SPX POWER TEAM HT75 User manual

MODEL C

IN-LINE HYDRAULIC FLOW TESTER

The 75 GPM (300l/min.) and 200 GPM (750 l/min.) inline hydraulic flow testers are compact, self-contained, portable

instruments for testing hydraulic systems in the shop or field. To simplify identification of the testers in this instruction

sheet, the two versions are identified by their English (GPM) flow capacities. Individual components are identified in

Figure 3.

SAFETY PRECAUTIONS

WARNING

●●Before operating the pump, all hose connections must be tightened with the proper tools. Do not

overtighten. Connections should only be tightened securely and leak-free. Overtightening can cause

premature thread failure or can cause high pressure fittings to split at pressures lower than their rated

capacities.

●●Should a hydraulic hose ever rupture, burst, or need to be disconnected, immediately shut off the pump.

Never attempt to grasp a leaking pressurized hose with your hands. The force of the escaping hydraulic

fluid could cause serious injury.

●●Do not subject the hose to potential hazard such as fire, sharp surfaces, heavy impact or extreme heat or

cold. Do not allow the hose to kink, twist, curl or bend so tightly that the oil flow within the hose is

blocked or reduced. Periodically inspect the hose for wear because any of these conditions can damage

the hose and result in personal injury.

●●Do not use the hose to move attached equipment. Stress may damage the hose and cause personal injury.

●●Hose material and coupler seals must be compatible with the hydraulic fluid used. Hoses also must not

come in contact with corrosive materials such as creosote-impregnated objects and some paints. Consult

the manufacturer before painting a hose. Never paint the couplers. Hose deterioration due to corrosive

materials may result in personal injury.

