Sullair SUPERVISOR I User manual

SUPERVISOR

Part Number 02250051---610

eSullair Corporation, 1994

Effective 1/94

INSTRUCTION MANUAL

I

AIR CARE

SEMINAR TRAINING

Sullair Air Care Seminars are 3---day courses that provide hands---on instruction

in the proper operation, maintenance and service of Sullair equipment.

Individual seminars on Industrial compressors and compressor electrical

systems are presented at regular intervals throughout the year at a dedicated

training facility at Sullair’s corporate headquarters in Michigan City, Indiana.

Instruction includes discussion of the function and installation of Sullair service

parts, troubleshooting of the most common problems, and actual equipment

operation. The seminars are recommended for maintenance and service

personnel.

For detailed course outlines, schedule and cost information contact:

Sullair Corporate Training Department

1---800---SULLAIR or 219---879---5451 (ext. 1816)

--- O r W r i t e ---

Sullair Corporation

3700 E. Michigan Blvd.

Michigan City, IN 46360

Attn: Service Training Department

TABLE OF CONTENTS

Section 1 PAGE

SAFETY 11.1 GENERAL

11.2 ELECTRIC SHOCK

11.3 DECALS

Section 2

DESCRIPTION 32.1 INTRODUCTION

32.2 INSTRUMENTATION, FUNCTIONAL

DESCRIPTION

42.3 GENERAL

42.4 PURPOSE OF CONTROLS

52.5 AUTOMATIC OPERATION

52.6 SUPERVISOR IOUTPUT RELAYS

52.7 SUPERVISOR ISPECIAL FUNCTION INPUTS

62.8 SUPERVISOR IAUXILIARY DIGITAL INPUTS

62.9 OPTIONAL FACTORY CONFIGURATIONS

Section 3

PROGRAMMING PROCEDURES

73.1 SUPERVISOR IMICROCONTROLLER

PROGRAMMING

Section 4

START-- UP PROCEDURES

84.1 MOTOR ROTATION DIRECTION CHECK

84.2 INITIAL START --- UP PROCEDURE

84.3 SUBSEQUENT START --- UP PROCEDURE

84.4 SHUTDOWN PROCEDURE

Section 5

MAINTENANCE AND

TROUBLESHOOTING 95.1 CONTROL SYSTEM ADJUSTMENT

95.2 TROUBLESHOOTING GUIDE

12 5.3 MESSAGE DISPLAY DEFINITIONS

12 5.4 TROUBLE INDICATION SETPOINTS

Section 1

SAFETY

1

1.1 GENERAL

Sullair Corporation and its subsidiaries designs and

manufactures all of our products so they can be op-

erated safely. However, the responsibility for safe

operation rests with those who use and maintain

these products. For safe machine operation it is vi-

tally important to review all safety precautions noted

in the Safety Section of your compressor’s Opera-

tor’s Manual. The precautions listed there, as well

as those following, are offered as a guide which, if

conscientiously followed, will minimize the possibil-

ity of accidents throughout the useful life of this

equipment.

The compressor should be operated only by those

who have been trained and delegated to do so, and

who have read and understood their compressor’s

Operator’s Manual. Failure to follow the instruc-

tions, procedures and safety precautions listed

here and in the Operator’s Manual may result in ac-

cidents and injuries.

NEVER start the compressor unless it is safe to do

so. DO NOT attempt to operate the compressor with

a known unsafe condition. Tag the compressor and

render it inoperative by disconnecting and locking

out all power at source or otherwise disabling its

prime mover so others who may not know of the un-

safe condition cannot attempt to operate it until the

condition is corrected.

Use and operate the air compressor only in full com-

pliance with all pertinent OSHA requirements and all

pertinent Federal, State, and Local codes or re-

quirements. Read the CIMA Safety Manual (P/N

250023-146) prior to operation or performing main-

tenance on this equipment.

DO NOT modify the compressor and/or controls in

any way except with written factory approval.

1.2 ELECTRICAL SHOCK

A. Keep all parts of the body and any hand-held

tools or other conductive objects away from ex-

posed live parts of electrical system. Maintain dry

footing, stand on insulating surfaces and DO NOT

contact any other portion of the compressor when

making adjustments or repairs to exposed live parts

of the electrical system.

B. Attempt repairs only in clean, dry and well lighted

and ventilated areas.

C. Stay clear of the compressor during electrical

storms! It can attract lightning.

