STS M2 Series User manual

Surface to Surface Inc. ®

Operators Manual

** M2-E **

USE IN CONJUNCTION WITH OEM MANUALS (ENCLOSED)

Unit Serial No. _______________

Teco-Westinghouse Motor

Optim HE PLUS – Serial No. ______________

Gorman-Rupp® Pump

STS-GR82E2 – Serial No. ________________

Links relating to this Manual

www.stsmixers.com

www.grpumps.com

www.twmi.com

STS-103 Rev. 11/07/23 www.stsmixers.com

Dealer

2

*** NOTICE ***

THIS UNIT IS TO BE INSTALLED, SET-UP, AND

WIRED BY A QUALIFIED ELECTRICIAN TO BE

COMMISSIONED BY THE END USER (CUSTOMER).

ALL CODES AND REGULATIONS ARE TO BE

FOLLOWED. SURFACE TO SURFACE ASSUMES NO

RESPONSIBILITY FOR DAMAGES OR PERSONAL

INJURIES CAUSED BY IMPROPER INSTALLATION.

If a problem or concern is found while installation is

being done, a call to the appropriate party is

recommended.

Teco-Westinghouse West 1-800-661-4023

East 1-800-268-4770

Surface to Surface Inc. 1-800-567-0978

STS-024 Rev. 01/04

3

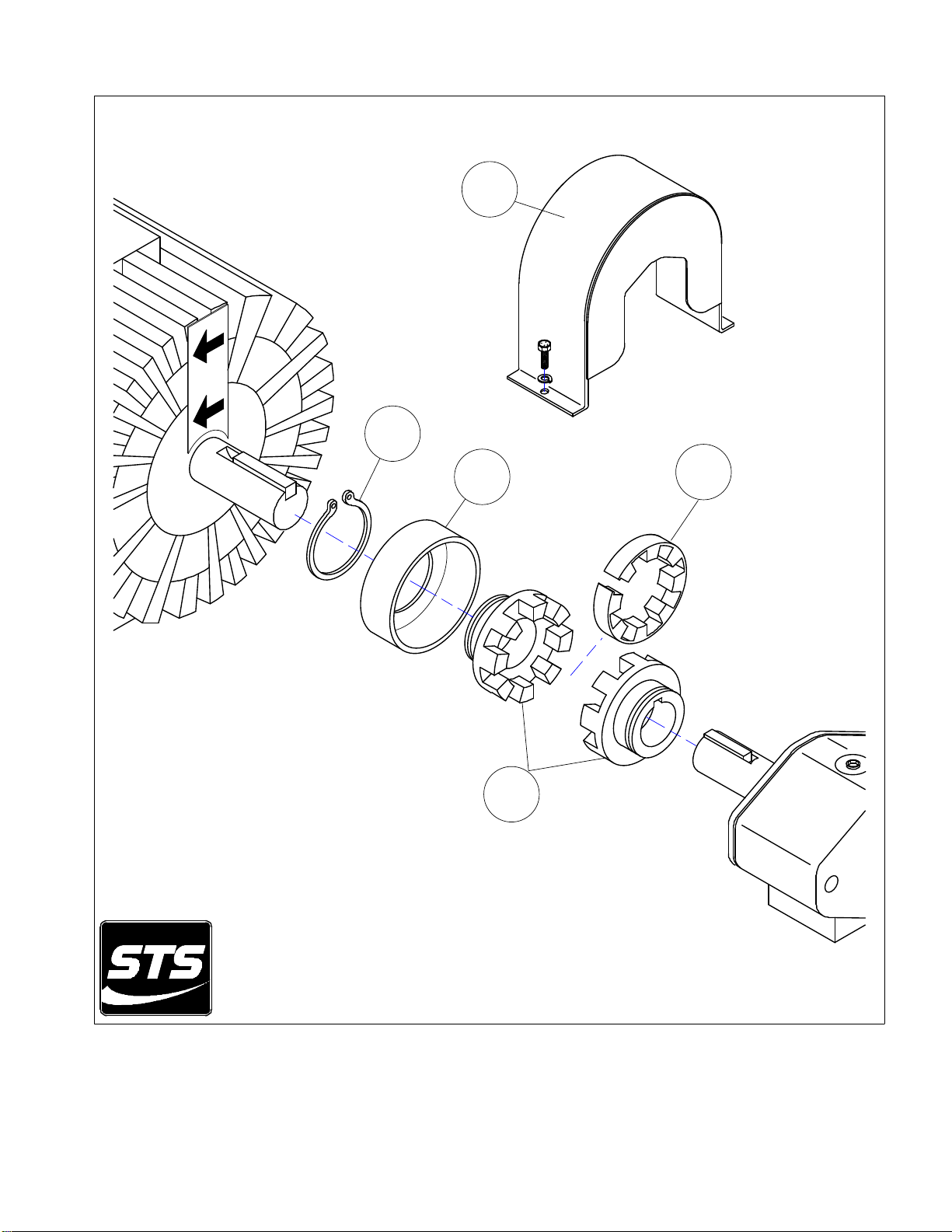

****** CAUTION ******

BEFORE STARTING THIS MOTOR, DISENGAGE THE

MOTOR/PUMP COUPLER (see FIG. 1) AND CHECK THE

MOTOR FOR PROPER ROTATION (see decal). IF THIS STEP

IS NOT FOLLOWED, THE IMPELLER MAY BECOME

SEPARATED FROM THE SHAFT AND CAUSE SUFFICIENT

DAMAGE TO THE PUMP AND IMPELLER AND OR

PERSONAL HARM.

To disengage the coupler, remove the guard (1). Using external snap ring

pliers, spread the snap-ring (2) and remove it from the groove in the coupler

(5) and backwards over the motor shaft. Now slide the retainer (3) also

backwards and over the motor shaft. The plastic fingered insert (4) is now

exposed. The insert (4) is a 1 piece split flexible unit and can be worked out

from between the 2 couplers (5) and set aside.

You can now power the motor to check rotation without rotating the pump.

Switch the motor on/off and as the shaft slows down, you will be able to see

the rotation direction. If the need be, change the wiring to provide the

proper rotation. Once proper rotation is established (see arrow decals) the

drive coupler can be reassembled in the reverse order as previously

explained.

IF A VARIABLE FREQUENCY DRIVE (VFD) IS USED IN

THE WIRING OF THE MOTOR OF THE MIXER, THE

REVERSE FUNCTION (IF EQUIPED) MUST BE DISABLED.

IF THIS FUNCTION IS NOT DISABLED, THE MOTOR CAN

INADVERTEDLY BE REVERSED BY THE OPERATOR AND

THE IMPELLER MAY BECOME SEPARATED FROM THE

SHAFT AND CAUSE SUFFICIENT DAMAGE TO THE PUMP

AND IMPELLER AND OR PERSONAL HARM.

To disable the reverse function (if equipped) refer to the manufacture’s

installation manual of the variable frequency Drive (VFD) or contact the

VDF manufacturer.

