Studer NEXT3 User manual

Studer Innotec SA 2021 V 1.2

4O9B

Accessories:

Remote control and communication….

Battery temperature sensor….................

Cables for communication………………

Studer Innotec SA

next3

2 V 1.3 © Studer-Innotec SA next3 Tech manual

Contents

1INTRODUCTION ...................................................................................................................................... 4

2GLOSSARY.............................................................................................................................................. 5

2.1 Symbols and conventions ............................................................................................................. 5

3GENERAL INFORMATION....................................................................................................................... 6

3.1 About this user manual.................................................................................................................. 6

3.2 Important safety instructions......................................................................................................... 7

3.3 Quality and warranty .................................................................................................................... 7

3.3.1 Exclusion of warranty................................................................................................................. 7

3.3.2 Exclusion of liability .................................................................................................................... 8

4HANDLING AND MOUNTING ................................................................................................................ 9

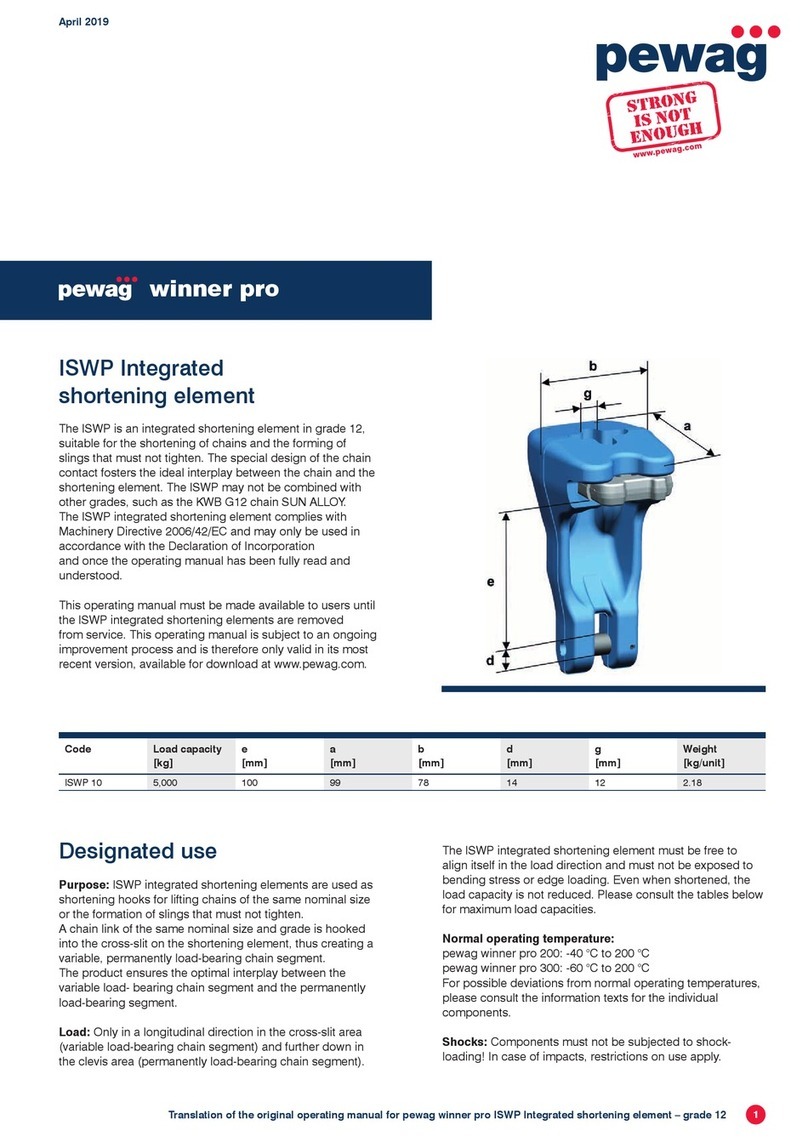

4.1 Handling and moving.................................................................................................................... 9

4.2 Storage............................................................................................................................................ 9

4.3 Dimensions ...................................................................................................................................... 9

4.3.1 Dimensions of wall mounted next3 ......................................................................................... 9

4.3.2 Dimensions of the 19’’ rack next3.......................................................................................... 10