1.3 DECALS

See Figure 1-1. The Supervisor I control panel con-

tains several decals which contain necessary in-

formation for safe performance. These decals

should never be removed. If a decal becomes dam-

aged, contact your nearest Sullair Distributor or the

Sullair Corporation factory Service Department for

replacement parts (Note: When ordering new de-

cals, use part number printed on decal face.).

Section 1

SAFETY

2

Figure 1-1 Decals

* OSHA and FDA guidelines are superceded by any Federal, State or Local regulations whenever applicable.

*

*

Section 2

DESCRIPTION

3

2.1 INTRODUCTION

Your compressor is equipped with a Supervisor I mi-

croprocessor controller, replacing the standard

electro-mechanical control of pushbuttons,

switches and gauges. This manual explains the

functions and operation of the Supervisor control as

well as how to program its features for your particuZ-

lar application.

2.2 INSTRUMENTATION, FUNCTIONAL DE-

SCRIPTION

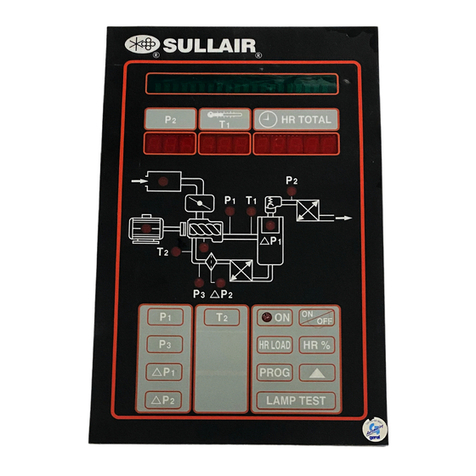

Refer to Figure 2-1. The Supervisor Icontrol panel

consists of displays for pressure, temperature, time

(run hours), and a status message. Default pres-

sure is line pressure (P2) which is normally dis-

played with pad selections for sump pressure, fluid

pressure, separator differential and fluid filter differ-

ential. Default temperature is unit discharge temper-

ature (T1) which is normally displayed with a pad

selection for injection fluid temperature. An LED

map provides a graphic illustration of the points be-

ing monitored. Operator controls consist of EMER-

GENCY STOP, ON/OFF, monitor display pads and

programming pads. All compressor control, pres-

sure and temperature displays are provided in the

Supervisor I.

SThe line (terminal) pressure transducer (P2) is

connected to the dry side of the receiver down-

stream from the check valve and continually moni-

tors the plant air pressure.

SThe sump pressure transducer (P1) monitors

the sump/unit discharge pressure.

SInjection oil pressure (P3) monitors oil pressure

at the point of injection into the compressor down-

stream of the oil filter.

SFilter oil pressure (P4) monitors oil pressure

ahead of the oil filter and is used with P3 to calculate

oil filter differential; Y P2=P4-P3.

SThe discharge temperature probe (T1) monitors

the temperature of the air leaving the compressor

unit. For both air-cooled and water-cooled compres-

sors the normal reading is approximately 180ºF

(82ºC) based on 80ºF (27ºC) ambient temperature.

SThe injection temperature probe (T2) monitors

the temperature of the fluid just before it is injected

into the unit.

SThe air filter maintenance switch monitors the

condition of the air intake filter. When the Supervi-

sor displays the message “AIR FILTER MAINT

RQD”, filter service is required.

STheON/OFF pad turns the compressor on and

off.

SThe hour display records cumulative hours of op-

Figure 2-1 Supervisor Control Panel

Section 2

DESCRIPTION

4

eration for the compressor and is useful for planning

and logging service operations. A selectable display

of “load” hours or “load” as a percent of “run” hours is

available by pressing “HR LOAD” or “HR%” respec-

tively.

SSeparator differential pressure can be dis-

played by pressing the “DP1” pad. When a differen-

tial of 10 PSID (0.7 bar) is reached, the message

“SEPARATOR MAINT RQD” is displayed and the

DP1 LED will flash.

SOil filter differential pressure can be displayed

by pressing the “DP2” pad. When a differential of 20

PSID (1.4 bar) is reached, the message “OIL FIL-

TER MAINT RQD” will be displayed and the DP2

LED will flash.

SThe “ON” LED indicates when the compressor is

running.

SThe amber light on the control panel indicates

when power to the compressor is supplied.

SThe green message display indicates the status

of the compressor.

2.3 GENERAL

While Sullair has built into this compressor a com-

prehensive array of controls and indicators to as-

sure you that it is operating properly, you will want to

recognize and interpret the reading which will call for

service or indicate the beginning of a malfunction.

Before starting your Sullair compressor, read this

section thoroughly and familiarize yourself with the

controls and indicators - their purpose, location and

use.

