SPIERINGS AT5 User manual

MANUAL SPIERINGS TRUCK AT5

AT5-UK-030626 01-12-09 I

Introduction

This manual is put together to provide the user of the Spierings truck, model AT5, with information about this

truck's construction, operation and maintenance.

The driver must have a driving license for driving a heavy truck and have sufficient technical knowledge.

The AT5 truck is built to serve as carriage for the Spierings folding crane, model SK598. For operation, technical

data and maintenance of this folding crane we refer to the subjoined manual.

Because the AT5 is provided with five axles, of which 3 axles are steered, excellent mobility is guaranteed on the

work site as well as on the road. The axles are hydro-pneumatically suspended, whereas the height can be

adjusted and/or blocked. Three axles are driven by a 12.6 litres DAF diesel engine and a gearbox with sixteen

gears forward and two gears reverse. After the gearbox is a high/low gear shift (transfer case), which has two

different gears and a neutral. A gear for driving on the road and a gear for driving off the road. Neutral serves for

the generator drive by the high/low gear shift PTO.

Furthermore, there is a hydraulic system for operating the crane's outrigger system and, when the crane is not

equipped with a separate engine on the upper frame, the truck has a 400 Volt generator to provide the crane with

the necessary power.

The following items are dealt with in this manual.

General data. In this chapter you will find a description of the measurements and technical specifications.

Location and explanation of controls.

Operating the AT5. This chapter gives you instructions for optimal use of the truck.

Maintenance of the AT5, maintenance schedules as well as explanation of the maintenance work to be

carried out. You will also find a maintenance plan containing the specification of the used parts and

lubricants.

Specification of drive line and steering system parts

Explanation of the hydraulic, pneumatic and electrical system.

You will find the outline drawings and diagrams referred to at the back of this manual in the enclosures.

Due to the continuous product development at Spierings Kranen the descriptions and pictures may not be all together similar to the condition on your vehicle.

Copyright 2003. No part of this publication may be reproduced or published, in any form or in any way, by print, photo print, microfilm or any other means without prior

permission from the manufacturer.

MANUAL SPIERINGS TRUCK AT5

AT5-UK-030626 01-12-09 II

Table of contents

Introduction..........................................................................................................................................I

Table of contents................................................................................................................................II

1. General data AT5.....................................................................................................................1-1

2. Operation..................................................................................................................................2-1

2.1. Get to know the truck.....................................................................................................2-1

2.2. Truck cab.......................................................................................................................2-4

2.3. Control Panel.................................................................................................................2-7

2.4. Driving the Spierings crane..........................................................................................2-16

2.4.1. Starting ..........................................................................................................2-16

2.4.2. Driving off.......................................................................................................2-17

2.4.3. Change gear..................................................................................................2-17

2.4.4. Stopping.........................................................................................................2-18

2.4.5. Turning off the engine....................................................................................2-18

2.5. Driving off the road.......................................................................................................2-18

2.5.1. Off the road gear shift High/Low transfer case...............................................2-18

2.5.2. Longitudinal differential lock...........................................................................2-19

2.5.3. Transverse differential lock............................................................................2-19

2.5.4. Hydraulic driven axle 1...................................................................................2-19

2.6. Braking system ............................................................................................................2-20

2.6.1. Operating brake.............................................................................................2-20

2.6.2. Parking brake.................................................................................................2-20

2.6.3. Vacuum brake/engine stop............................................................................2-20

2.6.4. Slowing down using the retarder (optional)....................................................2-20

2.7. Parking.........................................................................................................................2-21

2.8. Driving with a trailer .....................................................................................................2-21

2.9. Towing the crane .........................................................................................................2-22

2.9.1. Tow free.........................................................................................................2-22

2.9.2. Towing...........................................................................................................2-22

2.10. Independent rear axle steering ....................................................................................2-23

2.11. Driving with erected tower............................................................................................2-24

2.12. Axle height adjustment.................................................................................................2-25

3. Maintenance.............................................................................................................................3-1

3.1. General..........................................................................................................................3-1

3.2. Safety.............................................................................................................................3-1

3.2.1. Engine..............................................................................................................3-1

3.2.2. Moving components.........................................................................................3-1

3.2.3. Oils and coolant...............................................................................................3-1

3.2.4. Welding............................................................................................................3-1

3.2.5. Environment.....................................................................................................3-2

3.2.6. Cleaning of components..................................................................................3-2

3.3. Maintenance plan truck AT5 ..........................................................................................3-3

4. Periodic checks .......................................................................................................................4-1

4.1. Daily checks...................................................................................................................4-1

4.1.1. Check engine oil level......................................................................................4-1

4.1.2. Check coolant level..........................................................................................4-1

4.1.3. Tyres and rims.................................................................................................4-2

4.1.4. Lighting and controls........................................................................................4-2

MANUAL SPIERINGS TRUCK AT5

AT5-UK-030626 01-12-09 III

4.2. Weekly checks...............................................................................................................4-2

4.2.1. Check for leaks (oil, air, coolant)......................................................................4-2

4.2.2. Windscreen washer fluid level .........................................................................4-2

4.2.3. Clutch fluid level...............................................................................................4-2

4.2.4. Draining air vessels .........................................................................................4-3

4.2.5. Draining and bleeding fuel system water separator.........................................4-3

5. Lubrication...............................................................................................................................5-1

5.1. Central lubricating system..............................................................................................5-1

5.2. Manual lubrication..........................................................................................................5-3

5.2.1. Outrigger-cylinders ..........................................................................................5-3

5.2.2. Gear change mechanism.................................................................................5-3

5.2.3. Driven axles.....................................................................................................5-3

5.2.4. Cardan shafts ..................................................................................................5-4

5.2.5. Steering system...............................................................................................5-5

6. The drive system.....................................................................................................................6-1

6.1. The diesel engine ..........................................................................................................6-2

6.1.1. Specification diesel engine ..............................................................................6-2

6.2. Maintenance plan diesel engine ....................................................................................6-2