STS-024 Rev. July/2021

4

1

2

34

5

FIG. 1

5

TABLE OF

CONTENTS

PAGE

STS Inc. Warranty…………………….….……………………………….. 8

Safety Statements………………………………………………...………… 9-12

Safety Markings……………………………………………………………. 13

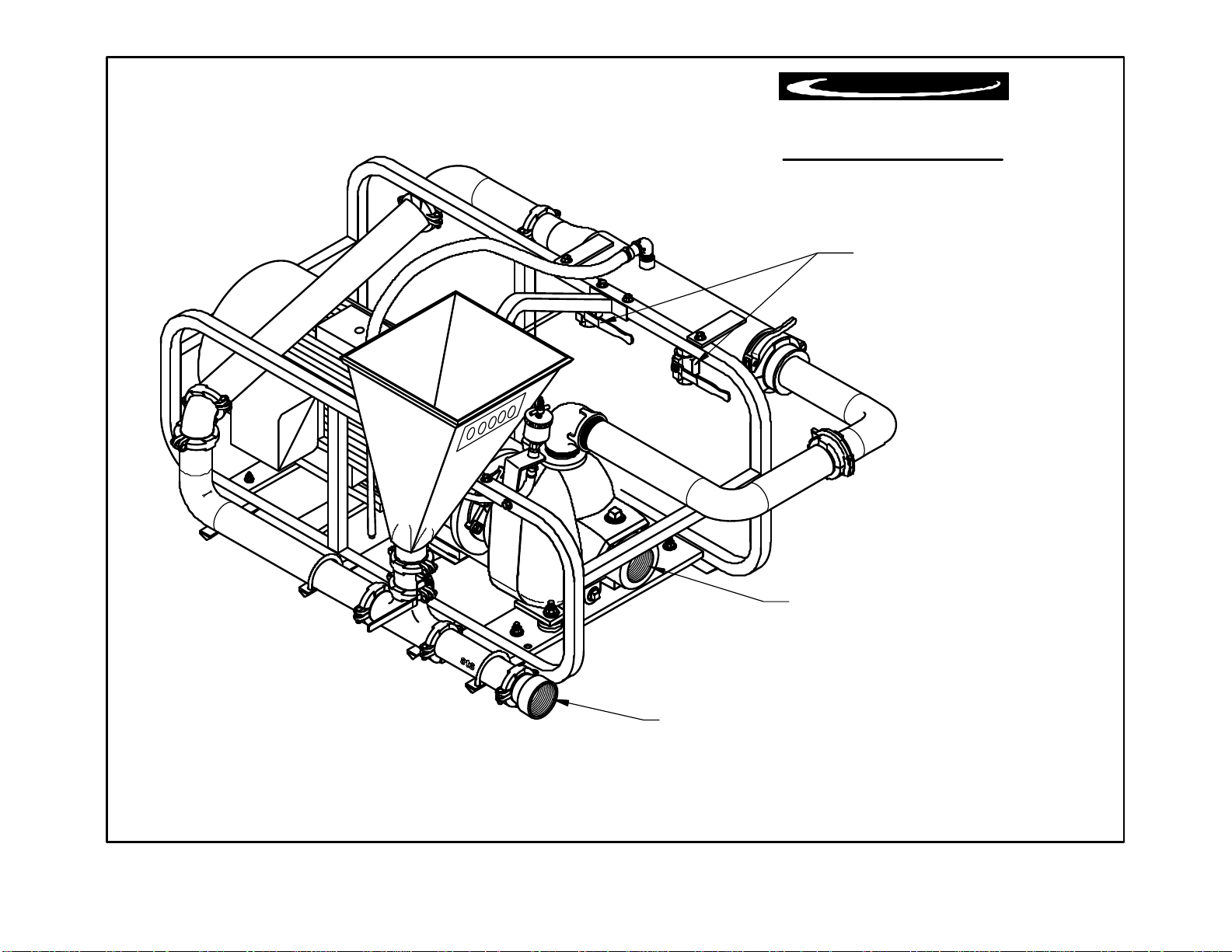

Main Working Components (Photo)……………………………………… 14

M2-E Hose Connections ……………….………………….……………. 15

Introduction to the M2 ……………….………..………..…………. 16

M2-E Foot Print (top view)……………………………….…………… 17

M2-E General Data Sheet…………………………………………………. 18

Identifying Your Machine & Components………………………………. 19

SECTION II (Description, Care and Maintenance)

Electrical powered centrifugal pump.…….…………….………….…. 21-24

Filter shear system……………………………………………………. 25-26

Venturi mixing tee……………………………..………..……………. 27

Wash wand……………………………………………………...……. 28

Dry hopper with table & hopper valve…………………………..…… 29

Internal tank jets ……………………………………...……………… 30-31

SECTION III (Set-up and installation of unit in Detail)

Permanent mounting of unit…………………………...…………….. 33

Portable use of unit…………………….…………………….………. 33

6

TABLE OF

CONTENTS

PAGE

SECTION IV (Operating the M2-E Unit.

Site set-up and pre-check…………………………………………….. 35

Starting the motor driven pump…………….….…....…….……… 36

Typical mixing operation……………………….……………………. 37-38

Typical transfer / off-loading operation……………………………… 39

Shutdown, cleanup & storage

Warm weather…………………………………….…………. 40

Cold/ freezing weather………………………………….…… 41

Prolonged periods of storage………………………………… 42

SECTION V (Trouble shooting)

Trouble Shooting the M2-E ………….…….….….…..…….....…… 44-45

SECTION VI (Periodic Maintenance & Repair Information)

Maintenance Schedule…………………….….………………….…... 47

Centrifugal Trash Pump Seal Replacement………………………..… 48

Bolt torque Specifications…………………………………….……... 49

Notes…………………………………………………….…………… 50

7

TABLE OF

CONTENTS

PAGE

SECTION VII (OEM Repair / Information)

GR Centrifugal Pump Owner’s Manual……………………..………… 52-63

Teco-Westinghouse Owner’s Manual excerpts …….…...….….….…. 64-70

Gruvloc® Pipe Couplings ………….…….….….………………..…… 71-73

Quick-Flex® Drive Coupling ………….……….….……………..…… 74-77

SECTION VIII (Parts Manual)

M2-E PARTS MANUAL…………………….…………….……. 79-81

8

Limited Warranty

United States and Canada

Surface to Surface Inc. or its subsidiary which last sold the product, warrants new products sold by it for use in the

United States and Canada to be, at the time of manufacture, free from defects in workmanship and materials. This

warranty covers for a period of Twelve (12) Months of operation from the date of delivery for initial use, whichever

comes first.