SET-UP

Battery Replacement and Inspection

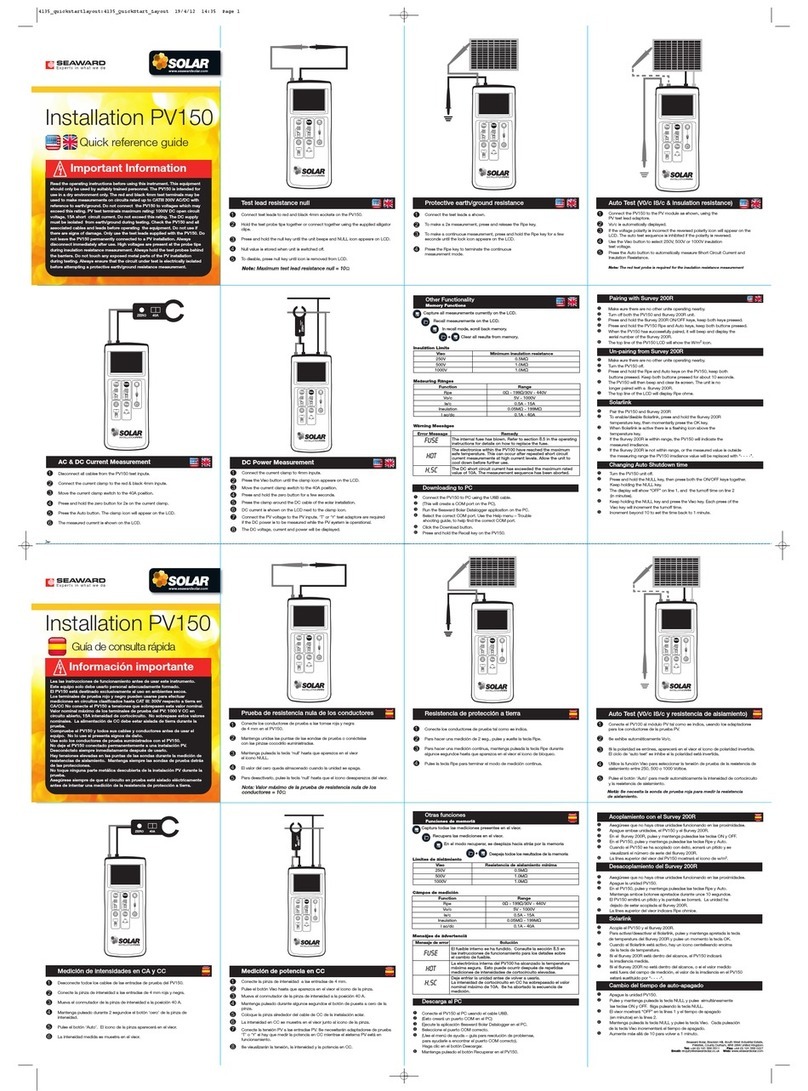

The testers are provided with two "C" size

batteries that are pre-installed at the factory.

To replace the batteries or inspect the unit

during trouble-shooting of either a 75 or 200

GPM tester, remove the three screws #16972

holding the digital display panel #352004 and

carefully lift the panel out of the opening. Do

not damage the circuit boards or components.

There is a "LO BAT." indicator on the LCD

display that shows when the batteries are low.

Battery life can be 500 hours. There is an

automatic shut off feature after 5 minutes and

the unit will have to be powered up after a time

out. Use only new "C" size alkaline batteries as

replacements. If the batteries have been jarred

out of their holder by impact, inspect the unit for

other possible damage.

Form No. 103509

HT75

HT200

Operating Instructions for:

Sheet No. 1 of 3

Rev. Date: 28 July 2005

"C" SIZE

BATTERIES

DIGITAL

DISPLAY

PANEL

Figure 1

© SPX Corporation

Tech. Services: (800) 477-8326

Fax: (800) 765-8326

Order Entry: (800) 541-1418

Fax: (800) 288-7031

SPX Corporation

5885 11th Street

Rockford, IL 61109-3699 USA

Internet Address:

http://www.powerteam.com

®

Operating Instructions, Form No. 103509, Back sheet 1 of 3

Fittings

75 GPM Tester: The inlet and outlet ports (shown in Figure 2) are designed for SAE straight o-ring union adapters,

1-1/16-12 male thread by 3/4 NPSM female straight union. When the tester is not being used,

always insert the port plugs to protect the unit from damage or contamination.

200 GPM Tester: The inlet and outlet ports (shown in Figure 2) are designed for SAE Standard 1 1/2 inch, 4-bolt split

flange fittings. Flange bolts must be 1/2-13 UNC by 1 1/2 inch long SAE Grade 5 with spring

lockwashers, torqued at 55/65 ft. lbs. When the tester is not being used, always assemble the

cover plates to protect the tester from damage or contamination.