6.2.1. Maintenance activities First service interval.....................................................6-2

6.2.2. Maintenance activities X service interval .........................................................6-3

6.2.3. Maintenance activities Y service interval .........................................................6-3

6.3. Carrying out maintenance work diesel engine ...............................................................6-3

6.3.1. Change engine oil............................................................................................6-3

6.3.2. Oil Filter Replacement .....................................................................................6-3

6.3.3. Air cleaner cleaning/replacement.....................................................................6-4

6.3.4. Fuel filter replacement .....................................................................................6-4

6.3.5. Change filter element water separator.............................................................6-5

6.3.6. Changing coolant.............................................................................................6-5

6.4. Inspections.....................................................................................................................6-6

6.4.1. Check for fuel leaks.........................................................................................6-6

6.4.2. Check components and hose connections for leaks........................................6-6

6.4.3. Radiator and intercooler element inspection/cleaning .....................................6-6

6.4.4. Cooling system hoses and air inlet system inspection.....................................6-6

6.4.5. Check outlet system for connection and leaks.................................................6-6

6.4.6. Check coolant antifreeze concentration...........................................................6-7

6.5. The clutch and gearbox .................................................................................................6-7

6.5.1. Specification gearbox ......................................................................................6-7

6.5.2. Fluid torque converter......................................................................................6-7

6.5.3. Bridging clutch.................................................................................................6-8

6.5.4. Freewheel clutch..............................................................................................6-8

6.5.5. Retarder...........................................................................................................6-9

6.5.6. Clutch ..............................................................................................................6-9

6.6. Carrying out maintenance work gearbox and clutch......................................................6-9

6.6.1. Bleeding Gearbox............................................................................................6-9

6.6.2. Drain oil gearbox............................................................................................6-10

6.6.3. Filling gearbox and converter with oil.............................................................6-10

6.6.4. Change / clean oil filter ..................................................................................6-10

6.6.5. Take off and replace the suction filter............................................................6-11

6.6.6. Clutch bleeding..............................................................................................6-11

6.6.7. Check clutch..................................................................................................6-11

6.7. The transfer case.........................................................................................................6-12

6.7.1. Specification transfer case.............................................................................6-12

6.8. Carrying out maintenance work transfer case..............................................................6-12

6.8.1. Bleeding.........................................................................................................6-12

6.8.2. Check oil level................................................................................................6-12

MANUAL SPIERINGS TRUCK AT5

AT5-UK-030626 01-12-09 IV

6.8.3. Change oil in transfer case............................................................................6-12

6.9. Axles/brakes................................................................................................................6-13

6.9.1. Specification axles/brakes .............................................................................6-13

6.10. Carrying out maintenance work axles/brakes ..............................................................6-13

6.10.1. Checking oil level differential housings and hubs ..........................................6-13

6.10.2. Change oil......................................................................................................6-13

6.10.3. Check the brake lining thickness ...................................................................6-14

6.10.4. Brake test.......................................................................................................6-14

7. The hydraulic system..............................................................................................................7-1

7.1. Structure hydraulic system.............................................................................................7-1

7.1.1. Hydraulic pump system....................................................................................7-1

7.1.2. Hydraulic steering system................................................................................7-2

7.1.3. Hydraulic suspension.......................................................................................7-3

7.1.4. Hydraulic outrigger system ..............................................................................7-3

7.1.5. Hydraulic drive axle 1 (option) .........................................................................7-3

7.2. Maintenance Hydraulic System .....................................................................................7-3

7.2.1. Check oil level..................................................................................................7-4

7.2.2. Change hydraulic oil ........................................................................................7-4

7.2.3. Change oil filter................................................................................................7-4

7.2.4. Fine filter replacement .....................................................................................7-4

7.2.5. Check accumulators ........................................................................................7-4

7.2.6. Check hydraulic hoses and connections..........................................................7-4

8. The Steering System...............................................................................................................8-1

8.1. Maintenance Steering System.......................................................................................8-1

8.1.1. Align.................................................................................................................8-1

8.1.2. Check steering arms and ball joints for play ....................................................8-1

9. The Pneumatic System ...........................................................................................................9-1

9.1. Structure Pneumatic System .........................................................................................9-1

9.1.1. Braking System................................................................................................9-1

9.1.2. Accessories .....................................................................................................9-1

9.2. Maintenance Pneumatic System....................................................................................9-2

9.2.1. Change filter element air-dryer ........................................................................9-2

9.2.2. Check air vessels.............................................................................................9-2

9.2.3. Check the air lubricator / water separator........................................................9-2

9.2.4. Check brake pressure......................................................................................9-2

10. Electrical System...................................................................................................................10-1

10.1. Structure Electrical System..........................................................................................10-1

10.1.1. Power for powering the crane........................................................................10-1

10.1.2. Fuses.............................................................................................................10-1

10.1.3. Lighting..........................................................................................................10-2

10.2. Maintenance Electrical System....................................................................................10-3

10.2.1. Charging batteries .........................................................................................10-3

10.2.2. Batteries Replacement...................................................................................10-3

11. Technical Data.......................................................................................................................11-1

12. Enclosures.............................................................................................................................12-1

MANUAL SPIERINGS TRUCK AT5

AT5-UK-030626 01-12-09 1-1

1. General data AT5

The AT5 carriage is especially designed for the Spierings SK598 folding crane. Extra attention is paid to a smooth

and comfortable transport to the work site. The crane is suited for driving on public roads, fully equipped with

counterweight and tools. The chassis is an especially rigid structure to create a good crane support.

In Picture 1-1 you will find the measurements of the SK598 with the AT5 carriage. The dimensions given are the

overall dimensions, axle bases and turning circle.

Picture 1-1

Drive unit:

12.6 litres DAF diesel engine with turbo compressor and intercooler (type XF 315 M).

ZF gearbox with fluid torque converter and retarder; 16 gears forward and two gears reverse.

STEYR high/low gear shift, transfer case, with high speed (road) and low speed (off the road) transmission.

