10

OPERATION

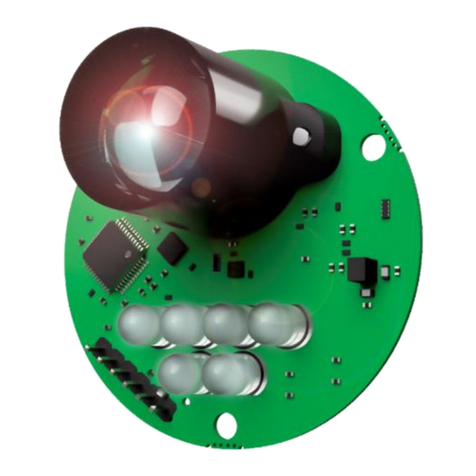

The HEI igniter is a Class 3 ignition source and is only in service during an ignition time trial dura-

tion. The HEI can operate during ignition and during oil gun shutdown and purge. Depending on the

application, the spark rod can be set in a fixed position or attached to a retraction assembly to move

it out of firing position. The spark rod should be fitted with the retraction assembly whenever the

HEI spark rod tip will be exposed to continuous temperatures above 149° C (300° F).

The burner management system provides the control signal that energizes the HEI during the igni-

tion time trial period. The power unit transforms the signal into short 12-joule discharges at the rate

of three sparks per second. The cable assembly transmits these discharges to the spark rod assembly.

TROUBLESHOOTING

If the HEI assembly malfunctions, ensure that the procedures described in the Commissioning Sec-

tion have been performed successfully. If problems persist, refer to Table 1 for troubleshooting infor-

mation.

WARNING: Hazardous voltage is present and serious injury to personnel can occur. Before open-

ing the power pack’s hinged cover, disconnect the electrical supply from the box. Allow at least 2

minutes for the capacitor to discharge. Exercise extreme care when the power pack cover is open.

MAINTENANCE

Fireye recommends performing the following preventive maintenance every six months.

SPARK TIP INSPECTION AND MAINTENANCE

Remove the spark rod from the guide tube and inspect the spark tip for damage due to overheating,

excessive use, and mishandling of equipment. A concave shape of the spark tip end represents nor-

mal wear. If the semiconductor material is chipped, cracked, or eroded, replace the spark tip. If the

inner electrode, tip center, or tube shows deterioration, wear, or erosion, also replace the spark

tip.When replacing the spark tip, observe the following steps:

1. Disconnect all electric power from the power unit, and ensure that all residual voltage is dissi-

pated. (See Safety section.)

2. Remove and replace tip using 1/2 inch wrench flats.

Table 1: Troubleshooting

SYMPTOM PROBABLE CAUSE REMEDY

Ceramic spark gap or spark

gap tube not flashing.

1. Input voltage low.

2. Power pack failure.

1. Provide correct voltage.

2. Replace power pack.

Ceramic spark gap or spark

gap tube weak or erratic.

1. Spark tip fouled and shorting

2. Tip insulator cracked or

damaged.

3. High tension cable inside rod

broken or insulation damaged.

1. Replace tip assembly and

adjust tip to gun setting as

specified in drawing.

2. Replace tip assembly and

adjust tip to gun setting as

specified in drawing.

3. Replace cable assembly.

Adjust tip to gun settings on

specified drawing.