Spartan TrapJumper User manual

SINCE 1943

FOR TOUGH CUSTOMERS.

PRODUCT MANUAL

Sewer Inspection Camera

© 2020 Spartan Tool LLC

Part #64052025

Spartan Tool LLC |1618 Terminal Road |Niles, Michigan 49120

order by phone 800.435.3866 order online SpartanTool.com

2

INTRODUCTION........................................................................................................4

Important Safety Instructions ...................................................................................................4

Safety Instructions for all Scanprobe Camera Systems............................................................................5

SAFETY INSTRUCTIONS ................................................................................................5

Intended Use ...................................................................................................................6

Labeling........................................................................................................................6

About Your Product.............................................................................................................7

Warnings, Risks, Safety Measures, and Care ......................................................................................7

Before Operation ...............................................................................................................7

Further Measures ...............................................................................................................8

PRODUCT OVERVIEW .................................................................................................10

Coiler ........................................................................................................................ 11

Keypad Layout ............................................................................................................... 11

Explorer Control Box Display .................................................................................................. 12

Settings Menu ................................................................................................................ 14

START-UP GUIDE......................................................................................................15

Camera Connection and Removal ............................................................................................. 15

Connectivity.................................................................................................................. 16

Mounting the Control Box .................................................................................................... 17

Plug / Socket Engagement .................................................................................................... 17

Brake Operation .............................................................................................................. 18

Push Rod Instructions......................................................................................................... 18

Sonde (Locator) Operation .................................................................................................... 19

Connectability................................................................................................................ 19

Charging and Power .......................................................................................................... 20

Charging Procedure .......................................................................................................... 20

Battery Icon Definitions ....................................................................................................... 21

Lithium-Ion Battery Benefits .................................................................................................. 21

Lithium Battery Shipping ..................................................................................................... 21

Battery Maintenance.......................................................................................................... 21

Charging and Recharging ..................................................................................................... 21

General Maintenance ......................................................................................................... 22

Rod Guide .................................................................................................................... 22

Connector and Cable Care .................................................................................................... 22

Cleaning and Maintenance.................................................................................................... 22

Fitting Protective Collar ....................................................................................................... 23

Contents

3

Basic Functions for Basic Recording ........................................................................................... 24

Writing text .................................................................................................................. 24

Date.......................................................................................................................... 24

Time ......................................................................................................................... 24

USER INTERFACE ......................................................................................................24

Counter ...................................................................................................................... 25

Counter Reset ................................................................................................................ 25

Recording .................................................................................................................... 25

Viewing, copy, and deleting recordings........................................................................................ 25

Viewing Recordings........................................................................................................... 25

Deleting Recordings .......................................................................................................... 25

Transferring Files ............................................................................................................. 25

Light Adjustment ............................................................................................................. 26

File Manager ................................................................................................................. 26

Mina Survey ................................................................................................................. 26

WinCan Survey ............................................................................................................... 27

WinCan Connection Setup .................................................................................................... 27

TECHNICAL DATA OVERVIEW ..........................................................................................28

4

Introduction

This user manual is a guide on how to use the TrapJumper camera system appropriately, effectively and reliably. With this in mind it is

important that you read this carefully before using the TrapJumper system. Please read the“safety instructions”section carefully and

follow them precisely to prevent accidental damage to yourself, your colleagues or the TrapJumper itself.

The following pages provide and grant you the authority to undertake certain functions with the TrapJumper camera system. Spartan

Tool, LLC requires you to read this carefully before using the inspection system and the related accessories. It provides important notes

to help you avoid accidents, damage and injury.

CONTACT US

Spartan Tool LLC

1618 Terminal Road

Niles, Michigan 49120

800.435.3866

SpartanTool.com

SYMBOLS

Warning: This safety icon points out dangers to which a risk of

death or injury could occur.

Atex: This symbol is in reference to areas specific to explosion

proof camera systems. This is not applicable for this system!

Caution: This icon points out dangers to which the system may be

damaged or damage could occur to other equipment.

Note: This icon is used to mention or remark on a certain area with

special requirements.

Maintenance: This symbol is used to give information on how the

equipment can be cleaned and maintained to prolong its life and

reduce repairs.

IMPORTANT SAFETY INSTRUCTIONS

WARNING: When using electrical equipment, basic safety precautions should always be followed to reduce risk of

fire, electric shock and personal injury including the following:

READ ALL INSTRUCTIONS

Double Insulation

Double insulation is used throughout this construction with two separate layers of electrical insulation or one double

thickness of insulation between you and the electrical equipment.

