Sullair WSPC User manual

Failure to follow the instructions

and procedures in this manual or,

misuse of this equipment will

VOID its warranty!

WARRANTY NOTICE

PART NUMBER:

KEEP FOR

FUTURE

REFERENCE

USER MANUAL

©SULLAIR CORPORATION

The information in this manual is current

as of its publication date, and applies to

compressor serial number:

and all subsequent serial numbers.

02250167-859 R01

200710010000

WSPC USER INTERFACE MANUAL

FOR THE WS CONTROLLER™

AIR CARE SEMINAR TRAINING

Sullair Air Care Seminars are courses that provide hands-on instruction for the proper operation, maintenance,

and servicing of Sullair products. Individual seminars on Industrial compressors and compressor electrical

systems are offered at regular intervals throughout the year at Sullair’s corporate headquarters training facility

located at Michigan City, Indiana.

Instruction includes training on the function and installation of Sullair service parts, troubleshooting common

faults and malfunctions, and actual equipment operation. These seminars are recommended for maintenance,

contractor maintenance, and service personnel.

For detailed course outlines, schedule, and cost information contact:

SULLAIR CUSTOMER CARE TRAINING DEPARTMENT

1-888-SULLAIR or

219-879-5451 (ext. 5623)

www.sullair.com

- Or Write -

Sullair Corporation

3700 E. Michigan Blvd.

Michigan City, IN 46360

Attn: Service Training Department.

TABLE OF CONTENTS

SECTION 1—SAFETY

5 1.1 GENERAL

5 1.2 PERSONAL PROTECTIVE EQUIPMENT

5 1.3 PRESSURE RELEASE

6 1.4 FIRE AND EXPLOSION

6 1.5 MOVING PARTS

7 1.6 HOT SURFACES, SHARP EDGES AND SHARP CORNERS

7 1.7 TOXIC AND IRRITATING SUBSTANCES

8 1.8 ELECTRICAL SHOCK

8 1.9 LIFTING

9 1.10 ENTRAPMENT

SECTION 2—OVERVIEW

11 2.1 MANUAL CONTENTS

12 2.2 SYSTEM COMPATIBILITY

12 2.3 INSTALLING THE WSPC USER INTERFACE SOFTWARE

12 2.4 INSTALLING OR UPDATING THE FRAMEWORK

12 2.5 UNINSTALL THE WSPC SOFTWARE

SECTION 3—GETTING STARTED

13 3.1 ACCESS PRIVILEGES

13 3.2 STARTING THE SOFTWARE

14 3.3 WINDOWS® BASIC

15 3.4 CONNECTING THE PC TO THE CONTROLLER

15 3.5 CONNECTING / DISCONNECTING THE WSPC USER INTERFACE AND

THE WS CONTROLLER

17 3.6 THE WSPC DISPLAY SCREEN

17 3.7 COMPRESSOR STATUS BAR

18 3.8 FILE MENU

19 3.9 REPORT

19 3.10 COM PORT

19 3.11 ABOUT

TABLE OF CONTENTS

SECTION 4—DISPLAY DESCRIPTIONS

21 4.1 COMPRESSOR STATUS BAR

22 4.2 COMPRESSOR DATA DISPLAY (DEFAULT SCREEN)

24 4.3 MACHINE INFO DISPLAY

24 4.4 SERVICE DISPLAY

27 4.5 MAINTENANCE DISPLAY

28 4.6 DISTRIBUTOR INFORMATION

29 4.7 SEQUENCE SYSTEM DISPLAY

30 4.8 ADJUSTMENTS DISPLAY

SECTION 5—MENU BAR

39 5.1 FILE MENU—USER PROFILES AND PREFERENCES

43 5.2 REPORTS

44 5.3 COMMUNICATIONS PORT

45 5.4 INFORMATION ABOUT WSPC

SECTION 6—VARIABLE SPEED DRIVE (VSD)

