TABLE

OF

CONTENTS

Title

_Page_

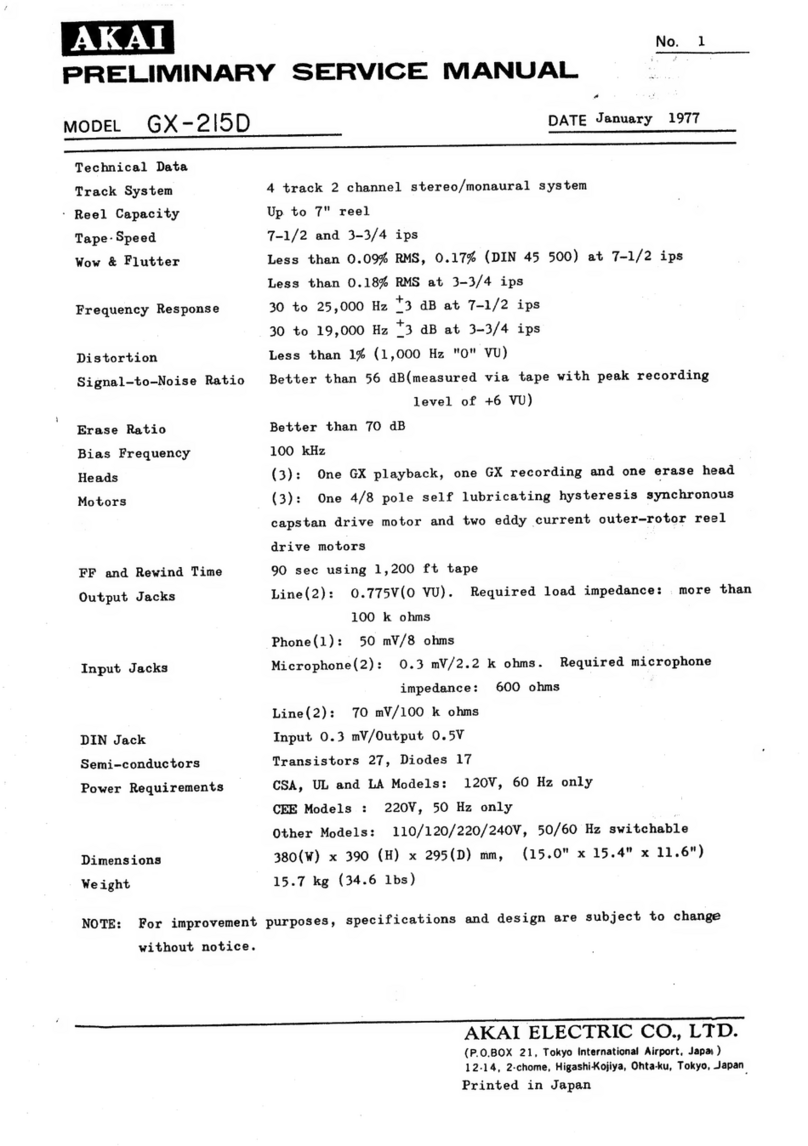

SPECIFICATIONS.

.........ceeeccccccceeeeesseeseeseseeeeeeeereeees

1

1.

GENERAL

DESCRIPTION

......

ccc

eee

2:

2.

BLOCK

DIAGRAM

.........:cc:cceeeeeeseseeeeesscceeeeeenesees

2

3.

CABINET

—

TOP

VIEW

—

o..iceceecccceeeeeeeeeeee

3

4.

CABINET

—

SIDE

VIEWS

—

ouu..c.ce

cc

eeeseeeeeeeeeeee

3

5.

CHASSIS

~—

TOP

VIEW

—

6.

CHASSIS

—

BOTTOM

VIEW

—

wu.

eeeeee

4

7.

DISASSEMBLY

.............0:

8.

