Strand Lighting CD80 User manual

Table of contents

Other Strand Lighting Lighting Equipment manuals

Strand Lighting

Strand Lighting Circular Saw User manual

Strand Lighting

Strand Lighting Wallrack User manual

Strand Lighting

Strand Lighting ClassicPalette User manual

Strand Lighting

Strand Lighting Contact Power Pack Original operating instructions

Strand Lighting

Strand Lighting EC21 User manual

Strand Lighting

Strand Lighting 100 User manual

Strand Lighting

Strand Lighting MX User manual

Strand Lighting

Strand Lighting MX Service manual

Popular Lighting Equipment manuals by other brands

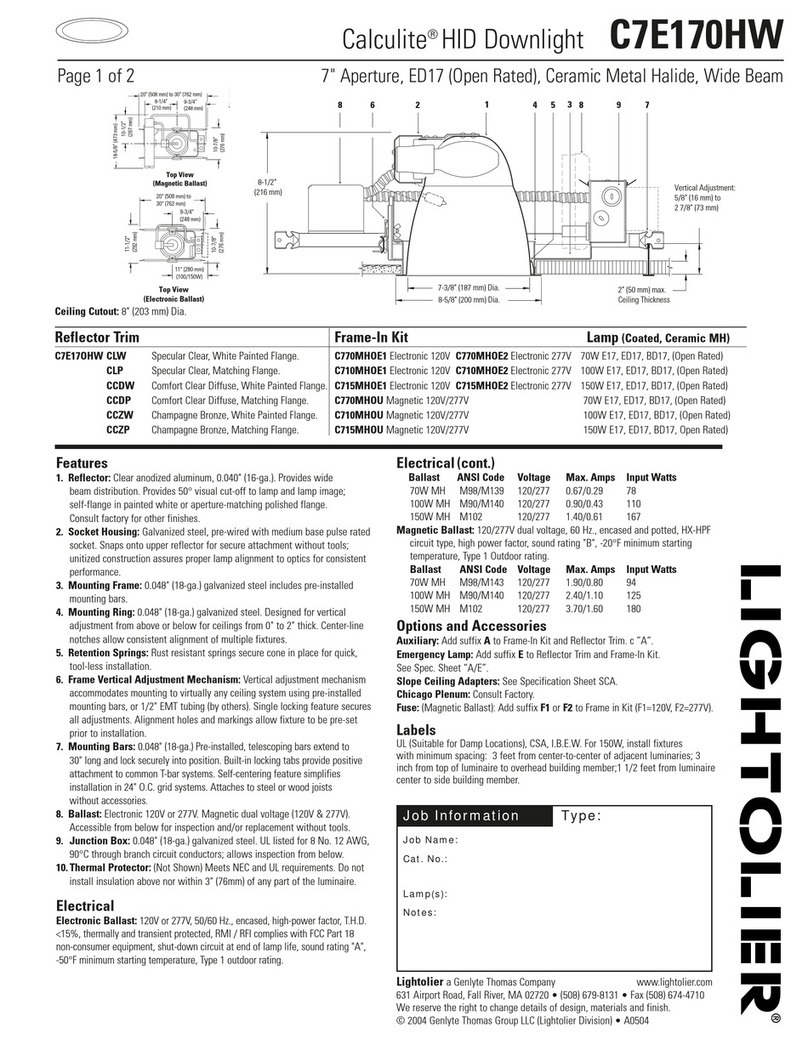

Lightolier

Lightolier Calculite C7E170HW specification

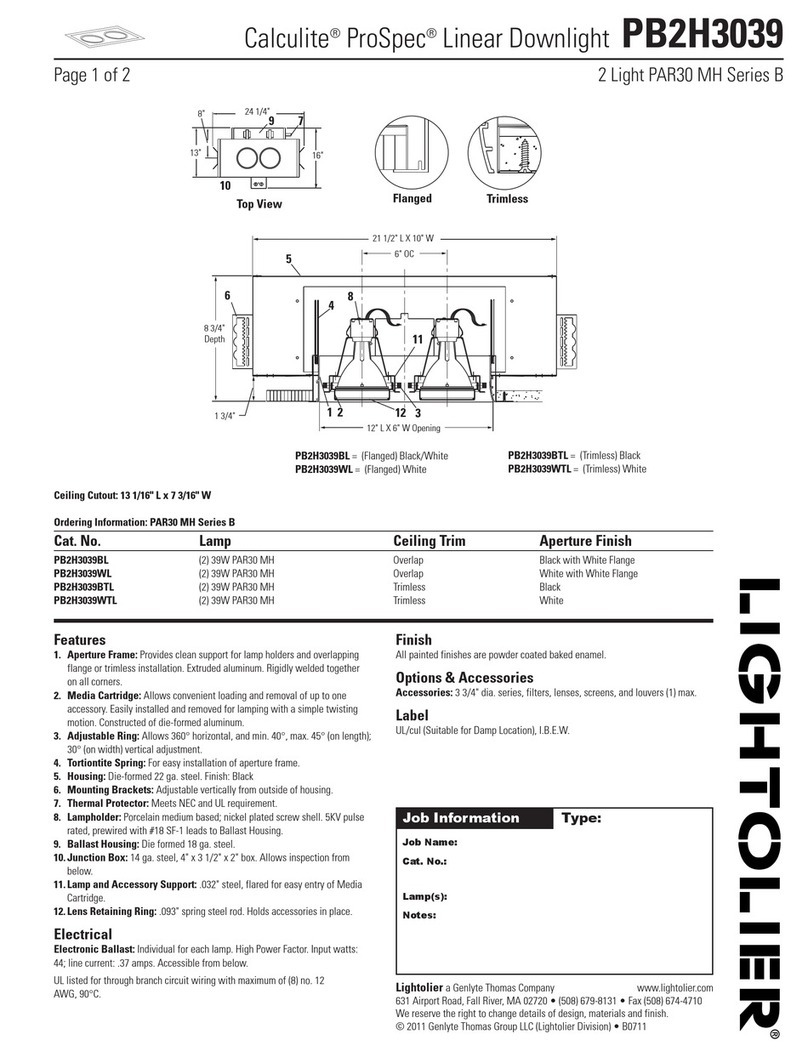

Lightolier

Lightolier Calculite ProSpec PB2H3039 specification

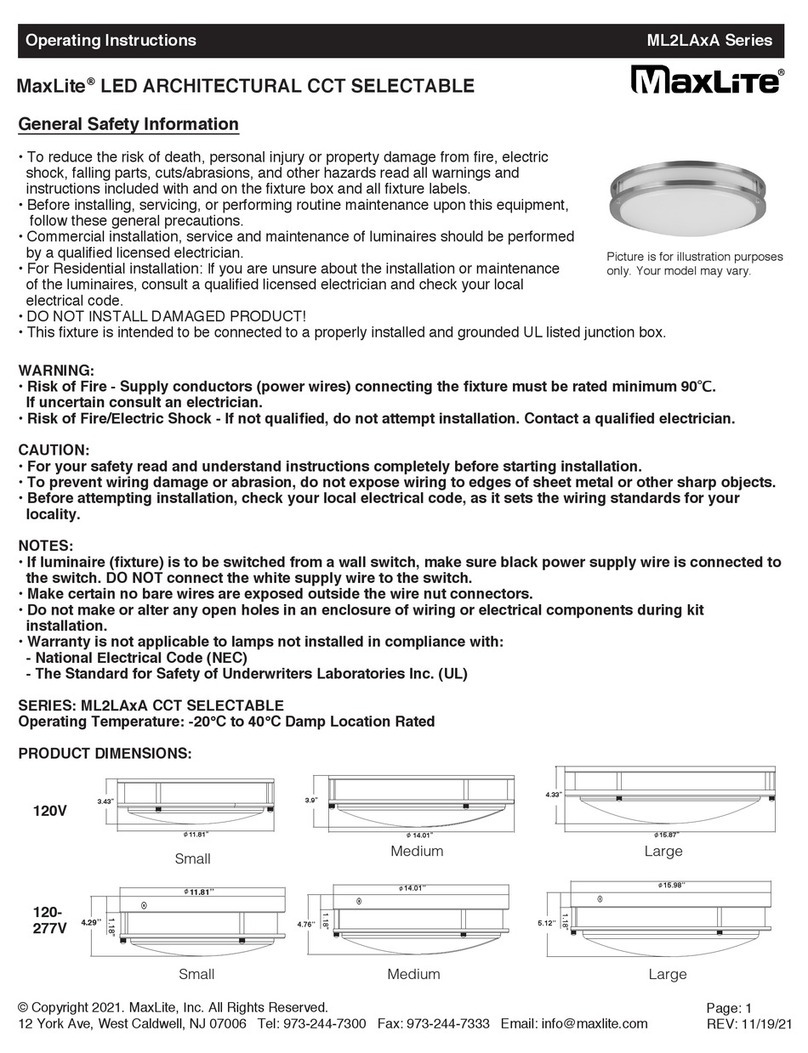

MaxLite

MaxLite ML2LALABNU249CSEM operating instructions

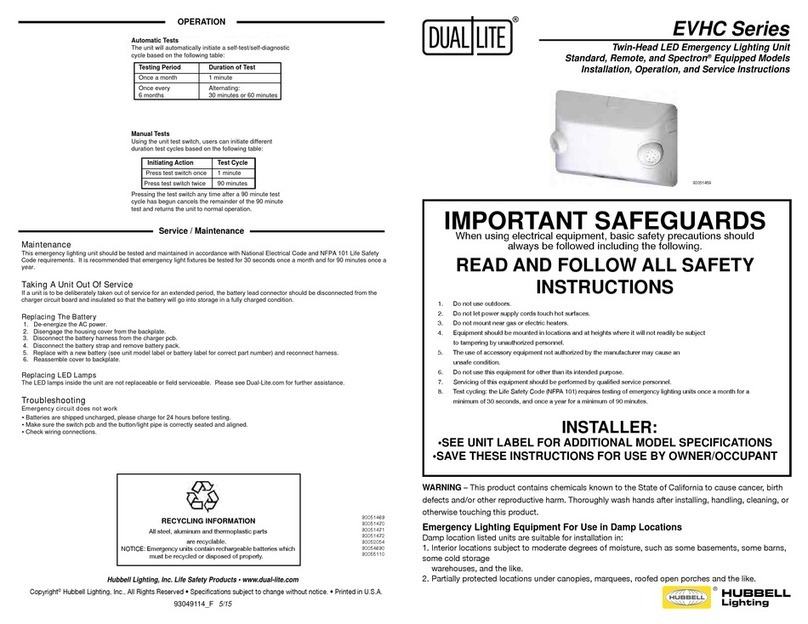

HUBBELL LIGHTING

HUBBELL LIGHTING DUAL LITE EVHC Series installation instructions

HumanTechnik

HumanTechnik lisa operating instructions

Crivit

Crivit 14141 user manual

Dust Free

Dust Free BIO-FIGHTER 4Xtreme Installation & operation manual

Sutter Instrument