Exclusions and Additional Limitations

1. This warranty relates to the condition of the product at the time of manufacture and does not cover parts or

service as a result of:

(a) Normal wear and tear or required maintenance including, without limitation, adjustments or replacement of

components subject to wear and tear, such as belts, hoses, seals and/or packing, fuses, bulbs,

switches and ignition parts.

(b) Abuse including, without limitation, neglect, improper operation, misapplication, overloading, accident or

alterations not approved by Surface to Surface Inc.

(c) Lack of maintenance, including, without limitation, failure to inspect and maintain, improper repair, use of

“unapproved parts”, cracked engine heads and blocks unless caused by the failure of

an internally lubricated part or repair of engine valves, rings or guides.

2. The Company’s warranty does not apply to purchased components manufactured by others where separate

warranty is made by the manufacture of such components and will be applied as interpreted by

the supplier.

3. All claims under his warranty shall be submitted in writing by the distributor to the Company, which will be the

sole judge in determining the merits of the claim.

4. The company shall have the right to have all products or parts claimed to be defective returned to it and the

cost of shipping such items shall be borne by the distributor.

……………………………………………………………………………………

Warranty Registration Card

In order to help us provide complete service for our product, please complete this card and return it.

If not returned, all requests for warranty will be denied.

Print Name: …………………………………………………………………….….

Address: …………………………………………………………………………...

City: ……………………State/Province………………Zip/PC…………………...

Model No. ………………………….. Serial No. …………………………………

Date of Purchase ………………………… Dealer ………………………………..

Return to: Surface to Surface Inc.

5150 Forest Rd. RR#3

Watford, Ontario, Canada

N0M 2S0

01/14/08

9

M2-E

SAFETY STATEMENTS

Your personal safety and the safe operation of this unit are the concern of Surface to Surface Inc., and by

reading and understanding this manual and understanding the safety statements, you will decrease the risk of

personal and equipment damage.

Safety statements are listed here and throughout this manual to draw your attention to potential hazards that

may be encountered while operating this piece of equipment. While reading this manual, you will notice that

certain safety statements will relate directly to the operation, or maintenance of that particular part of the unit and

should be followed carefully. Decals on the unit also follow the same format as the warnings in this manual, and

therefore should be kept in good repair to alert the operator and others of the potential hazard.

The engine / motor manual also contains hazard warnings which pertain to the engine / motor and should

also be followed.

This safety alert symbol appears with most safety statements.

It means attention, become alert, your safety is involved!

Please read and abide by the message that follows the safety alert symbol.

DANGER

WARNING CAUTION

CAUTION

Caution "without the safety alert symbol"

indicates an potentially hazardous

situtation that can cause damage to the,

machine, personal property and / or the

environment or cause the machine to

operate improperly.

Danger (the word "DANGER" is in white

letters with a red rectangle behind it)

indicates an imminently hazardous

situation, which, if not avoided, will

result in death or serious injury.

Danger is limited to the most extreme

situations.

Warning (the word "WARNING" is in black

letters with an orange rectangle behind it)

indicates an potentially hazardous

situation which, if not avoided, could

result in death or serious injury.

Caution (the word "CAUTION" is in black

letters with a yellow rectangle behind it)

indicates an potentially hazardous

situation which, if not avoided, may

result in minor or moderate injury.

10

M2-E

SAFETY STATEMENTS

The following caution statements have been drawn from the instructions in this manual. They

have been assembled here for ready reference.

WARNING

NEVER USE BODY PARTS,

OR FOREIGN OBJECTS

in an attempt to unplug or clean the

hopper v alv e or mixing tee.

Serious personal inj ury or

damage will result.

WARNING

Serious personal injury will result.

DO NOT REMOVE OR MODIFY

SAFETY COVERS OR GUARDS.

WARNING

while the unit is in operation.

Serious personal inj ury will result.

