Page 3/ 30

Contents

Introduction .........................................................................................................................................2

Read before use ...................................................................................................................................2

1. DECLARATION OF CONFORMITY......................................................................................................4

2. INTENDED USE .................................................................................................................................5

3. SAFETY INSTRUCTIONS.....................................................................................................................5

4. IDENTIFICATION AND PARTS............................................................................................................6

4.1. Identification plate ............................................................................................................................ 6

4.2. Maintenance and parts service ......................................................................................................... 6

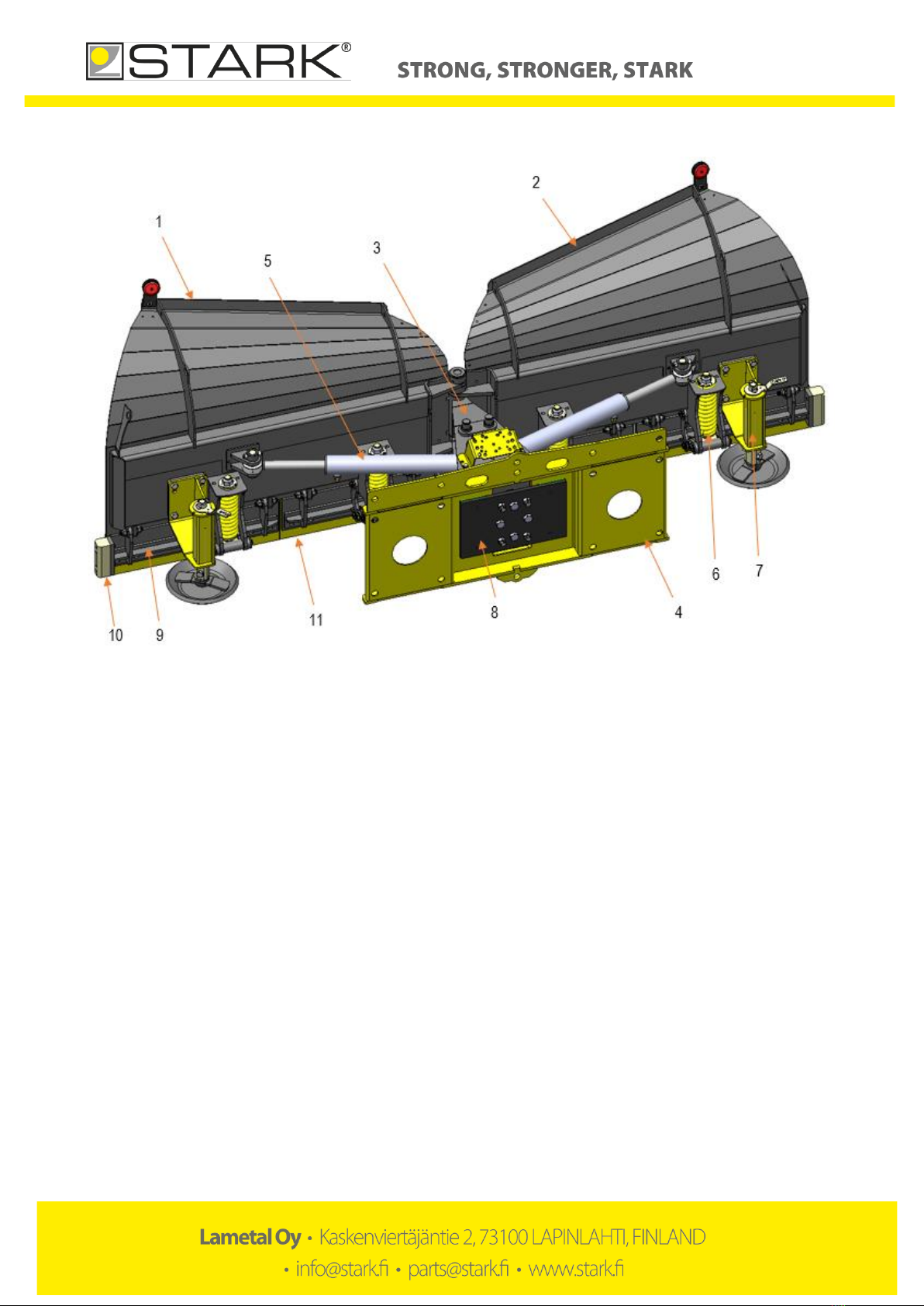

5. MAIN PARTS OF THE PLOW..............................................................................................................7

6. ATTACHING THE PLOW ....................................................................................................................8

6.1. Attaching the plow to a base machine.............................................................................................. 8

7. USING THE PLOW.............................................................................................................................9

7.1. Operating instructions....................................................................................................................... 9

7.2. Permitted driving directions for the plow in different positions .................................................... 10

7.3. Removing packed snow................................................................................................................... 13

7.4. Adjusting RELAX -blade system (NLR-models)................................................................................. 14

7.5. Adjusting ACS (Anti Collision System) -springs (NL-models) ........................................................... 16

7.6. Adjusting flotation........................................................................................................................... 18

7.7. Adjusting support legs..................................................................................................................... 19

7.8. Adjusting blades .............................................................................................................................. 19

7.9. Adjusting perforated blades............................................................................................................ 20

7.10. Adjusting flat blades .................................................................................................................... 21

7.11. Detaching the plow...................................................................................................................... 22

7.12. Transferring the plow .................................................................................................................. 22

7.13. Plow accessories.......................................................................................................................... 22

8. USING AND MAINTAINING.............................................................................................................23

8.1. General cautions concerning use and maintenance of the plow.................................................... 23

8.2. Tightening torque............................................................................................................................ 23

8.3. Daily maintenance........................................................................................................................... 23

8.4. Maintenance after 10 hours............................................................................................................ 23

8.5. Maintenance every 50 hours or weekly.......................................................................................... 23

8.6. Lubrication points............................................................................................................................ 24

9. HYDRAULICS...................................................................................................................................25

9.1. 2- and 3-hose hydraulics.................................................................................................................. 25

9.2. 4- and 5-hose hydraulics.................................................................................................................. 26

9.3. Diagonal valve (3/2 hoses) .............................................................................................................. 27

9.4. Relief valve....................................................................................................................................... 28

10. WARRANTY TERMS AND CONDITIONS ........................................................................................30