2

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

EN

Terminal Box

Series 8150/1, Series 8150/2

Contents

1 General Information ............................................................................................3

1.1 Manufacturer .......................................................................................................3

1.2 About these operating instructions ......................................................................3

1.3 Further documents ..............................................................................................3

1.4 Conformity with standards and regulations .........................................................3

2 Explanation of the symbols .................................................................................4

2.1 Symbols in these operating instructions .............................................................4

2.2 Symbols on the device ........................................................................................4

3 Safety ..................................................................................................................4

3.1 Intended Use .......................................................................................................4

3.2 Personnel qualification ........................................................................................4

3.3 Residual risks ......................................................................................................5

4 Transport and storage .........................................................................................7

5 Product selection, project engineering and modification .....................................7

5.1 Additional through holes in flange plates ............................................................8

5.2 Additional through holes in the enclosure ...........................................................9

5.3 External attached components (cable entries, stopping plugs, breathers) .......11

5.4 Internal built-in components (conductors, terminals, fuses) ..............................12

6 Mounting and installation ..................................................................................15

6.1 Mounting/dismounting, operating position ........................................................15

6.2 Installation .........................................................................................................16

7 Commissioning .................................................................................................19

8 Maintenance, overhaul, repair ..........................................................................19

8.1 Maintenance .....................................................................................................19

8.2 Maintenance .....................................................................................................19

8.3 Repair ...............................................................................................................19

9 Returning the device .........................................................................................20

10 Cleaning ............................................................................................................20

11 Disposal ............................................................................................................20

12 Accessories and Spare parts ...........................................................................20

13 Annex A ............................................................................................................21

13.1 Technical data ...................................................................................................21

14 Annex B ............................................................................................................23

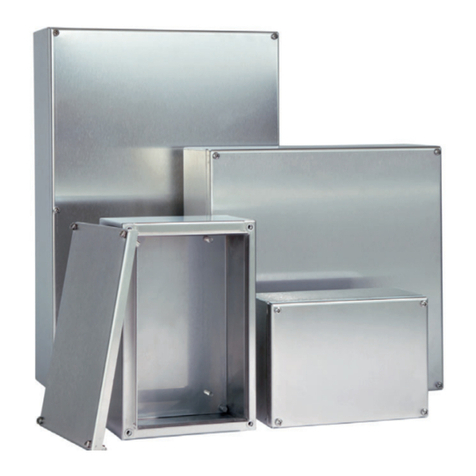

14.1 Dimensions / fastening dimensions ..................................................................23