Lightning: Before thunderstorms or other severe weather, disconnect the machine from wall

power (but to avoid life threatening lightning strikes, not during a storm). Similarly, before

any severe weather, disconnect all the power connections of other machines and antenna and

phone/network cables which may be interconnected so that no lightning damage or overload

results from such secondary connections.

Air circulation: Chassis openings offer ventilation and serve to protect the machine from over-

heating. Never cover or otherwise close off these openings. Never place the machine on a soft

surface (carpet, sofa, etc.). Make sure to provide for a mounting space of 4-5 cm/2 inches to

the sides and top of the unit when mounting the unit in racks or on cabinets.

Controls and switches: Operate the controls and switches only as described in the manual.

Incorrect adjustments outside safe parameters can lead to damage and unnecessary repair

costs. Never use the switches or level controls to effect excessive or extreme changes.

Repairs: Unplug the unit from all power and signal connections and immediately contact a quali-

ed technician when you think repairs are needed – or when moisture or foreign objects may acci-

dentally have gotten in to the housing, or in cases when the machine may have fallen and shows

any sign of having been damaged. This also applies to any situation in which the unit has not

been subjected to any of these unusual circumstances but still is not functioning normally or its

performance is substantially altered.

In cases of damage to the power supply and cord, rst consider turning off the main circuit

breaker before unplugging the power cord.

Replacement/substitute parts: Be sure that any service technician uses original replacement

parts or those with identical specications as the originals. Incorrectly substituted parts can

lead to re, electrical shock, or other dangers, including further equipment damage.

Safety inspection: Be sure always to ask a service technician to conduct a thorough safety

check and ensure that the state of the repaired machine is in all respects up to factory stan-

dards.

Cleaning: In cleaning, do not use any solvents, as these can damage the chassis nish. Use

a clean, dry cloth (if necessary, with an acid-free cleaning oil). Disconnect the machine from

your power source before cleaning.

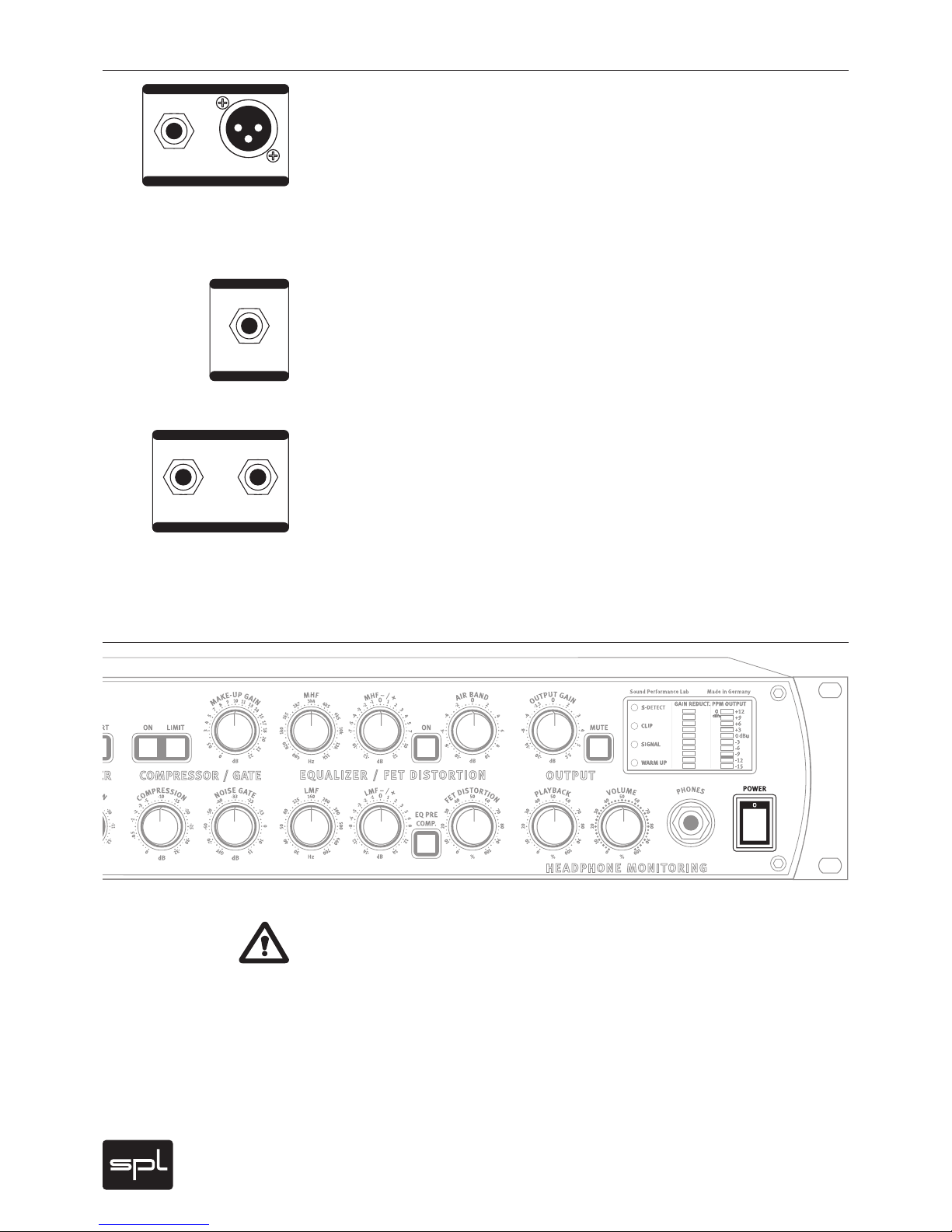

Be very careful to check that the rear chassis power selection switch is set to the correct

local line voltage position before using the unit (230 V position: 220-240 V/50 Hz, 115 V posi-

tion: 110-120 V/60 Hz)! When in doubt about a source, contact your dealer or a professional

electrician.

Before connecting any equipment make sure that any machine to be connected is turned off.

Follow all safety instructions on pages 4 and 5 and read further information about the rear

sockets and switches on pages 8, 9 an 10.

Placement

Place the unit on a level and stable surface. The unit’s enclosure is EMC-safe and effectively

shielded against HF interference. Nonetheless, you should carefully consider where you place

the unit to avoid electrical disturbances. It should be positioned so that you can easily reach

it, but there are other considerations. Try not to place it near heat sources or in direct sunlight,

and avoid exposure to vibrations, dust, heat, cold or moisture. It should also be kept away

from transformers, motors, power ampliers and digital processors. Always ensure sufcient

air circulation by keeping a distance of 4-5 cm/2 inches to the sides and top of the unit.

Important Security Information

Hook Up