6

Section 2

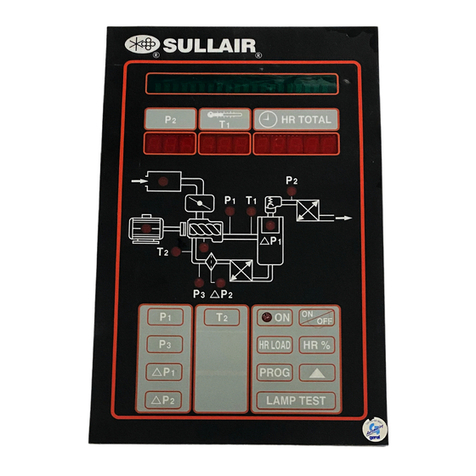

SUPERVISOR DESCRIPTION

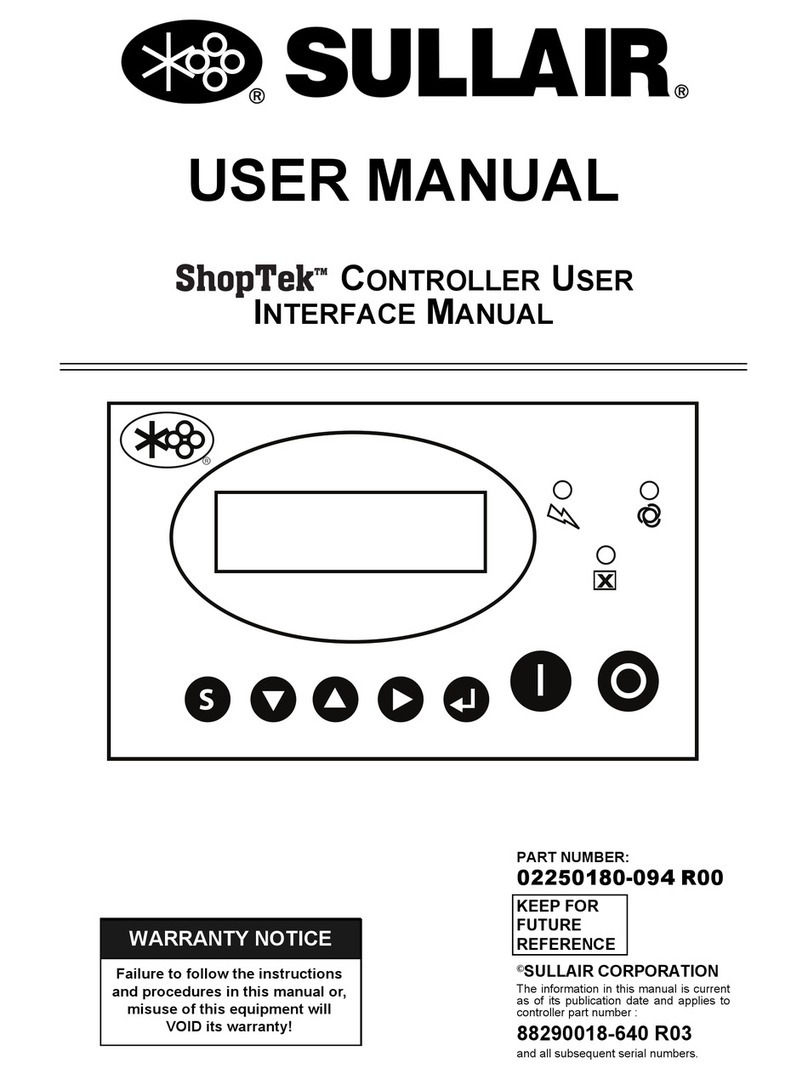

using the up arrow and down arrow keys, and push

the enter button. The value can be changed by

using the up arrow or down arrow keys. When edit-

ing is finished, pushing the enter key will fix the

value. If during a change the ESC key is pushed,

editing is terminated and the original value is reset.

The left and right arrow keys can be used to move

to other digits or letters in a value. For example to

change a value from 100 to 500, the left arrow key

can be used to position the cursor to the 1 digit in

the 100, and the up arrow key used to increment

the digit to 5.

Text fields can also be edited in the same manner.

Push the enter key to start the edit, use the left and

right arrow keys to move to the letter to be changed,

then use the up and down arrow to change the let-

ter. Push the enter key to complete the edit.

The following are detailed descriptions of the vari-

ous displays.

2.4 STATUS - CURRENT PRESSURES, TEMPERA -

TURES, INPUTS AND OUTPUTS

All inputs and outputs are displayed showing both

the designator and the description (eg. T1-

Discharge) along with the selected temperature (C

or F) or pressure (psi, bar, kPa) units. Digital inputs

and outputs are shown either as a ‘0’ (zero) or ‘1’

(one). Zero is off and one is on. This is a view only

display.

The order of display is :

Temperatures - T1 through T5 depending on

model.

Pressures - P1 through P4 depending on model.

Delta pressures - dp1 through dp3 depending on

model.

Load Hours - Hours machine has run loaded.

Run Hours - Hours machine has run loaded or

unloaded.

Load Cycles - Number of load/unload cycles.

Starts - Number of times machine has started.

E-Stop String - E-Stop push button.

Aux E-Stop - Auxiliary E-Stop, wired by customer.

Digital Inputs - D1 through D10, depending on

model.

Relay Outputs - K1 through K8, depending on

model.

2.5 CONTROL PARAMETERS - PRESSURE, TEM-

PERATURE AND TIMER SETTINGS

Parameters that control the operation of the

machine are viewed and set using this display.

These parameters may vary by machine model.

The Control Parameters are :

Unload pressure - The pressure where the

machine is unloaded. For example if this parameter

is set to 110 psi (7.6 bar) the machine will unload

when the line pressure is above 110 psi (7.6 bar).

Load delta - The pressure differential below the

unload pressure where the machine is loaded. For

example if the unload pressure is set to 110 psi (7.6

bar) and the load differential is set to 10 psid (0.7

bar), the machine will load when the line pressure

goes below 100 psi (6.9 bar).

Setpoint - (VSD packages only) The targeted pres-

sure for the variable speed controls. This is normal-

ly adjusted near the bottom of the load/unload band

above. The speed will be adjusted to maintain this

pressure. Refer to Section 6 for additional details.

Unload Time - If the machine is running in AUTO

mode, this parameter specifies the amount of time

that the machine will run unloaded before shutting

off. If the time is set less than 15 minutes (for

example 5), there may be times when the machine

will run unloaded for more than 15 minutes. This is

because there is another timer that keeps the

machine from being started more than four times an

hour. This secondary timer is disabled when a

machine is configured for VSD motor control.

Drain Interval - If the machine has an electric sole-

noid drain, this parameter and the following param-

eter (Drain Time) are used to turn on the drain. The

interval is the time between activations of the drain

and the Drain Time is the length of the time ener-

gized. This does not apply to the Sullair SCD zero

loss drain, which is not controlled or monitored by

the Supervisor.

Drain Time - Length of time that drain is energized.

Restart time -

Time to wait after power up before starting machine.

This parameter is used to keep several machines

from starting at the same time after power up, or to

delay start until other equipment is started. If dis-

abled parameter is zero, the machine will not auto-

matically start after power up. If this parameter is a

Enabling this function also enables automatic

restart after power recovery. Be sure to depress

the Emergency Stop button to defeat this function

when automatic start is to be prevented.