulse input (e.g. if the input wire is too long), but using of this filter is restricted only for sensor input, or for

detecting of slow pulses with maximum frequency of 2 Hz (minimum length of pulse is 250 ms).

WB169-SI2 14

Example of setting of port No 1 (index=0) mode to ”1” option with involved equalizing filter (slow pulses):

cfg#dmode1 1

Mode[1] = 1 - slow

cfg#

Detailed description of ”Leak” alarm function can be found in the paragraph 3.1.7 below. Detailed description of

”Burst” alarm function can be found in the paragraph 3.1.8 below. Detailed description of sensor input settings can

be found in the paragraph 3.1.9 ”Setting of sensor inputs” below. Detailed description of ”tariff switching” function

can be found in the paragraph 3.1.10 below.

3.1.7 Description and setting of ”Leak” alarm function

”Leak” function is used for detection of such situations in the consumption of gas, water or other liquids, when

there are permanent low-quantity losses caused by minor leaks in the distribution system. In view of the fact that

remote reading systems don’t record consumption continuously but in some steps (usually given by full turn of its

measuring disk), it could take quite long time until the trouble is discovered.

”Leak” function is based on the common pattern that during the normal long-term (e.g. day, week) operation there

are usually some regular time intervals, when the consumption is in its ”idle” status, because the gas/liquid is not

consumed from natural reasons (e.g. during the night, or out of working hours). In these idle time intervals the

consumption should be zero volume. If there are any leaks, time intervals with zero consumption practically either

do not occur, or there are only short intervals caused by discontinuity of measuring system (e.g. if one metering

pulse represents 100 litres, minor leak could become evident even after several hours, when such quantity will leak).

.

”Leak” function principle is shown in the figure 4. When setting of ”Leak” alarm function the length of detection

period must be entered by setting of ”Leak Detection Period” parameter. After expiration of this period the

system evaluates whether during this period at least one time occurred the situation, when the consumption was

in zero level during preset time interval (entered by ”Zero Period” parameter). If there is no leakage, it is highly

probable that zero consumption period occur at least once during the period and system evaluates the period as

”no alarm” status (see upper part of the figure 4). But if there is no one interval with zero consumption registered

during whole detection period, module transmits to superior system ”Leak” alarm message (see lower part of the

figure 4).

”Leak” function can be activated for chosen port by using of ”leakp[index]” command that defines the length of

detection period (”Leak detection period” parameter) in hours. By using of ”leakz[index]” command setup

concurrently for the same port the length of zero consumption interval (”Zero period” parameter) in minutes.

If one of these parameters is set to ”0” for some port, ”Leak” function is deactivated for that port.

Figure 4: ”Leak” alarm function principle

WB169-SI2 15

Example of setting ”Leak detection period” parameter for port No 1 (index ”0”) to 24 hours value:

cfg#leakp 0 24

Value[0] changed from 0 to 24

cfg#

Detection period can be set in range of 1 - 1090 hours, typical setting is 24 hours (daily operational cycle), or 168

hours (weekly operational cycle). Detection period starts running from module restart, or from the moment when

the parameter is changed. Alarm message is sent at the end of detection period.

Example of setting ”Zero period” parameter for port No 1 (index ”0”) to 60 minutes value:

cfg#leakz 0 90

Value[0] changed from 0 to 90

cfg#

Zero consumption period can be set in range of 1 - 1090 minutes with precision of ten minutes (rounded to tens of

minutes, e.g. 10, 20, 30...). If the command is entered with any other value (e.g. 36 minutes) the system will store

rounded value anyway (in this case 40 minutes). General principle is that setting of zero period parameter to longer

values means that the detection is more sensitive (it is capable to detect smaller leaks), but it is also less reliable

with higher probability to produce false alarm due to real consumption caused by random changes of operating

cycle (e.g. if somebody was held up at work few hours longer).

Setting of ”Leak” alarm function parameters appears in the List of configuration parameters (”show” command),

in the section of the particular port:

MBUS value[0] DIB : 04 00, VIB : 13 00 ,multiplier 1, divider 1

Leak detection period 24 hour(s), zero period 90 minutes

Structure of alarm message of ”Leak” type is described in the paragraph 3.3.2 ”Alarm message”.

3.1.8 Description and setting of ”Burst” alarm function

”Burst” function is used for detection of such situations in the consumption of gas, water or other liquids, when the

burst consumption caused by broken pipe (or similar fatal failure of distribution system) occurs. If the consumption

of liquid/gas is abnormally huge for some period of time, the module transmits to the superior system alarm message

of ”7” type (”Burst”).

”Burst” function principle is shown in the figure 5.”Burst” alarm function is set-up by entering of the burst

consumption limit (”burstp[index]” command), that means the limit over which the consumption is considered

as abnormal, and entering of ”Burst Check Time” period (”burstt[index]” command) that means the minimum

time period during which the consumption must be permanently over limit to detect the ”Burst” alarm.

In view of the fact that different meters connected to the module could have different conversion rate of volume per

measuring pulse, consumption limit is delimited universally as number of registered pulses per 10 minutes

time period. Conversion table between ”pulses per 10 minutes” and ”consumption per minute” for frequently

used conversion rates of watermeters is available in the figure 6.

”Burst” function can be activated for chosen port by using of ”burstp[index”] command that defines required

consumption limit in number of pulses per 10 minutes period. By using of ”burstt[index]” command setup

concurrently for the same port minimum duration of abnormal consumption (”Burst Check Time”) in minutes. If

one of these parameters is set to ”0” for some port, ”Burst” function is deactivated for that port.