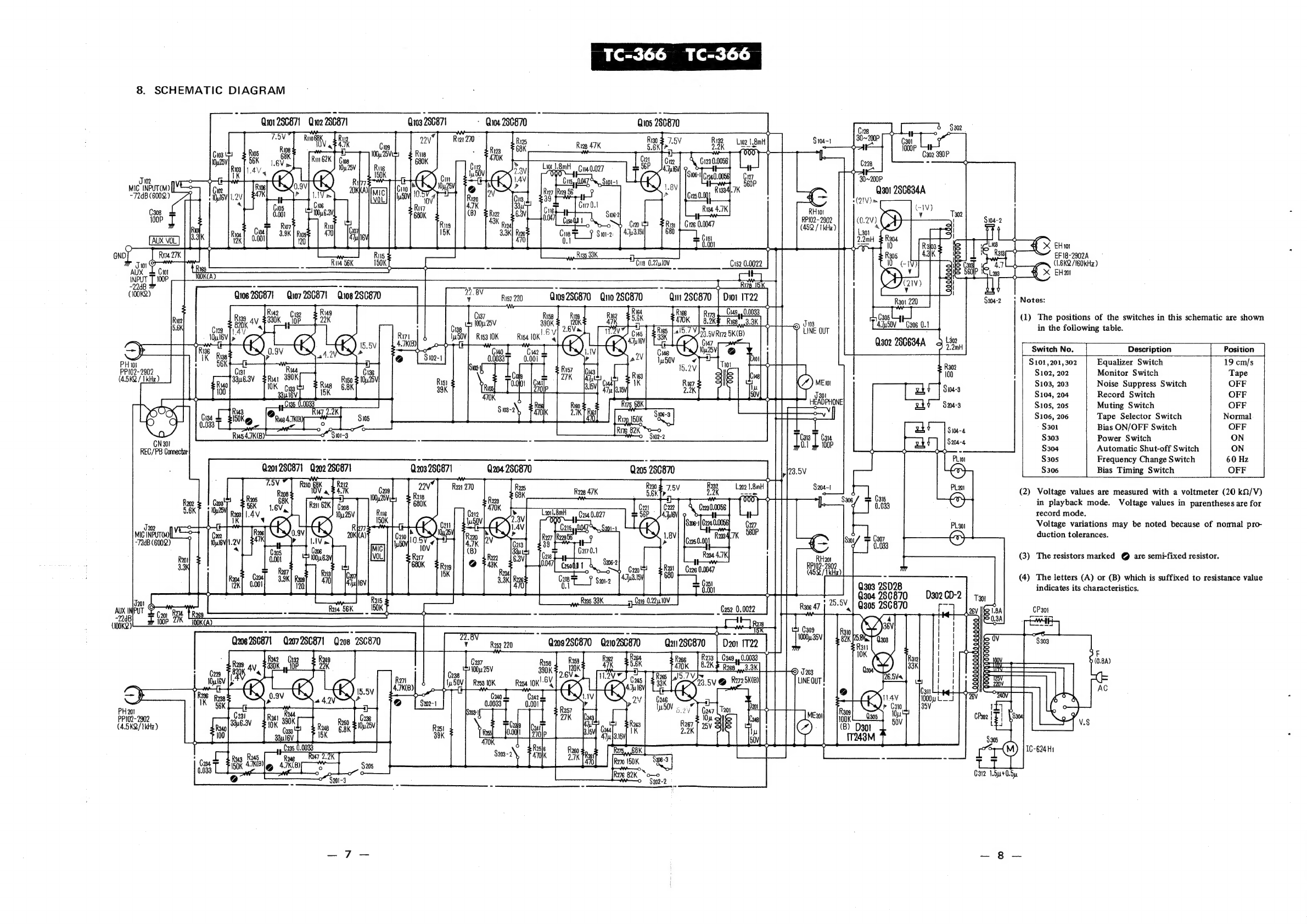

SCHEMATIC

DIAGRAM

9.

