TC-388-4

|

TABLE

OF

CONTENTS

Section

Title

Page

DPE

Cihicationst<s

we

Be

seesaw

2s

Oa,

eR

eh

oe

eta

ee

tat

Il

7.

OUTLINE

1-1.

PAN

POT

(Panoramic

Potentiometer).................

3

1-2.

MUTING/PAUSE

Lever

....

2.20.00...

2

ee

ee ee

ee

3

1-3.

Block

Diagram

......

2...

2...

ee

3

1-4.

External

View

.

2...

2.

2

ee

4

le5.°.

Internal’

Views:

#08

3:

a

ke

Oa)

AS

ee

hs

ple

ee

ee

ed

4

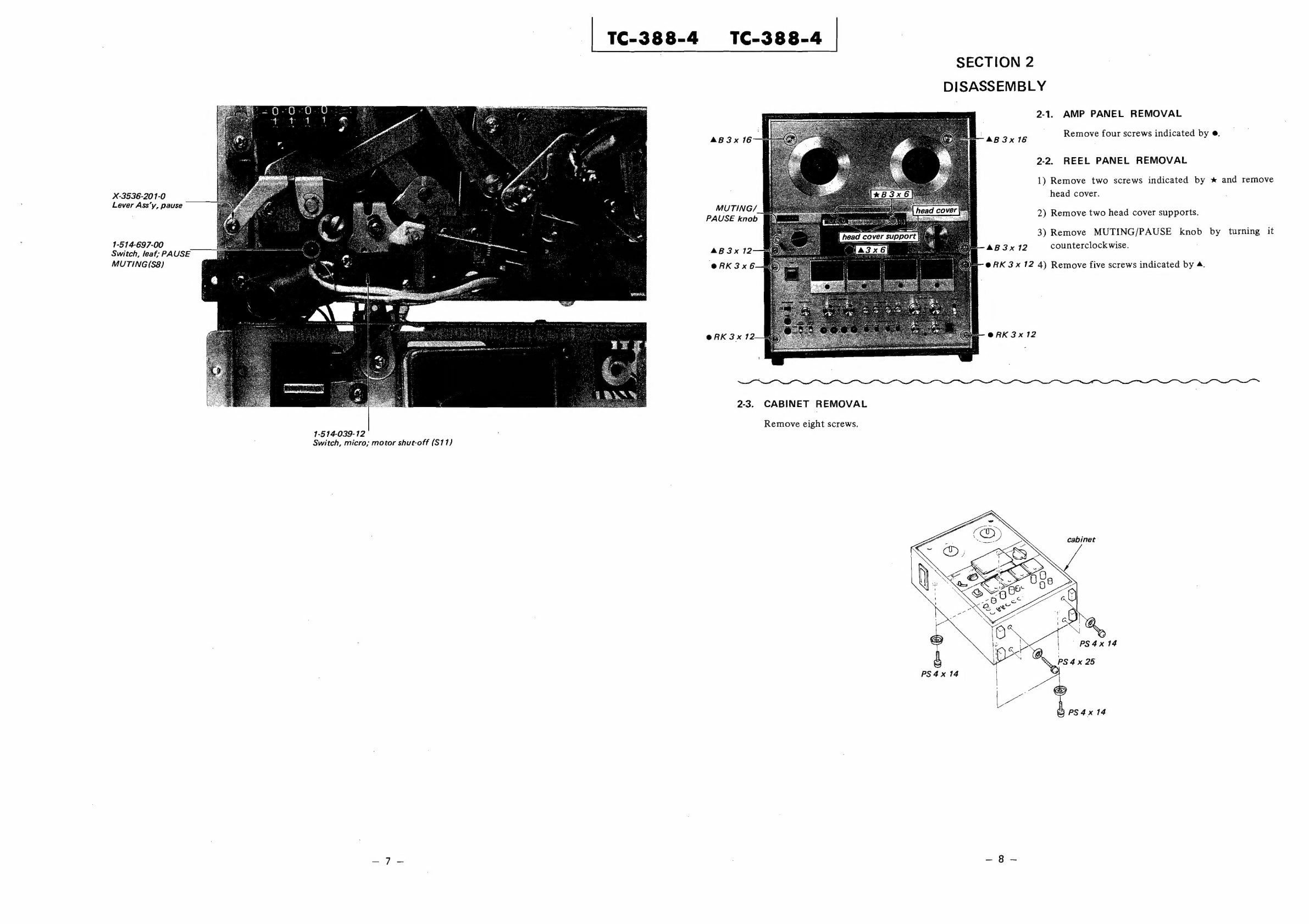

2.

