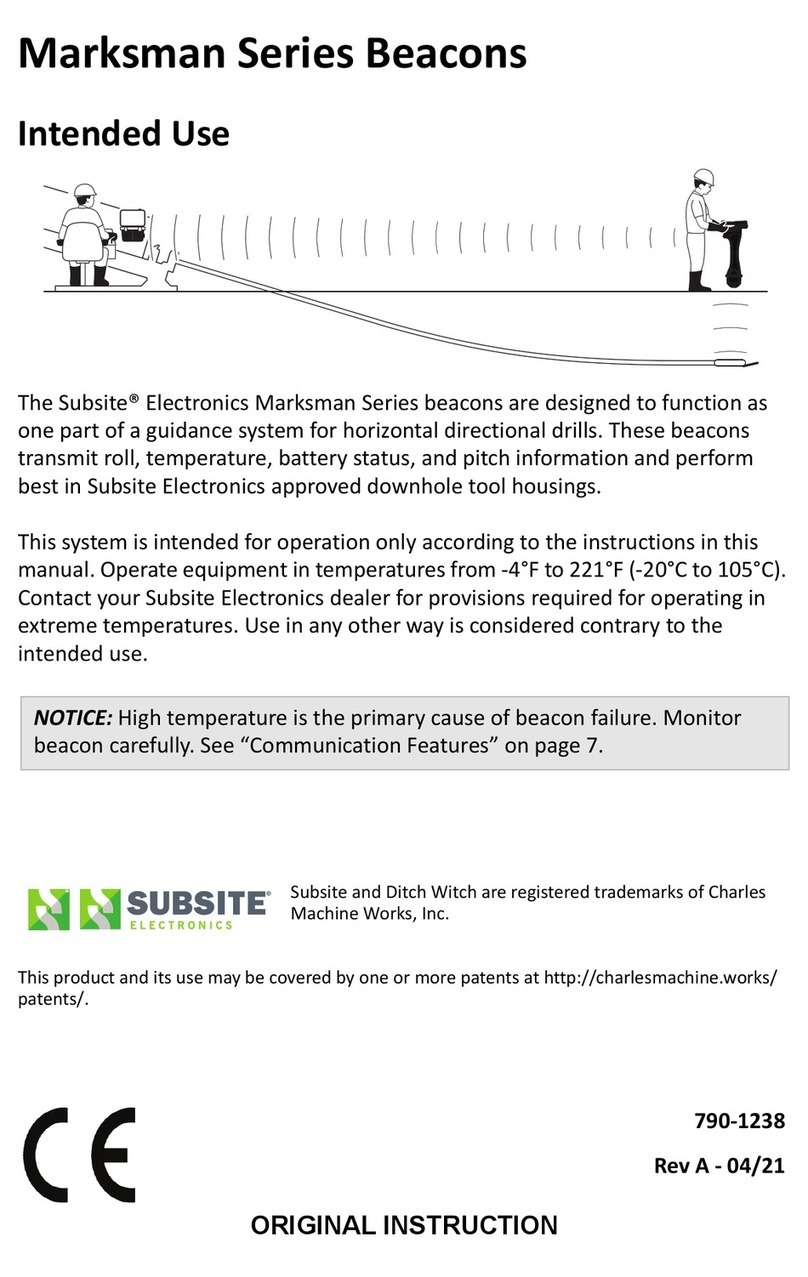

Install Batteries and

Select Frequency

1. Unscrew cap.

2. Check for and correct the

following conditions:

• dirty or damaged threads.

• missing, dirty or worn foam

washer on battery cap and

bottom of battery chamber.

• missing, worn or damaged

springs.

• missing, damaged or dirty

o-ring. Clean or replace as

needed.

3. Insert, positive end first, one Power Stick battery

(p/n 222-1369) or one Electrochem CC 3.67 V

Lithium.

Dual Frequency Beacons:

•To select 12 kHz frequency, hold beacon vertical

to the ground with the forward isolator pointed

toward the ground.

•To select 29 kHz frequency, hold beacon vertical

to the ground with the forward isolator pointing

toward the sky.

4. Install batteries. Keep beacon steady while hand

tightening cap firmly. Use tracker to confirm beacon

is functioning.

Note: Frequencies may be switched after they are

initially set. See “Switch Frequency While Drilling”

section.

IMPORTANT: For maximum performance, use only

Power Stick battery (p/n 222-1369) or Electrochem CC

3.67 V Lithium batteries. Standard “C” cell alkaline

batteries can cause intermittent operation and beacon

signal errors.

Test Operation

Use a tracker to test beacon function before leaving for

jobsite and after every battery change.

To test beacon function:

1. Turn on tracker, select frequency (if equipped with

dual frequency) and adjust gain so that signal

strength is approximately 50% (see tracker

operator’s manual).

2. Roll beacon and look at display for corresponding

roll positions.

IMPORTANT: When flat top on front isolator is at 12

o’clock, beacon should be sending 3 o’clock to

tracker.

3. Tilt beacon and look at display for corresponding

pitch positions.

4. Check beacon battery status and temperature.

For best results, replace batteries daily. (Using weak

batteries can cause erratic signal and/or damage.)

Recalibrate tracker to beacon after changing batteries.

Install Beacon into Tool Housing

IMPORTANT: Check beacon operation and condition of

both isolators before installing beacon into tool housing.

1. Lay beacon into tool housing with flat top isolator

toward bit and flat side facing up.

2. Check for proper beacon alignment by rolling

housing on the ground and watching for

corresponding roll positions on tracker display.

IMPORTANT: After installing beacon into tool housing,

calibrate tracker for each frequency before drilling.

Calibrate Tracker to Beacon

1. Select beacon frequency, if necessary.

2. Install beacon into drill head and place on ground

exactly 10’ (3 m) away from tracker. Make sure no

metal objects including drilling unit and drill pipe are

within 20’ (6 m) of tracker and toolhead.

3. Position tracker parallel to center of drill head.

4. Turn tracker on and press and hold depth and up

arrow keys until calibration mode is entered.

Release keys.

5. Verify calibration by moving tracker 15’ (4.5 m) away

from toolhead. Check depth. If reading is not 15’

(4.5 m), recalibrate tracker.

6. Repeat for other frequency, if needed.

Switch Frequency While Drilling

(Dual Frequency Option)

1. Allow beacon to go to sleep.

2. Rotate beacon within a minute of it going to sleep to

switch frequency.

If beacon is rotated after it has been asleep longer

than a minute, the frequency will not change.

Remove Beacon from Tool Housing

IMPORTANT: Remove beacon before mud in beacon

chamber hardens and locks beacon into housing.

1. Remove beacon from tool housing.

IMPORTANT: If beacon will not come out, do not

use force. Try soaking housing in water until dried

mud inside housing softens. If beacon still will not

come out, contact your Ditch Witch®dealer for

advice.

2. Clean beacon and remove battery.

3. Wash and lubricate tool housing.

This unit covered by one or more of the following

patents: U.S. 5,880,680; 7,251,567; 7,786,731;

7,999,551; 8,497,684; GB 2439495, UK0846841; other

US and foreign applications pending.