Spartan Mini Cam Setup guide

Page 1

( 8 0 0 ) 4 3 5 - 3 8 6 6

SPARTAN TOOL L.L.C.

S p a r t a n M i n i C a m

V i d e o I n s p e c t i o n S y s t e m

Owners Instruction Manual

Page 2

Table of Contents

Operating Section

Unpacking .................................................................................................................................... 3

Description ................................................................................................................................... 3

Safety Instructions ..................................................................................................................... 3-5

Familiarization ........................................................................................................................... 6-8

Monitor Control Panel ........................................................................................................ 7

VCR Control Panel ............................................................................................................ 8

Battery Operation & Charging ...................................................................................................... 9

VCR Recording and Playback .................................................................................................... 10

Recording ........................................................................................................................ 10

Playback .......................................................................................................................... 10

Video Head Cleaning....................................................................................................... 10

Microphone Operation .................................................................................................................11

External Video Reel (Optional) .............................................................................................. 11-13

Installing Push Cable Into Distance Counter ................................................................... 12

Removing Push Cable From Distance Counter ............................................................... 12

Setup Instructions ............................................................................................................ 13

Operating Instructions ................................................................................................................ 14

Operational Tips ......................................................................................................................... 14

Maintenance ............................................................................................................................... 15

Mini-Cam Troubleshooting ......................................................................................................... 16

VCR Troubleshooting ................................................................................................................. 17

Flex-Link Compression Tool (Optional) ................................................................................. 18-21

Parts Section

Final Assembly - 62013000 ................................................................................................... 22-23

Reel Assembly - 62012400 ................................................................................................... 24-25

Distance Counter Assembly - 62012500 ............................................................................... 26-27

Basket Assembly - 61030500 ..................................................................................................... 28

Detachable Flex-Link Assemblies .............................................................................................. 30

Internal Push Cable Assembly ................................................................................................... 31

External Push Cable Assemblies (Optional) ............................................................................... 31

Slip Ring Assembly - 62009200 (Optional) ................................................................................. 32

Removing and Reinstalling Slip Ring Assy ................................................................................. 33

Video Reel Frame Assembly - 62009000 (Optional) ............................................................. 34-35

Video Reel Drum Assembly - 61016700 (Optional) .................................................................... 36

Distance Counter Assembly - 62008000 (Optional) ................................................................... 37

Page 3

Unpacking

Before signing the shipping receipt, check and inspect unit for visible damage. If there is visible

damage, note so on the shipping receipt.

Description

The system is composed of a miniature closed circuit television camera and color LCD monitor

connected through flexible push type cable.

This unit operates on battery power, 110 Volt AC electrical current, or 12 Volt DC eletrical current.

Safety Instructions

WARNING: READ THE “OPERATORS MANUAL” THOROUGHLY BEFORE USING ANY SPARTAN

TOOL PRODUCTS. DRAIN/SEWER CLEANING CAN BE DANGEROUS IF PROPER

PROCEDURES ARE NOT FOLLOWED. KNOW THE PROPER OPERATION, CORRECT

APPLICATIONS AND THE LIMITATIONS OF ALL SPARTAN TOOL PRODUCTS BEFORE USE.

CAUTION #1

Use of any electrical equipment in a wet environment can cause fatal shock if equipment is

not properly grounded, adequately maintained, and if care is not used by the operator.

A. GROUNDING INSTRUCTIONS —

Before charging your Spartan Minicam, make sure a properly grounded, three hole electrical

outlet is available. If not, as in some older homes, use a three-prong adapter and connect the

green pigtail (or grounding lug) to a known ground such as a cold water pipe. A three- prong

adapter is available through Spartan Tool. Never cut off the grounding prong for use in a two

hole outlet receptacle. By doing so, you have cut off your protection from shock.

The Spartan Minicam must be grounded while charging or operating using the 110V power cord

to protect the operator from electrical shock. The Spartan Minicam comes with a three-conductor

cord and three-prong grounding type plug to fit the properly grounded receptacle. An adapter,

see sketches (B) and (C), is available for connecting, sketch (A) type plugs, to a two-prong

receptacle, except in Canada.