CAUTION: WHEN SERVICING, USE ONLY IDENTICAL REPLACEMENT PARTS SUPPLIED BY SPARTAN TOOL, LLC. Repair or

replace damaged cords.

5

Safety Instructions

SAFETY INSTRUCTIONS FOR ALL SCANPROBE CAMERA SYSTEMS

• Power Cord: Do not use any power cord except the one supplied with the unit.

• Lifting: Observe safe lifting procedures when lifting or moving any components of this system.

• Grounding: If the system or any auxiliary components are connected to the power supply, then the external equipment must be

grounded in accordance with the manufacturer's instructions. Failure to comply with this may cause risk of electrocution.

• Power Adapter: The power adapter supplied with the unit is not intended for use in outdoor environments. Do not attempt to

charge or operate the unit from the power supply outdoors.

• Health and Safety: Sewer systems and other watercourses can be a source of biological hazards. Always use the appropriate PPE and

take suitable precautions to prevent infection when using the TrapJumper.

• Checks: Before using the equipment, check all parts to ensure there is NO damage. Thoroughly inspect equipment to determine that

it will operate properly and perform its intended function.

NOTE: When using a TrapJumper, it is critical that the user has received the relevant training and has a detailed

knowledge of the entire contents of the TrapJumper user manual. They must at all times comply with the instructions

in the document.

If you have any questions on the use of the TrapJumper camera system or require any additional information that has

not been covered in this user manual, please contact Spartan Tool, LLC or one of its authorized agents.

1. Lights: The camera LEDs are very bright. Do not look directly at them or point them at other people's eyes when turned on.

2. Operating Temperature:

Battery:

Battery/Cell charging temperature range 50°F to 113°F / +10°C to +45°C

Battery/Cell discharging temperature range -4°F to 140°F / -20°C to +60°C

WARNING: Do not attempt to operate or charge the system outside the recommended temperature

specifications. Exposing the battery to temperatures above 140°F / 60°C may activate safety systems

and cause a permanent battery failure.

6

Safety Instructions

3. Battery:

NOTE: The battery is encapsulated within the Explorer control box and should not be tampered with. In the unlikely

event that the battery is exposed, please read the following instructions carefully.

a. Do not dismantle, open or shred secondary cells or batteries.

b. Do not short-circuit a cell or a battery. Do not store cells or batteries haphazardly in a box or drawer where

they may short-circuit each other or be short-circuited by other metal objects.

c. Do not subject cells or batteries to mechanical shock by dropping or hitting.

d. In the event of a cell leaking, do not allow the liquid to come in contact with the skin or eyes. If contact has

been made, wash thoroughly with clean water and seek medical attention.

e. Do not use any charger except the one specifically supplied with the equipment.

f. Do not leave the equipment on prolonged charge when not in use.

g. Do not expose cells or batteries to heat or fire. Avoid storage in direct sunlight.

h. Seek medical attention immediately if the cell or battery has been swallowed.

i. All replacement batteries must be supplied and installed by Spartan Tool, LLC.

j. Keep cells and batteries clean and dry.

k. After extended periods of storage, it may be necessary to charge and discharge the cells or batteries several

times to obtain maximum performance.

l. Keep this document in a safe place for future reference.

4. Disposal: The operator is solely responsible for the disposal of any equipment at the end of its service

life. Dispose of any battery products in accordance to local regulations.

INTENDED USE

The TrapJumper system was designed to examine pipework and record/report its findings. We at Spartan Tool, LLC hold no

responsibility for further use that is not considered as intended. Do not use the TrapJumper for other purposes. The system cannot be

used in pipelines with potentially explosive atmospheres or medium. Only specifically manufactured equipment maked with the

identification icon, can be used for this purpose.

LABELING

The TrapJumper components are clearly labeled. The label includes model number, serial number, and all certifications. You may require

this information when talking to Spartan Tool, LLC Customer Service, as these can be used when ordering accessories or spare parts for

your product.

7

Safety Instructions

ABOUT YOUR PRODUCT

The TrapJumper system was designed and manufactured as a pipeline inspection camera. All components are manufactured from high

grade materials. A system consists of a control box, color camera, and a push rod reel.

The TrapJumper is designed to survey pipes and sewers up to 40m in length. With a pressure-sealed camera allowing the camera to

be submerged up to 5m deep. The control box allows users to view and record the image, measure and document your findings to an

on-board storage device, overlay text via a keyboard and write a report onsite using the on-board reporting software. All data can be

exported via USB, SD card, wifi or ethernet interfaces.