NEVER ATTEMPT TO REMOVE

OR CLEAN THE FILTER SHEAR

CAUTION

DO NOT POSITION

ANY PART OF YOUR BODY

over the hopper, valve,

or mixing tee while cleaning.

CAUTION

WHEN THE UNIT

IS IN OPERATI ON,

the fluid in the piping may reach

pressures up to 50 p.s.i.

IN AN EMERGENCY

shut off all power (switch)

to halt the motor, pump, and fluid flow

DANGER

NEV E R A T T EM P T REP A I RS

OR DISASSEMBLY

without shutting off the motor and

disconnecting/lock-out the power source.

Serious personal inj ury will result.

DANGER

11

M2-E

SAFETY STATEMENTS continued

The following caution statements have been drawn from the instructions in this manual. They

have been assembled here for ready reference.

CAUTION

TRAPPED FL UID MAY BE PRESENT

and will spill out when p iping, hoses,

pump or filter shear are removed.

CAUTION

AVOID ALLOW ING FORE IGN MAT ERIAL

into the Vent uri Mixing Tee thr u the

Hop per, by keeping th e v alv e c losed

when not in use.

CAUTION

NEVER LEAVE LIQUID IN THE

PUM P CASIN G, PIPIN G, OR HOSES

durin g freezing weather condit ions,

as damage will result.

Follow instruction for winterizing.

CAUTION

CAUTION

CARE MUST BE TAKEN W HEN

INSTALLING TH E COUPLER GASK ETS.

If the gaskets are not properly lubricated

and in stalled, a leak may dev elop.

IMPR OPER IN STALLATION OF THE

MECH ANICAL o r GREASE SEAL

will result in leakage and possible

damag e to the seal. All mainten ance,

operating and repair of th is unit, must be

done per the instruct ions in t he oper ators

man ual for safety and reliability.

CAUTION

WH EN TRANSFERRING F LUID

to the drill ri g, fluid pressure may

reach or exceed 50 p .s.i.

CHECK the d rill rig manufact urers

speci fications r egarding maximum inlet

pres sures all owed f or their pu mp.

CAUTION

BEFORE STAR TING OR RESTAR TING

the motor and centrifugal pump, make

sure an y valves installed on the pump

suction inlet line are open, and the

fluid level in the tank is above

the suct ion line.

CAUTION

C h e ck t h e p u mp b y sl o wl y & c ar e f u l l y

opening the plug located on the top

of the centrifugal pump discharge elbow.

A visual inspection can be made if the fluid

escapes around the plug as it is loosened.

Remove the plug to view inside fluid level.

The centrifugal pump seal W ILL be

damaged if allowed to cavitate or run dry.

BEFORE STARTING THE MOTOR,

BE SURE THE PUMP IS PRIMED!

12

M2-E

SAFETY STATEMENTS continued

The following caution statements have been drawn from the instructions in this manual. They

have been assembled here for ready reference.

CAUTION

The manufacture r should be consulted

whe n considering alternativ e uses

for this piece of equipment.

This unit was de signe d for t he mix ing

and sheari ng of a dry additive, into a

liquid stre am.

Other uses may create unfores een safety

issues and personal inj ury r isk.

CAUTION

LIFTING LU GS OR THE L IFTING POINT(S)

identified and labelled on the skid

structure must be used in orde r to

safe ly lift and tra nspor t the unit.

WARNING

REFER TO THE SAFETY

STATEMENTS IN THE

OEM SUPPLIED MANUALS

AND

THIS MANUAL

REGARDING THESE

OPERATIONS.

13

M2-E

Safety Markings

Hazard and warning markings have been placed at appropriate points on the unit. International symbols

have been used, in order to ensure universal understanding of the nature of the hazard. Please comply

with all warnings and markings to ensure safe use of the equipment. These include but are not limited to:

a) Lifting points b) Flammable Liquids

c) High temperature areas d) Personal Protection recommendations

e) Personal dangers f) Equipment dangers

g) Operating instructions h) Fluid flow direction

SOME EXAMPLES THAT MAY BE FOUND ON THE EQUIPMENT

Liftin

g

Point

Personal Protection

,

Read and understand O

p

erator’s manual and Maintenance manual

Hot Surface

Fluid Flow Direction

Maintenance Instructions

Liftin

g

Point

CLEAN FILTER DAILY

14

15

"ALL HOSES SHOULD BE KEPT TO THE SHORTEST LENGHT POSSIBLE TO ACHIEVE MAXIMUN PREFORMANCE."