Page 4

Safety Instructions (cont)

The green-colored rigid ear (or lug), extending from the adapter must be connected to a

permanent ground such as a properly grounded outlet box.

Don’t assume that all three-hole outlets are properly installed. Check the outlet and

also the adapter, if used, with an outlet testing device which quickly indicates if a ground is

connected. Correct a faulty test indication before proceeding. The use of a Ground Fault

Interrupter is the safest means to check for proper grounding.

B. EXTENSION CORDS —

Plug the power cord attached to the Minicam directly into an inspected outlet. If an extension

cord must be used, it must be of an approved three-wire type in good condition, equipped with

a three-prong plug. Never cut off the grounding prong for use in a two hole outlet receptacle. By

doing so you have cut off your protection from shock.

C. OUTDOOR EXTENSION CORDS —

When Spartan Tool equipment is used outdoors, use an extension cord intended for use outdoors

and so marked.

D. AVOID ELECTRICAL CORD ABUSE —

Never move or lift Spartan Tool equipment by the cord. Do not yank cord at one end to disconnect

it from the receptacle. Keep cord away from heat, oil and sharp edges to avoid damage. Always

replace or repair damaged cords.

E. ALWAYS WEAR RUBBER BOOTS IN WET AREAS FOR ADDED PROTECTION

WARNING: SPARTAN TOOL PRODUCTS ARE NEVER TO BE OPERATED IN AN EXPLOSIVE

ENVIRONMENT.

CAUTION #2

Avoid eye or skin contact with acids or caustic substances while inspecting drains/sewers.

A. Always wear safety goggles when inspecting drain/sewers to avoid injury to eyes.

Page 5

Safety Instructions (cont)

B. Before beginning work, ask the customer if either acids or caustic substances are present in the

pipe. If in doubt, litmus paper used at the opening of the pipe may give an indication of the type

of substance in the line. Litmus paper (acids/caustics) can be purchased at most pharmacies.

C. Exposure to acids or caustic substances can cause the push cable to break or to become to

brittle. Depending upon the concentration of acids or caustic substances in the drain/sewer,

push cables may break or become brittle in the drum, in the pipe, or when placing the cable

back into the drum. If the push cable remains exposed to acids or caustic substances for any

length of time, the cable can continue to be damaged.

CAUTION #3

Drains/sewers carry bacteria and the possibility of infectious disease exists, if exposed.

A. Always wear safety goggles and Spartan Tool riveted gloves with rubber gloves inside the riveted

gloves to minimize exposure to infection from bacteria in pipes.

B. Avoid contact with ears, eyes, or mouth with contents of pipe to lower the risk of infection. DO

NOT SMOKE!

C. Avoid exposing any cuts to drains/sewers and sewer inspecting equipment

CAUTION #4

Follow all rules of safety and good housekeeping.

A. Keep work area clean.

B. Stay alert.

C. Place the unit and controls in a stable and accessible position for safe operation.

D. Properly store the tools.

E. Keep children away from all equipment.

F. Use only recommended equipment and accessories. Maintain tools in original working condition.

G. Do not exceed limitation of equipment or accessories.

H. Always wear recommended safety gear

I. Always lift with legs and not your back.

Page 6

Familiarization

EXTERNAL PUSH

CABLE CONNECTOR

MICROPHONE

SENSOR

SUN SHIELD

P/N: 62013200

5.6” LCD MONITOR

VCR

110V AC & 12V DC

POWER CORDS

FLEX-LINK

HOLDERS

TELESCOPING

HANDLE

100’ INTERNAL

PUSH CABLE

12V DC POWER

CORD P/N: 61032100

110V AC POWER

CORD P/N: 61032000

AC POWER

CORD FUSE

Page 7

Familiarization (cont)

MONITOR CONTROL PANEL

POWER

ON/OFF: Turns Minicam power ON or OFF.

ON – Red light indicates unit is powered on.

FULL CHARGE – A steady green light indicates unit is

fully charged. A flashing green light indicates unit is

charging.

DC LOW – Yellow flashing light indicates unit is

operating on low voltage and needs to be charged.