Figure 2 - TESTER CONNECTION PORTS

OUTLET

PORT

INLET

PORT

HOSE CONNECTOR

& SAFETY DISC

Figure 3

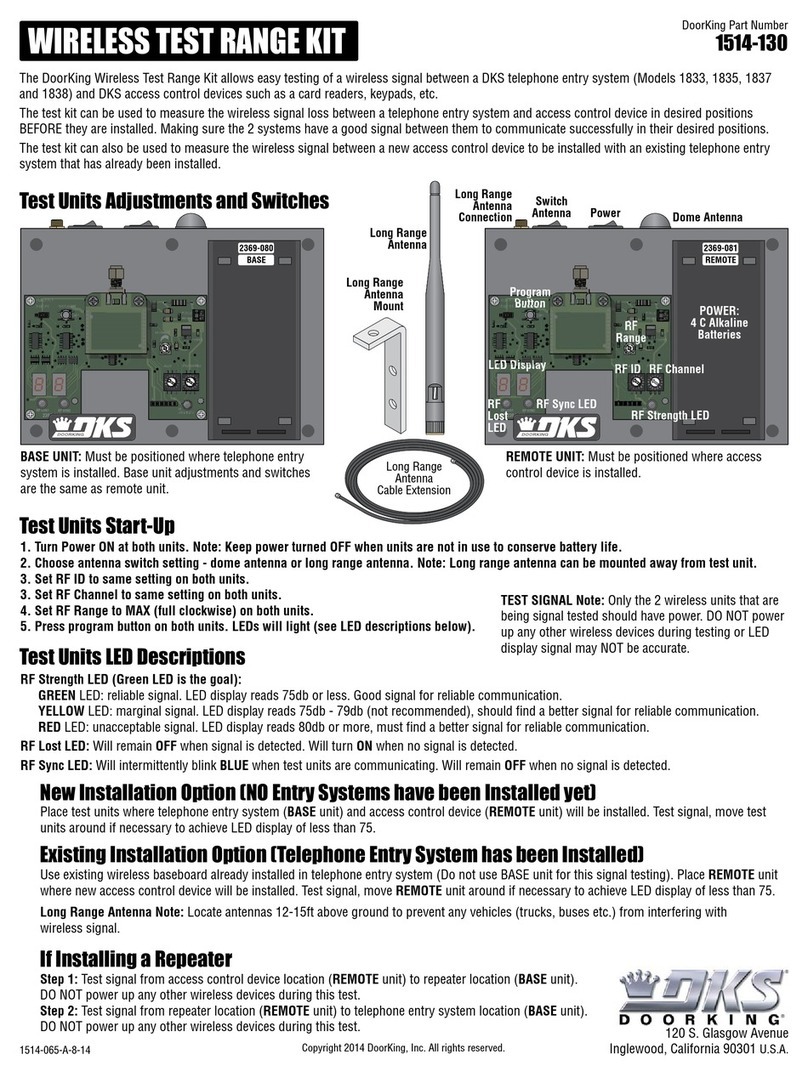

Operating Controls

HIGH

PRESSURE

GAGE

GAUGE

SNUBBER

KNOB

POWER

"ON/OFF"

SWITCH

FLOW / TEMP

(includes

bar graph)

FLOW / TEMP

SWITCH

(hold for temp)

ENGLISH / METRIC

SWITCH

PRESSURE

CONTROL

VALVE

LOW PRESSURE

GAGE

Operating Controls

Both testers have similar operating controls.

Refer to Figure 3.

POWER: Push this switch to turn the tester

ON; push to turn the tester OFF. When the

tester is not being used, the power switch

may be used to turn if off or it will

automatically shut off in five minutes.

DIGITAL DISPLAY: The display shows flow

and temperature readings, depending on the

setting of the FLOW/TEMP switch. An

analog bar at the bottom of the display

shows a real-time analog representation of

the portion of full-scale reading displayed.

LO BAT.: This indicator alerts the operator that

battery power is low, which can result in

false readings.

FLOW/TEMP: When the FLOW/TEMP switch

is held down, fluid temperature is displayed

on the meter temperature scale in either

degrees Fahrenheit and Celsius. When the

toggle switch is released, the meter returns

to its previous mode "flow". Flow is

displayed by default when the unit is on.

ENGLISH/METRIC: Units of flow or

temperature are alternately selected in

ENGLISH or METRIC whenever this switch

is pushed.

Hoses

1. Connect the pressure hose from the pump or

pressure line of the system to the tester INLET port.

2. Connect the return hose to the tester OUTLET port.

NOTE: If the hoses are connected wrong, the tester

gives flow readings but the pressure control valve

does not function. No damage to the unit occurs.

DIGITAL

DISPLAY

Operating Instructions Form No. 103509

PRESSURE CONTROL VALVE: The pressure control valve regulates system pressure by restricting the flow to

develop back pressure in the system. The control valve maintains the pressure setting during and after change in

flow. To increase pressure, turn the control valve clockwise; to reduce pressure, turn the control valve

counterclockwise.

WARNING: Before testing the system, open the pressure control valve all the way by turning

the valve counterclockwise. Increase pressure SLOWLY during the test.

NOTE:

●●Oil the pressure control valve threads regularly.

●●Each time the flow tester is connected to a hydraulic system for testing, the unit may be noisy the first

time pressure is increased with the control valve. The noise is caused by air trapped in the internal parts

of the control valve. To flush the air out, increase pressure to approximately 2000 PSI and then back to 0

PSI.

