SolarWorld SW poly/RGA Series Operation manual

1

User Information

SolarWorld O Grid Solar modules

Stand: 01.03.2010

Carefully read through these instructions before installing,

operating, or servicing the PV system. Failure to follow these

instructions may result in bodily injury or damage to property.

Keep these instructions!

Classification of safety guidelines

Warning symbol, signal word Warning levels

DANGER! Warns of imminent danger of death.

WARNING! Warns of possible danger of death

and/or serious injury.

CAUTION! Warns of possible personal injury.

ATTENTION Warns of damage to property without

the possibility of personal injury.

Important information.

▹ Working on a PV system requires specialized knowledge

and must therefore be carried out only by appropriately

qualified and authorized personnel. Keep children away.

▹ If the products are used in the USA please pay attention to

the information marked [USA].

▹ This User Information gives you information on installati-

on and safety when handling photovoltaic modules from

SolarWorld AG (in the following referred to as “modules”).

Safety information

DANGER!

Danger of death from electric shock

▹ Modules generate electricity as soon as they are exposed

to light. Connections variations can cause high voltages

and/or high currents. Do not fit modules and wiring with

wet plugs and sockets.

▹ Exercise extreme caution when carrying out work on

wiring.

▹ The inverter can produce dangerous, high voltages, even

when not connected.

▹ Exercise extreme caution when working on the inverter

and wiring.

DANGER!

Danger of death from arcing

▹ Modules generate direct current (DC) when any amount

of sunlight shines on them. When breaking a connected

string of modules (e.g. when disconnecting the DC line

from the inverter under load), a lethally strong arc can

occur.

▹ Never remove the module from the inverter while it is

still connected to the main grid.

▹ Ensure that the cable connections are in perfect condi-

tion (no cracking, no soiling, or other contamination).

WARNING!

Danger of falling

▹ There is a danger of falling while working on the roof

as well as when climbing up to or down from the roof.

It is very important that you pay attention to accident

prevention regulations and use adequate fall prevention

devices.

WARNING!

Falling objects

▹ When assembling on roofs there is the risk of tools,

assembling materials or a module falling o the roof and

injuring persons below.

▹ Create a hazard zone on the ground level before

beginning with the assembly and warn persons in the

surrounding area.

WARNING!

Flammable materials

▹ Modules may not be operated in the proximity of devices

or rooms from which flammable gasses or dust may

escape or collect.

▹ Roof construction and assembly may have eects on fire

protection.

CAUTION!

Risk of hand injuries

▹ Risk of squeezing hands when mounting support frame

and module.

▹ Work may be carried out by trained personnel only.

▹ Wear protective gloves.

You can receive further information about

▹ dimensioning and setting up photovoltaic systems

▹ wiring

▹ connection technology

▹ elevation

from your photovoltaic dealer.

Intended use

Modules use the photovoltaic eect to transform light into

electricity. The modules are used outdoors and, depending

on type, mounted on support frames, stands, or flat surfaces.

Multiple modules can be connected serially or parallel. The

number of connectable modules is limited, see chart “Types

of modules”. Connect only modules of the same type within

one system. Modules must not be directly connected to an

electrical consumer. Do not take the modules apart and do

not remove the type plate. Do not drill into the frame or into

the glass of the module, this will void your warranty.

Intended use also includes following the installation guide-

lines, as well as following the mentioned maintenance and

cleaning instruc-tions. The manufacturer will not be held lia-

ble for damages caused by failure to observe the installation

guidelines.

2

A fitting of the module as overhead glazing or vertical

glazing (facade) is prohibited in several countries. It is

absolutely essential that you adhere to the current legal

requirements – such as building permission – of local,

regional, and national authorities.

To ensure proper operation of the system and prevent

damage please make sure that:

▹ the module is not shadowed by trees, antennas etc.,

▹ the module is suciently ventilated from the back side,

▹ the back sides of the modules are not treated with paint or

adhesives.

▹ sunlight is not concentrated on the modules via mirrors or

lenses.