(Hose Hook-ups)

Surface to Surface Inc.

M2Series

FLUID OUTLETS

[to Drill Rig & Tank Guns]

**1 1/2" NPT**

** 2" NPT**

PUMP INTAKE

[in from Tank]

This line should have a valve installed at

the tank to facilitate shut down or reapirs.

FLUID RETURN

[out to Tank]

Thisline should discharge above themaximun fillline

of the tank. Theair space will stopthe siphon action of the fluid.

** 2" NPT**

16

M2-E

Operators Manual

Congratulations on your acquisition of the world renowned M2 Mixing System. You have acquired the

fastest and most efficient mixing system manufactured for mixing Bentonite drilling slurry (mud). As a

manufacturer of HDD support equipment, we are well aware of the extreme conditions that HDD

equipment is exposed to on a daily basis. Surface To Surface Inc. strives to overcome these conditions,

with better design and manufacturing practices. Please feel free to call our toll free number

(1-800-567-0978) if you have any questions or concerns about your M2 series mixer.

Thank you, for choosing the M2 series mixer.

The M2 mixing unit was designed to mix dry or liquid drilling products with clean

water, into a slurry. The slurry is continually circulated through the mixing cycle until it

reaches the desired consistency. The operator can then transfer the final product to a holding

reservoir or directly to the drilling equipment.

The M2-922 mixing unit consists of an electric powered centrifugal pump, filter/shear

unit, venturi mixing tee assembly, dry hopper with a table, a set of tank internal jets

(customer installed).

These components are all mounted on a frame type skid, built for lifting or solid mounting.

For ease of interpretation, looking at the mixing unit hopper straight on will be considered

looking at the front of the unit. Hence the other long side, will be the rear and the ends will be

right or left end.