●●It may be difficult to adjust the pressure control valve when testing in a closed center system or under

high back pressure. Even when the control valve stem threads are lubricated with a good grade of oil, the

valve becomes difficult to adjust by hand at approximately 1100 PSI back pressure and almost impossible

to adjust by hand at approximately 1600 PSI back pressure.

PRESSURE GAUGES: Pressure readings are taken from the high pressure (0-6000 PSI, 0-410 BAR) and low

pressure (0-600 PSI, 0-41 BAR) gauges on the flow block. As pressure increases, the low pressure gauge gives

readings up to 500 PSI (35 BAR) and then cuts out, switching to the high pressure gauge.

GAUGE SNUBBER KNOB: A gauge snubber knob is located at the lower left corner of the gauge block. To dampen

(slow) the movement (pulsation) in the gauge needles, turn the snubber knob clockwise at a low pressure setting.

NOTE: When the gauges are dampened, the reaction time of the needles will be slow. Build pressure very

slowly to allow time for the needles to react.

OVERLOAD PROTECTION SAFETY DISC: A safety disc located at the back of the tester (See Figure 2) protects the

flow tester from extreme pressure. If pressure exceeds the ranges listed in the following chart, the disc ruptures,

relieving oil and reducing pressure before damage can occur. A hose connector surrounds the disc to act as a shield

against oil spray should the disc rupture. For more protection, a 1 1/4 inch I.D. hose should be inserted into the

connector and clamped in place. This hose should be long enough to direct oil back to the reservoir or another

container.

Safety Disc Burst Range

75 GPM 5510/6093 PSI @ 60° F

5250/5835 PSI @ 160° F

200 GPM 5220/6790 PSI @ 105° F

6000/7000 PSI @ 72° F

Sheet No. 2 of 3

Rev. Date: 28 July 2005

Operating Instructions, Form No. 103509, Back sheet 2 of 3

TYPICAL TESTING PROCEDURES

The following test procedures show how the tester can be used to locate a problem in the hydraulic system by

checking the efficiency of each component. In this example, the system consists of a reservoir, pump, relief valve,

directional control valve and double-acting cylinder.

EXAMPLE OF A PROBLEM: The cylinder’s piston moves out at almost normal speed under no load, but

gradually slows down as the load increases.