WARNINGS, RISKS, SAFETY MEASURES, AND CARE

To reduce the risk of injury, all operators and maintenance personnel must read and understand the user manual before operating,

changing accessories, or performing maintenance on this camera equipment. Understanding these instructions will reduce the

risk of injury and damage to equipment and property. Care must be exercised by everyone using, maintaining, or working near this

equipment. They serve for your own safety as well as your coworkers.

BEFORE OPERATION

Risk of harm occurring must be considered before operating the equipment, as these can cause severe or fatal injuries. Please consider

the following:

CAUTION

1. Risk of Explosion!

Explosive atmospheres can be caused by flammable gases, mists or vapors, or by combustible dusts. If there is enough of the

substance, mixed with air, then all it needs is a source of ignition to cause an explosion. Never use a Spartan Tool inspection system

in pipelines that may contain these substances. In order to survey such conditions, contact Spartan Tool, LLC to obtain information

and equipment designed for such circumstances.

2. Environmental Risk!

Cross contamination and risk of infection: Contamination of drinking water sources by sewage can occur when waste water

inspection systems are used in fresh water pipelines. If sewage contaminates drinking water sources, harmful bacterial can cause

disease from the ingestion of micro-organisms such as E-Colia, Giardia, Cryptospordium, Hepatitis A, and Helminths.

Never use an inspection system alternately between waste water and fresh water surveys. Cleaning your inspection system is not

sufficient. Always use a separate unit dedicated for that particular environment.

Risk of infection and illnesses are not uncommon. Although mild cases of gastroenteritis and potentially fatal diseases, such as

leptospirosis (Weil's disease) and hepatitis do pose a serious risk.

To reduce the chances of contracting these diseases when surveying sewage pipelines ensure that employees and line

management understand the risks through proper instruction, training and supervision.

Provide suitable personal protective equipment, which may include waterproof/abrasion resistant gloves, footwear, eye and

respiratory protection. Face visors are particularly effective against splashes. Speaking to your doctor for preventative injections and

advice is recommended.

8

Safety Instructions

3. Electric Shock

Risk of death by electric current.

• Check the connector cable and push rod for damage, such as kinks or crushed areas. If damage has occurred, disconnect the

power supply immediately. Safeguard the socket against renewed connection and inform Spartan Tool, LLC Customer Service

Team or an authorized repair center.

• Ensure no liquid can enter the control box. Fit all rubber blanking bungs and check connector facia rubber flap is closed tight

when operating in the rain. When survey is finished, wipe the rubber keypad dry and leave the lid open in a warm environment

to allow any condensation to evaporate. Should any water penetrate the box, do not connect the power cords and inform

Spartan immediately.

• All work on the electrical system can only be carried out by Spartan Tool, LLC or authorized repair centers. If any work exceeds

the tasks described in the Maintenance chapter, please contact Spartan Tool, LLC for assistance.

4. General Precautions/Risks

As with all work, accidents can happen. Please keep the following in mind before any work is carried out. Stay vigilant at all times,

be aware of your surroundings and use the correct personal protetctive equipment—tools, warning signs, barriers, etc.