4.3.3 Dimensions of the nx-interface .............................................................................................. 11

4.4 Unpacking and mounting........................................................................................................... 12

4.4.1 Mounting place ....................................................................................................................... 12

4.4.2 Unpacking and mounting process........................................................................................ 13

5WIRING ................................................................................................................................................. 21

5.1 General overview ........................................................................................................................ 21

5.1.1 System block diagram ............................................................................................................ 21

5.1.2 General recommendations ................................................................................................... 22

5.1.3 Connections overview ............................................................................................................ 23

5.1.4 Tightening torques ................................................................................................................... 26

5.1.5 Max permissible cable cross-sections summary .................................................................. 26

5.2 Connecting the battery .............................................................................................................. 27

5.2.1 Dimensioning the battery ....................................................................................................... 28

5.2.2 Battery cable cross-section, DC protective and disconnection devices ........................ 29

5.2.3 Connecting the battery.......................................................................................................... 29

5.2.4 Earthing of battery................................................................................................................... 31

5.2.5 Precautions when using batteries.......................................................................................... 31

5.2.6 Battery temperature sensor connection (nx-tempSensor)................................................. 32

5.2.7 Battery with communicating BMS: CAN connection.......................................................... 33

5.3 Connecting the AC (Alternative Current) ................................................................................ 34

5.3.1 Sizing of AC protective devices............................................................................................. 35

5.3.2 AC Neutral and Earthing system............................................................................................ 37

5.4 Connecting the Photovoltaic generator .................................................................................. 40

5.4.1 PV string dimensioning ............................................................................................................ 40

5.4.2 Connection .............................................................................................................................. 42

5.4.3 Earthing of PV........................................................................................................................... 43

5.4.4 Cables and cross-section ....................................................................................................... 44

5.4.5 Protection devices................................................................................................................... 45

5.5 Lightning protection .................................................................................................................... 45

5.6 Connecting the Studer communications cables .................................................................... 46

5.6.1 Connection of the nx-interface ............................................................................................. 47

5.6.2 Connection to Internet ........................................................................................................... 49

5.7 Wiring auxiliary I/O ....................................................................................................................... 50

5.7.1 Auxiliary contacts .................................................................................................................... 50

5.7.2 Command Inputs..................................................................................................................... 51

5.7.3 RS485i......................................................................................................................................... 51

5.8 Multi-unit configurations .............................................................................................................. 52

5.8.1 Extension of an existing installation........................................................................................ 52

6POWER-UP OF THE EQUIPMENT........................................................................................................... 53

6.1 Initial configuration ...................................................................................................................... 53

6.2 Front panel Button ....................................................................................................................... 53

6.3 Front panel LED indicator............................................................................................................ 54

Studer Innotec SA

next3

Technical user manual V1.3 © Studer-Innotec SA 3

6.4 Beep indicator (Buzzer) ............................................................................................................... 56

7HMI: USE OF NX-INTERFACE................................................................................................................ 57

7.1 General navigation and use ...................................................................................................... 58

7.1.1 Screens map ............................................................................................................................ 59

7.1.2 Embedded documentation................................................................................................... 61

7.1.3 Accessibility .............................................................................................................................. 62

7.2 Displaying the state of the energy system on the NX-interface ............................................ 64

7.2.1 Simple dashboard ................................................................................................................... 64

7.2.2 Synoptic .................................................................................................................................... 65

7.2.3 Simple chart ............................................................................................................................. 66

7.2.4 Messages .................................................................................................................................. 66

7.3 The nx-interface functionalities .................................................................................................. 67

7.3.1 Remote Control ....................................................................................................................... 67

7.3.2 Update...................................................................................................................................... 69

7.3.3 Installation Configuration........................................................................................................ 71

7.3.4 Monitoring & dataloging ........................................................................................................ 73

8CONFIGURATION AND OPERATION OF THE NEXT3 ENERGY SYSTEM.............................................. 77

8.1 Essentials to know about a next3 system .................................................................................. 77

8.1.1 Understand the General Energy Strategy ............................................................................ 78

8.1.2 Standard use cases ................................................................................................................. 81

8.2 Configuration ............................................................................................................................... 83

8.2.1 Configuration Wizard .............................................................................................................. 83

8.3 AC-Source..................................................................................................................................... 91