1. Check all hoses and connections for leakage before beginning any test.

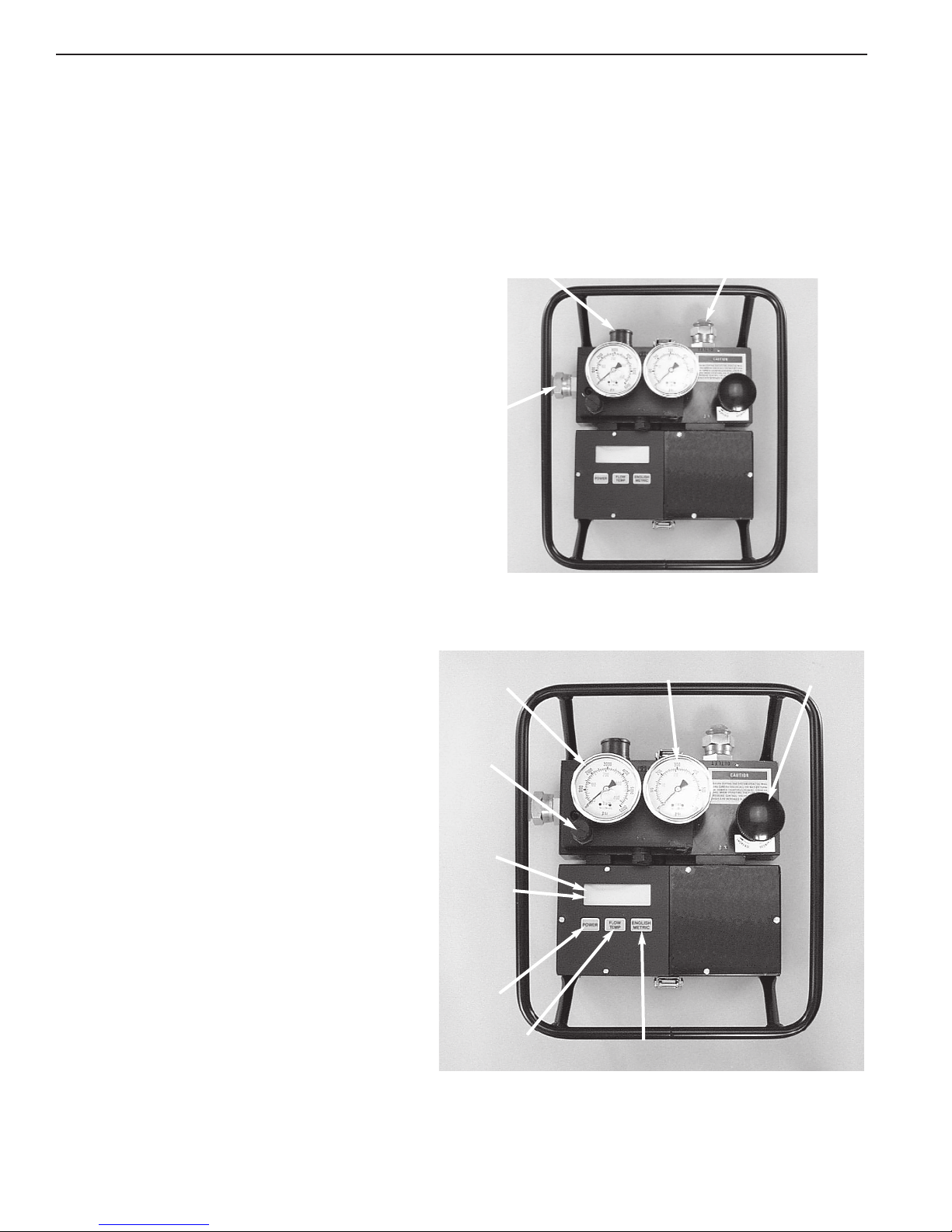

TESTING THE PUMP (See Figure 4)

IMPORTANT: Do not allow the pressure reading on the tester gauges to exceed the maximum relief valve

pressure of the pump. Serious damage to the pump can result because the system relief valve no longer

protects the pump.

1. Shut the pump OFF, and place the control valve in the neutral position. Disconnect the line between the pump and

relief valve.

2. Connect line “A” (outlet from the tester) to the pressure port of the relief valve.

3. Connect line “B” (inlet of the tester) to the discharge port of the pump.

4. Open the pressure control valve on the tester all the way by turning the knob counterclockwise several turns. Turn

the dampener knob counterclockwise several turns.

5. Start the pump and set engine RPM for the rated speed of the pump (equipment manufacturer’s specific RPM

level for a given rate of flow).

Symptom: If the action of the gauges is erratic, and severe pulsations occur even after the dampener knob has been

adjusted, cavitation could be a problem. Solution: Check the oil level, filter and suction line.

6. Induce a load on the pump with the tester pressure control valve at approximately 50% of the maximum system

pressure. Slowly increase pressure by turning the control valve clockwise while watching the pressure gauges on

the tester.

7. When normal operating temperature is reached (per manufacturer’s specification), open the tester pressure

control valve. Record the volume at low pressure displayed on the flow display.

8. Increase pressure by turning the handle clockwise, maintaining required engine RPM at all pressure check points.

Record the volume at various increments up to maximum pressure.

9.

Open the pressure control valve

and shut off the pump. Compare the test result against the manufacturer’s

specifications.

Symptom: Low flow readings. Solution: Repair pump, suction line or filter. If the flow readings are OK, test the

relief valve next.

Figure 4

Operating Instructions Form No. 103509

TESTING THE RELIEF VALVE (See Figure 5)

IMPORTANT: When testing the system relief valve, refer to the valve manufacturer’s manual to determine the

relief valve setting.