Example of setting ”LIMIT” parameter for port No 1 (index ”0”) to 15 pulses per 10 minutes:

cfg#burstp 0 15

Value[0] changed from 0 to 15

cfg#

Consumption limit alarm value can be set in practically unlimited range (1 to 65535 pulses per 10 minutes).

Example of setting ”Burst Check Time” parameter for port No 1 (index ”0”) to 40 minutes value:

WB169-SI2 16

Figure 5: ”Burst” alarm function principle

Figure 6: Conversion table between ”LIMIT” value and corresponding minute flow

cfg#burstt 0 40

Value[0] changed from 0 to 40

cfg#

Minimum duration of abnormal consumption (”Burst Check Time”) can be set up in range 1 - 1090 minutes with

precision of ten minutes (rounded to tens of minutes, e.g. 10, 20, 30...). If the command is entered with any other

value (e.g. 36 minutes) the system will store rounded value anyway (in this case 40 minutes). General principle

is that setting of Burst Check Time parameter to longer values means that the detection is more reliable, with

lower probability to produce false alarm due to random changes in normal operation (e.g. during filling a tank with

water), but in the same time it will prolong the response time between the breakdown and sending of alarm.

Setting of ”Burst” alarm function parameters appears in the List of configuration parameters - in the section of the

particular port:

MBUS value[0] DIB : 04 00, VIB : 13 00 ,multiplier 1, divider 1

Broken pipe min. 15 pulse/10 min. during 40 minutes

Structure of ”Burst” alarm message is described in the paragraph 3.3.2 ”Alarm message”.

3.1.9 Setting of sensor inputs

Any two-state sensors of ”on/off” (0/1) type with contact, relay, or electronic binary output (e.g. door contacts,

flood detectors, fire detectors, electronic seals...etc.) can be connected to any WB169-SI2 module port. If the port

is not preset to ”alarm mode”, the module only stores number of 0/1 transitions of the sensor into the counter and

WB169-SI2 17

Table of contents

Other SOFTLINK Conference System manuals

Popular Conference System manuals by other brands

Microchip Technology

Microchip Technology 3DTouchPad user guide

Williams AV

Williams AV BluePOD Conference Mate user manual

Edis

Edis CS17-1 user manual

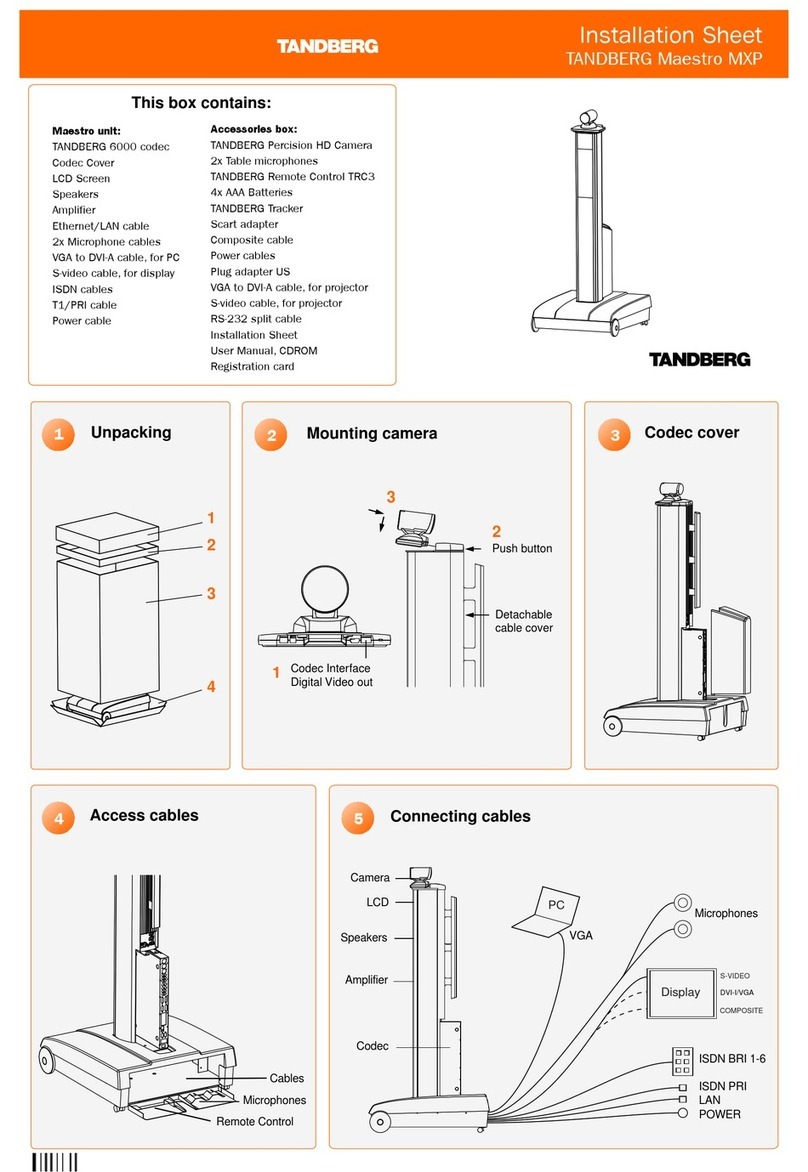

TANDBERG

TANDBERG Maestro MXP Installation sheet

Danish Interpretation Systems

Danish Interpretation Systems DCS 6000 user manual

Polycom

Polycom Trio Series manual