2.4 PURPOSE OF CONTROLS

CONTROL OR INDICATOR PURPOSE

ON/OFF PAD Depress to turn compressor ON. Depress again to turn

compressor OFF. If a fault shutdown occurs, or

EMERGENCY STOP, the ON/OFF button must be

pressed once to acknowledge the fault and silence the

alarm. Once the fault has been cleared, ON/OFF must

be pressed once to return to MANUAL SHUTDOWN in

preparation for start.

HOUR DISPLAY Displays accumulated hours of compressor operation;

useful for planning and logging service schedules. Al-

ternate displays by use of their respective touchpads

are - hours ON LOAD and percentage of hours running

when ON LOAD.

PRESSURE DISPLAY Continuously monitors service line air pressure (P2).

Located on dry side of receiver downstream of mini-

mum pressure/check valve. Selectable alternate dis-

plays via touchpad include:

SUMP PRESSURE (P1) displays sump/unit discharge

pressure.

SEPARATOR DIFFERENTIAL (DP1) displays the

differential pressure across the separator element/s. A

preset limit of 10 PSID (0.7 bar) will trigger the DP1

LED and a message will warn that a separator change

is required.

OIL FILTER DIFFERENTIAL (DP2) displays the dif-

ferential pressure across the fluid filter. A preset limit of

20 PSID (1.4 bar) will trigger the DP2 LED and a mes-

sage will warn that a filter change is required.

TEMPERATURE DISPLAY Continuously monitors the temperature of the air leav-

ing the compressor unit (T1). The normal readings

should be approximately 180ºF to 205ºF (82ºC to

96ºC). An alternate display of injection fluid tempera-

ture (T2) is available from the touchpad. Normal read-

ings should be approximately 130ºF to 160ºF (54ºC to

71ºC).

AIR FILTER MAINTENANCE Indicates when the air filter change is required. The

LED shown on the air filter of the graphic map will flash

and a message of “AIR FILTER MAINT RQD” will be

displayed.

Section 2

DESCRIPTION

5

2.4 PURPOSE OF CONTROLS (Cont’d.)

CONTROL OR INDICATOR PURPOSE

“POWER ENERGIZED” LIGHT Indicates when the control panel is receiving power.

“ON” LED Indicates when the compressor is running. If the ON

LED is flashing while the compressor is stopped, it is

indicating that the compressor was stopped by a re-

mote START/STOP contact and could be restarted

without notice.

2.5 AUTOMATIC OPERATION

For applications with varied periods of time when

there are no air requirements, Supervisor’s Auto-

matic mode allows the compressor to stop (time

delayed) when no compressed air requirement is

present and restart as compressed air is needed.

AUTOMATIC also incorporates the 10 second un-

loaded STOP MODE feature which allows the motor

to stop from an unloaded condition when the ON/

OFF pad is pressed or after the timed stop period. If

immediate stop is required when operating in AU-

TOMATIC mode, press the EMERGENCY STOP

button on the control panel.

2.6 SUPERVISOR IOUTPUT RELAYS

PARAMETERS OPERATION

COMPRESSOR RUN Initiates starter controls and all auxiliary contacts that

operate simultaneously with the main starter. Supervi-

sor assumes compressor is running if contact is closed

and P1 discharge pressure is at a satisfactory level.

LOAD/UNLOAD SOLENOID VALVE Controls regulator bypass solenoid valve to load or un-

load the compressor as demand varies.

COMMON FAULT ALARM Initiates to provide a common signal for remote indica-

tion of a fault shutdown.

WYE-DELTA TRANSITION Contact is used to control Wye-Delta starter transi-

tions logic. This contact is controlled by the Wye to

Delta timing function.

DRAIN SOLENOID VALVE Controlled by the drain time and drain interval timers,

this contact is used to control an optional condensate

drain solenoid valve.

2.7 SUPERVISOR ISPECIAL FUNCTION INPUTS

PARAMETER OPERATION

REMOTE STOP/START (J1/1-2) Closing this contact initiates the STOP mode. Opening

this contact permits a compressor start if permissives

are satisfied. Please note that AUTOMATIC/MANUAL

mode characteristics are maintained even though re-

mote STOP/START is used. The RUN LED will flash if

stopped with remote contact.

PARAMETERS SELECT (J1/15-16) With this contact open, compressor operates within

pressure range P2A. With this contact closed, com-

pressor operates within pressure range P2B. Suitable

for 2 compressor base/load sequencing.