47 6.1 VSD OPERATION

47 6.2 COMPRESSOR DATA TAB

48 6.3 VSD PERFORMANCE DATA

49 6.4 CLEAR RECENT DATA

49 6.5 DELIVERY HISTORY

50 6.6 SERVICE DISPLAY TAB

50 6.7 MAIN MOTOR VFD STATUS BOX

51 6.8 ADJUSTMENTS TAB

52 6.9 ADMINISTRATOR LEVEL VSD ADJUSTMENTS

SECTION 7—ADMININISTRATOR LEVEL FUNCTIONS

53 7.1 ADMINISTRATOR LEVEL FUNCTIONS

53 7.2 ACCESSING THE ADMINISTRATOR LEVEL

54 7.3 COMMISSIONING A CONTROLLER

56 7.4 MAINTENANCE DISPLAY

59 7.5 ADMINISTRATOR ADJUSTMENTS (ADMIN) DISPLAY

67 7.6 MODBUS FUNCTIONS

69 7.7 DRYER SETUP DISPLAY

Section 1

5

SAFETY

1.1 GENERAL

Sullair Corporation and its subsidiaries design and

manufacture all of their products so they can be

operated safely. However, the responsibility for safe

operation rests with those who use and maintain

these products. The following safety precautions are

offered as a guide which, if conscientiously followed,

will minimize the possibility of accidents throughout

the useful life of this equipment.

The compressor should be operated only by those

who have been trained and delegated to do so, and

who have read and understood this Operator's

Manual. Failure to follow the instructions, procedures

and safety precautions in this manual may result in

accidents and injuries. NEVER start the compressor

unless it is safe to do so. DO NOT attempt to operate

the compressor with a known unsafe condition. Tag

the compressor and render it inoperative by

disconnecting and locking out all power at source or

otherwise disabling its prime mover so others who

may not know of the unsafe condition cannot attempt

to operate it until the condition is corrected.

Install, use and operate the compressor only in full

compliance with all pertinent OSHA regulations and/

or any applicable Federal, State, and Local codes,

standards and regulations. DO NOT modify the

compressor and/or controls in any way except with

written factory approval.

While not specifically applicable to all types of

compressors with all types of prime movers, most of

the precautionary statements contained herein are

applicable to most compressors and the concepts

behind these statements are generally applicable to

all compressors.

1.2 PERSONAL PROTECTIVE

EQUIPMENT

A. Prior to installing or operating the compressor,

owners, employers and users should become

familiar with, and comply with, all applicable

OSHA regulations and/or any applicable Federal,

State and Local codes, standards, and regula-

tions relative to personal protective equipment,

such as eye and face protective equipment,

respiratory protective equipment, equipment

intended to protect the extremities, protective

clothing, protective shields and barriers and elec-

trical protective equipment, as well as noise

exposure administrative and/or engineering con-

trols and/or personal hearing protective equip-

ment.

1.3 PRESSURE RELEASE

A. Install an appropriate flow-limiting valve between

the service air outlet and the shut-off (throttle)

valve, either at the compressor or at any other

point along the air line, when an air hose exceed-

ing 1/2" (13mm) inside diameter is to be con-

nected to the shut-off (throttle) valve, to reduce

pressure in case of hose failure, per OSHA Stan-

dard 29 CFR 1926.302(b)(7) and/or any applica-

ble Federal, State and Local codes, standards

and regulations.

B. When the hose is to be used to supply a mani-

fold, install an additional appropriate flow-limiting

valve between the manifold and each air hose

exceeding 1/2" (13mm) inside diameter that is to

be connected to the manifold to reduce pressure

in case of hose failure.

C. Provide an appropriate flow-limiting valve at the

beginning of each additional 75 feet (23m) of

hose in runs of air hose exceeding 1/2" (13mm)

NOTE

OPERATOR IS REQUIRED TO READ

ENTIRE INSTRUCTION MANUAL.

SECTION 1

6

inside diameter to reduce pressure in case of

hose failure.

D. Flow-limiting valves are listed by pipe size and

flow-rated. Select appropriate valves accordingly,

in accordance with their manufacturer's recom-

mendations.

E. DO NOT use air tools that are rated below the

maximum rating of the compressor. Select air

tools, air hoses, pipes, valves, filters and other

fittings accordingly. DO NOT exceed manufac-

turer's rated safe operating pressures for these

items.