Five Ginaf axles, where axles two, three and five are driven.

Electronic accelerator "E-gas” with speed control.

Built-in generator for powering the crane.

Steering:

Axles 1, 2, 4 and 5 are steered.

Mechanically coupled steering, where axle four and five are steered in the opposite direction of axle one and

two, realizing a small turning circle.

MANUAL SPIERINGS TRUCK AT5

AT5-UK-030626 01-12-09 1-2

Axle four and five can be uncoupled mechanically. Independent rear axle steering is now possible using a

small joystick. Lift axle three to use this option.

Hydraulic powered steering system.

Fitted with an emergency steering pump, so when the main steering pump or diesel engine malfunctions, the

truck remains steerable until it is at a standstill.

Provisions for driving off the road:

-axle height adjustable

-high/low gear shift transfer case can be put in low gear for driving off the road

-longitudinal and transverse differentials can be locked

Suspension:

Hydro-pneumatic suspension

The suspension can be blocked (e.g. when driving with erected tower).

Braking system:

Pneumatic brakes with anti-blocking system (ABS).

4-point outrigger system:

Wide support base : 7.2 m x 7.2 m

Narrow support base : 7.2 m x 5,65 m

Power supply:

When there is no separate diesel engine on the upper frame, the upper frame can be supplied with power in two

different ways:

External power-supply 40 kVA during rigging up/rigging down, 40 kVA during operation

The truck built-in Leroy Somer 70 kVA generator for power supply to the upper frame when (sufficient)

external power is lacking.

Further data:

Maximum speed limited to 85 km/h

Minimum speed at 1250 rpm: 1.9 km/h (is 32 m/min)

Truck weight including upper frame 60,000 kg

The axle load is 12,000 kg per axle

MANUAL SPIERINGS TRUCK AT5

AT5-UK-030626 01-12-09 1-3

Identification:

Engine number: left-hand side on the engine block above the fuel pump.

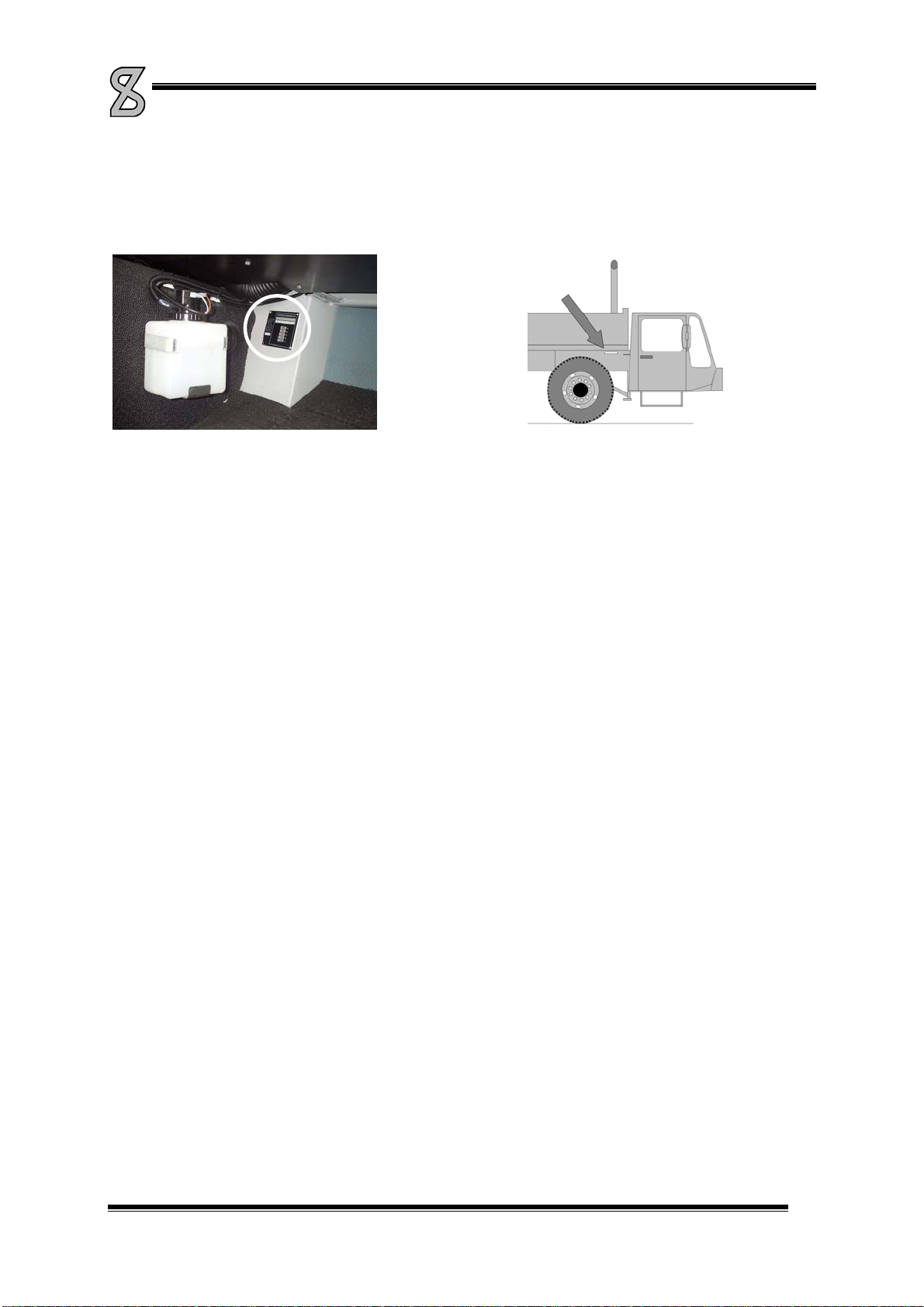

Carriage frame number: on the identification plate in the co-driver's leg-room (See Picture 1-2) and

stamped in the right frame girder in front of the first axle (See Picture 1-3).