RS 232 SERIAL PORT (J4) Full 2-way communication and control that provides

analog display transmission, signal status and com-

pressor status indication, as well as remote STOP/

START via computer. A great tool for preventive main-

tenance programs and customer DCS management

packages. Baud rates are factory settable from 150 to

4800. Consult factory for communication protocol.

Section 2

DESCRIPTION

6

2.8 SUPERVISOR IAUXILIARY DIGITAL INPUTS

PARAMETERS OPERATION

MOTOR/OVERLOAD (J1/7-8) Monitors normally closed compressor motor overload

contact. Will initiate compressor shutdown, flash the

motor LED on the graphic map and display the mes-

sage “MOTOR OVERLOAD” if the contact opens.

COOLING SYSTEM MONITOR (J1/9-10) Monitors cooler fan overload (AC), water pressure

switch (WC), and/or canopy fan motor overload. Nor-

mally closed signal when opened will initiate compres-

sor shutdown and display the message “FAN OL/LOW

WATER”

DRY-SIDE DISCHARGE TEMPERATURE Separate electronic switch monitors discharge

(J1/11-12) (T3) temperature on the dry side of the separator and will

initiate a shutdown if greater than 235ºF (113ºC).

Message display is “HIGH TEMP T3”.

INTERSTAGE TEMPERATURE (J1/13-14) (T4) Only used on tandem compressors. Parameters are

same as T3. Message display is “HIGH TEMP T4.

2.9 OPTIONAL FACTORY CONFIGURATIONS

A. MULTIPLE PRESSURE RANGES

Supervisor I offers the convenience of programming

1, 2, or 3 UNLOAD/LOAD pressure ranges that can

be enabled at the flip of a switch. The standard pro-

gram offers “A” or “B” ranges that are selectable

based on the status of the J1/15-16 terminals. With

the terminals open, the “A” range is selected. With

the terminals closed, the “B” range is selected. With

this modification range “C” is provided. To select the

“C” range, close terminals 1-2 on additional input

board. All ranges may be programmed irrespective

of the range selected for operation.

B. AUXILLARY DRY CONTACTS

With the addition of an extra 8-relay output board,

auxillary dry contracts can be provided to remotely

indicate each annunciation point as listed below.

ON EXISTING RELAY BOARD K6 - Max Press P1 Prealarm

(J10 Slot #7) Indicates at 98% of Max Press P1 shutdown.

Does not latch.

K7 - Low Press P3 Prealarm

Indicates at 5 PSI above Min Press P3

shutdown. Does not latch.

K8 - High Temp T1 Prealarm

Indicates at 225ºF. Does not latch.

ON ADDITIONAL 8 RELAY OUTPUT BOARD K1 - Max Press P1 shutdown, P1 or P2 sensor

(J11 Slot #8) failure.

K2 - Min Press P3 shutdown, P3 or P4 sensor

failure.

K3 - High Temp T1, T2, T3, T4 shutdown, T1 or

T2 sensor failure.

K4 - Compressor Motor Overload.

K5 - Fan Overload/Low Water Pressure.

K6 - Oil Filter Maintenance Required.

K7 - Separator Maintenance Required.

K8 - Inlet Filter Maintenance Required.

Section 3

PROGRAMMING PROCEDURES

7

3.1 SUPERVISOR IMICROCONTROLLER PRO-

GRAMMING

Several display and operational functions are user

programmable from the Supervisor keypad. Re-

peatedly pressing the “PROG” pad will scroll the

message display through the various program-

mable parameters. The cursor pad (Y) is used to

change parameter values. A built-in timed delay fea-

ture returns the message display to operation mode

after 5 seconds of inactivity.

PARAMETER (IN SEQUENTIAL ORDER) OPERATION

LANGUAGE Press the cursor pad for 2 seconds to change to next

language for the message display. Languages in order

are: French, German, Italian, Spanish and English.

AUTOMATIC/MANUAL The controller default state is AUTOMATIC operation.

If line pressure is adequate and/or the sump pressure

is greater than 5 to 10 PSIG (0.3 to 0.7 bar), pressing

the ON/OFF pad will put the control in STANDBY

mode until line pressure drops to the programmed dif-

ferential value and the sump pressure is low enough to

permit a START. AUTOMATIC mode provides a timed

STOP with automatic restart operation. Automatic re-

start after power failure is also included in AUTOMAT-

IC mode.

MANUAL mode ignores the line pressure permissive

of AUTOMATIC and starts the compressor with ON/

OFF as long as the minimum sump pressure and other

fault conditions are satisfied. The compressor is only

stopped manually with no time stop and no automatic

restart after power failure.