F. Secure all hose connections by wire, chain or

other suitable retaining device to prevent tools or

hose ends from being accidentally disconnected

and expelled.

G. Open fluid filler cap only when compressor is not

running and is not pressurized. Shut down the

compressor and bleed the receiver tank to zero

internal pressure before removing the cap.

H. Vent all internal pressure prior to opening any

line, fitting, hose, valve, drain plug, connection or

other component, such as filters and line oilers,

and before attempting to refill optional air line

anti-icer systems with antifreeze compound.

I. Keep personnel out of line with and away from

the discharge opening of hoses or tools or other

points of compressed air discharge.

J. DO NOT use air at pressures higher than 2.1 bar

for cleaning purposes, and then only with effec-

tive chip guarding and personal protective equip-

ment per OSHA Standard 29 CFR 1910.242 (b)

and/or any applicable Federal, State, and Local

codes, standards and regulations.

K. DO NOT engage in horseplay with air hoses as

death or serious injury may result.

1.4 FIRE AND EXPLOSION

A. Clean up spills of lubricant or other combustible

substances immediately, if such spills occur.

B. Shut off the compressor and allow it to cool.

Then keep sparks, flames and other sources of

ignition away and DO NOT permit smoking in the

vicinity when checking or adding lubricant or

when refilling air line anti-icer systems with anti-

freeze compound.

C. DO NOT permit fluids, including air line anti-icer

system antifreeze compound or fluid film, to

accumulate on, under or around acoustical mate-

rial, or on any external surfaces of the air com-

pressor. Wipe down using an aqueous industrial

cleaner or steam clean as required. If necessary,

remove acoustical material, clean all surfaces

and then replace acoustical material. Any acous-

tical material with a protective covering that has

been torn or punctured should be replaced

immediately to prevent accumulation of liquids or

fluid film within the material. DO NOT use flam-

mable solvents for cleaning purposes.

D. Disconnect and lock out all power at source prior

to attempting any repairs or cleaning of the com-

pressor or of the inside of the enclosure, if any.

E. Keep electrical wiring, including all terminals and

pressure connectors in good condition. Replace

any wiring that has cracked, cut, abraded or oth-

erwise degraded insulation, or terminals that are

worn, discolored or corroded. Keep all terminals

and pressure connectors clean and tight.

F. Keep grounded and/or conductive objects such

as tools away from exposed live electrical parts

such as terminals to avoid arcing which might

serve as a source of ignition.

G. Remove any acoustical material or other material

that may be damaged by heat or that may sup-

port combustion and is in close proximity, prior to

attempting weld repairs.

H. Keep suitable fully charged Class BC or ABC fire

extinguisher or extinguishers nearby when ser-

vicing and operating the compressor.

I. Keep oily rags, trash, leaves, litter or other com-

bustibles out of and away from the compressor.

J. DO NOT operate the compressor without proper

flow of cooling air or water or with inadequate

flow of lubricant or with degraded lubricant.

K. DO NOT attempt to operate the compressor in

any classification of hazardous environment

unless the compressor has been specially

designed and manufactured for that duty.

1.5 MOVING PARTS

A. Keep hands, arms and other parts of the body

and also clothing away from couplings, fans and

other moving parts.

B. DO NOT attempt to operate the compressor with

the fan, coupling or other guards removed.

SECTION 1

7

C. Wear snug-fitting clothing and confine long hair

when working around this compressor, especially

when exposed to hot or moving parts.

D. Keep access doors, if any, closed except when

making repairs or adjustments.

E. Make sure all personnel are out of and/or clear of

the compressor prior to attempting to start or

operate it.

F. Disconnect and lock out all power at source and

verify at the compressor that all circuits are de-

energized to minimize the possibility of acciden-

tal start-up, or operation, prior to attempting

repairs or adjustments. This is especially impor-

tant when compressors are remotely controlled.

G. Keep hands, feet, floors, controls and walking

surfaces clean and free of fluid, water or other

liquids to minimize the possibility of slips and

falls.

1.6 HOT SURFACES, SHARP

EDGES AND SHARP

CORNERS

A. Avoid bodily contact with hot fluid, hot coolant,

hot surfaces and sharp edges and corners.