When the yellow flashing light turns into a solid yellow

light, the unit has approximately 30 seconds before it

shuts down. Once the unit shuts down, you can press

the power button to turn the unit ON for an additional

30 seconds. This may be used for critical situations

that require finishing the pipe inspection.

LIGHTS

MIN: Decreases light intensity

MAX: Increases light intensity

COUNTER

POS: Positions text in different locations on screen. (center, each corner, no text)

RESET: Zeros counter.

MIC

MIC: Turns microphone on or off.

BLUE LED – Indicates microphone is recording.

Page 8

Familiarization (cont)

VCR CONTROL PANEL

1. Cassette Compartment

The power is on automatically when the cassette is inserted even if the power was off. When the cassette is

inserted, Auto Tracking Adjustment operates automatically.

2. Power Key

When the Minicam is powered on, the power indicator lamp will always light up in red.

The Power On and Power OFF mode

will be toggled by pressing this key.

When the POWER is switched on,

the power lamp will light up in red

and the other keys will light up in

green.

3. Cassette-In Lamp

When the cassette is inserted, the

CST-IN lamp will light up in green.

4. Eject Key

Press this button to eject tape.

5. Stop Key

Press this button to stop tape.

6. Rewind Key

If this key is pressed in the PLAYBACK mode, the VCR enters the reverse picture search mode, and “REW”

indicator lamp will be blinked.

If pressed in STOP mode, then the tape will rewind at high speed, the indicator lamp will light up in red.

7. Play / Re-Auto Tracking

Press this key to playback a recorded tape, or to release special operation such as the search mode.

In the PLAYBACK mode the playback indicator lamp will be lit in red and Auto Tracking will be displayed on the

monitor screen.

When the playback picture is noisy, press this key to operate Re-Auto Tracking.

8. Fast Forward / Cue Key

If this key is pressed in the PLAYBACK mode, the VCR enters the forward picture search mode, and “FF”

indicator lamp will be blinked.

If pressed in STOP mode, the tape will fast forward at high speed and the indicator lamp will light up in red.

9. REC Key

Press the REC key for at least one second to start recording.

10. DEW/HEAT Lamp

When power is on, this indicator flashes red to indicate excessive moisture buildup inside the VCR.

The unit will not operate until it dries out sufficiently (the tape can be ejected from the unit).

When DEW mode has been activated, leave the unit on and allow it to dry out completely.

11. Hi-Fi Lamp

In the Hi-Fi out mode, the lamp will light up in red.

12. Auto Repeat Lamp

Not Available.

13. Audio/Video in Jacks

Not Available.

Page 9

Battery Operation & Charging

BATTERYOPERATION

The Spartan Minicam is designed to operate using internal battery power, 110V AC (household

current), or 12V DC (automobile). A fully charged battery will last approximately 4 hours. When

using the VCR, the battery will last approximately 2 hours. NOTE: Battery run time will vary

depending on which camera head is being used (color or black/white), beacon or non-beacon, and

the light intensity setting. The yellow DC LOW light will begin to flash when the battery begins to

run low. When the flashing yellow light changes to a solid yellow light you will have approximately

30 more seconds before the unit shuts down. If the unit shuts down, you can power the unit up for

an additional 30 seconds by pressing the POWER ON button. This feature may allow you to finish

the pipe inspection in critical situations.

BATTERYCHARGING

110V AC – To charge the internal battery using a 110V power source you will need to uncoil

the 110V power cord (see Pic. 1) and plug the end into a 110V electrical outlet. The green

FULL CHARGE light will begin to flash indicating that the unit is being charged. When the

green FULL CHARGE light turns into a solid green light, the unit is fully charged. Once the

batteries are fully charged, the battery charger will automatically switch to trickle charge.

12V DC – To charge the internal battery using a 12V DC power source you will need to

uncoil the 12V DC power cord (see Pic. 1) and plug the end into an automobile power port

(cigarette lighter). The green FULL CHARGE light will begin to flash indicating that the unit

is being charged. When the green FULL CHARGE light turns into a solid green light, the unit

is fully charged. Once the batteries are fully charged, the battery charger will automatically

switch to trickle charge.

Battery Recharge Time: Approximately 4-6 hours.