PRESSURE UNITS Selects bar or PSIG; use cursor key to select. 1 bar =

14.5 PSIG.

TEMPERATURE UNITS ºC OR ºF; use cursor key to select.

MAXIMUM PRESSURE P2A Use the cursor key to set the OFF LOAD pressure set-

ting. Depressing the cursor pad for more than 2 se-

conds will initiate a fast scrolling mode to quickly reach

the desired setpoint for all programmable setpoints. A

wraparound feature (on all functions) returns the value

to its lowest limit if scrolling exceeds the high limit. Typ-

ically set for 110 PSIG (7.6 bar).

PRESSURE DIFFERENTIAL P2A Selects the ON LOAD setting by subtracting the differ-

ential from P2A. Normally set for 10 PSIG (0.7 bar).

MAXIMUM PRESSURE P2B Same as P2A, but provides a second OFF LOAD set-

ting for base/load operation.

PRESSURE DIFFERENTIAL P2B Same as P2A, but provides a second ON LOAD set-

ting for base/load operation.

UNLOAD TIME Adjusts timed stop function if compressor is running

unloaded for 0 to 60 minutes.

WYE TO DELTA TIME Adjusts transition timer for Wye-Delta starters from 0

to 30 seconds. ON LOAD function is delayed by the

value of Wye to Delta time. A separate relay contact is

provided with this function. It is recommended that a

transition time of 8 seconds not be exceeded.

DRAIN TIME AND DRAIN INTERVAL A timed contact is furnished to control a condensate

(OPTIONAL) removal solenoid valve. Both drain dura-

tion time (1 to 10 seconds) and time internal between

drains (1 to 10 minutes) may be set from these modes.

Section 4

START-- UP PROCEDURES

8

4.1 MOTOR ROTATION DIRECTION CHECK

After the electrical wiring has been done, it is neces-

sary to check the direction of the motor rotation.

With the control system in MANUAL mode, press

the ON/OFF pad twice in succession to bump start

the compressor. When looking at the motor from the

end opposite the compressor unit, the shaft should

be turning counterclockwise for direct drive pack-

ages and clockwise for gear driven packages. If the

motor shaft is not turning in the proper direction, dis-

connect the power to the starter and exchange any

two of the three motor leads, then re-check rotation.

A “Direction of Rotation” decal is located on the cou-

pling guard between the motor and compressor to

show proper motor/compressor rotation.

4.2 INITIAL START-UP PROCEDURE

The following procedure should be used to make the

initial start-up of the compressor:

1. Read the preceding pages of this manual thor-

oughly.

2. Be sure that all preparations and checks de-

scribed in the Installation Section have been

made.

3. Crack open the shut off valve to the service line.

4. Set the compressor in MANUAL mode and start

the compressor by pressing the ON/OFF pad.

5. Check for possible leaks in piping.

6. Slowly close the shut-off valve and check that the

maximum pressure (P2) and pressure differen-

tial (P2) are correctly programmed.

7. Observe the operating temperature. If the operat-

ing temperature exceeds 205ºF (96ºC), the cool-

ing system or installation environment should be

checked.

8. Observe return line sight glasses and mainte-

nance indicators.

9. Open shut-off valve to service line.

10. Reinspect the compressor for temperature and

leaks the following day.

4.3 SUBSEQUENT START-UP PROCEDURE

On subsequent start-ups, check that the proper lev-

el is visible in the fluid sight glass and simply press

the ON/OFF pad. When the compressor is running,

observe the control panel for maintenance indica-

tions.

4.4 SHUTDOWN PROCEDURE

To shut the compressor down, simply press the

ON/OFF pad. On MANUAL operation shutdown is

immediate; on AUTOMATIC operation, shutdown

is preceded by a 10 second UNLOAD mode.

Section 5

MAINTENANCE AND TROUBLESHOOTING

9

5.1 CONTROL SYSTEM ADJUSTMENT

Refer to Figure 2-1. Before starting the compressor,

but with power applied, press the PROG pad on the

Supervisor panel three times to enter the PRO-

GRAMMING mode. Continue pressing the PROG

pad until “MAX PRESS P2A” is displayed. Use the

cursor (UP arrow) pad to set the desired UNLOAD

pressure (110 PSIG [7.6 bar]). Note that pressing

the pad for over 2 seconds will initiate fast scrolling

of the value being set.