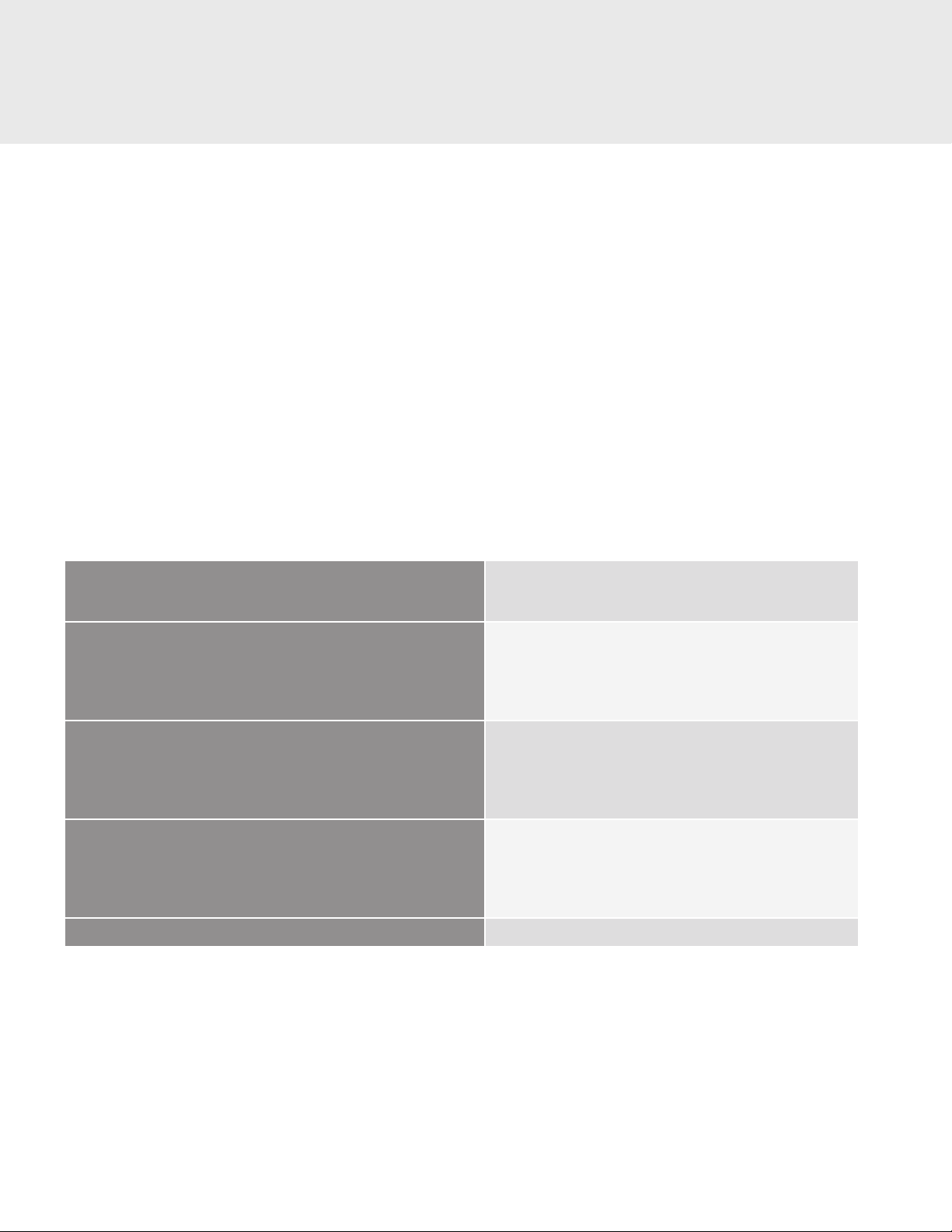

RISK DETAILS OF SPECIFIC HAZARD

CONFINED SPACE

• Working in a confined space (manhole/drain)

• Lowering and raising operatives via tripod and winch

Lack of oxygen

Unconsciousness

Suffocation

SLIPS, TRIPS, AND FALLS

• Trailing hoses / cords

• Storage of materials

• Blocked access and egress

• Collision with materials and equipment Public Safety

Bruising

Cuts

Sprains

Fractures

MANUAL HANDLING

• Lifting of manhole covers

• Use of hand tools

• Handling and use of equipment

Prolapsed disc injuries (back)

Damage to muscles, ligaments, and tendons

Hernias

Cuts, bruises, and fractures

Burns

EXPOSURE TO ASBESTOS

Shortness of breath

Plural plaques

Asbestosis

Lung cancer

Mesothelioma

EXPOSURE TO NOISE AT WORK Short-term damage to hearing

FURTHER MEASURES

The TrapJumper system was designed and engineered to the highest standards to the guidelines of safety engineering regulations.

Nevertheless, accidents can happen, that could endanger life, the health of its users or third parties and could damage the inspection

system itself as well as other machinery.

The user assigned to operate the inspection system must have read and understood the user manual completely before any work is

carried out.

9

Safety Instructions

WARNING

1. Users of the inspection system should work as safely and risk-free as operationally possible. The following

measures will help achieve this:

• Regularly inspect and perform any maintenance as required

• Ensure all personnel follow the safety guidelines laid out in this manual at all times.

• Keep up to date with any training courses.

• Always have the instruction manual available when using the inspection system.

2. Personal Safety: Any users of the inspection system, whether it's to operate, maintain or set up the equipment,

must be fully trained or instructed by an expert. Fully trained operators have sufficient knowledge of the

inspection system through their technical training and experience. They would also be familiar with the

appropriate health and safety regulations as well as accident prevention, giving them the knowledge to operate

the inspection system within safe working conditions.

• Read, understand, and follow all safety requirements specified in this instruction manual

• Carry out a risk assessment prior to any work

• Observe the relevant accident prevention regulations

• Attend and pass any site induction, if required

• Be instructed on the handling of any dangerous goods

• Be vigilant at all times of your work space and surrounding area

3. Avoid damage to property. As the operator of the TrapJumper system, it is your responsibility for the following:

• Do not use the TrapJumper outside the parameters of "intended use" (see page 6)

• Observe the operating conditions for this camera system as noted in this instruction manual

• Keep the equipment clean and in full working order. See cleaning instructions.