Types of modules

SW xx poly/

RGA

SW xx poly/

RHA

SW xx poly/

RIA

SW xx poly/

R6A

SW xx mono/

R5A

Performance

[W]

30-45 50-70 70-90 100-140 70-90

Dimensions

lxwxh [mm]

572 x 680

x 34

806 x 680

x 34

1058 x 680

x 34

1508 x 680 x 34 1229 x 556 x 34

Pmax [W] 30 – 35 – 40

– 45

50 – 60 – 70 70 – 75 – 80 –

85 – 90

100 – 110 – 120

– 130 – 140

70 – 75 – 80 –

85 – 90

Weight [kg] 4,6 6,7 8,1 11,8 8,2

max. system

voltage

IEC 1000 VDC

NEC 600 VDC

IEC 1000 VDC

NEC 600 VDC

IEC 1000 VDC

NEC 600 VDC

IEC 1000 VDC

NEC 600 VDC

IEC 1000 VDC

NEC 600 VDC

max. number

of modules

connected

parallel

5 3 3 2 3

Image

Diodes 2 x F1200D 2 x F1200D 2 x F1200D 2 x F1200D 2 x F1200D

Unpacking, interim storing and handling

During assembly and electrical installation cover the modu-

les with opaque material to prevent electricity from being

generated.

Do not assemble on roofs and buildings during high winds.

Wind also increases the risk of injury when lifting or moving

support frames with several mounted modules.

▹ Leave modules in packaging until ready to install.

▹ Do not hold or transport the module by the junction box.

▹ Do not step or stand on the module.

▹ Do not drop the module and do not let anything fall onto

the module.

▹ Do not place heavy objects on the module.

▹ Do not set the module roughly onto the floor, particularly

not onto the corners.

Do not use any module with broken glass.

Assembly

▹ Recommended angle of inclination for photovoltaic opera-

ted stand-alone systems/year-round use.

Latitude Fixed angle of inclination

0° - 15° 15°

15° - 25° equal to the latitude

25° - 30° Latitude + 5°

30° - 35° Latitude + 10°

35° - 40° Latitude + 15°

over 40° Latitude + 20°

Your local photovoltaic dealer can give you information

about a suitable installation location.

Modules must be attached to support frames or with assem-

bly sets to a solid base. The whole photovoltaic system must

withstand the mechanical loads typical for the specific region.

When selecting support frames ensure that they withstand

strong winds and snow loads and comply with local ordinan-

ces and regu-lations. Ensure that the modules are not exposed

to undue forces caused by thermal expansion of the support

frame. The support frames should be made of resistant,

corrosion-proof, and UV resistant material.

Ground mounting: Choose the height of the frame so that

the module can not be covered by snow or plants for a longer

period of time.

Roof mounting: When mounting on roofs and buildings

ensure that the roof construction is adequate. In some cases a

special support frame may be required.

Mast mounting: When installing a module on a masthead

it must be ensured that the mast has sucient stability to

resist expected wind speeds and wind gusts without notably

bending. The mast must have an adequate foundation. Use an

assembly frame to attach the module to the mast.

Mounting

Screw the modules onto the four attachments designated for

this purpose. Consult your dealer if you plan to assemble the

modules in other places than those designated.

The modules can be mounted to the substructure by clamping

on (example A) at the front side or by screwing (example B) at

the back side. The clamping area (example A) of the washer

must cover at least 135 mm² per fixation point.

A torque wrench must be used for assembly.

1

2

33

1

Example A: clamping on Example B: Screwing

1 V2A-Serrated ange nut

2 V2A-Clamping washer

3 V2A-T-head bolt

Image 1: Mounting

3

Cable protection

We recommend securing the cables to the mounting system

using UV resistant cable ties. Protect exposed cables from

damage (for example by laying them in plastic pipes). Avoid

direct exposure to sunlight. A bending radius of minimum 35

mm must be maintained.

SolarWorld AG recommends laying all electrical cables and

connections in compliance with national regulations for

electrical instal-lations. Bypass diodes are factory installed.

