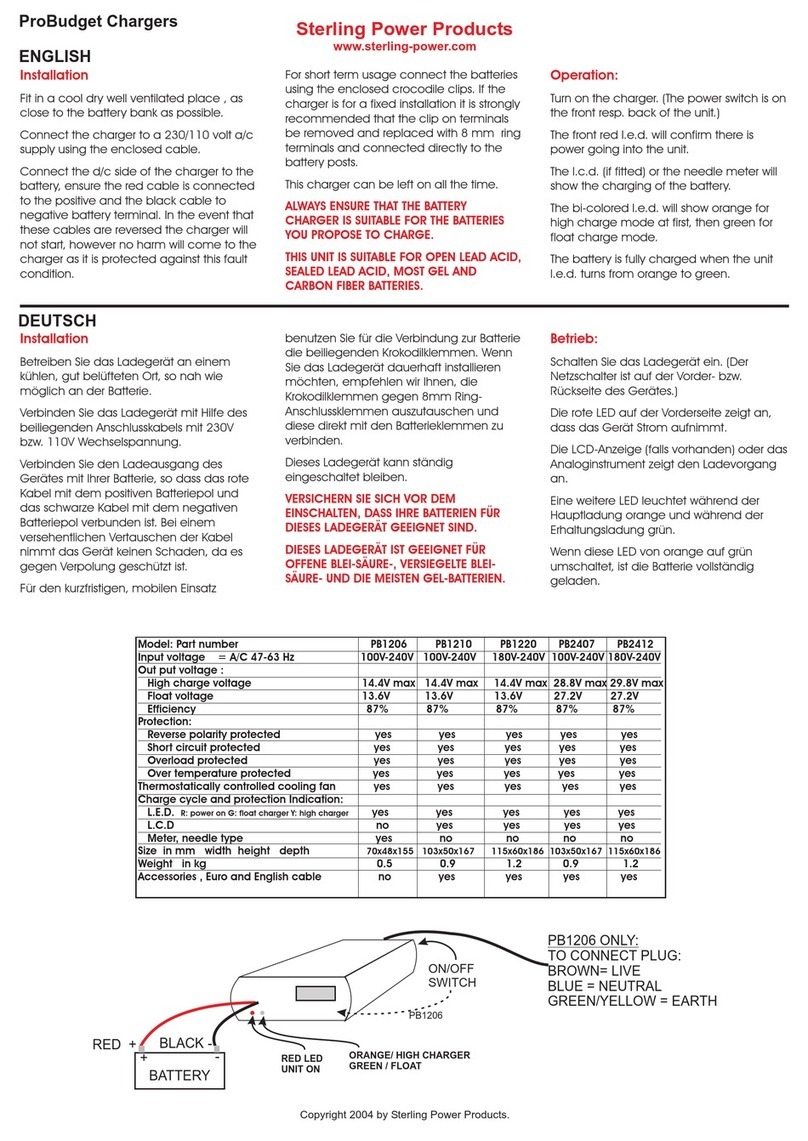

Sterling Power Products

Copyright

and the 230V /110V AC isolated, then, connect the input

positive cable first, then the output positive cable, then

the negative.

Remote sense, because the unit can compensate for

voltage drop (if required and fitted) it is best to

fit the unit as close as possible to the battery charger.

in the cable

Setting the Main Battery charger ( not the module ).

The main a/c mulatable output battery charger must be

set to the lowest battery type setting , ie if you want to

charge a gel( 14.4 ) and a open lead acid battery ( 14.8 )

then the main charger must be set at the lowest voltage (

14.4 ) the battery module can only increase the voltage

above the main charger it cannot decrease the main

charger voltage. Failure to do this will prevent the Battery

chemistry unit from working correctly

Battery type selection -

Battery temperature sensor:

Battery temp trip

This program is, as per the

recommendation of Exide, set at a voltage of 14.4V for

about 10-12 hrs. The unit then drops to float.

This is set to a maximum

charging voltage of 14.4V with a software program to

match most of these battery types. Some AGM batteries

only want 14.1V, if so, set the unit to the American gel

setting. If in doubt ask the battery supplier.

, should only be used with a Battery

Management System for the batteries to balance and

protect them.