8.3.1 General information ................................................................................................................ 91

8.3.2 AC-source Information............................................................................................................ 91

8.3.3 AC-source Settings for Grid .................................................................................................... 93

8.3.4 AC-source Settings for Genset ............................................................................................... 94

8.4 Solar PV ......................................................................................................................................... 96

8.4.1 General information ................................................................................................................ 96

8.4.2 Solar Information...................................................................................................................... 96

8.4.3 Solar Settings ............................................................................................................................ 98

8.5 Battery ......................................................................................................................................... 100

8.5.1 General information .............................................................................................................. 100

8.5.2 Battery Information................................................................................................................ 100

8.5.3 Battery Settings ...................................................................................................................... 101

8.5.4 Battery: additional explanations.......................................................................................... 103

8.6 AC-Loads .................................................................................................................................... 107

8.6.1 General information .............................................................................................................. 107

8.6.2 AC-Loads Information ........................................................................................................... 107

8.6.3 AC-Loads settings .................................................................................................................. 108

8.7 AC-Flex ........................................................................................................................................ 111

8.7.1 General information .............................................................................................................. 111

8.7.2 AC-Flex as source; information and settings ...................................................................... 111

8.7.3 AC-Flex as Loads; information.............................................................................................. 111

8.7.4 AC-Flex as load; Settings....................................................................................................... 113

8.8 Device and I/O: Aux contacts, Inputs and communication................................................ 120

8.8.1 General points ....................................................................................................................... 120

8.8.2 Device Information................................................................................................................ 121

8.8.3 AUX-contacts settings ........................................................................................................... 121

8.8.4 IN-CMD settings...................................................................................................................... 123

8.8.5 RS485i Settings ........................................................................................................................ 123

8.9 System settings ........................................................................................................................... 124

8.9.1 Earthing Relay ........................................................................................................................ 124

8.9.2 Source priority ........................................................................................................................ 125

9MAINTENANCE OF THE INSTALLATION ............................................................................................. 127

10 TECHNICAL DATA .............................................................................................................................. 128

11 PRODUCT RECYCLING....................................................................................................................... 131

12 CONFORMITY..................................................................................................................................... 131

Studer Innotec SA

next3

4 V 1.3 © Studer-Innotec SA next3 Tech manual

1INTRODUCTION

Congratulations! You are about to install and use an equipment from the

Studer NEXT range. You have chosen a high-tech converter that will play a

central role in the energy production of your solar electrical installation. The

next3 has been designed to work as a solar battery charger and hybrid

inverter working in both modes “on-grid” and ”off-grid”. Its advanced and

completely configurable functionalities will guarantee a perfect functioning

of your energy system in any situations.

The NEXT range is a family of hybrid inverters, with or without included solar

chargers. All models are designed with Swiss quality to have outstanding

performances in offgrid and ongrid applications.

When the next3 is connected to batteries and photovoltaic panels, it

automatically recharges batteries in an optimal way with all the available

solar power. According to the selected programming, the solar can be

injected to the grid or used for self-consumption only. The accuracy of the Maximum Power Point

Tracking (MPPT) algorithm, the high output and low internal consumption ensure an optimal

valorisation of the energy produced by the PV modules.

The battery charge profile may be set freely according to the battery type or the operation mode.

The charging voltage is corrected depending on the temperature thanks to the external sensor nx-

tempSensor. If using lithium batteries, the next3 communicates with battery BMS through a CAN-bus

and ensure an optimal operation according to the manufacturer of the battery.

The control, display and programming unit nx-interface allows an optimal setup of the system and

guarantees the user a permanent control over all important parameters for the installation.

Moreover, it enables the recording of the system data to analyse later its functioning (data logging).

The nx-interface also acts as a communication center to connect the energy system to the remote

monitoring web portal https://portal.studer-innotec.com for distant supervision. The remote

supervision can also be done with the APP Studer Easy Monitoring, available for both IOs and

Android.

The next3 operates as an independent device and is also designed to be included into a Studer

energy system together with other NEXT compatible devices, display modules and the

communication modules.

The parallel operation of several inverters is possible and offers modularity and flexibility enabling an

optimum dimensioning of your system according to your energy requirements. Working together,

these different devices have a synchronised behaviour for a better management of the battery and

of the solar resource. The next3 is available in models without the solar charger or without the AC-

transfer to fit in various types of systems.