Opening the junction box

DANGER!

Danger of death from electric shock

▹ In order to ensure protection against electrical shock the

junction box MUST be disconnected from all external

power sources while installing the cables! DO NOT

CONNECT UNDER LOAD‼!

To open, use a screwdriver with

a 3 – 5 mm wide flat head. Insert

the screwdriver into the marked

opening. Move flap until hook

re-leases the lid. Do not pull the

lid out at once.

Image 2: Open junction box

Wiring

▹ Strip 11 mm of insulation from cable.

▹ Open cable gland nut.

▹ Use a small flathead screwdriver to press and hold down

terminal clamp.

▹ Push cable through cable gland and lead it to terminal

clamp. Pay attention to polarity.

▹ Removal of tool causes a frictional connection.

▹ Tighten cable gland nut (SW 13) with 1.3 – 1.5 Nm.

Image 3: Side view of junction box (cross section)

After completing the electrical connection…

Hang the lid on the housing and, by locking the lid in place,

secure it to the lower part of the housing. Make sure that the

lid fits level on the lower part of housing and that the seal is

fitted into the area intended. To ensure this the lid must be

pressed down all around.

An expert grounding of the module frame lies in the respon-

sibility of the installing company. If the building already has

a lightning protection system or if one is intended, the PV

system must be integrated into the protection system against

direct lightning strike. Country specific standards must be

adhered to. A UL authorized grounding method is mandatory

in the USA and Canada.

In the examples shown, the tightening torque is at least 5 Nm

(using M6 screws made of V2A). Use the existing holes for

securing the module; do not drill any additional holes (doing

so will void the warranty). Use appropriate corrosion-proof

fastening materials.

Installation

Correct wiring scheme

To decrease voltage caused by indirect lightning strikes, all

connecting cables should be as short as possible. Check that

the wiring is correct before commissioning the system. If the

measured open circuit voltage diers from the specifications,

then there is a wiring fault. Ensure that the polarity is correct.

Comparison: Serial connection and parallel connection

Serial connection is applied in case of high operating voltages

(for battery storage with high operating voltage). The voltages

of the individual modules add up, the electricity stays the

same.

Parallel connection, for use when a great amount of electricity

is needed (for battery storage with high capacity). The electri-

city of the individual modules adds up, the voltage stays the

same. The modules must be protected by suitable blocking

diodes against return currents > 12 A.

Use of appropriate materials

Use only special solar cables (for example PV1-F or [USA]:

PV-Wire) and appropriate connectors. Ensure that they are in

perfect electrical and mechanical condition. Use only single

wire cables made of copper strand with a diameter between

2.5 mm² (AWG 14) and 4 mm² (AWG 12). Select an appropriate

conductor diameter to minimize voltage drop. The outer dia-

meter of the cable must be between 4.5 mm and 6.9 mm

Underwriters Laboratories Information (U.S. and Canada)

▹ The solar module electrical characteristics are within

+/-10% of the module label indicated values of Isc, Voc,

and Pmpp under Standard Test Conditions (irradiance of

100 mW/cm2, AM 1.5 spectrum, and a cell temperature of

25°C/77°F)

▹ Under normal conditions, a photovoltaic module is likely

to experience conditions that produce more current and/

or voltage than reported at standard test conditions.

Accordingly, the values of Isc and Voc marked on this

module should be multiplied by a factor of 1.25 when

determining component voltage ratings, conductor

capacities, fuse sizes, and size of controls connected to the

PV output.

▹ Refer to section 690-8 of the National Electric Code (NEC)

for an additional multiplying factor of 125% (80% de-rating)

which may be applicable

▹ Over-current protection shall be in accordance with the

requirements of Article 240 of the NEC

▹ Conductor recommendations: 14-12 AWG (2.5-4 mm2) USE-2

or PV-wire, 90°C wet rated

▹ Cable conduits should be used in locations where the

wiring is accessible to children or small animals

▹ Modification or tampering of diodes by unqualified

personnel is not permitted. Please consult a SolarWorld

Service Center for additional information regarding diode

replacement/repair.