Picture 1-2

Picture 1-3

MANUAL SPIERINGS TRUCK AT5

AT5-UK-030626 01-12-09 2-1

2. Operation

2.1. Get to know the truck

Picture 2-1

MANUAL SPIERINGS TRUCK AT5

AT5-UK-030626 01-12-09 2-2

1a. Truck cab

Besides driving the crane, with the controls in the truck cab you can support the crane on outriggers, adjust the

carriage axle height and switch the generator on and off.

2a. Hydraulic oil tank / battery box

On this side of the truck, under the engine cowling, you will find the

hydraulic oil tank (See Picture 2-2, nr.3) and air cleaner (nr.2).

Behind the oil tank, you’ll find the battery-box (nr.1).

2. Battery switch

On the left side behind the cab, you’ll find the battery switch.

Picture 2-2

3. Toolbox at the rear / power box

You will find the power-box in this storage box by opening the right sliding door.

With the selector switch on the power-box, the power supply for the crane is selected. Either an external power

supply can be connected to this power box, or the built-in generator supplies the power. Power can also be

branched off for accessory equipment.

4. Steel support plates

To obtain a solid support base on a week ground, support plates have to be used. In this place, 4 steel support

plates are stored.

5. Storage room support plates

Under the truck cab, there are 2 storages with 2 synthetic support plates each (or 3 each in combination with steel

support frames).

These synthetic support plates have to be used to rig up the crane on narrow support base, after which the steel

support plates can be placed, using the crane. After placing the steel support plates you can outrigger to wide

support base.

6. Outriggers

At both sides of the truck there are 2 extending outrigger beams, and to each beam a hydraulically operated

outrigger (See Picture 2-3). These outriggers provide stability during hoisting operation. The outrigger beams

have an antiskid coating to prevent skidding. The outrigger pad holders can be used to facilitate stepping on the

outrigger beam.

With a separate (remote) control box the outriggers can be radio controlled. On the rear outrigger beams are

levels to check if the crane set-up is level.

MANUAL SPIERINGS TRUCK AT5

AT5-UK-030626 01-12-09 2-3

Picture 2-3

7. Fuel tank

The fuel tank capacity is 600 litres.

8. Bumper

The crane has a standard bumper at the rear. When the bumper is folded up, the towing hook can be used (refer

“Driving with a trailer”).

9. Jib turning pipe

Through a hole in the deck you can reach the jib turning pipe. This pipe is used to swing the jib in front of the

tower during assembly and back when dismantling the crane.

10. Work lamps

To the rear of the cab and truck are mounted work lamps, which can be

switched on/off from the cab.

By unscrewing the knob, the lamp support can be moved to the left and right

(See Picture 2-4).

Picture 2-4

11. Truck ladders

To facilitate getting on the truck three ladders are mounted. Two ladders

are mounted between axle 2 and 3. To pull you up, brackets are mounted

on the deck.

The third ladder is mounted on the deck on the side of the electrical

cabinet of the crane. Pick up the free end of the ladder so the pin comes

out of the deck (See Picture 2-5) and swing the ladder outside the frame.

When swinging back the ladder, make sure the pin returns in the hole.

Picture 2-5

MANUAL SPIERINGS TRUCK AT5

AT5-UK-030626 01-12-09 2-4

12. Central lubricating system

This is the grease reservoir for the truck's central lubricating system.

13. Concrete bucket / brick gripper support (optional)

On the bumper a support can be mounted to carry a concrete bucket or a brick gripper.

14. Rear-/side view cameras (optional)

To broaden your view at the rear and right-hand side of the truck cameras can be installed. In the cab a monitor is

installed, showing the camera view.

Standard, the view of the side camera is shown. When putting the transmission in reverse, the monitor

automatically switches over to rear camera view.

2.2. Truck cab

In the truck cab you drive the crane safely and comfortably to its destination. This chapter makes you familiar with

the cab.

Getting in

Use the step under the door. Make use of the steering wheel to hold on to.

Doors

Turn the handle up to open the door from the inside. The door can only be locked up from the outside. There is an

ashtray on the inside of the door. After opening the ashtray, you push the locking device down to remove the

ashtray from the holder to empty it.

Wing mirrors

The wing mirrors may be adjusted by hand. Make sure the mirrors are adjusted before driving off, so that you

have satisfactory view. The mirror heating can be switched on with the switch on the control panel. (No. 10)