1. Shut the pump OFF, and place the control valve in the neutral position. Disconnect the line between the relief

valve and the directional control valve.

2. Connect the line “A” (outlet from the tester) to the pressure port of the directional control valve.

3. Connect the line “B” (inlet of the tester) to the discharge line of the pump after the relief valve.

4. Open the pressure control valve on the tester all the way by turning the knob counterclockwise several turns. Turn

the dampener knob counterclockwise several turns.

5. Start the pump and set engine RPM for the rated speed of the pump (equipment manufacturer’s specific RPM

level for a given rate of flow).

6. When normal operating temperature is reached (per manufacturer’s specification), maintain the required engine

RPM at all pressure check points.

7. Turn the tester pressure control valve clockwise until the relief valve setting has been reached. (The relief valve

setting is easily recognized. The pressure gauge needle will fluctuate, indicating unloading or bypassing of oil over

the relief valve. The GPM indicator will shown a decrease in flow through the tester indicating that the balance of

pump output is going through the relief valve.) Record volume and pressure at various increments to maximum

pressure.

Symptom: The pressure at which the flow falls to 0 (the relief pressure) is lower than maximum operating pressure.

Solution: Adjust the relief valve.

Symptom: The flow reading on the tester is not the same as the pump. Solution: The relief valve is leaking and

must be repaired. If the problem is not in the relief valve, test the directional valve next.

TESTING THE DIRECTIONAL VALVE (See Figure 6)

1. Shut the pump OFF, and place the control valve in the neutral position. Disconnect the line between the cylinder

and the tee. Plug the port on the tee.

2. Connect line “A” (outlet from the tester) to reservoir.

3. Connect line “B” (inlet of the tester) to the outlet port on the directional control valve.

4. Open the pressure control valve on the tester all the way by turning the knob counterclockwise several turns. Turn

the dampener knob counterclockwise several turns.

5. Start the pump and set engine RPM for the rated speed of the pump (equipment manufacturer’s specific RPM

level for a given rate of flow).

6. When normal operating temperature is reached (per manufacturer’s specification), shift the directional valve from

neutral to the advance (lift) position. This directs the oil to line “B” (the inlet port of the tester).

7. Turn the tester pressure control valve clockwise until the relief valve setting has been reached. Record volume and

pressure at various increments to maximum pressure, maintaining required engine RPM at all pressure check

points.

8. Repeat this test procedure on the other side of the directional control valve.

Symptom: Full volume and pressure can not be reached. Solution: Repair or replace the directional

control valve. If full rated volume at full pressure is recorded, the problem must be in the cylinder.