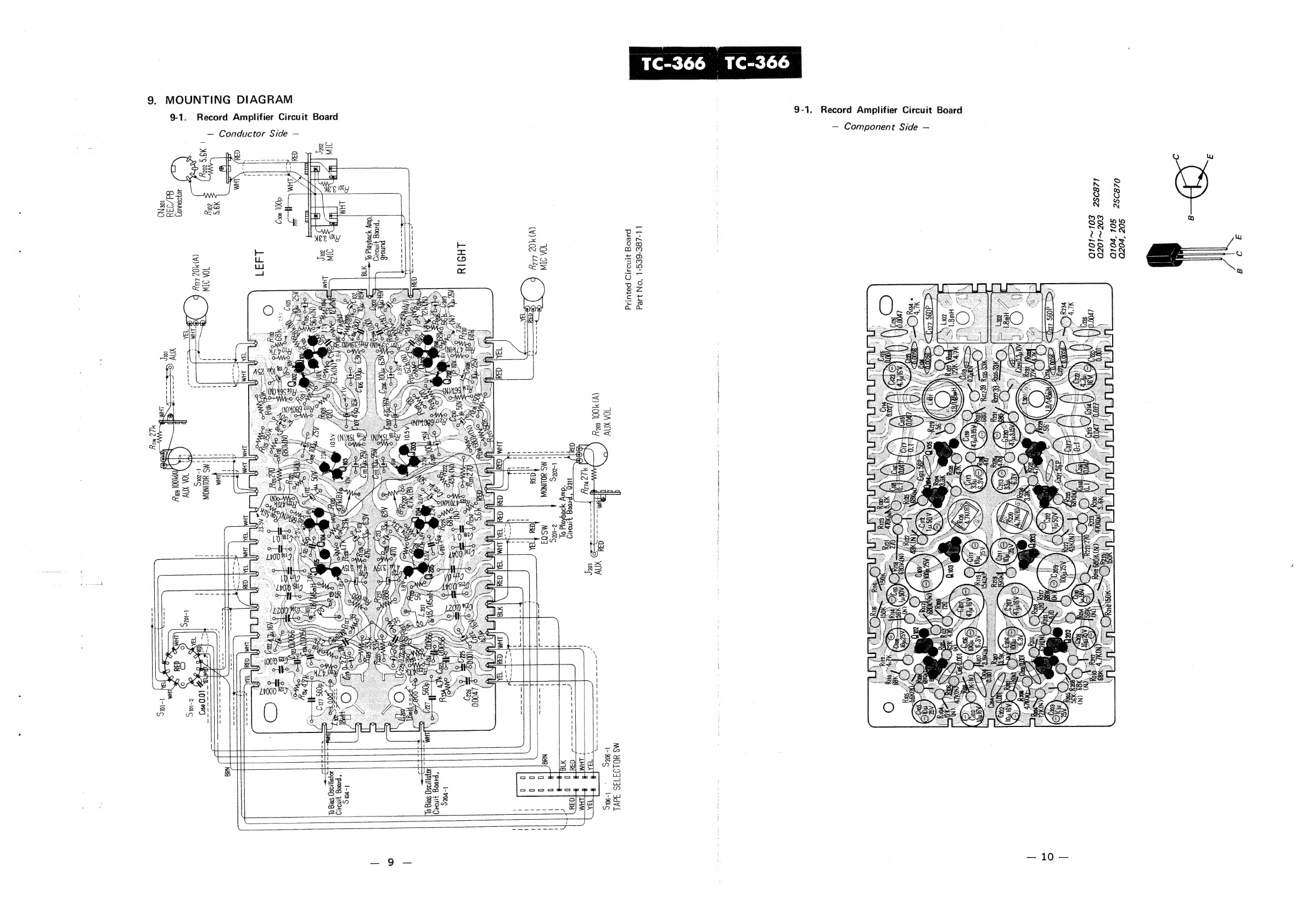

MOUNTING

DIAGRAM

9-1.

Record

Amplifier

Circuit

Board

.........