B. Keep all parts of the body away from all points of

air discharge.

C. Wear personal protective equipment including

gloves and head covering when working in, on or

around the compressor.

D. Keep a first aid kit handy. Seek medical assis-

tance promptly in case of injury. DO NOT ignore

small cuts and burns as they may lead to infec-

tion

1.7 TOXIC AND IRRITATING

SUBSTANCES

A. DO NOT use air from this compressor for respi-

ration (breathing) except in full compliance with

OSHA Standards 29 CFR 1910 and/or any appli-

cable Federal, State or Local codes or regula-

tions.

B. DO NOT use air line anti-icer systems in air lines

supplying respirators or other breathing air utili-

zation equipment and DO NOT discharge air

from these systems into unventilated or other

confined areas.

C. Operate the compressor only in open or ade-

quately ventilated areas.

D. Locate the compressor or provide a remote inlet

so that it is not likely to ingest exhaust fumes or

other toxic, noxious or corrosive fumes or sub-

stances.

E. Coolants and lubricants used in this compressor

are typical of the industry. Care should be taken

to avoid accidental ingestion and/or skin contact.

In the event of ingestion, seek medical treatment

promptly. Wash with soap and water in the event

of skin contact. Consult Material Safety Data

Sheet for information pertaining to fluid of fill.

F. Wear goggles or a full face shield when adding

antifreeze compound to air line anti-icer systems.

G. If air line anti-icer system antifreeze compound

enters the eyes or if fumes irritate the eyes, they

should be washed with large quantities of clean

water for fifteen minutes. A physician, preferably

an eye specialist, should be contacted immedi-

ately.

H. DO NOT store air line anti-icer system antifreeze

compound in confined areas.

I. The antifreeze compound used in air line anti-

freeze systems contains methanol and is toxic,

harmful or fatal if swallowed. Avoid contact with

the skin or eyes and avoid breathing the fumes. If

DANGER

Death or serious injury can result from

inhaling compressed air without using

proper safety equipment. See OSHA stan-

dards and/or any applicable Federal, State,

and Local codes, standards and regulations

on safety equipment.

SECTION 1

8

swallowed, induce vomiting by administering a

tablespoon of salt, in each glass of clean, warm

water until vomit is clear, then administer two

teaspoons of baking soda in a glass of clean

water. Have patient lay down and cover eyes to

exclude light. Call a physician immediately.

1.8 ELECTRICAL SHOCK

A. This compressor should be installed and main-

tained in full compliance with all applicable Fed-

eral, State and Local codes, standards and

regulations, including those of the National Elec-

trical Code, and also including those relative to

equipment grounding conductors, and only by

personnel that are trained, qualified and dele-

gated to do so.

B. Keep all parts of the body and any hand-held

tools or other conductive objects away from

exposed live parts of electrical system. Maintain

dry footing, stand on insulating surfaces and DO

NOT contact any other portion of the compressor

when making adjustments or repairs to exposed

live parts of the electrical system. Make all such

adjustments or repairs with one hand only, so as

to minimize the possibility of creating a current

path through the heart.

C. Attempt repairs in clean, dry and well lighted and

ventilated areas only.

D. DO NOT leave the compressor unattended with

open electrical enclosures. If necessary to do so,

then disconnect, lock out and tag all power at

source so others will not inadvertently restore

power.

E. Disconnect, lock out, and tag all power at source

prior to attempting repairs or adjustments to

rotating machinery and prior to handling any

ungrounded conductors.

1.9 LIFTING

A. If the compressor is provided with a lifting bail,

then lift by the bail provided. If no bail is provided,

then lift by sling. Compressors to be air-lifted by

helicopter must not be supported by the lifting

bail but by slings instead. In any event, lift and/or

handle only in full compliance with OSHA stan-

dards 29 CFR 1910 subpart N and/or any appli-

cable Federal, State, and Local codes, standards

and regulations.

B. Inspect points of attachment for cracked welds

and for cracked, bent, corroded or otherwise

degraded members and for loose bolts or nuts

prior to lifting.