Figure 5

Figure 6

Sheet No. 3 of 3

Rev. Date: 28 July 2005

Operating Instructions, Form No. 103509, Back sheet 3 of 3

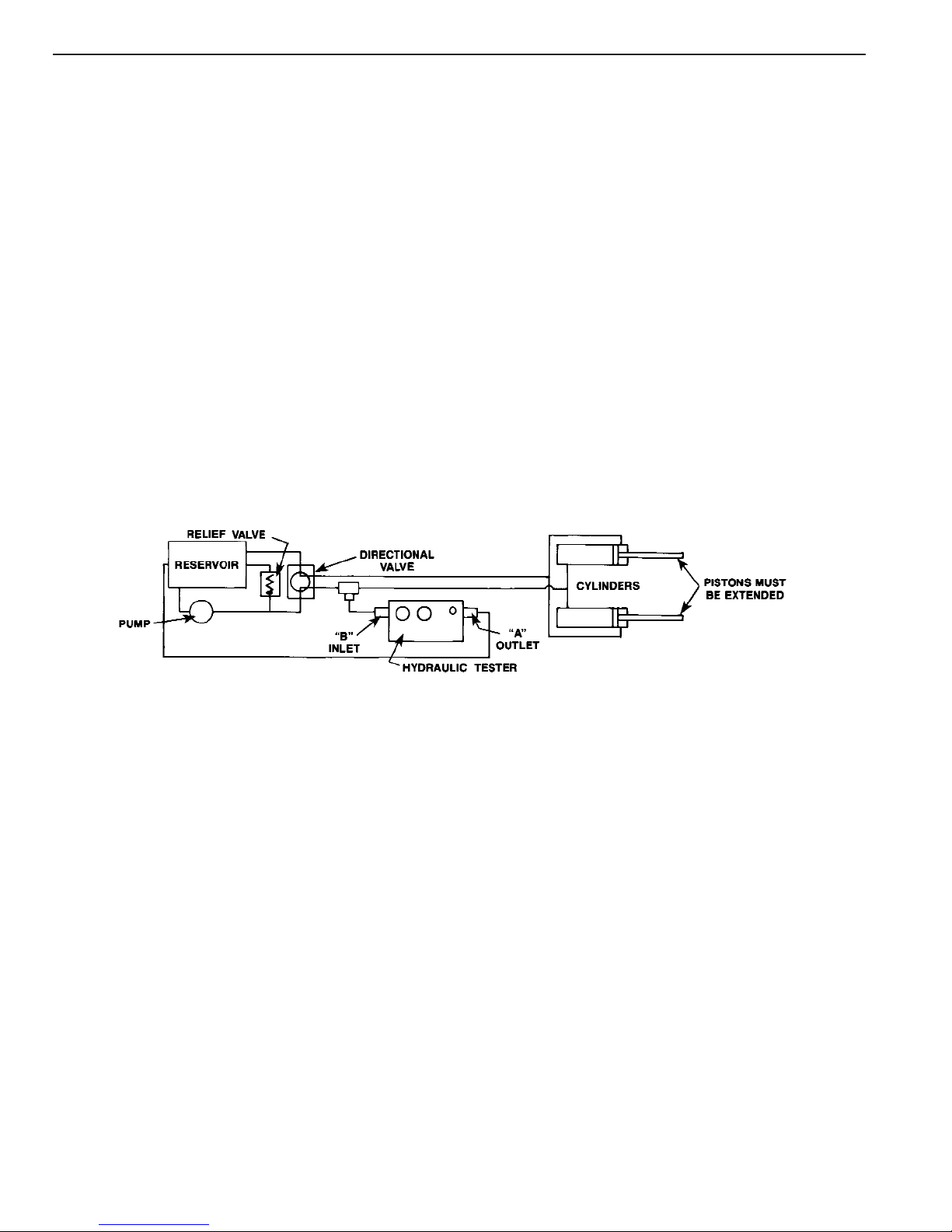

TESTING WITH A TEE CONNECTION (See Figure 7)

The following procedure illustrates a method of testing overall circuit performance.

1. Shut the pump OFF, and place the control valve in the neutral position.

2. Connect line “A” (outlet from the tester) to reservoir.

3. Connect line “B” (inlet of the tester) to a tee connection in the circuit between the control valve and cylinder.

4. Open the pressure control valve on the tester all the way by turning the knob counterclockwise several turns. Turn

the dampener knob counterclockwise several turns.

5. Start the pump and set engine RPM for the rated speed of the pump (equipment manufacturer’s specific RPM

level for a given rate of flow).

6. When normal operating temperature is reached (per manufacturer’s specification), shift the directional valve from

neutral to the cylinder extend position.

7. Partially close the tester pressure control valve to allow the cylinders to extend and “dead-end.” NOTE: If design

characteristics of the cylinder make a “dead-end” inadvisable, a greater-than-capacity load can be put on

the unit to simulate dead-ending. Oil will flow to the reservoir either through the tester or through leaks in

components of the circuit.

8. Record the flow at no load. Increase the load on the circuit by slowly closing the tester pressure control valve.

Record the flow at various pressure check points, maintaining required engine RPM. The difference in readings

indicates oil lost because of leaks somewhere in the circuits.

Figure 7

This manual suits for next models

1

Table of contents