NOTE: When using the 12V DC power cord to charge the Minicam, make sure to unplug the

12V DC power cord from the automobile power port before starting the vehicle.

12V DC

POWER CORD

P/N: 61032100

110V AC POWER CORD

P/N: 61032000

Pic. 1

Page 10

VCR Recording and Playback

To use the built in VCR follow the steps below.

RECORDING

1. Insert a VHS tape into the cassette compartment. The VCR will automatically power on.

2. Press the POS button to position the distance counter text in a location other than the upper left corner of

the monitor screen. NOTE: During recording, the distance counter text will be recorded and displayed on

the monitor screen during playback. If you do not want the distance counter text to be recorded, press the

POS button until the text is not shown on the screen.

3.When you are ready to begin recording, press the REC button. The REC button will light up in red and the

text REC will appear in the upper left corner of the monitor screen to indicate the unit is recording.

4. To end recording, press the STOP button. The word STOP will appear in the upper left corner of the

monitor screen to indicate the unit is no longer recording.

NOTE: To use the microphone feature, refer to the section below titled “Microphone Operation”.

PLAYBACK

1. To view a previously recorded tape, insert the VHS tape into the cassette compartment.

2.Press the PLAY button. The PLAY button will light up in red and the word PLAY will appear in the upper left

corner of the monitor screen. The recorded image should now be displayed on the screen. NOTE: This

VCR features an auto tracking feature that will adjust the tracking automatically when a taped is played.

3.To rewind or fast forward during playback, press the REW or FF button. The chosen button will blink in red

and no text will be displayed on the monitor screen. For faster rewinding or fast forwarding, stop the tape by

pressing the STOP button and then press either the REW or the FF button. The chosen button will light up

in red and the proper text will be displayed on the monitor screen. The tape will now rewind or fast forward

at high speed.

NOTE: If the microphone feature was used during recording, the sound will not be heard during

playback on the Minicam. You must use a VCR that is hooked to an audio/video source such as a

home television.

VIDEO HEAD CLEANING

The video heads enable the VCR to read video information pictures from the tape during playback. In the

unlikely event that the heads become clogged with dirt video playback will be impossible. This can easily be

determined during playback of a known good tape, there is good sound, but the picture is extremely snowy.

If this is the case, contact Spartan Tool.

NOTE: During normal operation of the VCR, the video and audio heads can accumulate dirt over a period of

time, especially when using an old or poor quality tape. When the heads are dirty, the picture can get snowy

and the tracking control will have little or no effect. If this condition occurs, head cleaning cartridges may

take care of the problem and restore normal picture. We recommend that head cleaning cartridges be used

sparingly since they are very abrasive and can damage the video heads during prolonged use. If the problem

is not resolved with the head cleaning cartridge then contract Spartan Tool.

Page 11

Push Rod with

Flex-link and

camera

Distance

Counter

Assy

Slip Ring

Assembly

t

t

t

Drain Hole

Drain

Hole

Drain Hole

Microphone Operation

The Spartan Minicam is equipped with a built-in, hands-free, super sensitive microphone. To use this feature,

follow the steps below.

1. Begin recording using the built-in VCR. (Refer to section titled VCR Recording and Playback).

2. Press the MIC button on the monitor control panel. The blue light next to the button will illuminate

to indicate the microphone is now recording.

3. Start recording your voice. NOTE: The microphone sensor is very sensitive.

4. When finished recording your voice, press the MIC button to turn the microphone off. The blue

light should no longer be illuminated.

External Video Reel (Optional)

The Spartan Minicam has the ability to connect to an external Spartan video reel. This feature allows you to use a stiffer

push-cable at longer lengths (up to 300 feet). To use this feature, you will need to purchase a Spartan video reel

assembly and a 15’ patch cable to connect the external video reel to the Minicam.