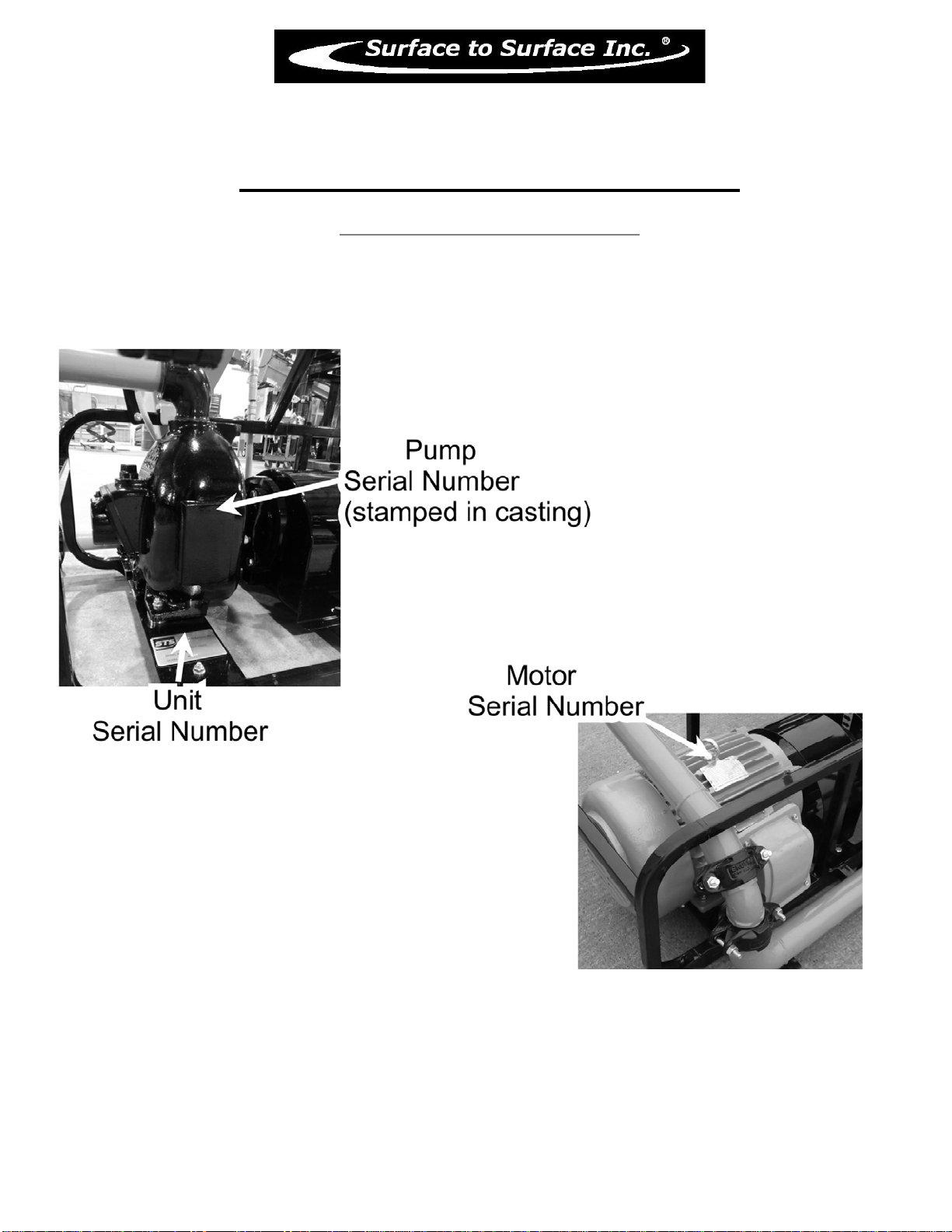

RECORD OF OWNERSHIP:

• Unit Serial No. __________________________________________

• Motor Serial No.________________________________________

• Pump Serial No:_________________________________________

• Date Purchased/Leased:___________________________________

• Dealer Purchased/Leased From:_____________________________

• Special Custom Features:__________________________________

17

46 1/2"

31 1/2"

27"

REV.

DA TE.DWR. NUM.

Surface to Surface Inc.

®

* Due to ourcontinuing product improvement, specifications are subject to change without notice. *

M2-E (Electric)

M2-E Footprint

02 / 27 / 18

Dry Weight: 460 Lbs (209 Kg)

