WATTrouter M - user manual

How to fit and setup the device

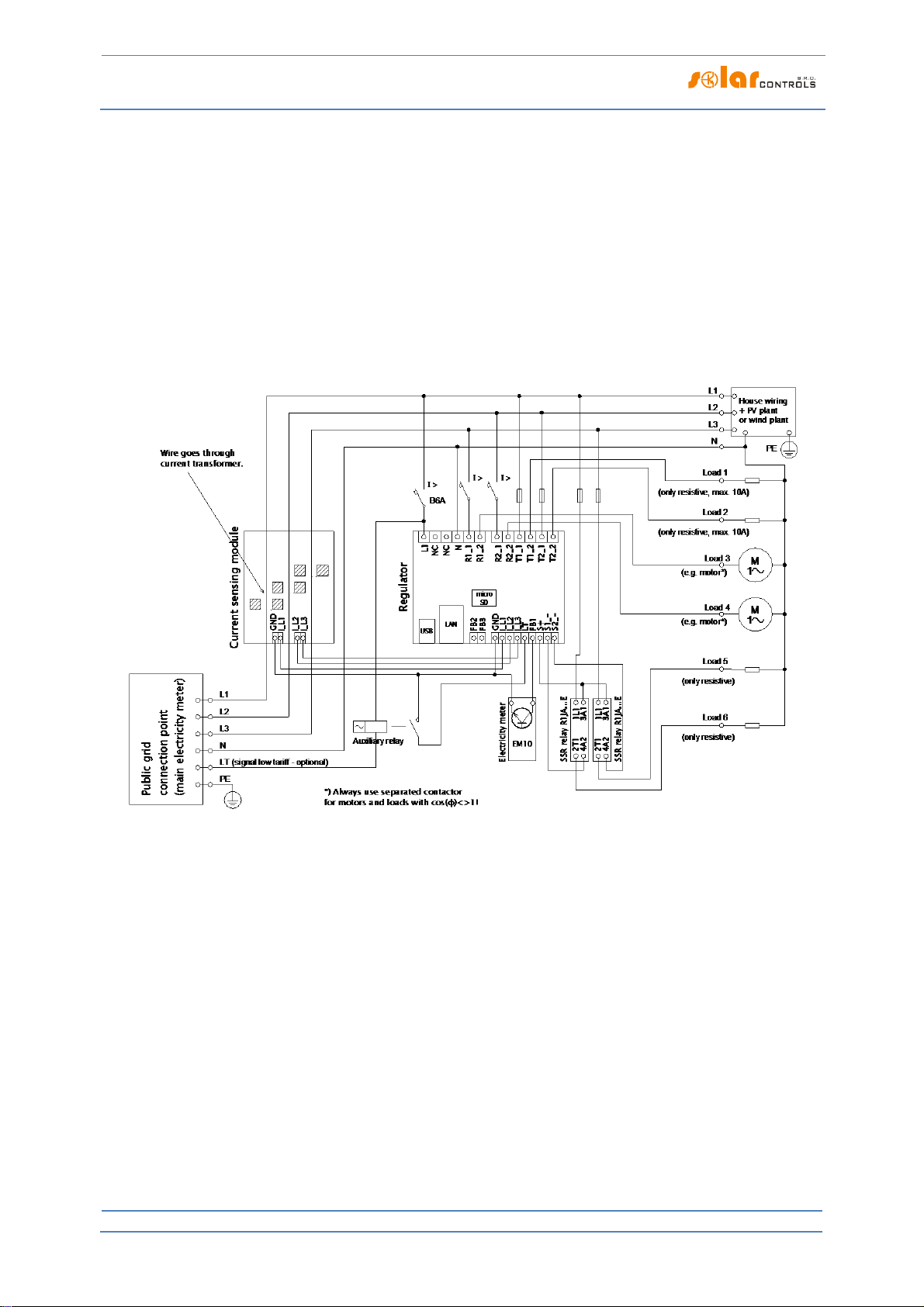

The current sensing module measures electric current in real time and on all phases. The regulator evaluates

the measured electric currents and if it determines the available surplus energy produced by the PV-plant, it

will switch on connected loads according to adjustable priorities, while constantly trying to maintain zero

energy flow through the current sensing module, the so called "virtual zero" (the sum of active power outputs

on all three phases = 0) or optionally, on each phase separately, so called "phase zero".

Switching according to priorities is done in the following way:

By default (during night), all loads are turned off. If surplus energy generated by PV-plant is determined in the

morning, the output with the first (highest) priority is switched on.

The switching time is different according to selected output function.

Triac/SSR/PWM outputs (proportional outputs) are switched on almost immediately after surplus

energy is detected and the controller is gradually (synchronous control or PWM modulation)

maintaining "virtual zero" or "phase zero", according to the control settings.

Relay outputs are switched on only if the surplus energy exceeds the preset load‘s nominal power.

Alternatively, relay outputs may be operated in "prepend" mode if there is sufficient power at any

proportional output with nearest higher priority. This allows for maximum utilization of the produced

surplus power even for relay outputs - refer to the "Prepend before triacs/SSRs" function.

When load with 1st priority is switched on (for proportional output it means switching on the maximum

power), the system waits until the power output of PV-plant increases again (beginning of dawn). If electric

production is determined even when this load is switched on, load with second priority in the same mode is

switched on as well.

If the power output of PV-plant is still increasing, additional connected loads are switched on in the same

mode.

If the power output of the PV-plant decreases, or if another load - not connected to the WATTrouter device is

switched on, the switched (active) outputs are disconnected - again according to preset priorities but in reverse

order (the load with lower priority is disconnected first).

For relay outputs there may be set a minimum switching time. If, simultaneously with a relay output the

proportional output with higher priority is switched on, and the available surplus energy is reduced, then this

proportional output will reduce the power output of the of the load (even down to zero) in order to maintain

virtual zero or phase zero on the current sensing module, if possible.

Except for the situation specified in the paragraph above, the controller never violates the established

priorities.

The above specified principle applies only to standard connection of the current sensing module, connected

right behind the facility’s main energy meter, so the WATTrouter device uses only the actual PV-plant surpluses

(recommended settings). However, WATTrouter controller is versatile device and can be connected according

to your needs. For example, you can place the current sensing module just next to the PV inverter and then you

can maintain the virtual or phase zero on that line.

The above specified basic control mode may be combined with another mode of output switching, provided

that low tariff signal (double tariff rate) is available (CombiWATT mode), or with switching based on preset time

conditions (time schedules).

This device is not designed for precise active power measurement (it is not a replacement for a

wattmeter or electricity meter). Active power is measured with sufficient precision in order to

maintain all control functions.