{

Qty

Req'd

Part

Number Description

62009115 Video reel assembly with 150’ push-cable

62009120 Video reel assembly with 200’ push-cable

62009125 Video reel assembly with 250’ push-cable

62009130 Video reel assembly with 300’ push-cable

1 61042400 15’ Patch cable

1

Reel (Back View) Reel (Front View)

15’ Patch Cable

Page 12

External Video Reel (Optional)

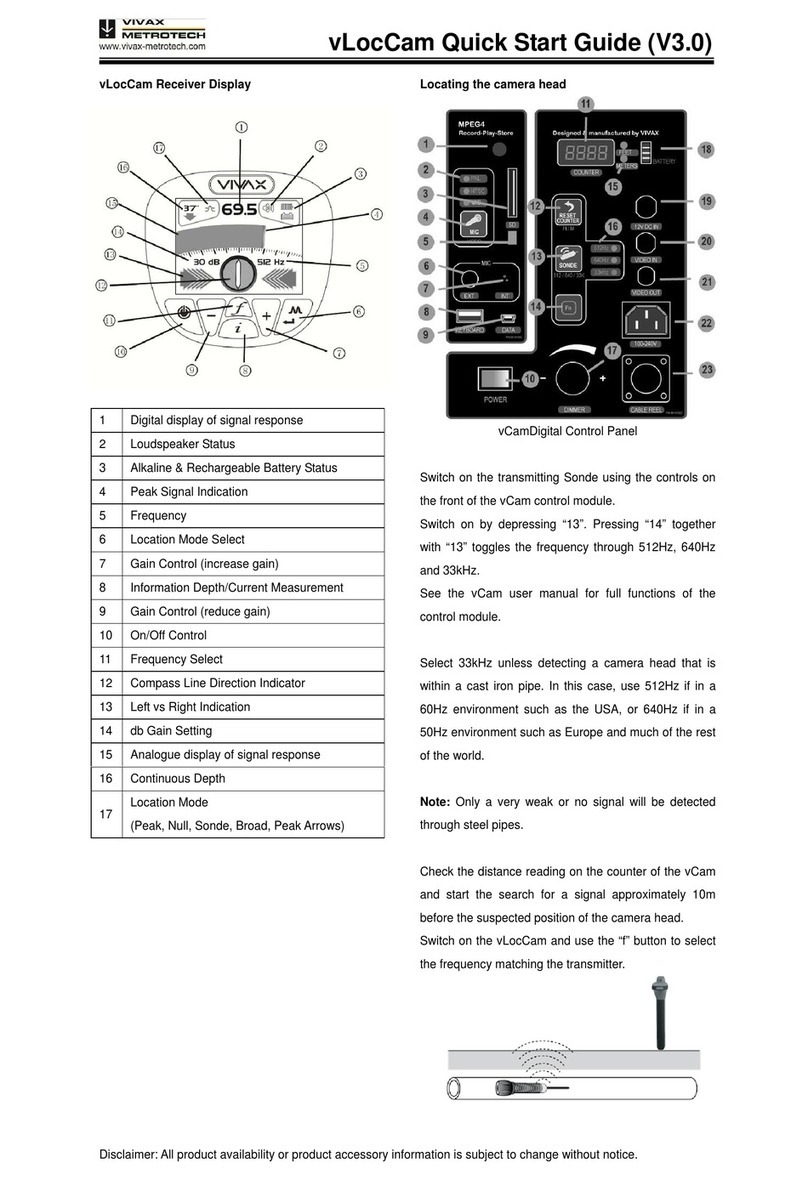

INSTALLING PUSH CABLE INTO DISTANCE COUNTER:

1. Loosen Adjusting Knob on Counter Assembly. (See Fig. 1)

2. Lift Swing Bolt up, and then rotate clockwise until the Swing Bolt is out of the Adjusting Block Seat. Allow the Roller

Arm Assembly to swing downwards until it contacts the stop pin. (Refer to Fig. 1 & 2)

3. Remove the Camera/Flex-link end of the push cable from inside the reel and position push cable above the Guide

Roller and Support Roller. (Refer to Fig. 2)

Figure 4Figure 3

Jam Nuts

Counter Drive Rollert

t

Guide Roller

Figure 2

Figure 1

t

t

t

t

Adjusting Knob

Adjusting Block Seat

Swing

Bolt

Roller Arm Assembly

t

Guide Roller

t

Support Roller

4. Seat the push cable in the groove of the Guide Roller and then rotate Roller Arm Assembly upwards until push cable

is in contact with Counter Drive Roller. (See Fig. 3) Now rotate Swing Bolt counter-clockwise into Adjustment Block Seat

and hand tighten Adjusting Knob until Jam Nuts contact the lower surface of the Adjustment Block Seat. (Refer to Fig.