C. Make sure entire lifting, rigging and supporting

structure has been inspected, is in good condi-

tion and has a rated capacity of at least the

weight of the compressor. If you are unsure of

the weight, then weigh compressor before lifting.

D. Make sure lifting hook has a functional safety

latch or equivalent, and is fully engaged and

latched on the bail or slings.

E. Use guide ropes or equivalent to prevent twisting

or swinging of the compressor once it has been

lifted clear of the ground.

F. DO NOT attempt to lift in high winds.

G. Keep all personnel out from under and away

from the compressor whenever it is suspended.

H. Lift compressor no higher than necessary.

DANGER

All field equipment must be tested for elec-

trostatic fields prior to servicing or making

contact with the machine using the follow-

ing or equivalent test equipment:

• 90-600 VAC: Volt detector such as

Fluke Model 1AC-A

• 600-7000 VAC: Voltage detector

such as Fluke Networks Model

C9970

It is the responsibility of each organization

to provide/arrange training for all their

associates expected to test for electrostatic

fields.

SECTION 1

9

I. Keep lift operator in constant attendance when-

ever compressor is suspended.

J. Set compressor down only on a level surface

capable of safely supporting at least its weight

and its loading unit.

K. When moving the compressor by forklift truck,

utilize fork pockets if provided. Otherwise, utilize

pallet if provided. If neither fork pockets or pallet

are provided, then make sure compressor is

secure and well balanced on forks before

attempting to raise or transport it any significant

distance.

L. Make sure forklift truck forks are fully engaged

and tipped back prior to lifting or transporting the

compressor.

M. Forklift no higher than necessary to clear obsta-

cles at floor level and transport and corner at

minimum practical speeds.

N. Make sure pallet-mounted compressors are

firmly bolted or otherwise secured to the pallet

prior to attempting to forklift or transport them.

NEVER attempt to forklift a compressor that is

not secured to its pallet, as uneven floors or sud-

den stops may cause the compressor to tumble

off, possibly causing serious injury or property

damage in the process.

1.10 ENTRAPMENT

A. If the compressor enclosure, if any, is large

enough to hold a man and if it is necessary to

enter it to perform service adjustments, inform

other personnel before doing so, or else secure

and tag the access door in the open position to

avoid the possibility of others closing and possi-

bly latching the door with personnel inside.

B. Make sure all personnel are out of compressor

before closing and latching enclosure doors.

10

BLANK PAGE

Section 2

11

WSPC USER INTERFACE MANUAL

OVERVIEW

The WSPC User Interface is a Windows-based

software program that allows complete monitoring

and control of Sullair air compressors equipped with

a Sullair WS Controller. The software can monitor a

single compressor operating as an individual unit or

multiple machines connected in a sequence. The

WSPC program receives data about the compressor

from the WS Controller, assigns control parameters

to the controller, displays controller operating

characteristics including faults and warning

messages, and provides functionality that assists the

user with controller diagnostics.

2.1 MANUAL CONTENTS

This manual describes the features and operation of

the WSPC User Interface program. Part 1 covers

material pertaining specifically to persons operating

the program with User Level access. Part 2 covers

advanced functions available to experienced users

and persons with Administrator Level access.

This manual describes WSPC software part number

02250174-081 when operated with WS Controller

software 02250174-082 or later. This version of

WSPC is compatible with all previously released

versions of WS Controller software, but certain

features described in this manual are not available in

earlier versions.

Part 1:

Section 2: OVERVIEW provides the necessary

information to install the WSPC software. Included

are the minimum hardware and software

requirements.

Section 3: GETTING STARTED presents steps to

getting the program up and running quickly. Basic

MS Windows functions and those features necessary

to using the software are explained in this section.

Section 4: DISPLAY DESCRIPTIONS provides an

explanation of each display screen available to user

level operators. Detailed descriptions of the

operation of each display component are provided.

Section 5: MENU BAR provides steps to setting user

preferences for operating the WSPC program. This

section guides the user in creating and modifying

user profiles.

Section 6: VARIABLE SPEED DRIVE (VSD)

describes the WSPC functions that apply to Variable

Speed Drive compressors.