Please read this manual carefully to ensure the perfect start up and operation of your system. It

contains all the necessary information regarding the operation of the next3 charger. The installation

of such a system requires special expertise and may only be carried out by qualified personnel

familiar with the local standards in force.

Studer Innotec SA

next3

Technical user manual V1.3 © Studer-Innotec SA 5

2GLOSSARY

•AC: Alternative Current

•AC-Flex: The AC-Flex is a physical connection for 3 phases and neutral. It can be configured

for a use as a secondary AC source, or for a use as a controlled secondary AC loads.

•AC-Transfer: with “transfer” we mean the fact that the AC-Source is connected to the AC-

Loads with the internal relays of the next3.

•PE: Protective Earth

•Solid neutral: when the AC-Source and the AC-Loads neutral are physically connected with

a bridging cable.

•Transfer: have a transfer means be connected to the AC-source with the internal relay. The

inverter switch to a current source mode.

2.1 SYMBOLS AND CONVENTIONS

This symbol is used to indicate safety instructions, which, if not followed, could result

in a risk of electrical shock with possible serious personal injury or death to the

operator or the user.

This symbol is used to indicate a risk of material damage and/or the cancellation of

the guarantee.

This symbol is used to indicate a procedure or function that is important for a safe

and correct use of the equipment. Failure to respect these instructions may lead to

the cancellation of the guarantee or to a non-compliant installation.

This symbol placed on the product indicates that its surfaces may reach

temperatures higher than 60°C.

This symbol placed on the product indicates that its use must follow the instructions

in the user manual.

PE= protective earth (connected to the enclosure of the device).

Studer Innotec SA

next3

6 V 1.3 © Studer-Innotec SA next3 Tech manual

3GENERAL INFORMATION

3.1 ABOUT THIS USER MANUAL

This manual contains all the necessary information and procedures to install, configure, use and

troubleshoot the next3 hybrid inverters. It is the most detailed documentation about this product.

A summary is provided in the Quick Installation Guide, delivered with the product in a printed version.

Type of documents

It does not contain information about photovoltaic modules (PV) or batteries of various brands that

can be connected. For this kind of information, please refer to the instructions of each specific

manufacturer.

It does not contain specific information on national rules/regulations about electrical installation. It

contains only safety requirements about the use of the device next3 according to following

International and European standards; IEC/EN 62109 for power converters used in photovoltaic

systems and IEC/EN 62477 for power converters used in general systems.

General information that can help you for system design can be found in the Studer System Design

Book. Schematics and explanations for various specific cases can be found in “ next3 Systems design

: Application notes, typical configurations and schematics”.

This manual covers the next3 following models and accessories:

•Hybrid inverter charger (with any options) with software version up to 1.9.99

•Interface: with software version up to 1.9.99

•Battery temperature sensor:

Brochure

Quick Installation Guide

Application notes / Wiring examples

Detailed Technical Manual / Studer System Design Book

This manual is an integral part of the equipment and must be kept available for

the operator and/or the installer. It is provided under digital form in the usb key

delivered with every unit.

The latest version of the manuals can be downloaded on Studer website:

https://www.studer-innotec.com

The content of this manual is copyrighted by Studer-Innotec SA, Rue des

Casernes 57, 1950 Sion, Switzerland

Simple/commercial

Detailed /technical

Studer Innotec SA

next3

Technical user manual V1.3 © Studer-Innotec SA 7

3.2 IMPORTANT SAFETY INSTRUCTIONS

This manual contains important safety instructions. Please read carefully the safety and operation

instructions before using a next3 device. Take into consideration all the warnings mentioned both on

the equipment and in this manual, following all the instructions regarding the operation and use.

The installation and commissioning of the next3 must be entrusted to qualified personnel. The

installation and use must comply with the local safety instructions, laws, and standards in force in the

country.

Do not excess the maximum rated characteristics of the equipment shown on the Type label and in

the datasheet.

HIGH-VOLTAGE DC AND AC INSIDE THE DEVICE: DANGER OF DEATH

When the next3 is under operation, it generates voltages that can be potentially

lethal (up to 900Vdc and 400Vac). Any work on or close to the installation must be

carried out only by thoroughly trained and qualified personnel. Do not try to carry

out ordinary maintenance on this product yourself.