4)

REMOVING PUSH CABLE FROM DISTANCE COUNTER

1. Loosen Adjusting Knob on Counter Assembly.

2. Lift Swing Bolt up, and then rotate clockwise until the Swing Bolt is out of the Adjusting Block Seat. Allow the Roller

Arm Assembly to swing downwards until it contacts the stop pin.

3. Remove push cable from counter assembly and place the camera/flex-link end of push cable inside reel for storage.

4. Rotate Roller Arm Assembly upward and then rotate Swing Bolt counter-clockwise into Adjustment Block Seat.

5. Hand tighten Adjusting Knob until Jam Nuts contact the lower surface of the Adjustment Block Seat.

6. Unit is now ready for transportation.

Page 13

External Video Reel (Optional)

SETUP INSTRUCTIONS

1. Turn the Minicam power off.

2. Using the 15’ patch cable connect the female end (no pins) to the male connector (pins exposed) on the external

video reel. (See Pic. 2)

3. Connect the other end of the 15’ patch cable to the external video reel connector on the Minicam. (See Pic. 3)

4. After both ends of the 15’ patch cable are connected, press the power button to turn the Minicam on. The Minicam

will automatically switch to the external video reel. The image on the monitor should now be coming from the

external video reel.

5. The unit is now ready for pipe inspection using the external video reel.

Pic. 2 Pic. 3

15’ PATCH CABLE

FEMALE END

(NO PINS)

MALE

CONNECTOR

EXTERNAL

VIDEO REEL

CONNECTOR

Page 14

Operating Instructions

1. Flip the monitor lid up and open the sun shield for maximum viewability.

2. Press the POWER ON/OFF button to turn the unit on. The red LED should light up to indicate

that the unit is powered up.

3. Insert camera and push-cable into pipe opening.

4. Adjust the light intensity of the camera head by pressing either the MIN or MAX button. NOTE:

You can either press the button repeatedly or hold the button in.

5. To use the distance counter, press the POS button until the text is in a desirable location. Now

press the RESET button to zero the counter. The display should read 000.0 f (feet) with 000.0

m (meters) directly below it. NOTE: When pulling the push-cable out of the reel, the distance

will increase. Pushing the push-cable back into the reel will cause the distance to decrease.

6. System is now ready for pipe inspection.

Operational Tips

Adjustable centering skids are available for centering camera in lines up to 24" in diameter.

Color camera head - Spartan part number: 62002000

Black & white camera head – Spartan part number: 61019400

If you get stuck in a line try to rotate the push-cable by hand first clockwise then counter-

clockwise.

The use of a lubricating agent on the push-cable itself can often increase the distance you are

able to push the unit. Be certain to abide by all regulations regarding the use of oils (such as

vegetable or mineral oils) or other lubricating additives down drain lines. Also, if a lubricating

agent is being used, be sure to clean push-cable before it is pushed back through distance

counter rollers.

Consider using a water repellant (such as Rain-X®) on the camera lens if you are experiencing

fogging or water spotting on the camera lens in wet lines.

If glare appears in the pipe, reduce the light intensity on the control panel.

Page 15

Maintenance

The Spartan Mini-Cam is designed for easy maintenance and trouble free operation. Regular maintenance

will prolong the life of the product. Follow these simple procedures:

Do not store outdoors and do not allow the unit to sit in a truck or automobile overnight.

Never operate in standing water.

After each inspection, always wash camera head while fully attached to the flex-link/push-cable. Immersing

the camera head independently may allow water to gather in the camera and cloud the picture.

During retrieval, clean off push-cable thoroughly to ensure accuracy and longevity of distance counter.

Clean distance counter rollers frequently using a mild cleaning detergent.

The connectors may accumulate dirt on the pins with prolonged system use. Use a cotton swab

impregnated in a drop of standard alcohol to clean them. Normally a clean pin inserted in the receptacle

will wipe the internal contact and make a good connection. If this does not suffice, a drop of alcohol can

be inserted in the bad contact hole to clean it.