4

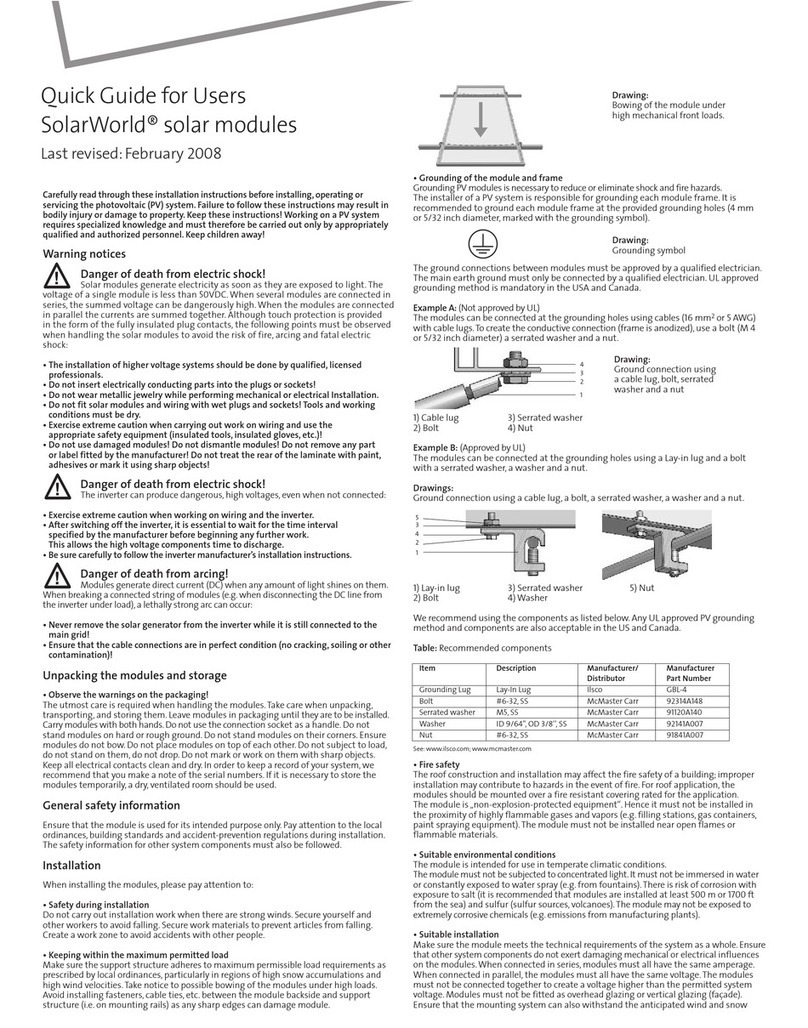

Example UL [USA]:

The modules can be connected to the grounding holes using

a lay-in lug and a bolt with serrated washer, washer, and nut

(see image: “Correct connection of grounding wire“).

1

2

3

4

5

1 Nut

2 Serrated washer

3 Washer

4 Bolt

5 Lay-in lug

Image 4: Ground connection using a cable lug, a bolt, a serrated washer,

washer, and nut.

We recommend using the components listed blow.

Any UL approved PV grounding method and components are

also acceptable in the US and Canada.

Table: Recommended components

Item Description Manufacturer

/ Distributor

Manufacturer

/ Part number

Grounding lug Lay-in lug Ilsco GBL-4

Bolt #6-32, SS McMaster Carr 92314A148

Serrated washer M5, SS McMaster Carr 91120A140

Washer ID 9/64“, OD

3/8“, SS

McMaster Carr 92141A007

Nut #6-32, SS McMaster Carr 91841A007

See www.ilsco.com; www.mcmaster.com

WARNING!

Warns of explosion risk from batteries

▹ If modules are used to load batteries, the battery is to be

installed in such a manner that the performance of the

system and its users are not endangered.