9~10

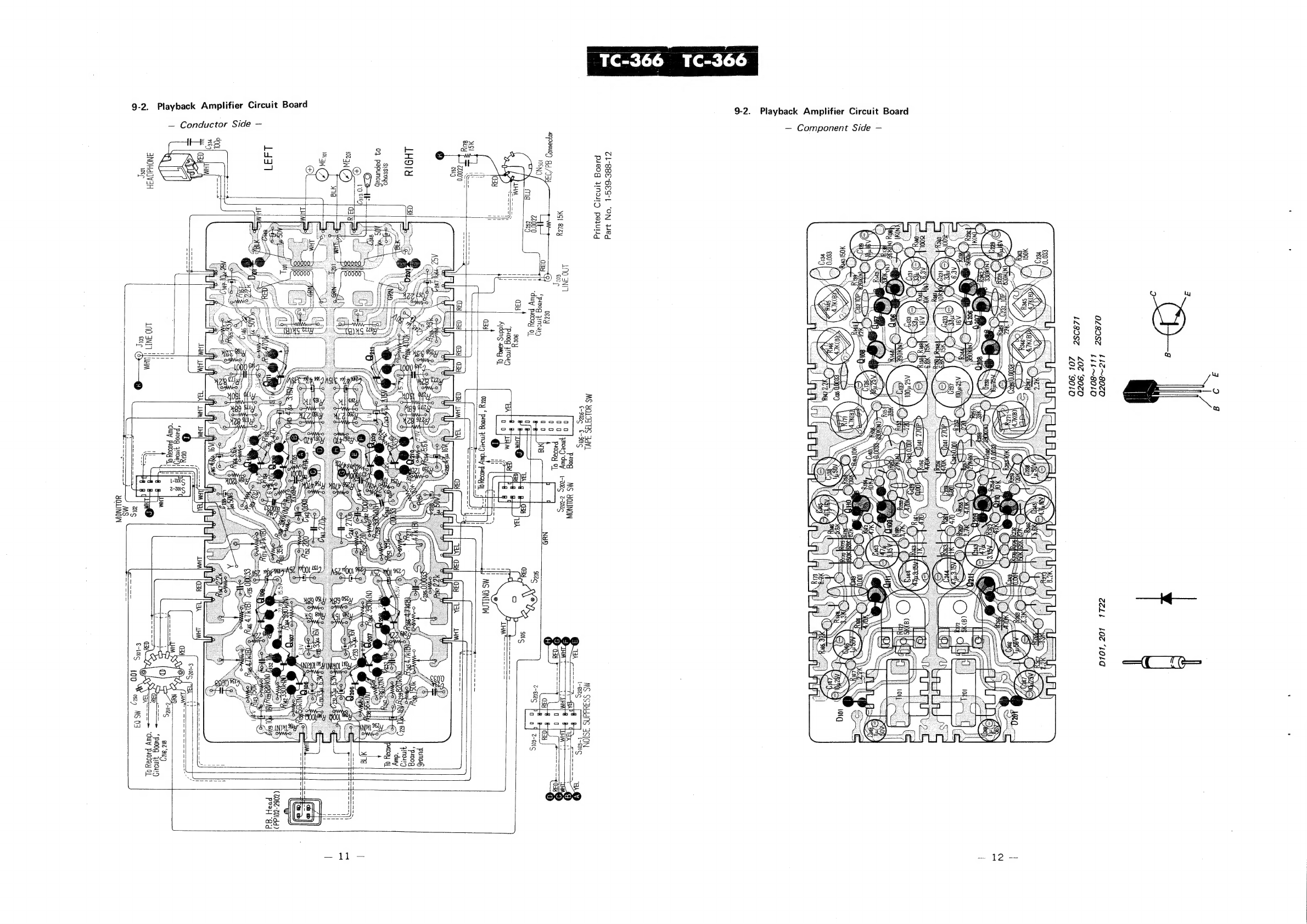

9-2.

Playback

Amplifier

Circuit

Board

......

11)