Keep all connector threads clean to ensure proper tightness and mechanical connection.

Wash the push-cable, flex-link, and camera head when the inspection is complete. Inspect the clean

push-cable for damage such as peel off, deep scratches, cracks, kinks, or any other signs of failure.

Caution: Never use a damaged push-cable even if the system appears to function properly.

Even the smallest drop of water that penetrates will eventually corrode the wires and produce

shorts and malfunctions. Do not use electrical or other type of tape to cover a crack or tear in any

push-cable of this system.

Wipe the camera lens cover glass clean with soft cloth. The cover is constructed of special scratch-

resistant, high-impact glass, and provides maximum transparency under adverse inspection environment

conditions.

Page 16

Mini-Cam Troubleshooting

Symptom Possible Causes Corrective Action

No Power POWER ON/OFF button has Press the POWER ON button

not been pressed

Battery may be run down Charge battery or operate minicam using

either 110V AC or 12V DC power cord.

No Power with 110V power 110 Volt outlet is not powered Test outlet for proper current

cord connected

110V power cord has failed Test unit using alternative power cord or

12V power cord

AC power cord fuse may be Check the integrity of the fuse.

blown (See page 6 for location)

The power unit may have failed Contact Spartan Tool Customer Sevice

at (800) 435-3866. NEVER ATTEMPT

TO REPAIR THE POWER UNIT ON

THE MINICAM

No Power with 12V power Faulty 12 volt power cord or Test unit using alternative power cord or

cord connected faulty connections 110V power cord

Fuse in 12 volt power cord may Check the integrity of the fuse located

be blown inside the body of the 12 volt power cord

The power unit may have failed Contact Spartan Tool Customer Sevice

at (800) 435-3866. NEVER ATTEMPT

TO REPAIR THE POWER UNIT ON

THE MINICAM

Picture is dim or hard to see The light intensity adjustment Press the MAX button to increase the

may be too low light intensity

Water may have accumulated Place the camera unit in a warm, dry,

in the camera unit climate controlled environment for

72 hours and then retest

Distance counter text is not Position of text is in the off Press the POS button until the text is

displayed on monitor screen screen position displayed on the screen

Distance counter is not Rollers may be binding Check rollers to make sure they spin

counting or counting freely

inaccurately

Rollers may be slipping on Clean rollers with a mild cleaning

push cable detergent

Page 17

Symptom Possible Causes Corrective Action

Noise bars on screen. Tracking is not adjusted. Adjust the picture by pressing the Re-

trackin

g

(

Pla

y)

.

Operation key does not work. If the cassette or the VCR is not

in normal condition, every

indicator LED/LAMP lights up

and the VCR does not work.

Turn off the power and turn on the power

again by pressing the POWER button.

Cassette is ejected upon

inserting

Safety device works to protect

the cassette when it is inserted

incorrectl

y

.

Pull the cassette out (unloading) and insert

it firmly into the cassette compartment.

Power indicated with

backlighting-unit will not

operate.

(Unit in dew mode) Dew feature

activated

Retain power to recorder and allow unit

time to get rid of moisture. (After 30

minutes if dew indicator is still on,

completely switch power off from unit and

resupply after a minute. This can reset

dew indicator if moisture eliminated.)

No ta

p

e in unit. Insert the ta

p

e.

Poor video/snow picture or line

on screen.

Dirty heads. Clean head using tape cartridge cleaner.

VCR Troubleshooting

Page 18

Flex-Link Compression Tool (Optional)

FLEX-LINK COMPRESSION TOOL P/N: 61040600

Items Included:

(1) 61040601 Inner Tube

(1) 61040602 Outer Tube

(2) 61040603 Retaining Clip

(1) 61040604 Camera Seat

(2) 61040605 O-Ring

Tools Needed:

(1) Needle Nose Pliers

(1) 1/16" Hex Key

INNER TUBE

OUTER

TUBE

CAMERA SEAT

RETAINING CLIP

O-RING

INSTALLATION & REMOVAL OF CAMERA/FLEX-LINK ASSY FROM PUSH CABLE

Installation Procedure:

1. Determine which end of the Camera Seat is needed.

Black & White camera: Use the small I.D.