MANUAL SPIERINGS TRUCK AT5

AT5-UK-030626 01-12-09 2-5

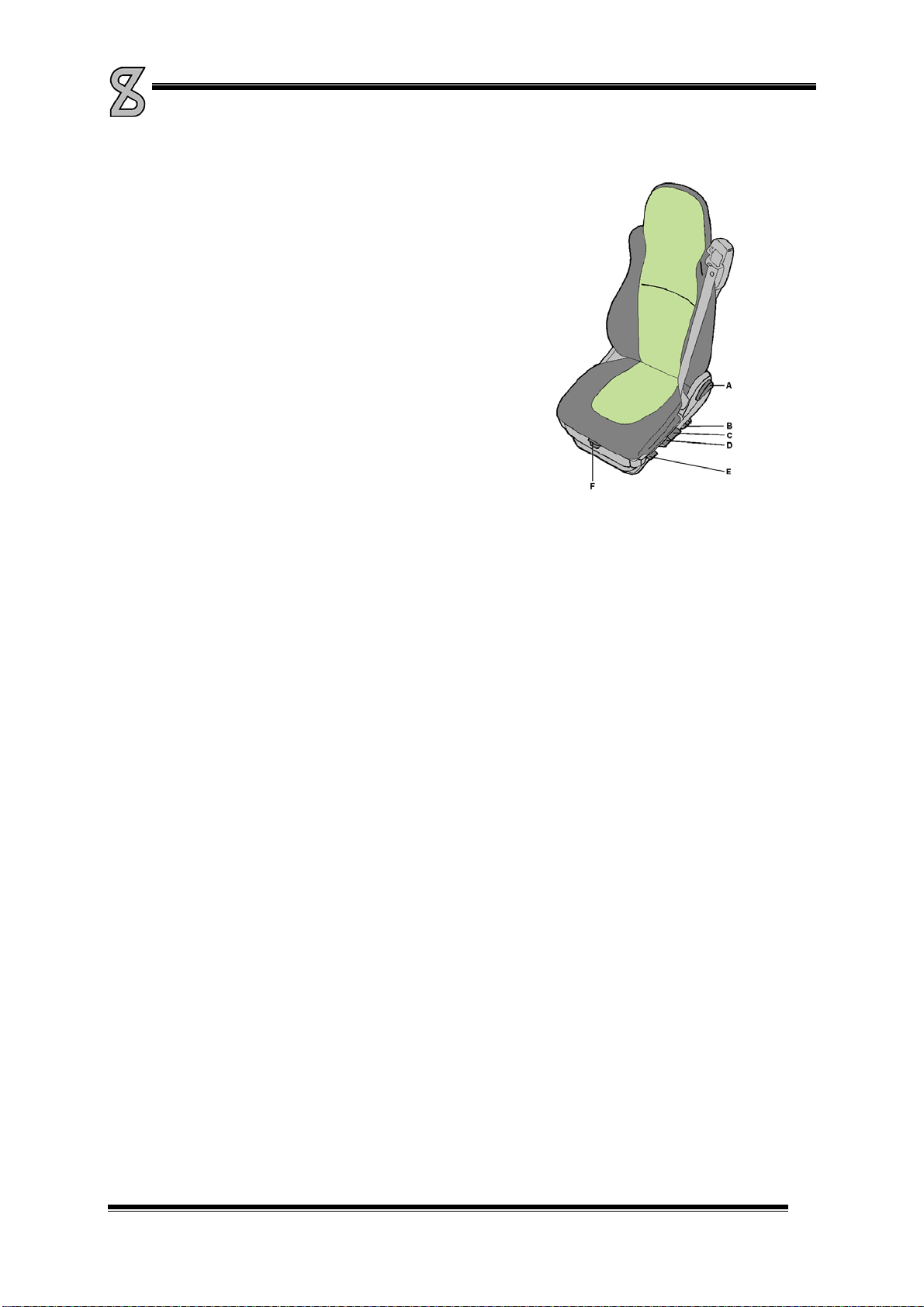

Seats

The cab has room for the driver and a co-driver. Only the driver's

seat has pneumatic suspension. The seats' position can be adjusted.

This should only be done when the vehicle stands still.

A) Back adjustment

B) Lumbar support adjustment (push = pumping up and pull =

deflating)

C) Height adjustment (pulling the handle = up and pushing it =

down)

D) Tipping the seat

E) Handle fast lowering

F) Adjustment seat

Picture 2-6

Safety belts

The seats are fitted with safety belts. Driver and co-driver must wear them when driving. Do not modify the belt or

its attachment by yourself. Regularly check its operation by jerking the belt from its winding mechanism. The belt

must lock when doing this. Have the locking device repaired or replaced when it does not function properly. When

the belt was heavily loaded during a collision, it must be completely replaced, even if it looks like there is nothing

wrong with it.

Storage room

In the middle of the cab ceiling is a storage compartment. It has a lockable lid at the driver's side and at the side

of the co-driver. There is another storage compartment at the co-driver's side in the dashboard (See Picture 2-7,

A).

Sun blind

To prevent sunlight from blinding you, a sun blind is mounted above the windscreen for the driver and the co-

driver. Pull down the blind with the joggle in the middle of the blind. The blind will remain in the desired position.

Push the button on the side of the blind to roll it up.

Fuse box

The fuse box is at the co-driver's side in the centre console (See Picture 2-7, B). You will find the fuses listed in

the enclosures.

Windscreen washer reservoir (See Picture 2-7, C)

Central lubricating system (optional)

The central lubricating system controls are on the centre panel at the co-driver's side. It can be opened by means

of 2 clamps (See Picture 2-7, B).

MANUAL SPIERINGS TRUCK AT5

AT5-UK-030626 01-12-09 2-6

Picture 2-7

Battery charger remote control batteries

You will find the battery charger for the remote controls on the left under the dashboard at the driver's side (See

Picture 2-7).

Every remote control comes with 2 batteries each.

While the batteries are charged, the indicator lamp lights. As soon as they are fully charged, the lamp starts

flashing.

Fire extinguisher

One fire extinguisher is behind the co-driver's seat.

On the right behind the control box in the crane cab is the second fire extinguisher.

The fire extinguishers must be inspected every year by the authorities.