Once the correct value is selected, press the PROG

pad to proceed to the display “PRES DIF P2A”. This

valueisusedtosettheLOADpressurewherethe

compressor will begin building pressure (10 PSID

[0.7 bar]). This will provide LOAD/UNLOAD opera-

tion at 100 to 110 PSIG [6.7 to 7.6 bar]). These val-

ues will be entered when the display is returned to

operating mode condition by continuing to press

PROG through the end of the PROGRAMMING

menu or allowing the display to automatically return

to operating mode status after 5 seconds of inactiv-

ity. While scrolling with the PROG pad, all existing

user programmable values will be displayed.

5.2 TROUBLESHOOTING

The information contained in the Troubleshooting

chart has been compiled from field report data and

factory experience. It contains symptoms and usual

causes for the described problems. However, DO

NOT assume that these are the only problems that

may occur. All available data concerning the trouble

should be systematically analyzed before undertak-

ing any repairs or component replacement proce-

dures.

A detailed visual inspection is worth performing for

almost all problems and may avoid unnecessary

additional damage to the compressor.

a. Check for loose wiring.

b. Check for damaged piping.

c. Check for parts damaged by heat or an electrical

short circuit, usually apparent by discoloration or

a burnt odor.

Should your problem persist after making the rec-

ommended check, consult your nearest Sullair Dis-

tributor or the Sullair Corporation factory Service

Department.

Section 5

MAINTENANCE AND TROUBLESHOOTING

10

5.2 TROUBLESHOOTING GUIDE

SYMPTOM PROBABLE CAUSE REMEDY

COMPRESSOR WILL NOT START Main Disconnect Switch Open Close switch.

Line Fuse Blown Replace fuse.

Control Transformer Fuse Blown Replace fuse.

Motor Starter Overloads Tripped Reset. Should trouble persist, check

whether motor starter contacts are

functioning properly.

Low Incoming Line Voltage Check voltage. Should voltage check low,

consult power company.

Supervisor Panel Fuse is Blown Replace fuse.

Replace Supervisor controller if no display

or erratic display.

COMPRESSOR SHUTS DOWN

WITH AIR DEMAND PRESENT Loss of Control Voltage Reset. If trouble persists, check that line

pressure does not exceed maximum

operating pressure of the compressor

(specified on nameplate).

Low Incoming Voltage Consult power company. The Sullair

Supervisor will provide indication of most

maintenance problems if control power has

not been lost. Shutdowns will occur upon a

faulty condition or a bad sender condition.

Excessive Operating Pressure Check maximum P2 pressure setting.

“High Press P1” display; Max P1 pressure

may be set too low. Consult factory for

recalibration.

Defective solenoid valve; solenoid valve

should cause control lever to move to

unload stop when the load/unload relay

contact opens. Repair if defective.

Defective blowdown valve; blowdown valve

should exhaust sump pressure to 40 to 50

PSIG (2.8 bar to 3.4 bar) when maximum

operating pressure is reached. Repair if

defective.

Open or shorted P1, P2, P3 or P4 sender

message; replace sender indicated.

“High Temp T1“ or “T3” Message Cooling water temperature too high;

Displayed increase water flow (water-cooled only).

Cooling water flow insufficient; check water

lines and valves (water-cooled only).

Cooler plugged; clean tubes. If plugging

persists, install water conditioner

(water-cooled only).

Cooling air flow restricted; clean cooler and

check for proper ventilation.

Ambient temperature is too high; provide

sufficient ventilation.

Low fluid level; add fluid.

Clogged filter; change the fluid filter

element as indicated by Supervisor control.

Thermal valve not functioning properly;

replace element (air-cooled only).

Water flow regulating valve not functioning

properly; change (water-cooled only).

Open or shorted T1 or T2 sender; check for

a short or open circuit to probe and

correct wiring.

Section 5

MAINTENANCE AND TROUBLESHOOTING

11

5.2 TROUBLESHOOTING GUIDE (continued)

SYMPTOM PROBABLE CAUSE REMEDY

COMPRESSOR SHUTS DOWN

WITH AIR DEMAND PRESENT

(cont’d.) Low Fluid Pressure

(“Low Pressure P3” display) Check fluid level.

Low Water Pressure Check starting switch gear.

(“Fan OL/Low Water“ display) Check the cooling fan motor or water

flow system.

COMPRESSOR WILL NOT BUILD

UP FULL DISCHARGE PRESSURE Air Demand is Too Great Check service lines for leaks or open

valves.

Dirty Air Filter Check for filter maintenance message on

Supervisor panel and change or clean

element if required.

Pressure Regulator Out

of Adjustment Adjust regulator according to control

adjustment instructions in the Maintenance

Section.