Color camera: Use the large I.D.

2. Insert the Camera Seat inside the Outer Tube. If you are using a Color camera, slide the large I.D. end in first.

If you are using a Black & White camera, slide the small I.D. end in first.

3. Insert one of the Retaining Clips into the notch of the Outer Tube. Secure using an O-Ring.

4. Assemble the Inner Tube assembly using the other Retaining Clip and O-Ring.

5. Slide camera/flex-link assembly inside Outer Tube assembly until the camera head centers in the Camera

Seat. NOTE: Make sure that the 3 set screws on the spring coupler (opposite end of the camera head) are

not threaded in past the I.D.

Fi

g

. 1

Å

Ç

Page 19

6. Slide the Inner Tube assembly over the flex-link and inside the Outer Tube assembly. Now compress the

spring until the pin slides in the groove and into the first notch.

7. Screw the male connector from the flex-link assembly into the female connector of the push cable. NOTE:

Be sure pins are properly aligned to prevent the pins from being bent.

8. Using needle nose pliers, place the aircraft cables into the holes in the back-shell connector. NOTE: Be sure

the aircraft cables are not twisted around each other.

9. Uncouple both tube assemblies from each other. Make sure to have a good hold of both tube assemblies’

because of the spring tension. Also check to make sure the back-shell connector slides into the spring with

both aircraft cables still attached.

10. On the Inner Tube assembly, remove the O-ring from the retaining clip and slide the retaining clip from the

tube assembly. Now slide the Inner Tube back over the push cable and remove using the slot in the Inner

Tube.

11. Press tapered back-shell tight against spring coupler and tighten all 3 set screws using a 1/16" hex key.

Flex-Link Compression Tool (cont)

Fi

g

. 5

First Notch

Fig. 6

Male Connector

Push Cable

Back-Shell

Connector

Fig. 7 Fi

g

. 8

Tapered

Back-Shell

Spring

Coupler

Set Screws

Fi

g

. 9

Fi

g

. 10

Aircraft Cable

Page 20

Flex-Link Compression Tool (cont)

Removal Procedure:

1. Loosen all 3 set screws in the spring coupler. (Refer to Fig. 10)

2. Slide Inner Tube onto push cable and place the notch between the tapered back-shell and the spring coupler.

Insert Retaining Clip between tapered back-shell and spring coupler and secure using an O-ring. (Refer to Fig. 9

& 10)

3. Setup the Outer Tube assembly by referring to steps 1 thru 3 in the Installation Procedure.

4. Slide the Outer Tube assembly over the Inner Tube assembly and compress the spring until the pin locks into the

first notch. (Refer to Fig. 5)

5. Using needle nose pliers, pull the aircraft cables out of the holes in the back-shell connector. (Refer to Fig. 7 & 8)

6. Unthread the male connector from the push cable. (Refer to Fig. 6)

REMOVAL & INSTALLATION OF CAMERA HEAD FROM FLEX-LINK ASSEMBLY

Removal Procedure:

1. Setup the Inner Tube assembly. (Refer to Fig. 3)

2. Loosen all 3 set screws on spring coupler. (Refer to Fig. 11)

3. Insert the camera/flex-link assembly into the Inner Tube assembly.

4. Slide the Outer Tube (without Camera Seat & Retaining Clip) over the camera/flex-link assembly and then insert

the Retaining Clip between the spring coupler and camera head. Secure Retaining Clip using an O-ring. (Refer

to Fig. 13 & 14)

5. Compress the spring until the pin slides into the second notch. (Refer to Fig. 15)

Fi

g

. 12

Other manuals for Mini Cam

2

Table of contents

Other Spartan Analytical Instrument manuals

Popular Analytical Instrument manuals by other brands

minCam

minCam minCord manual

VOLTCRAFT

VOLTCRAFT 2250945 Important information

Etatron

Etatron eSelect M2 PH(RX)-CL Operating instructions and maintenance

Extech Instruments

Extech Instruments BR200 user manual

Chicago Electric

Chicago Electric 93765 Set up and operating instructions

Teledyne

Teledyne 311-D instruction manual