MANUAL SPIERINGS TRUCK AT5

AT5-UK-030626 01-12-09 2-7

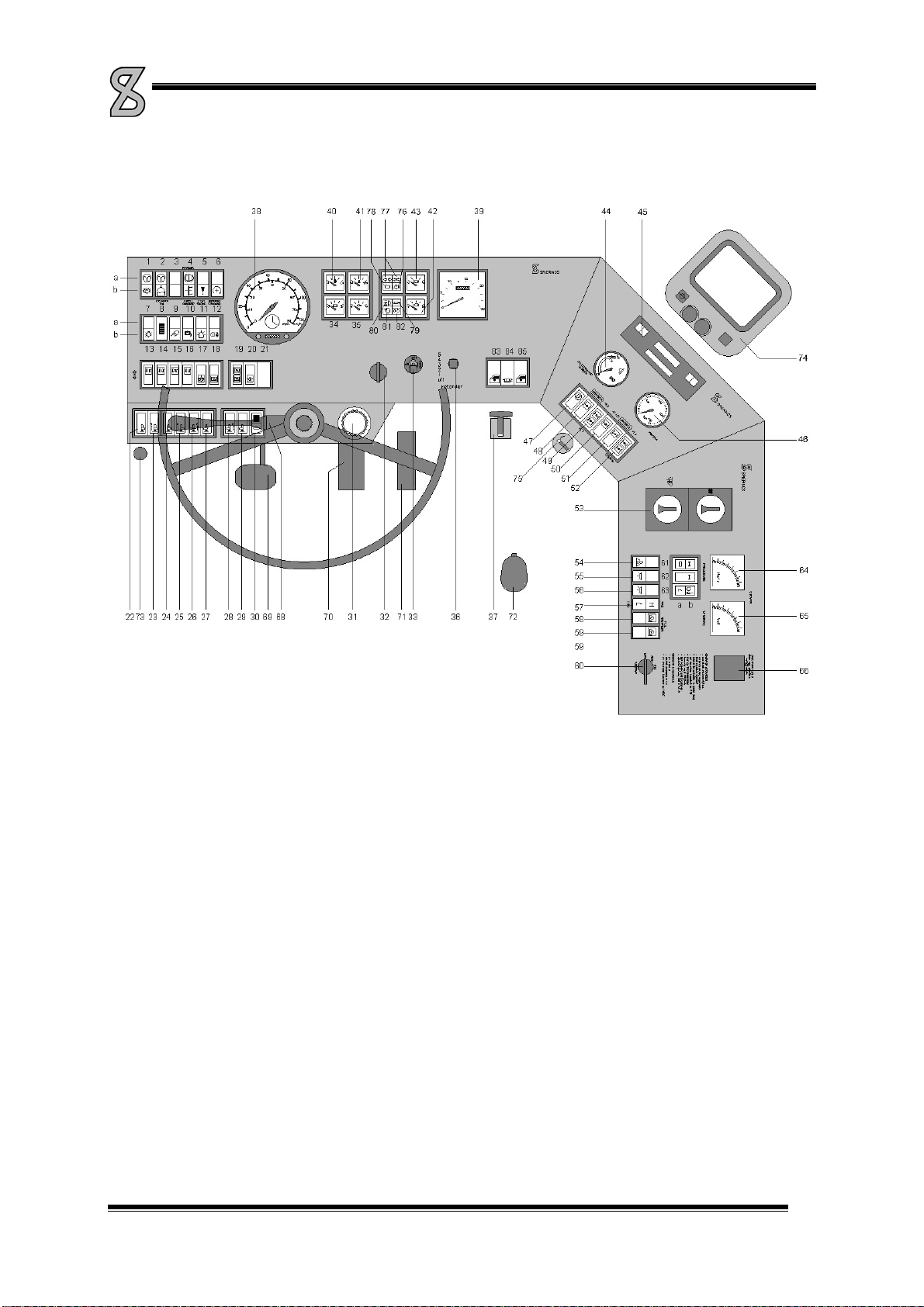

2.3. Control Panel

1a Indicator lamp steering pressure circuit

1b Indicator lamp parking brake

2a Indicator lamp steering pressure circuit 2

2b Indicator lamp coolant level

3 Not in use

4a Indicator lamp retarder on

4b Indicator lamp fluid torque converter on

5a E-gas malfunction diagnosis switch

6 Switch increase rpm

7 Light switch, off/parking light/dipped beam

8 Dimmer dashboard lighting

9 Switch work lamps

10 Switch mirror heating

11 Switch rota flares

12 Switch fog tail-light

13 Switch alls axles up/down

14 Switch axles 1 and 2 up/down

15 Switch axle 3, 4 and 5 left-hand side up/down

16 Switch axle 3, 4 and 5 right-hand side

up/down

17 Switch/indicator lamp levelling

18 Switch driving/blocking

19a Indicator lamp off the road mode

19b Indicator lamp blocking

20 Indicator lamp max. pressure outrigger-

/suspension system

21 Not in use

22 Switch outrigger beam front left-hand side

retract/extend

23 Switch outrigger front left-hand side

retract/extend

24 Switch outrigger beam rear left-hand side

retract/extend

25 Switch outrigger rear left-hand side

retract/extend

26 Switch outrigger front right-hand side

retract/extend

27 Switch outrigger beam front right-hand side

retract/extend

28 Switch outrigger rear right-hand side

retract/extend

29 Switch outrigger beam rear right-hand side

retract/extend

30 Switch outrigger controls on/off

31 Reservoir clutch fluid

32 Ignition lock

33 Speed control

34 Voltmeter batteries

35 Oil-pressure gauge (lubrication circuit)

36 Switch retarder control

37 Lever parking brake

38 Tachograph, speedometer, mileage counter,

clock

39 Revolution counter, hour counter

40 Fuel gauge

41 Coolant temperature gauge

42 Air-pressure gauge circuit 2

43 Air-pressure gauge circuit 1

44 Oil temperature gauge retarder

45 Radio

46 Gauge pump pressure steering system

47 Indicator lamp oil temperature fluid torque

converter

48 Switch/indicator lamp transverse differential

lock axle 2,3 and 5

49 Indicator lamp transverse differential lock

axle 2 and 3

50 Indicator lamp transverse differential lock

axle 5

51 Switch/indicator lamp longitudinal differential

lock

52 Indicator lamp longitudinal differential lock

53 Control heater/fan

54 Switch alarm light

55 Switch cab lighting on the left

56 Switch cab lighting on the right

57 Indicator lamp high/low gear shift

58 Indicator lamp PTO

59 Switch PTO

60 Switch position high/low gear shift, high/low,

PTO on/off

61 Switch first axle drive, power on (Option)

62 Switch/Indicator lamp first axle drive (Option)

63a Indicator lamp Low gear

63b Indicator lamp splitter Low

64 Frequency meter generator

65 Voltmeter generator

66 230 V socket

67

68 Switch for blinker, windscreen wiper, horn,

signal, full beam headlamp

69 Clutch pedal

70 Brake pedal

71 Accelerator pedal

72 Lever range selector with splitter

73 Vacuum brake/engine stop

74 Monitor reverse-/side camera (optional)

75 Cigarette lighter/24V-connection

76 Indicator lamp charging voltage batteries

77 Indicator lamp blinker

78 Indicator lamp air-pressure

79 Indicator lamp oil pressure (transmission oil)

80 Indicator lamp full beam headlight

81 Indicator lamp air cleaner

82 Indicator lamp flame starting system

83 Control electrical window (left-hand)

84 Switch aeronautical warning light on jib and

tower

85 Control electrical window (right-hand)

Picture 2-8

MANUAL SPIERINGS TRUCK AT5

AT5-UK-030626 01-12-09 2-8

1a. Indicator lamp steering pressure circuit 1

This Lamp lights up as soon as the oil pressure in steering circuit 1 is too low. Have the malfunction

repaired as soon as possible. If this lamp lights together with lamp 2a: STOP IMMEDIATELY!