Defective Pressure Regulator Check diaphragm and replace if necessary

(kit available).

LINE PRESSURE RISES ABOVE

UNLOAD P2 PRESSURE

SETTING ON THE

SUPERVISOR Leak in Control System Causing

Loss of Pressure Signals Check for leaks.

Defective Solenoid Valve Check that Sullicon Control lever is moved

to unload stop when Supervisor is in NO

LOAD mode. Repair or replace if

necessary (kit available).

Defective Blowdown Valve Check that sump pressure is exhausted to

the atmosphere when in the OFF LOAD

mode. Repair or replace if necessary

(kit available).

Plugged Control Line Filter Clean or repair if necessary.

EXCESSIVE FLUID

CONSUMPTION Clogged Return Line Strainer

or Orifice Clean strainer (screen and o-ring replace-

ment kit available).

Clean orifice.

Separator Element Damaged or

Not Functioning Properly Change separator.

Leak in the Lubrication System Check all pipes, connections and compo-

nents.

Excess Fluid Foaming Drain and change.

Fluid Level Too High Drain excess fluid.

PRESSURE RELIEF VALVE

OPENS REPEATEDLY Defective Pressure Relief Valve Replace pressure relief valve.

Check Separator Differential

(plugged) DP1.

Section 5

MAINTENANCE AND TROUBLESHOOTING

12

5.3 MESSAGE DISPLAY DEFINITIONS

In addition to programming prompts, the 20-charac-

ter electro-luminescent display provides information

regarding machine status and trouble conditions.

These messages can be displayed in any one of five

languages; English, French, Spanish, German or

Italian. The following table explains what each mes-

sage means as it relates to the compressor.

MESSAGE DISPLAY DEFINITIONS

MACHINE STATUS MESSAGES EXPLANATION

MANUAL SHUTDOWN The machine is ready to be started. Machine

control is powered up; permissives are made;

machine has been stopped via the ON/OFF

pad, the remote start/stop contact (if the

RUNNING LED is flashing), or a computer com-

mand through the RS232 port.

STANDBY The machine is in AUTOMATIC mode and a

start was initiated, but either the line pressure

P2 is higher than the LOAD setpoint or sump

pressure P1 is higher than 14.5 PSIG. Machine

start will occur when these pressures are satis-

fied.

ON LOAD The compressor is running and P2 is less than

the UNLOAD setpoint. The LOAD/UNLOAD

solenoid valve relay (output J10/50-51) is en-

ergized. The compressor is attempting to meet

the system air demand.

OFF LOAD The compressor is running and P2 has exceed-

ed UNLOAD setpoint, but has not dropped

below the LOAD setpoint (DIFF PRESS P2). The

UNLOAD solenoid valve relay is deenergized

and the compressor is unloading.

STOP MODE The machine is in AUTOMATIC mode and a

stop command has been initiated either via

the ON/OFF pad or the remote STOP/START

contact (J1/1-2). This mode runs the com-

pressor for 10 seconds with the LOAD/UNLOAD

valve relay deenergized before stopping.

5.4 TROUBLE INDICATION SETPOINTS

CONDITION/DISPLAY CAUSE

P1 High Discharge Pressure Shutdown Default is 135 PSIG, factory settable for

HIGH PRESSURE P1 high pressure machines.

50 - 200 PSIG

Machine will shut down and must be cleared

and reset by pressing ON/OFF once before

restart is possible.

P1 High Discharge Pressure Prealarm Indicates at 98% of Max Press P1.

HIGH PRESSURE P1

Failure to Run, P1 Pressure Loss Since no run contact is used to indicate run

PRESSURE LOSS status, the Supervisor examines P1 pressure

to see if a minimum of 14.5 PSIG is being

produced when the RUN output is energized.

Reading is overridden for 1 minute at startup.

Section 5

MAINTENANCE AND TROUBLESHOOTING

13

5.4 TROUBLE INDICATION SETPOINTS (Cont’d.)

CONDITION/DISPLAY CAUSE

Low Oil Pressure P3 Shutdown Min Press P3 is factory preset at 10 PSIG.

(Injection Oil Pressure) Factory adjustable 3 - 145 PSIG. Requires

LOW PRESSURE P3 clearing of shutdown by pressing ON/OFF once

to reset.

Low Oil Pressure P3 Prealarm Set for 5 PSIG above Min Press P3. Not

LOW PRESSURE P3 latching.

High Temperature T1 Shutdown Pre-programmed shutdown at 235ºF (113ºC).

(Compressor Discharge Temperature) Requires ON/OFF reset to clear.