▹ The recommendations and regulations of the battery

manufacturer concerning installation, operation, venti-

lation, and maintenance must be adhered to.

▹ Batteries should be kept away from persons and ani-

mals and protected from sunlight, rain, snow, or falling

objects.

▹ When loading most batteries generate gaseous

hydro-gen which can also explode. To prevent this from

happening sucient ventilation must be provided and

open flames and sparking must be avoided. For outdoor

installations the batteries should be kept in a ventilated

container provided especially for this purpose.

Maintenance

SolarWorld recommends inspecting the system in regu-

lar intervals: All PV modules should be inspected yearly for

safe electrical connections, corrosion and intact mechanical

connections. Loose connec-tions can damage the module or

the module series. During this inspection it should also be

ensured that the wiring is in good condition. Given a sucient

tilt (over 15°) it is usually not necessary to clean the modules

(rainfall will have a self-cleaning eect). Modules that are

installed horizontally (0 – 15° tilt angle) must be cleaned more

often because a sucient self-cleaning from rainfall, as with

stronger tilted modules, is not given.

In case of heavy soiling we recommend cleaning the modules

using lots of water (from a hose) without any cleaning agents

and using a gentle cleaning implement (a sponge). Dried dirt

must never be scraped or rubbed away, as this may cause mic-

ro-scratches. Any problems that may arise should be solved by

an authorized specialist. Please also observe the maintenance

information of all components used, such as support frames,

charging regulators, inverters, batteries etc.

Disclaimer of liability

SolarWorld accepts no liability for the use and functionality

of the modules in case of non compliance with this User

Information. Since compliance with this guide and the

conditions and methods of installation, operation, use and

maintenance of the modules are not checked or monitored

by SolarWorld AG, SolarWorld AG accepts no liability for

damage arising through improper use or incorrect installation,

operation, use or maintenance.

SolarWorld AG

Martin-Luther-King-Str. 24

53175 Bonn

Germany

Telefon: +49 - 228 - 55920 - 0

Telefax: +49 - 228 - 55920 - 99

www.solarworld.de

SolarWorld Ibérica, S.L.

C/La Granja 15, Bloque B-1°B

28108 Alcobendas, Madrid

Spain

Tel.: +34 - 91 - 4905999

Fax: +34 - 91 - 6574967

www.solarworld.es

SolarWorld California Inc.

4650 Adohr Lane

Camarillo, CA 93012

USA

Tel.: +1 - 800 - 947 - 6527

Fax: +1 - 805 - 388 - 6395

www.solarworld-usa.com

SolarWorld France

Hôtel de l’Entreprise,

Bouchayer-Viallet

31, rue Gustave Eiel

38000 Grenoble

France

Tel + 33 (0) 43 821 00 50

Fax +33 (0)4 38 21 00 59

http://www.solarworld.fr

SolarWorld Africa Pty. Ltd.

20th Floor

1 Thibault Square

Cape Town, 8001

South Africa

Tel.: +27 - 21 - 421 - 8001

Fax: +27 - 21 - 421 - 8002

www.solarworld-africa.co.za

SolarWorld Asia Pacific Pte. Ltd.

72 Bendemeer Road

#07-01, Luzerne

Singapore 339941

Singapore

Tel.: +65 - 6842 - 3886

Fax: +65 - 6842 - 3887

www.solarworld.sg

This manual suits for next models

4

Other SolarWorld Solar Panel manuals

SolarWorld

SolarWorld Sunmodule SW xx poly RGA User manual

SolarWorld

SolarWorld Sunmodule Protect Series User manual

SolarWorld

SolarWorld Sunmodule SWA XL mono Series User manual

SolarWorld

SolarWorld Sunmodule Plus User manual

SolarWorld

SolarWorld Sunmodule SW xx poly RHA User manual

SolarWorld

SolarWorld SunCarport User manual

SolarWorld

SolarWorld Suntub User manual

SolarWorld

SolarWorld Kit User guide

SolarWorld

SolarWorld Sunmodule SW *** poly User manual

SolarWorld

SolarWorld solar modules User manual