The next3 is in overvoltage category III (OVCIII) on AC side, in accordance with the

safety standard IEC/EN 62109-1.

While working on the electrical installation, it is important to make sure that the

source of DC voltage coming from the battery as well as the source of DC voltage

coming from the photovoltaic generator, have been disconnected from the

electrical installation.

Be also certain the sources of AC voltage coming from a generator or network have

been disconnected from the electrical installation.

Even when the next3 is disconnected from the power sources, a potentially

dangerous voltage may remain at the terminals. To eliminate this, you must wait for

at least 120 seconds to allow the electronics to discharge.

After disconnection, check all the terminals voltage with a multimeter in AC and DC

modes. The connections compartment can then be opened and the task carried

out safely. All other cover parts of the device shall never be opened without written

authorisation of Studer Innotec SA company.

The next3 can be installed at altitudes up to 3000m. For installations at higher

altitudes, please contact Studer Innotec SA.

Nobody is authorized to proceed with any change, modification, or repair of the equipment without

the prior written authorisation of Studer Innotec. Use only original parts for any authorised

modification or replacement.

3.3 QUALITY AND WARRANTY

During the production and assembly of the next3, each unit undergoes several checks and tests

which strictly comply with established procedures and device safety requirements. The

manufacturing, assembling, and testing of each next3 are entirely carried out in our factory in Sion

(CH). The warranty for this equipment depends upon the strict application of the instructions in this

manual.

The next3 inverter has a six (6) years warranty (starting from the date of purchase) against material

and manufacturing defaults. The defective product will be either repaired or replaced at the

discretion of Studer Innotec. A warranty extension up to 12 years is possible with the Studer Care

program, giving also other advantages.

3.3.1 Exclusion of warranty

No warranty claims will be accepted for damages resulting from handling, use or treatment that are

Studer Innotec SA

next3

8 V 1.3 © Studer-Innotec SA next3 Tech manual

not explicitly mentioned in this manual. Damages arising from the following causes are excluded

from the warranty:

•Voltage higher than 900V across PV terminals.

•Voltage higher than 70V across battery terminals.

•Accidental presence of liquids in the equipment or oxidation due to condensation.

•Damage resulting from falls or mechanical shocks.

•Modifications carried out without the explicit authorisation of Studer Innotec.

•Nuts or screws that have been too much or not enough tightened during the

installation or maintenance.

•Damage due to atmospheric surge voltage (lightning).

•Damage due to inappropriate transportation or packaging.

•Damages due to improper installation

•Disappearance of original identification marks.

3.3.2 Exclusion of liability

The installation, commissioning, use, maintenance, and servicing of the next3 cannot be subject of

monitoring by Studer Innotec. Therefore, we disclaim all responsibility and liability for damage, costs

or losses resulting from an installation that does not comply with the instructions, a faulty operation or

inadequate maintenance. The use of Studer Innotec equipment is in any case under the responsibility

of the customer.

This equipment is neither designed nor guaranteed to supply installations used for vital medical care

nor any other critical installation entailing potential risks of important damage to people or to the

environment.

We assume no responsibility for the infringement of patent rights or other third parties’ rights resulting

from the use of the inverter.

Studer Innotec reserves the right to make any modifications to the product without prior notification.

Studer Innotec is not liable for incidental, direct or indirect damages of any kind, including any profit

loss, revenue loss or damages caused to equipment or goods due to defective equipment.

Never take off or damage the rating plate showing the serial number. It enables to

check and follow-up the data specific to each equipment and is vital for any

warranty claim.

Studer Innotec SA

next3

Technical user manual V1.3 © Studer-Innotec SA 9

4HANDLING AND MOUNTING

4.1 HANDLING AND MOVING

The weight of the next3 with the package is about 60kg. Use an appropriate lifting method as well

as help from a third party when installing the equipment.

4.2 STORAGE

The equipment must be stored in a dry environment at an ambient temperature between -20°C and

60°C. Store it in the location where it is to be used a minimum of 24 hours before commissioning to

avoid thermal shocks and condensation problems.