HIGH TEMPERATURE T1

High Temperature T1 Prealarm Pre-programmed indication at 225ºF (107ºC).

HIGH TEMPERATURE T1 Not latching.

High Temperature T2 Shutdown Pre-programmed shutdown at 235ºF (113ºC).

(Injection Oil Temperature)

HIGH TEMPERATURE T2

High Temperature T3 Shutdown Separate RTD controller board provides

(Dry-side Discharge Temperature) a digital input at J1/11-12. Preset at

HIGH TEMPERATURE T3 235ºF (113ºC).

High Temperature T4 Shutdown Second channel of RTD controller board

(Tandem Interstage Temperature) provides a digital input at J1/13-14. Preset

HIGH TEMPERATURE T4 at 235ºF (113ºC). (Note: J1/13-14 must be

jumpered if not a tandem compressor).

P1 - P4 Shorted Sensor Shutdown Signal voltage > 4.82 volts (196 PSIG).

SHORT CIRC Px SENDER

P1 - P4 Open Sensor Shutdown Signal voltage < 0.15 volts.

OPEN CIRC Px SENDER

T1 - T2 Shorted Sensor Shutdown Resistance < 81 ohms (-45 C).

SHORT CIRC Tx SENDER

T1 - T2 Open Sensor Shutdown Resistance >176 ohms (200 C).

OPEN CIRC Tx SENDER

Inlet Filter Maintenance Required Vacuum Switch connected to J1/5-6 and

AIR FILTER MAINT RQD preset for 22” WC. Indicates when inlet

filter is too dirty for proper air flow. Not

latched and not a shutdown condition.

Separator Maintenance Required Calculated: P1 - P2 - 2 PSIG

SEPARATOR MAINT RQD Preset to warn at 10 PSIG. Warnings will

occur in unloading/unloaded states and

should be ignored. Only valid at full load

condition. Not latched and not a shutdown

condition.

Oil Filter Maintenance Required Calculated: P4 - P3. Preset at 20 PSIG. P4

OIL FILTER MAIN RQD is located on the high pressure side of the

oil filter. P3 is the injection oil pressure on the

low pressure side of the oil filter. Not latched,

not a shutdown condition.

Emergency Stop Indicates if Emergency Stop button is depress-

EMERGENCY SHUTDOWN ed or if optional sensors wired in series with

the E-Stop button and its master control relay

are open. Must be cleared and reset by press-

ing ON/OFF once.

Section 5

MAINTENANCE AND TROUBLESHOOTING

14

5.4 TROUBLE INDICATION SETPOINTS (Cont’d.)

CONDITION/DISPLAY CAUSE

Fan Overload/Low Water Pressure Shutdown of canopy or cooler fan motor

FAN OL/LOW WATER overload as well as water pressure switch for

water-cooled machines. Normally closed

contact wired to J1/9-10. (Water pressure

switch is normally open and closes with 10

PSIGminimumwaterpressure.Faultmustbe

cleared and reset by pressing ON/OFF pad

once.

Printed in U.S.A.

Specifications Subject To

Change Without Prior Notice

WORLDWIDE SALES AND SERVICE

R

SULLAIR EUROPE, S.A.

Chemin de Genas BP 639

69800 Saint Priest, France

Telephone: 33-72232425

FAX: 33- 78907168

SULLAIR CORPORATION

Subsidiary of Sundstrand Corporation

3700 East Michigan Boulevard

Michigan City, Indiana 46360 U.S.A.

Telephone: 1-- 800-- SULLAIR (U.S.A. Only) or

1-- 219--879-- 5451

FAX: (219) 874-- 1273

SULLAIR ASIA, LTD.

ROOM 2304A

Shartex Plaza Ctr.

No. 88 Zun Yi Nan Rd.

Shanghai, P.R.C.

Telephone: 21-2192066

FAX: 21- 2196568

FAX: (219) 874--1835 (Parts)

FAX: (219) 874-- 1805 (Service)

Table of contents

Other Sullair Controllers manuals

Sullair

Sullair 02250165-411 R01 User manual

Sullair

Sullair ShopTek User manual

Sullair

Sullair WSPC User manual

Sullair

Sullair SUPERVISOR CONTROLLER User manual

Sullair

Sullair Supervisor II User manual

Sullair

Sullair SUPERVISOR CONTROLLER User manual

Sullair

Sullair EC2000 User manual

Sullair

Sullair 900 User manual

Sullair

Sullair SUPERVISOR II Series User manual

Sullair

Sullair Supervisor IE User manual