10

Product Overview

The TrapJumper system consists of the following components:

1. System box

2. Coiler

3. Push rod

4. Camera head

The following sketch demonstrates a typical set-up:

1

2

3

4

11

1. Push rod

2. Coiler brake

3. Explorer control box

mounting plate

4. Nylon rod guide

5. Sonde ON/OFF

6. Monitor lead

7. Handle

Product Overview

1

2

3

4

5

6

7

KEYPAD LAYOUT

1. Help button

2. mina survey

3. Wincan survey

4. General text overlay

5. Text font

6. Text size

7. Meterage placement

8. File manager

9. Settings

10. Sonde ON/OFF button

11. Lights OFF

12. Power ON/OFF

13. Lights down

14. Lights up

15. Video functions

16. Snapshot

17. Footage counter reset

18. Navigation keys

19. QWERTY keyboard

COILER

1

2345678910

11 12

13

14

15

16

17

18

19

12

Product Overview

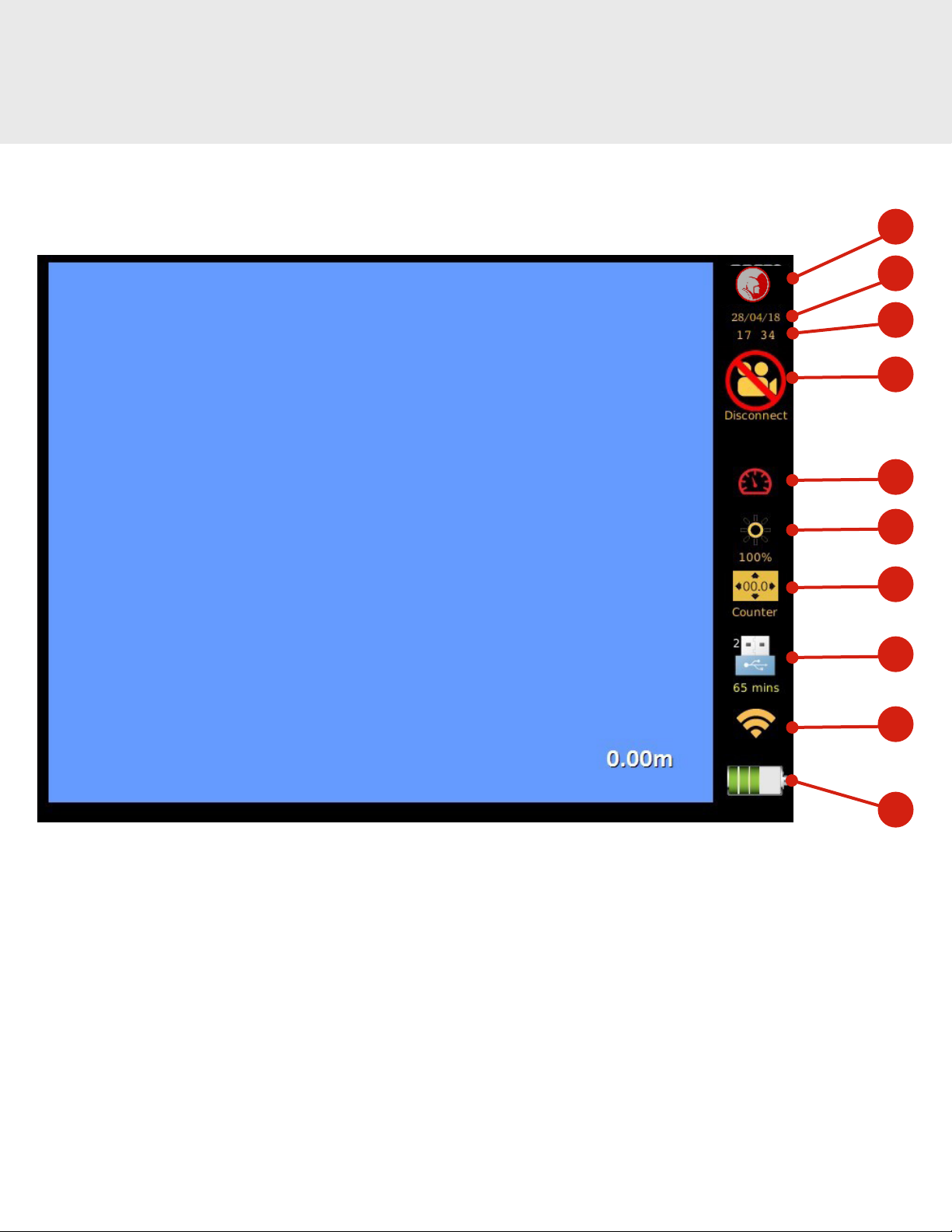

1. Function display: this allows users to determine what mode you're in, i.e. Wincan, mina, etc.

2. Date: used on a survey file as a reference

3. Time

4. Camera connectivity: informs you if there is a camera present

5. Pressure status: (not applicable with TrapJumper) this allows users to determine whether the camera is water-tight

6. LED brightness: indicates the level of brightness

7. Counter placement: allows the user to position the counter anywhere on the screen and change the font/size

8. Storage device: indicates the device to which your files are stored to

9. Wi connection

10. Battery status: ref. charge procedure

EXPLORER CONTROL BOX DISPLAY 1

2

3

4

5

6

7

8

9

10

13

Product Overview

Camera

connected

Recording

Pressure ok

Sonde

switched ON

Sonde

frequency

14

SETTINGS MENU

The Settings Menu allows users to access the mainframe of the TrapJumper system. The status menu can be accessed through the

settings, which provides a health check of the components. Users can adjust the time/date, connect to WinCan Web, and view the

camera temperature/pressure.

Product Overview

System

details

TemperaturePressure

sensor 2

Pressure

sensor 1

Onscreen

counter

settings

Monitor settings &

software update menu Wifi

connection WinCan

Web & FTP WinCan

settings

NOTE: The pressure sensors and temperature are not applicable for the TrapJumper system.

15

Start-Up Guide

The following guide offers instructions on how to set up your TrapJumper system correctly and safely. Please read these instructions in

full before the system is set up. Your TrapJumper system has been built to your specification, the camera and overall setup remains the

same. Please pay close attention to any Notes and Warnings.

