Section 2

SEQUENCING WITH MULTIPLE SUPERVISOR CONTROLS

5

120 seconds, if the pressure continues to drop the timer will count down faster. When the

timer expires or the pressure drops below 90 psig (6.2 bar) the first machine is started. If

the pressure does not go above 90 psig (6.2 bar) for 10 seconds (Recovery Time) the next

machine will start and so on until all machines are started.

As machines are started and loaded, there will be only one machine that is modulating, the

others will be forced to "FULL LOAD". The modulating (trim) machine will load at 2psig (.14

bar) above the load pressure parameter, 102 psig (7.03 bar) in this example, and unload at

2 psig (.14 bar) below unload pressure parameter, 108 psig (7.4 bar) in this example. The

reason for this narrower load/unload band is to keep all machines from loading and unload-

ing at the same time. The trim machine will be identified on the display as "TRIM" operat-

ing state. If the pressure rises above the unload pressure -2 psig (.14 bar)(108 psig (7.4bar)

the trim machine will unload (display will say "UNLOADED") and the next machine in the

sequence will switch from full load to trim. If after Recovery Time the pressure is still above

108 psig (7.4 bar) then the trim machine will unload and so on until all machines are

unloaded. Then if the pressure falls below load pressure + 2 psig (.14 bar) or 102 psig (7.03

bar) the first machine in the sequence will load and be the trim machine. If after the

Recovery Time the pressure is still below 102 psig (7.03 bar) then the trim machine will go

to full load and the next machine in the sequence will load and become the trim machine.

2.6 SYSTEM SETUP AND TUNING

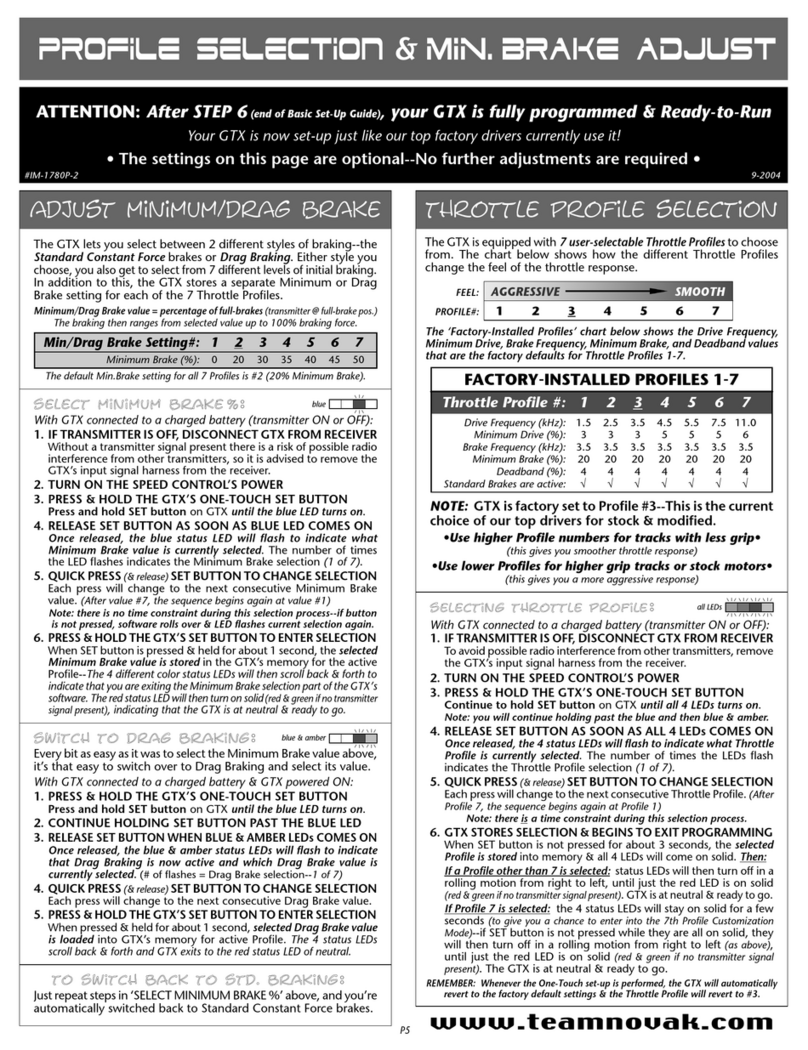

The following shows the settings for a system of low pressure 90-100 psig (6.2 to 6.9 bar)

machines. The Trim High & Low Setpoints are not settable parameters, they are calculated

from the Unload and Load pressures. The Trim High Setpoint is 2 PSI (.14 bar) below the

Unload pressure and the Trim Low Setpoint is 2 PSI (.14bar) above the Load pressure.

100 psig (6.9 bar) Unload

98 psig (6.8 bar) Trim High Setpoint (calculated parameter)

92 psig (6.3 bar) Trim Low Setpoint (calculated parameter)

90 psig (6.2 bar) Load

85 psig (5.9 bar) Lowest pressure

10 Recover time (seconds)

Note that the unload pressure is set to 100 psi (6.9 bar) and not 110 psi (7.6 bar) as is nor-

mal on a stand alone machine.A stand alone machine set up at 100 psi (6.9 bar) to 110 psi

(7.6 bar) , starts to modulate above 100 psi (6.9 bar) and the horsepower is reduced.

However, in a sequenced system a machine may be forced to full load, which would draw

more than the rated horsepower above 100 psi (6.9 bar). Therefore the modulation band

of machines in a system should be set up to be 10 psi (.7 bar) lower than their rated pres-

sure.

All running machines operate either at full load or unloaded except for the one that will here-

after be called the trim machine. The trim machine unloads when the line pressure rises

above the Trim High setpoint.

The Trim High and Low setpoints are necessary because the trim machine must unload

before the fully loaded machines and load before the unloaded machines, otherwise all