~12

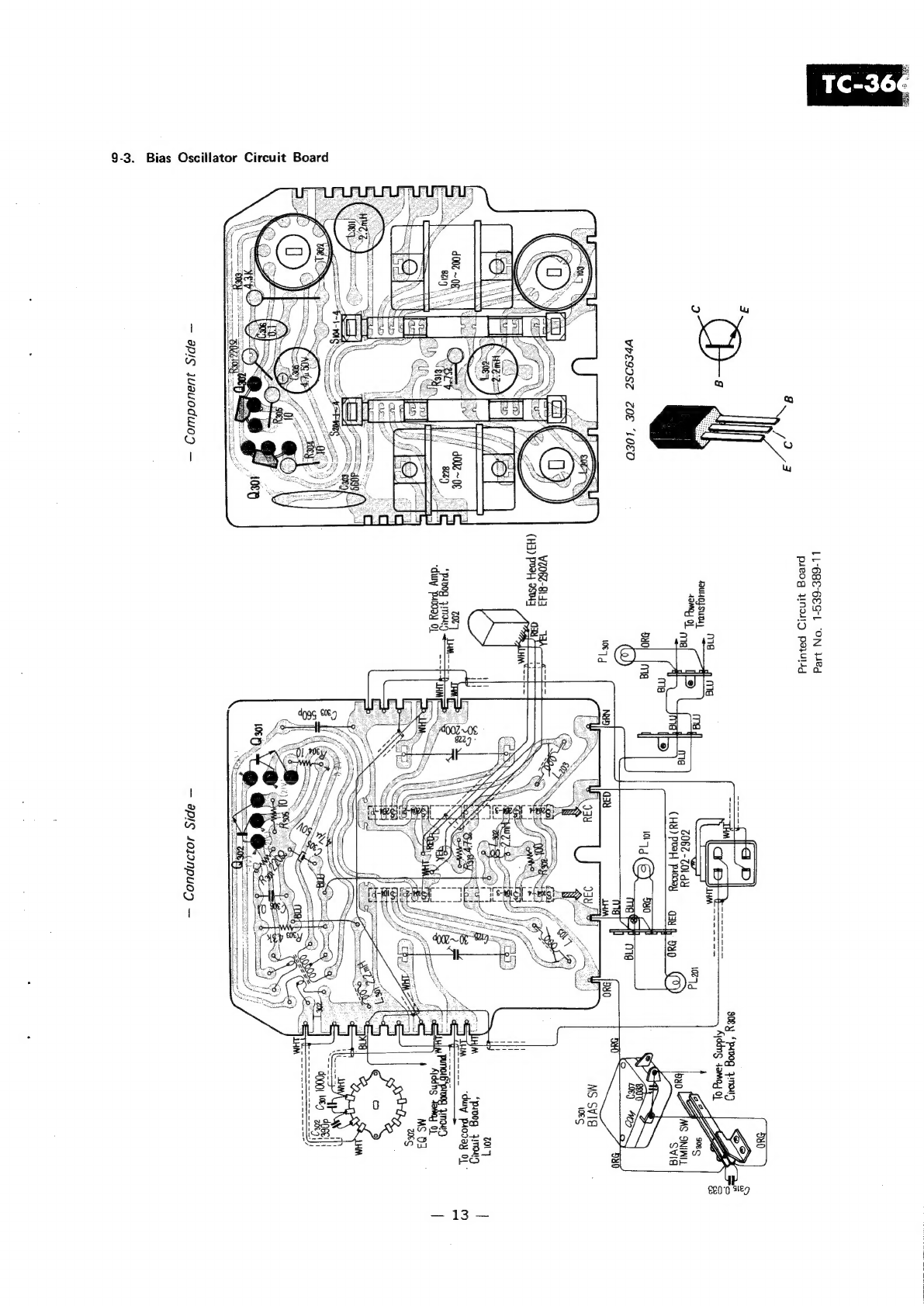

9-3.

Bias

Oscillator

Circuit

Board...

ee

13

9-4,

Power

Supply

Circuit

Board

.......

eee

14

10.

LEVEL

DIAGRAM

uu...

eeeccccce

eee

ceteeeeree

anne

ane

eeaeees

15

1.

GENERAL

DESCRIPTION

The

SONY

Model

TC-366

which

is

the

one-

motor,

three-head

stereo

deck

type

tape

recorder

equips

with

the

following

features,

Tape

Tension

Regulator

The

machine

can

operate

always

under

the

stable

tape

running

by

the

tape

tension

regulator

which

quickly

responds

to

the

subtle

change

of

tape

tension,

so

that

the

tape

tension

regulator

can

reduce

the

wow

and

flutter

extremely.

14.

ELECTRICAL

PARTS

LIST

15.

EXPLODED

VIEW

Title

Page

11.

MECHANICAL

ADJUSTMENT.

................

16

~

24

12.

ELECTRICAL

ADJUSTMENT

.................

25~39

13.

CONVERSION

TO

DIFFERENT

POWER

LINE

FREQUENCY

15-1.

Packing

15-2.

Cabinet

—

top

view

—

15-3.

Amplifier

Chassis

—

top

view

(1)

«++

46

15-4.

Amplifier

Chassis

—

top

view

(2)

—

47~48

15-5.

Head Deck

—

top

view

—_

«--.-

49~

50

15-6.

Chassis

—

top

view

(1)

—

-.:--ee

eee

SI~

52

15-7.

Chassis

—

top

view

(2)

—

.---+

53

~

54

16.

HARDWARES

oo

eesessececcsscecesssesecessessrstseeeneens

55

Hardware

Nomenclature

.........eeeeeeeeeeeeees

55

Automatic

Shut-off

Mechanism

When

threading

the

tape,

the

shut-off

lever

is

held

by

the

threaded

tape

in

operating

position.

If

tape

runs

out

or

breaks,

the

shut-off

lever

swings

outward

and

activates

the

automatic

shut-off

mecha-

nism.

As

a

result,

the

function

selector

knob

can

return

to

the

STOP

position

without

setting

it

manually.

Note:

When

threading

the

tape,

make

certain

that

there

is

no

slack

in

the

threaded

tape,

otherwise

the

function

selector

knob

will

not

be

set

at

the

desired

2.

BLOCK

DIAGRAM

position.

Quy

Qm

Qua

Qua

Qos

ag

Tehet

AME

BIAS.

OSC

Mx

sey

ay

nee

a

A

ic

"

iF

:

V\\

EHX

\

MIG

Ss

i)

——

RH

Sias-e

I

en

OX

H

ll

REC/PB

i

Connec'

Soa

©

LINE

OUT

—

LINE

AMP

—

Qho

On

ME

IE

—o5V]]

Heapprione

——

PLAYBACK

AMP

—

To

Toot

Q393

3

VOLTAGE

REGULATOR

="

as

AC

(NPUT

|

50,

B0Hz

Q304

O05