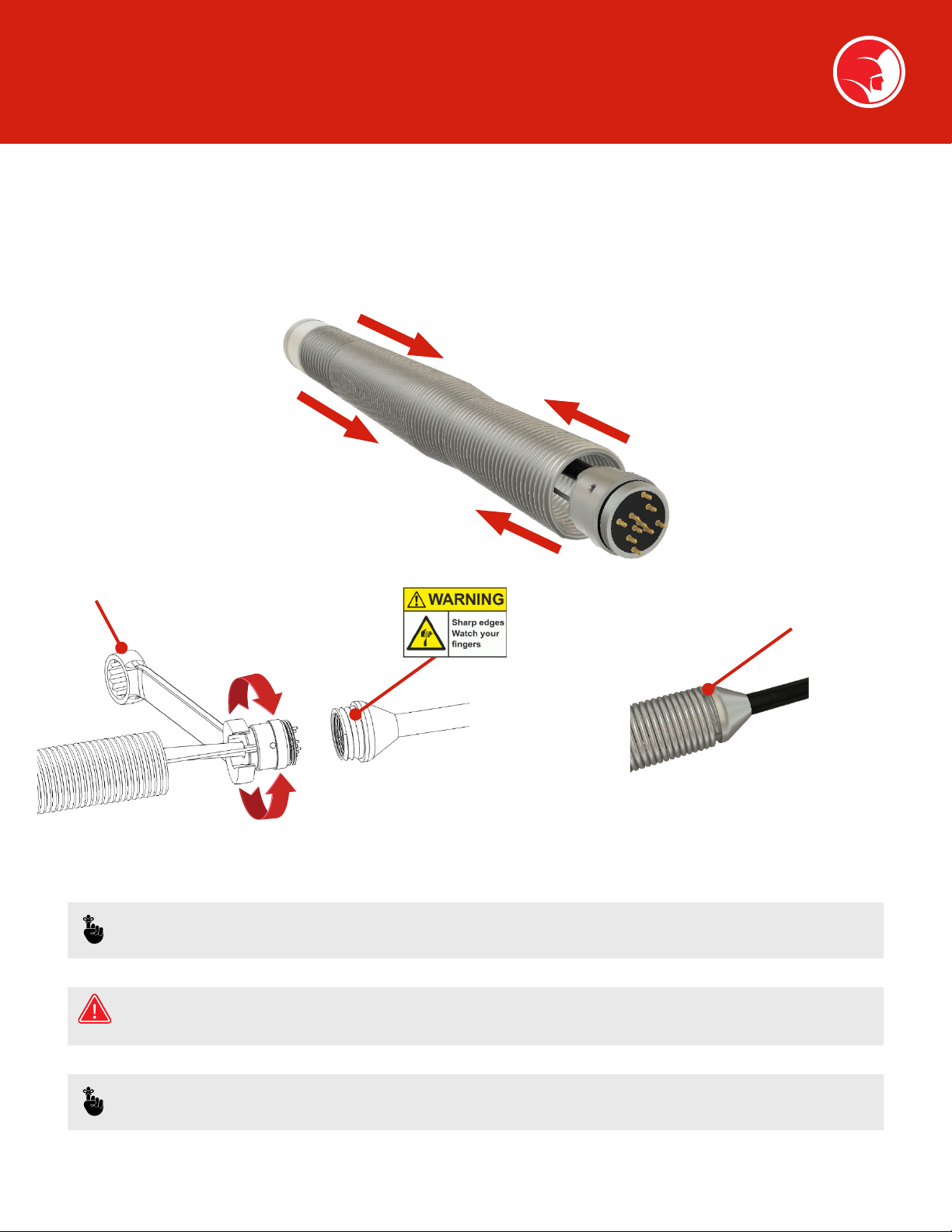

CAMERA CONNECTION AND REMOVAL

1. Compress the spring together to reveal

the connector.

2. Using a 12mm wrench (as below), screw

the male connector into the rod.

Spring end

12mm Wrench

Tighten

Loosen

3. Finally, screw the spring over the rod

connector hand tight.

Repeat this process in reverse to remove the camera head.

NOTE: If the spring is difficult to unscrew when removing the camera, use the camera removal tool provided in the

accessory kit. Align the inner tool with the end of the spring (see above) and apply the required force.

WARNING: Wear gloves! The spring thread contains sharp edges and should not be touched without hand

protection. Take care with the connector thread and avoid extreme force. Do not over tighten!

NOTE: Always ensure the connector is clean and the electrical contacts remain grease free at all times.

16

CONNECTIVITY

Start-Up Guide

USB (1)

USB (2)

SD Card Socket

Ethernet Socket

Headphones

Microphone

Pressure valve

Monitor lead

input socket (10 pin)

Identification label

VGA output

Battery charging

socket

Monitor lead input

socket (7 pin)

Battery light

indicator

17

Click!