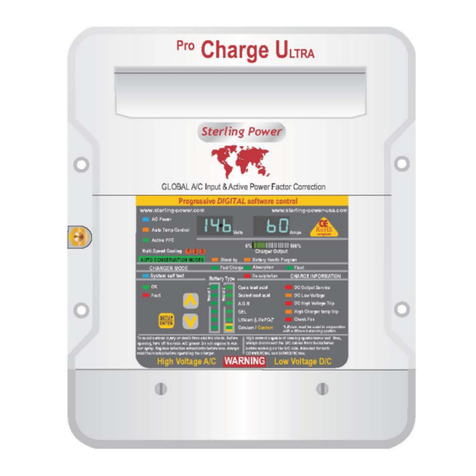

this is simple to do, simply

remove the lid exposing the rotary switch (number 16 on

Fig 1). Look closely for the small arrow to indicate what

position it is pointing at. On start up the top blue (number

7 on fig 1) LED will flash xnumber of times to indicate the

setting. E.g. 4 flashes when unit fires up every time =

position 4 on the switch. If this is not the correct setting

then simply rotate the knob to correct the position. Then

switch the battery charger off ( wait a few minutes ) then

back on again and the flashes will change. Ensure you

have the correct number of flashes for your battery type

(note: the incorrect battery setting for a few minutes will

not cause any damage to your batteries).

The battery type voltages are on the front label of the

product and on the table over leaf.

After selecting the battery type, make sure the voltages

fall into the battery companies range for their battery

requirements. It may be necessary to use a different

o

battery type to obtain the correct voltages you need for

your battery. Remember, it's the voltages which are more

important than our battery types - we have simply tried to

decipher a quagmire of different companies’

requirements and group them in some sort of order for

the general public to make what sense of them they can.

The voltage requirements of the battery company will

override our recommendations as it is them who are

supporting the battery warranty etc. Adjust to suit their

requirements.

o

Some basic battery type information

o

Gel / Exide spec.

Gel U.S.A. spec.

Sealed lead acid / A.G.M.

Lithium LiFePO4

Flooded

For some reason known to someone,

but not to us, the American gel manufactures want a

different charging regime than the European ones. Don't

ask us why, if in doubt, ask the battery supplier, this

setting has a max charging voltage of 14.1V.

Fit the unit, as close as possible (taking into account the

above requirements) to the battery charger.

If you must fit it in an enclosed engine room (i.e. a small

yacht, where the engine room is fully enclosed with

sound proofing all over the place) then fit any equipment

as low as possible. It is best to fit it outside the engine

room near the battery box.

Simply connect one of

the enclosed temperature sensor to a battery terminal

post (negative) and to the 2 x small terminals marked

battery temperature sensor. Simply insert one wire into

each side, there is no polarity on these wires. Make sure

you do not crush the temp sensor which is a small device

inside the yellow ring terminal, as this will destroy the

processor chip. The output voltage will be reduced in

accordance with manufacturer’s battery charging

temperature curves. In the event of the battery

temperature increasing due to battery failure, if the

batteries exceeds 55 C, the unit would trip.

( daisy chain ) or BMS trip. This unit

has a circuit which, if opened circuited, the unit will stop

working (connector 1 on the information drawing). The

product comes with a link wire across the two terminals

to neutralise this trip, if you wish to use this circuit to

daisy chain or allow a BMS to trip the unit then remove

the link and add the devices. This can be used to daisy

chain high temp trips (the blue ones). These are

normally 60 C temperature trips, as such, they can be

linked in series to any number of batteries. If a battery

or open lead acid batteries, where you can reaches over 60 C the link is broken - the product trips.

unscrew the lid of the battery and are able to top it up with Or, this can be linked to a BMS ( Battery Management

water, these are by far the best types for fast charging System) for lithium this can break the circuit to trip the

and long life (max voltage 14.8V). high charged side of the unit.

WHAT CABLE TO USE (mm sq)

A charger or inverter up to cable run distance 0-1.5m 1.5m - 4m

0-25 amps 6 mm sq 10 mm sq

25-45 amps 16 mm sq 25 mm sq

45-85 amps 25 mm sq 35 mm sq

85-125 amps 35 mm sq 50 mm sq

Please note that if there is a problem obtaining for example 90 mm sq cable, simply

Use 2 x 50 mm sq , or 3 x 35 mm sq , the cable is simply copper, and all you require

Is the copper. It does not matter if it is one cable or 10 cables as long as the square

area adds up. Performance of any product can be improved by thicker cable, so, if in doubt round up.