18

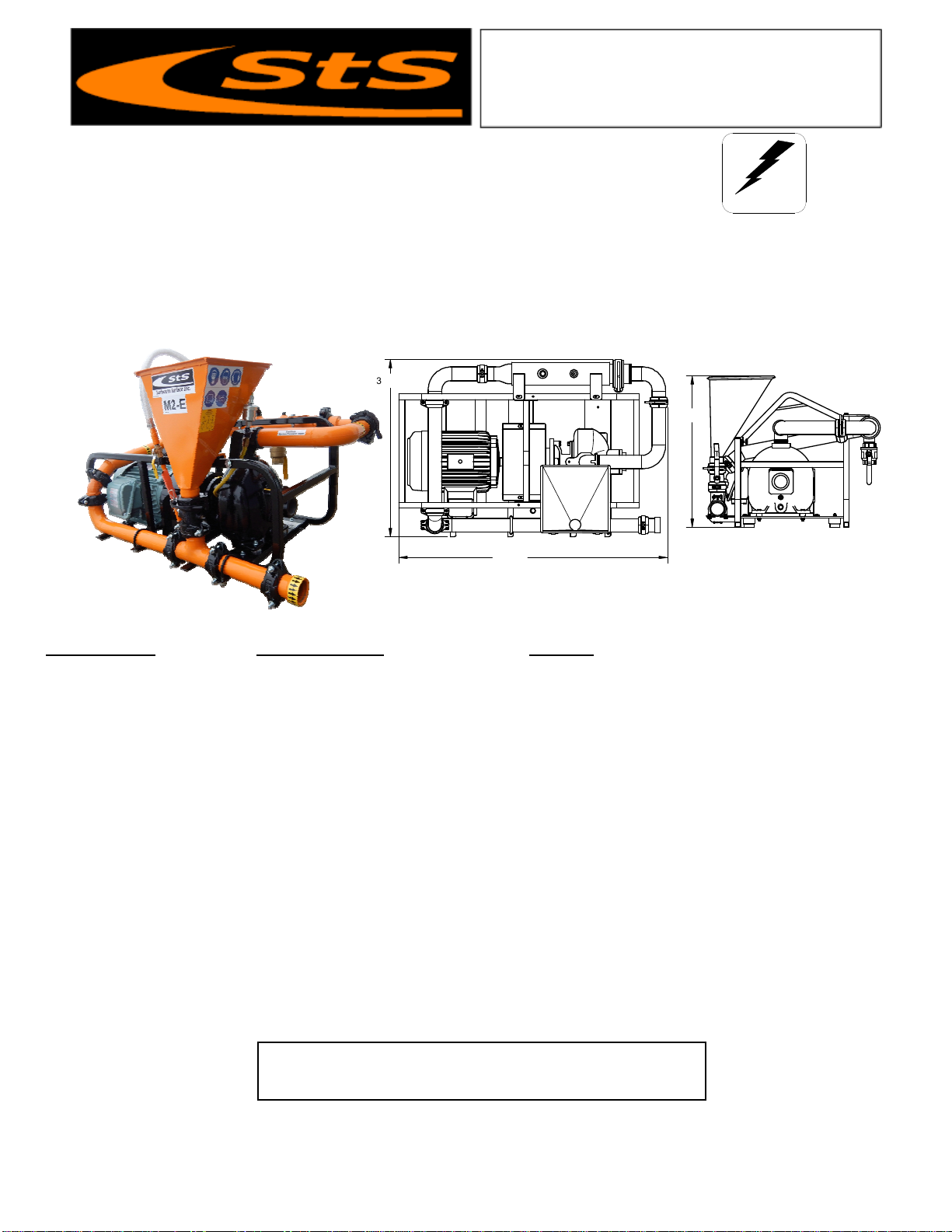

Specifications M2-E922 Mixer Benefits

Dimensions 31 1/2” W x 46 ½” L x 27” H Small space saving footprint.

Weight 460 lbs. (209 Kg) Light weight for easy transportation.

Hopper Height & Size 27” High Holds ½ of a bag Low hopper height reduces back strain.

Mixing System 2” Proprietary StS Mixing System Fast & efficient with high shearing ability.

Flow Valves Brass and Steel construction Withstand the abuse of daily operations

Skid Frame 1” steel tube with lifting bale Built tough for the construction trade.

Motor 10 HP Teco 230V/460V 60Hz Industrial rated for longer service life

Pump 2” Cast iron centrifugal trash pump Gorman-Rupp 80 series

Pump / Motor Connection Bearing Block to Lovejoy® Coupler Large bearings & oversized coupler (service life)

Pipe Couplers Bolt & Snap-groove type Fast cold weather draining of system.

Pressure Wand Hopper maintenance wand Removal of build-up caused by additive.

Internal Jet Guns (supplied) Eductor Nozzles (5-1 fluid output) Fast and effective rolling and mixing action.

Mechanical Seal Self-Pressurizing Grease Seal Greaseable seal for more rugged working conditions

Replaceable Wear Plate Hardened plate ahead of Impeller Less wear on internal pump parts and is replaceable.

With a 40 second viscosity, the M2 produces 90 gpm @ 36psi through the nozzle and 52 gpm @ 36psi to the tank

internal jet guns (5-1 mixing equals 260 gpm of mixing / rolling action in tank) and a discharge rate of 80 gpm @

36psi

Features and Benefits M2-E Mixer