Start-Up Guide

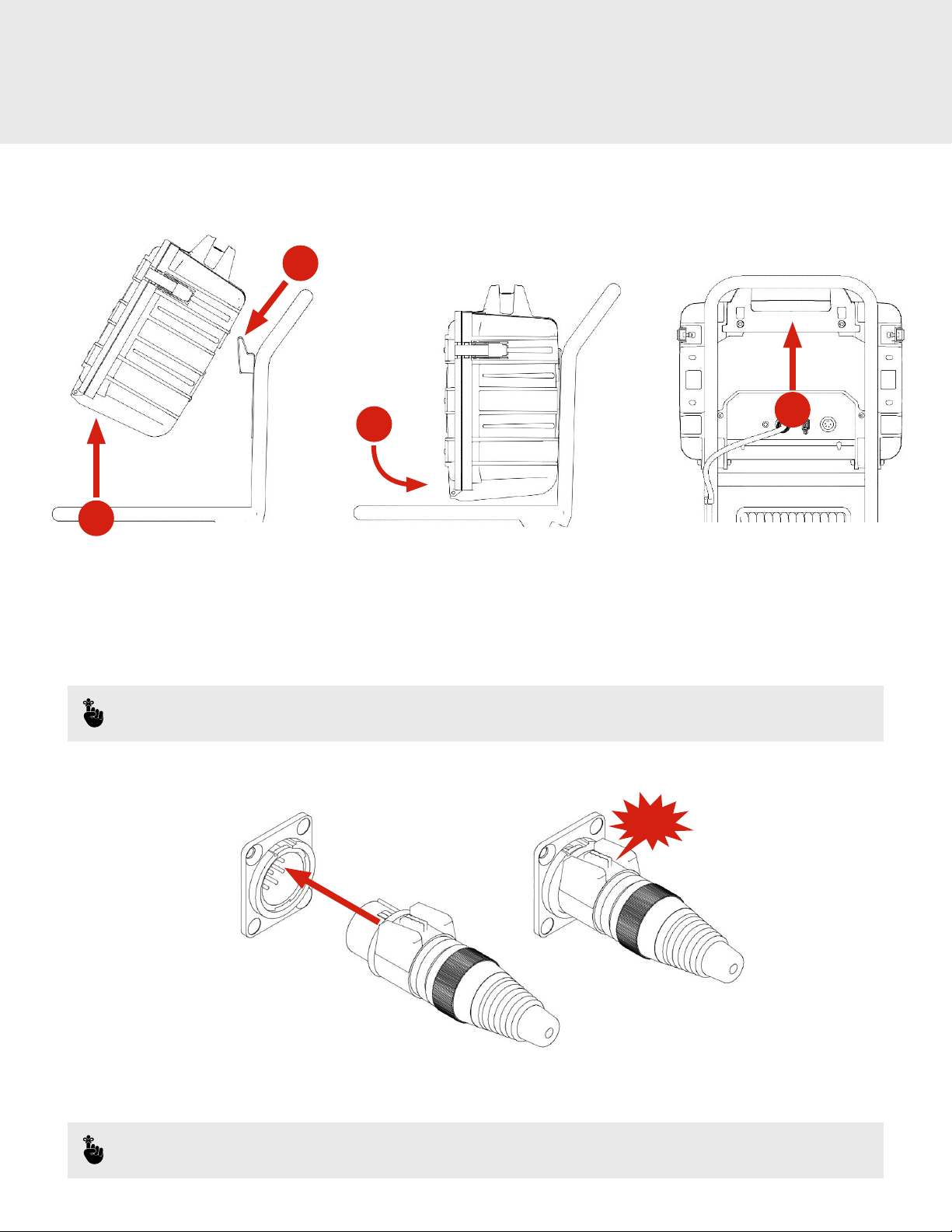

MOUNTING THE CONTROL BOX

1

2

34

1. Lift box at an angle above the mounting plate.

2. Align the base of the handle and clip over the plate.

3. Lower box against the handle.

4. Check the box is central to the frame.

NOTE: To remove the box, disconnect the cables and repeat the steps above in reverse.

PLUG / SOCKET ENGAGEMENT

7 pin-din:

• Align the keyway clip at 12 o'clock with the socket

• Push connector into the socket until you hear the click of it locating

NOTE: Please ensure all connectors are clean and dry before connection. Do not twist.

18

Start-Up Guide

BRAKE OPERATION

Lock

Release

WARNING: Be careful your hands don't get trapped or pinched.

• Turn the handle counterclockwise to release reel and clockwise to apply the brake.

PUSH ROD INSTRUCTIONS

• When loading the push rod onto the frame, be sure to align the rod and do not cross it over. This will reduce the risk of damage and

an imprecise meterage reading.

CAUTION: Excessive force on the push rod will cause damage and can even snap the inner cores. Do not over exert

when surveying or reeling back onto the coiler. Different push rods are designed for different environments; be

sure the rod you are using is fit for the pipe it's being used on. If you are unsure, contact Spartan Tool, LLC for help

and advice.

19

Start-Up Guide

SONDE (LOCATOR) OPERATION

Sonde ON/OFF

button

• Engage the push button to turn on the 512 Hz sonde.

• The red light will illuminate to indicate the sonde is active.

CONNECTABILITY

CAUTION: When connecting or disconnecting any cables or cameras, ensure the system is switched off and

disconnected from power supply.