4.3 DIMENSIONS

4.3.1 Dimensions of wall mounted next3

The next3 must be installed vertically. Distances of at least 12cm around the units and 25cm above

the equipment are required to guarantee adequate ventilation (see mounting section of this

manual).

2 removable handles on each side of the device can be screwed to help the lifting of the device

and then leave adequate space for them. Never lift the device by handling the plastic cover part!

If the next3 is installed in a closed cabinet, it must have a sufficient ventilation to guarantee that the

ambient temperature is kept within the operating limits of the next3.

Studer Innotec SA

next3

Technical user manual V1.3 © Studer-Innotec SA 11

4.3.3 Dimensions of the nx-interface

The nx-interface can be fixed on the inverter with dedicated mounting frame or remotely wall

mounted. It can also be integrated on a control panel. See the mounting section for details of

installation.

See the Wiring chapter for cabling of communication.

Studer Innotec SA

next3

12 V 1.3 © Studer-Innotec SA next3 Tech manual

4.4 UNPACKING AND MOUNTING

When unpacking, check that the next3 has not been damaged during transport and that all

accessories listed below are present. Any fault must be immediately reported to the product

distributor or the contact mentioned at the back of this manual. Check carefully the packaging as

well as the next3.

Contents:

•Quick Installation Guide and user interface guide

•Next3 inverter-charger

•Nx-interface with

oMounting structure

oUSB stick with detailed technical manual, to be used for datalogging with the nx-

interface.

oKit for front panel fixing

o1m communication cable

•Sunclix connectors for PV cables (4 pairs)

•Male connectors for

oCAN lithium battery communication

oRS485

o2 pieces for AUX contacts

o1 piece for CMD inputs

•Temperature sensor nx-tempSensor (with male connector)

•Mounting plate (for wall mounted version) with 1 screw for fixing on the body of the next3.

The screws for the wall are not provided. Choose the appropriate screws for your wall.

•Fixing belt with 2 screws

•4 handles

•Cable-glands for battery and AC (for wall mounted version)

4.4.1 Mounting place

Next3 is designed for indoor use (IP30) and the place of installation must satisfy the following criteria:

•Protected from any unauthorised person.

•Protected from water and dust and in a place with no condensation.

•It must not be situated directly above vented lead acid batteries, or in a cabinet with it, due

to corrosive gas.

•No easily inflammable material should be placed directly underneath or close to the next3.

•Ventilation holes must always remain clear and be at least 20cm from any obstacle that may

affect the ventilation of the equipment (see mounting schematics).

•In mobile applications, it is important to select an installation site that ensures the lowest

Studer Innotec SA

next3

Technical user manual V1.3 © Studer-Innotec SA 13

possible vibration level.

•According to the IEC/EN 62109-1 standard, the level of pollution at the mounting place should

not exceed PD2 (second-degree environment), which means that there can be pollution as

long as it becomes not electrically conductive.

•Protected from direct solar radiation or heat sources.

As much as possible, reduce exposure to sudden temperature variation: important heat

variation may create undesired and harmful condensation inside the equipment.

4.4.2 Unpacking and mounting process

1. Unscrew the 8 screws situated on the side of the casing.

2. Remove top cover.

3. Take the manual, the fixation structure, check the content.

Studer Innotec SA

next3

14 V 1.3 © Studer-Innotec SA next3 Tech manual

4. Remove the external casing

5. cut the strings maintaining the next 3 to the bottom of the casing.

6. fix the 4 handles on the two sides of the next3 and remove the loops if you don’t need

them to move the next3.

7. Fix the mounting plate on the wall, leaving enough space around the unit for the

ventilation and cabling. Don’t forget to put the fixing-belt in place before screwing the

mounting plate on the wall:

Fixation and lifting eyes

Remove them if

not needed

Attach the 4

handles

Studer Innotec SA

next3

Technical user manual V1.3 © Studer-Innotec SA 15

In vehicles (road or marine), or when the support undergoes significant vibrations, the next3 is to be

mounted on anti-vibration elements. The fixing belt use is mandatory in those cases.

For the wall mounting plate, use the 5 screws and buffers capable to stand the weight of the inverter

in full safety.

When drilling the holes, keep at least 542 mm from the top screws to the ceiling to respect the 250mm

clearance above the device.