1b. Indicator lamp parking brake

As long as the parking brake is engaged, this lamp is on (when starting the engine the parking

brake remains engaged as long as the air-pressure is below 5.5 bar).

2a. Indicator lamp steering pressure circuit 2

This lamp lights up as soon as the oil pressure in steering circuit 2 is too low. Have the malfunction

repaired as soon as possible. If this lamp lights together with lamp 1a: STOP IMMEDIATELY! When

the vehicle stands still, this lamp will light.

2b. Indicator lamp coolant level

This lamp lights up as soon as the coolant level is too low. Replenish coolant.

4a. Indicator lamp retarder

This lamp lights when the retarder is switched on.

4b. Indicator lamp fluid torque converter running

Refer to “Driving the Spierings Crane”

5a. E-gas diagnosis lamp/switch

This lamp starts flashing, when a error occurs.

To reset the system:

1. Turn off the engine and ignition

2. Push this button and turn on the ignition.

3. Wait for approx. 5 seconds and then release the button.

If the error is still active, the indicator lamp gives a flashing code. By means of the flashing code the

nature of the malfunction can be determined. The amount of long flashes is the tens and the short

flashes the single numbers. (if -is a long flash and .a short flash, ---... means error 23)

6. Switch increase rpm

By pressing this switch, you switch on the rpm-control.

Use this switch only when the vehicle stands still !!

MANUAL SPIERINGS TRUCK AT5

AT5-UK-030626 01-12-09 2-9

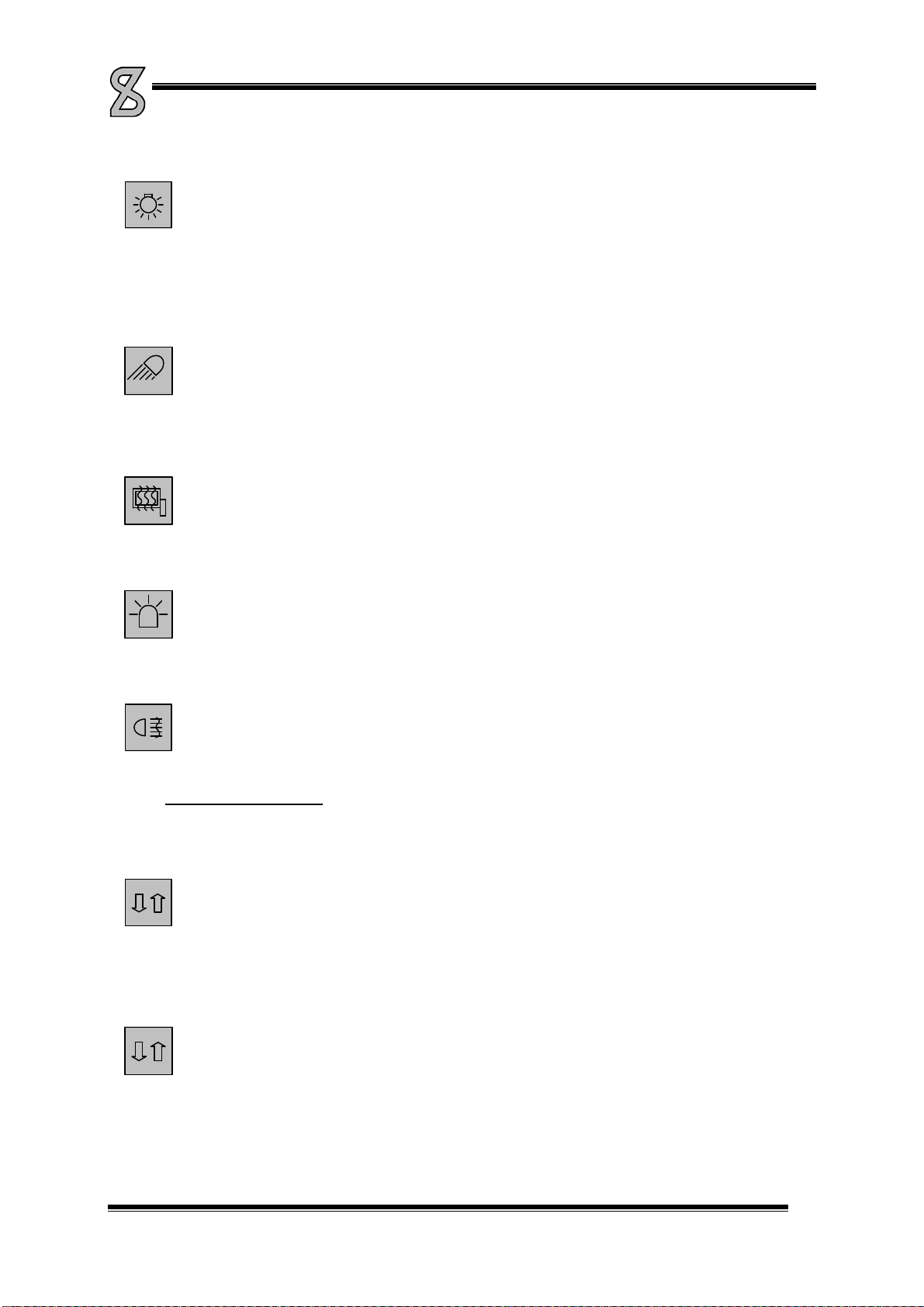

7. Light switch

By pressing this switch halfway, the parking lights are switched on. By pressing the switch all the

way, the dipped beams are switched on.