DISASSEMBLY

¢.4-

sc6

0006

wee

ee

ee

ee

a

ee

Se

8

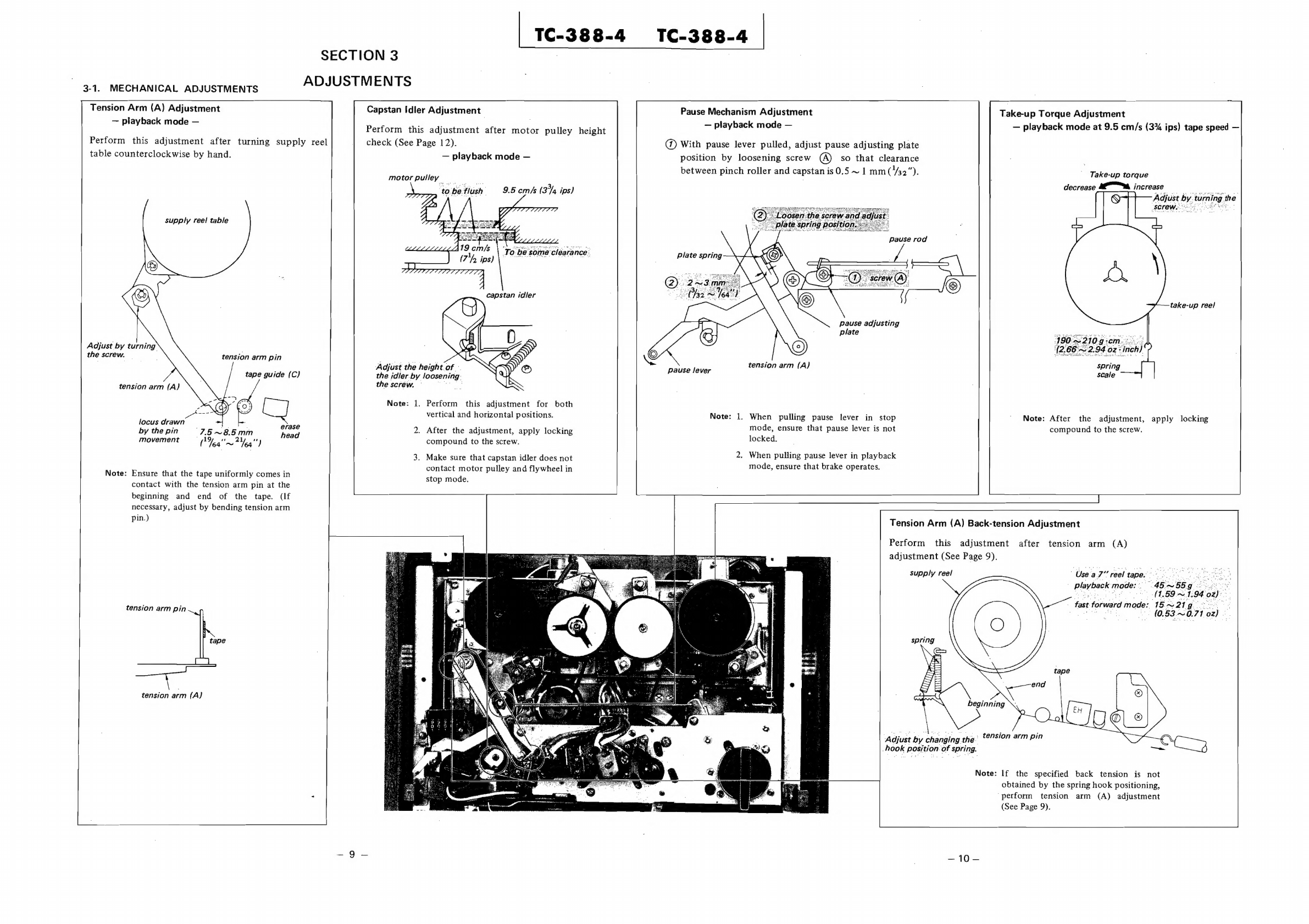

3.

ADJUSTMENTS

3-1.

Mechanical

Adjustments

....

2.2.2.2...

00000

eee

eee

9

3-2.

Electrical

Adjustments...

2...

0...

ee

15

4.

DIAGRAMS

4-1.

Schematic

Diagram...

...

2...

2...

0...

ee

ee

24

4-2.

Mounting

Diagrams.

...........0

0.2.00

2

eee

eee

eee

27

4-3...

Level.

Diagrams:

3.

.30200cn

ee

A

a

a

ee

PS

33

5.

PACKING

AND

EXPLODED

VIEWS

...................

34

6.

ELECTRICAL

PARTS

LIST

............-2....0-02004.

45

7.

HARDWARE!

:.

5:

ares

alg

ae

be

eed

hk

ee

Geral

&

Db

ek

ere

50