Keep at least 290mm to the nearest on the left wall (150mm+454mm/2-90mm=287mm) and 350mm

to the next next3 (120mm+454mm/2=347); distance from the middle of the plate.

Keep sufficient space below for the cabling.

>550 mm

>350 mm

>290 mm

Those are not provided in the package, select

the proper screws for your wall type and ensure

a solid mounting.

The diameter of the holes in the plate are

meant for 8mm screws.

Studer Innotec SA

next3

16 V 1.3 © Studer-Innotec SA next3 Tech manual

The next3 is a heavy equipment (~60kg) and must be mounted to a

support/structure designed to bear such a load. It is imperative to ensure

a complete and safe fastening of the equipment. If simply hung, it may

fall down and cause severe damages.

For the next steps there must be 2 people at least!

8. Hang the next3 on the structure

Studer Innotec SA

next3

Technical user manual V1.3 © Studer-Innotec SA 17

9. Fix the structure at the bottom with the provided screw

10. Fix the belt on the sides with the screws provided

11. Fix the nx interface with 2 screws provided. Install the communication cable on the

screen before mounting.

The nx-communication cable goes in the plug on the left of the nx interface and is easier to

install before the mounting on the nx device. The ethernet cable (LAN) goes on the right.

See the wiring sections for details.

Special installation on the wall or in a cabinet is shown in the following chapter below.

12. Open the bottom panel and proceed to wiring.

fixing screw

Studer Innotec SA

next3

18 V 1.3 © Studer-Innotec SA next3 Tech manual

Go to the wiring section of this manual for all explanations about electrical connexions.

4.4.2.1 Nx-interface wall mounting

The nx-interface can be hanged on a wall with two screws. The head of the screw goes in the

dedicated slot on the back of the nx-interface.

AC-Source

L1-L2-L3-N

AC-Flex

L1-L2-L3-N

AC-Loads

L1-L2-L3-N

BAT-

BAT+

AC PE earth

connection

Button

battery for

clock (RTC)

Use suitable screws

and buffers.

The maximum

diameter

of the screws is 8mm.

Maintain a space of

3mm between the

screw head and the

wall.

Studer Innotec SA

next3

Technical user manual V1.3 © Studer-Innotec SA 19

nx-interface is supplied with a 1m communication cable to mount on the device.

Cables of different lengths (3m, 10m and 50m) can be ordered. Item reference is:

nx-ethernetCab 3m/10m/50m. The length in meters is specified in reference.

You can buy your own ethernet cable for communication; it must be ethernet cat5

with 26AWG.

The maximal distance between the inverter and the nx-interface depends then on

the rest of the cabling. The total communication cable length in one system for the

Studer-nx-bus is 75m.

Studer Innotec SA

next3

20 V 1.3 © Studer-Innotec SA next3 Tech manual

4.4.2.2 Nx-interface panel mounting

The nx-interface can be integrated in a panel. The maximum thickness of the panel cannot exceed

4mm.

The opening cut in the front panel must be 122 x 190mm

with a maximum radius of 1mm in the corners

Mounting Instructions:

1. Insert the device from the front into the cut-out of the panel and push it carefully until it is fully

inserted

Insert the mounting elements (1) into the provided lateral T cut-outs (2) and push them

sideways (3) so that they are locked.

2. For the first mounting elements in a corner, tighten the fixing screw (4)until it presses on the

plate. Tighten the fastening screws to a maximum torque of 0.2 Nm.

3. Repeat procedure 3 for opposite mounting element

4. Repeat procedure 3 for remaining mounting elements

Mounting elements and screw

are provided

Observe the maximum tightening

torque of the fastening screws of

the mounting elements otherwise

they may be damaged.

Tighten the fastening screws of the

mounting elements to a maximum

Torque of 0.2Nm.

Table of contents

Other Studer Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

TriangleTube

TriangleTube MAXI-FLO MF 350 PT Series Installation and maintenance manual

Virutex

Virutex EB140 quick start guide

GEZE

GEZE Slimchain 230V AC Wiring diagram

Asco

Asco P152 Series Installation and maintenance instructions

LEITZ

LEITZ HSK-F63 instruction manual

MaxVac

MaxVac DUSTBLOCKER 500 instruction manual