Sutter Instrument Lambda 421 Operation manual

Jinbei

Jinbei EFT-360 RGB manual

HYBRYD

HYBRYD ALU SGN LED Installation and maintenance manual

Beamz Pro

Beamz Pro COB150 RGBW user manual

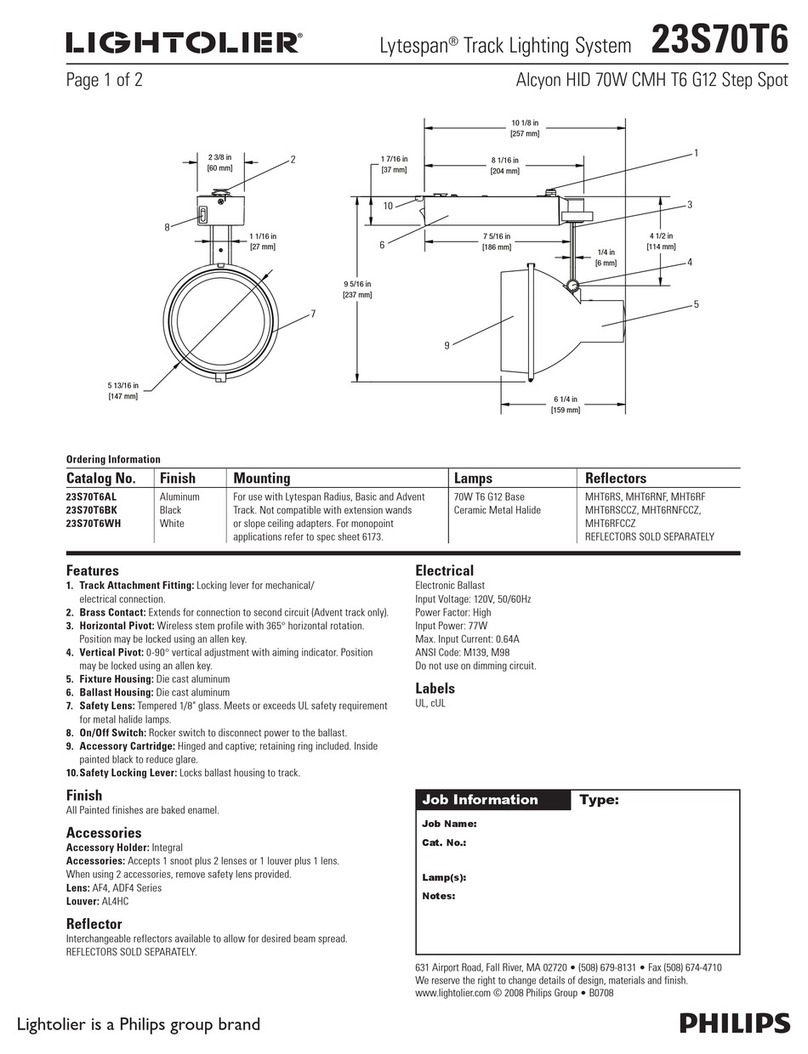

Lightolier

Lightolier Lytespan 23S70T6 specification

olympia electronics

olympia electronics OLY-1004/LT/WP installation instructions

SGM

SGM G-7 BEAST user manual

DOTLUX

DOTLUX RETROFITastrodim 1665-127360T user manual

Utilitech

Utilitech CMG-NYC-M3 installation instructions

Beamz professional

Beamz professional BPP225 instruction manual

ColorKey

ColorKey WaferPar HEX 12 MK II user manual