8. Dimmer dashboard lighting

When switching on the vehicle lighting also the dashboard lighting goes on. With this dimmer you

can change the dashboard lighting intensity.

9. Work Lamps

At the rear of the cab and truck are 2 work lamps each. With this switch the 4 work lamps are

switched on and off.

10. Mirror heating

With this switch the mirror heating in the left en right wing mirror is switched on and off.

11. Rotaflare

With this switch the rota flares can be switched on and off.

12. Fog tail-light

With this switch the fog tail-light on the cab can be switched on and off.

Axle Height Adjustment

13. Switch for all axles up/down

ALL

AXLES

With this switch the cylinders of all axles are moved in and out simultaneously (e.g. when

supporting the crane on outriggers).

14. Switch axles 1 and 2 up/down

AXLES

1-2

With this switch the cylinders of axles one and two can be moved in and out.

MANUAL SPIERINGS TRUCK AT5

AT5-UK-030626 01-12-09 2-10

15. Switch axle 3 left-hand side up/down

LEFT

3-4(-5)

With this switch the cylinders on the left side of the third, fourth and fifth axle can be moved in and

out.

16. Switch axle 3 right-hand side up/down

RIGHT

3-4(-5)

With this switch the cylinders on the right side of the third, fourth and fifth axle can be moved in and

out.

17. Switch/indicator lamp levelling

18. Switch/indicator lamp driving/blocking.

19a Indicator lamp off the road mode

19b Indicator lamp blocking

20. Indicator lamp max. pressure outrigger-/suspension system

This lamp goes on and a buzzer sounds at the rear outriggers as soon as the pressure in the

outrigger/suspension system becomes too high. This may happen when the outriggers, the axles or

the outrigger beams are fully in or out, or because there is an obstacle in the way when extending

the outrigger beams.

During leveling operation and when moving the axles up or down, this light could also go on. This

does not present a problem.

If there’s no action of the outrigger-/suspension system, the lighting of this lamp means, that an

error is occurred.

Outrigger Operation

(on the dashboard from left to right)

22. Switch outrigger beam front left-hand side retract/extend

MANUAL SPIERINGS TRUCK AT5

AT5-UK-030626 01-12-09 2-11

23. Switch outrigger front left-hand side retract/extend

24. Switch outrigger beam rear left-hand side retract/extend

25. Switch outrigger rear left-hand side retract/extend

26. Switch outrigger front right-hand side retract/extend

27. Switch outrigger beam front right-hand side retract/extend

28. Switch outrigger rear right-hand side retract/extend

29. Switch outrigger beam rear right-hand side retract/extend

30. Switch outrigger controls on/of

f

Switch off the outrigger controls when the outriggers are not operated or when the crane is rigged

up/rigged down or in operation. The remote control is also de-activated. Failing to switch off the

controls means the crane can not be set to the full hoisting program (full support base).

32. Ignition lock

By turning the key to the right, three positions are possible, from left to right:

0 = ignition off

1 = ignition on

2 = flame start system (push the key before turning)

3 = starting

33. Rpm/speed control.

With the speed control you can keep your current speed constant without using the accelerator

pedal. The speed control doesn’t work at a speed under 30 km/h.

Set: Switch on and adjusting the speed control.

If you are at the desired speed, move the lever to “set”. The speed control will

hold on to this speed.

If the speed control is already switched on, the speed will increase by keeping

the lever to “set”. If the speed control is switched on, you still can accelerate

by using the accelerator pedal.

When the switch “increased rpm” is switched on, you can adjust the rpm of the

engine with this lever.

MANUAL SPIERINGS TRUCK AT5

AT5-UK-030626 01-12-09 2-12

By moving the lever to setyou can decrease the speed. Keep the lever down

until you reach the desired speed.

Memo: When you brake or press the clutch, the speed control will switch off. By

moving the lever to “memo”, the speed control will switch on again. It will adjust

the speed back to the last saved speed (if speed >30 km/h). The shifted gear

has to be the same as the last time you set the speed control.

The memory will reset when you shut down the engine.

Of

f

: You can switch off the speed control by moving the lever to “off”. The

speed control will also switch off by braking, pressing the clutch and in case of

an accident.

Tip-up,Tip-down:

When you move the lever briefly to “set” or “set”, you will increase or decrease the speed with

one km/h. The difference between the current speed and the new adjusted speed can not be more

than 5 km/h.

34. Voltmeter batteries

On this meter you can read the battery condition. The meter must be in the middle (approx. 24 Volt)

35. Oil-pressure gauge lubrication circuit

When starting this gauge will read approx. 5 bar. As soon as the oil is warm approx. 3 bar.

36. Retarder (Optional)

Refer to “Slowing down using the retarder”

37. Lever parking brake

By pulling this lever. backwards the parking brake is engaged. Pulling out the knob and pushing the lever

forwards will release the parking brake. To release the parking brake, the pressure must be at least 5.5 bar.

38. Speedometer/tachograph

The truck is equipped with a VDO tachograph. On this device you can read the driving speed and the

number of kilometres driven. The tachograph also contains a clock (1). This clock drives a diagram disc. On

this disc the activities of the driver are written by means of scribers. The disc can be replaced by opening

slot 2 (See Picture 2-9). Never leave a disc in the tachograph for longer than 24 hrs (else it would overwrite

itself). In case there is no disc in the tachograph, indicator lamp 3 will light up.

By means of switches 4 and 5 the drivers' activities can be shown. Indicator lamp 3 goes on as soon as the

driving speed exceeds 80 km/h. When at a certain speed button 6 is pressed, exceeding this speed will light

up the indicator lamp. However, when the ignition is switched off, the indicator lamp will be set to 80 km/h.

The clock may be set to the correct time by operating wheel A.

For more details on how to use the tachograph we refer to the tachograph manual (in the glove

compartment).

Table of contents

Other SPIERINGS Truck manuals