• Do not expose mains cables/charges to rain or moisture.

• Keep all power cables clean. Contamination will increase the risk of electric shock.

• Connect all cables in accordance with the connector diagram.

• Check charging cables are not damaged. Do not use if damage is located. Purchase a new replacement from

Spartan Tool, LLC or a recommended repair center.

No. Description Part No.

1TrapJumper Camera 1024-1002-0

2TrapJumper Coiler 1024-1001-0

3Explorer Control Box 6405CBOX

20

Start-Up Guide

CHARGING AND POWER

1

23

4

5

1. 230v Power lead

2. 110v Power lead (64051697)

3. 24v Explorer control supply PSU

4. 12v Car charger (64051821)

5. Explorer control box (6405CBOX)

NOTE: Observe power voltage: the voltage of the power source must correspond with the information provided on

the equipment or power supply label.

CHARGING PROCEDURE

To begin charging, insert the power supply or car charger into the battery charging socket (connect to a source with a power cord using

PSU). Charging begins as soon as power is connected. The charging procedure automatically recognizes the charge state of the battery.

Charge current will fluctuate according to the battery temperature and voltage. This protects the battery, which is always fully charged

when connected to a power source.

• Explorer control box, estimated battery life: 9 hours

• Explorer control box, estimated charging cycle: 4 hours

• Battery indication light will flash red and an alarm will sound to warn of low battery power.

NOTE: Batteries and life cycles are given as estimates. To increase the batteries' life, health and longevity, please read

the battery maintenace section.

Table of contents

Other Spartan Analytical Instrument manuals