The M2-E universal mixer is designed around the time proven M series mixers of STS. Powered by a 10HP

Teco/Westinghouse electric motor, driving a 2” centrifugal pump, making effective use of the proprietary 4 point mixing

system. The M2-E may be used as a new installation or retrofitted into an existing system of tank(s). Since the unit is

connected by hoses and not hard pipe, the placement of the mixer verses the tank(s) is less restricted and a

configuration to suit the needs of the contractor is easier to achieve. The small size also makes it a portable,

independent unit that is easier to transport from site to site.

Surface to Surface Inc.

Also available in Hydraulic (M2-H), Diesel (M2-D) or Gasoline (M2-G) models.

∗∗∗ All Specifications Subject to Change Without Notice ∗∗∗

Universal 2” Mixer

Model M2-E

Surface to Surface Inc.

5150 Forest Road, R.R.#3, Watford, Ontario, N0M 2S0

Tel: 1-800-567-0978

Check our website for the latest products and specifications

www.stsmixers.com

03

/

09/18

Electric

46 1/2"

31 1/2"

27"

19

M2-E

Identifying Your Machine & Components

Location of Tags and PIN Plates

20

SECTION #II

Description, Care and Maintenance

This manual suits for next models

2

Table of contents

Other STS Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Meler

Meler 200-ST Series Technical manual

General Measure

General Measure Checkweigher user manual

Vega

Vega VEGASON 64 operating instructions

WERMA Signaltechnik

WERMA Signaltechnik KombiSIGN 71 manual

Ecotech Italia

Ecotech Italia DW45 Manual for use and maintenance

SCHUNK

SCHUNK SWS-I-011 Assembly and operating manual