Part 2:

Section 7: ADMININISTRATOR LEVEL FUNCTIONS

describes those functions that apply specifically to

Administrator level operators. Each administrator

level display is presented and details of the display

components are described.

Features of the WSPC User Interface software

include:

• Two-way communication channel between the user

and the compressor controller.

• A comprehensive view of the compressor control-

ler’s operation at the WSPC interface.

• Adjustment of all modifiable parameters of the com-

pressor controller.

• Ability to control the compressor remotely.

• Access to data relating to all compressors con-

nected as a sequence system.

• Password protection capabilities to limit access to

data and controls.

• A data log feature which compiles operational, ser-

vice, and error data of the compressor or compres-

sor system.

WSPC USER INTERFACE MANUAL SECTION 2

12

2.2 SYSTEM COMPATIBILITY

• Before beginning the installation process, your

computer should meet the following minimum

requirements.

• PC–compatible computer (Pentium® IV based, 1.0

Ghz processor recommended)

• Windows 2000 or Windows XP operating systems.

Windows 2000 may require special processing soft-

ware to properly operate the WSPC software.

• CD ROM drive

• 125 Mb of available hard disk space

• 256 Mb of available RAM memory

• Color monitor

• RS232 communications capability

2.3 INSTALLING THE WSPC

USER INTERFACE

SOFTWARE

Follow the instructions accompanying the WSPC

Installation package. The actual installation media

may be CD, internet, network, USB drive, or other

means, and the procedure will be specific to that

media. This installation will create a folder on your

disk drive, and install the necessary files into that

folder. Make a note of this location, as it may be

necessary for future updates. The default location for

all saved files will also be in that folder, but you may

browse to save into any other location in your PC as

desired. By default, the folder will be "WSPC" and will

be located in a "Sullair" folder. Recommended

locations are "C:\Sullair\WSPC" or

"D:\Sullair\WSPC”.

2.4 INSTALLING OR UPDATING

THE FRAMEWORK

The WSPC software requires the Microsoft .net®

Framework support program in order to run on the

PC. If Microsoft .net is already on the PC, you will be

able to run as soon as the installation is completed.

To install the framework, or update to the latest

version, use the following procedure for a free

download.

1. Connect the PC to the internet.

2. Go to the site: www.microsoft.com/down-

loads

3. Search for “.NET Framework”

4. Follow the instructions for downloading and

installation.

2.5 UNINSTALL THE WSPC

SOFTWARE

To uninstall the WSPC software:

1. Right-click any desktop shortcuts that were

created.

2. Click “Delete” to delete the shortcut.

3. Open “My Computer” and browse to the

folder created in Section 2.3.

4. Delete the folder and its contents.

NOTE

Contact your network administrator if you

are unable to perform the software

installation due to access limitations.

Section 3

13

WSPC USER INTERFACE MANUAL

GETTING STARTED

3.1 ACCESS PRIVILEGES

The WSPC User Interface program may be

accessed at two levels.

User Level: Allows users to access the program

without entering a password. The user should be an

individual with specific authorization to use the

WSPC software and knowledge of the compressor

operation. This level includes all data and

adjustments for normal applications of the

compressor. At this level a user has access to the

following displays: Compressor Data, Machine Info,

Service, Maintenance, Sequencing, and

Adjustments.

Administrator Level: This provides additional

functions for maintenance, service, and setup for

trained compressor technicians. Administrator level

functions are described in Part 2 of this manual. A

password is required to access this level.

3.2 STARTING THE SOFTWARE

1. Click the shortcut located on the computer

desktop to start the WSPC User Interface

program.

2. When the program opens, a dialog box will

appear as shown in Figure 3-1. Click OK to

open the WSPC program. If the program

was last closed while operating at the

Administrator level the dialog box will require

a password as shown in Figure 3-2.

Do the following to select a user-level profile:

A. Click the down arrow next to the “User Name”

box. A drop-down list of user profiles will be pre-

sented. See Figure 3-3.

B. Click on a profile that is set for “User Level”

access (Default User) and click “OK”. User level

profiles do not require password access. More

profile options may be available in the User

Name list than the ones shown in Figure 3-3.

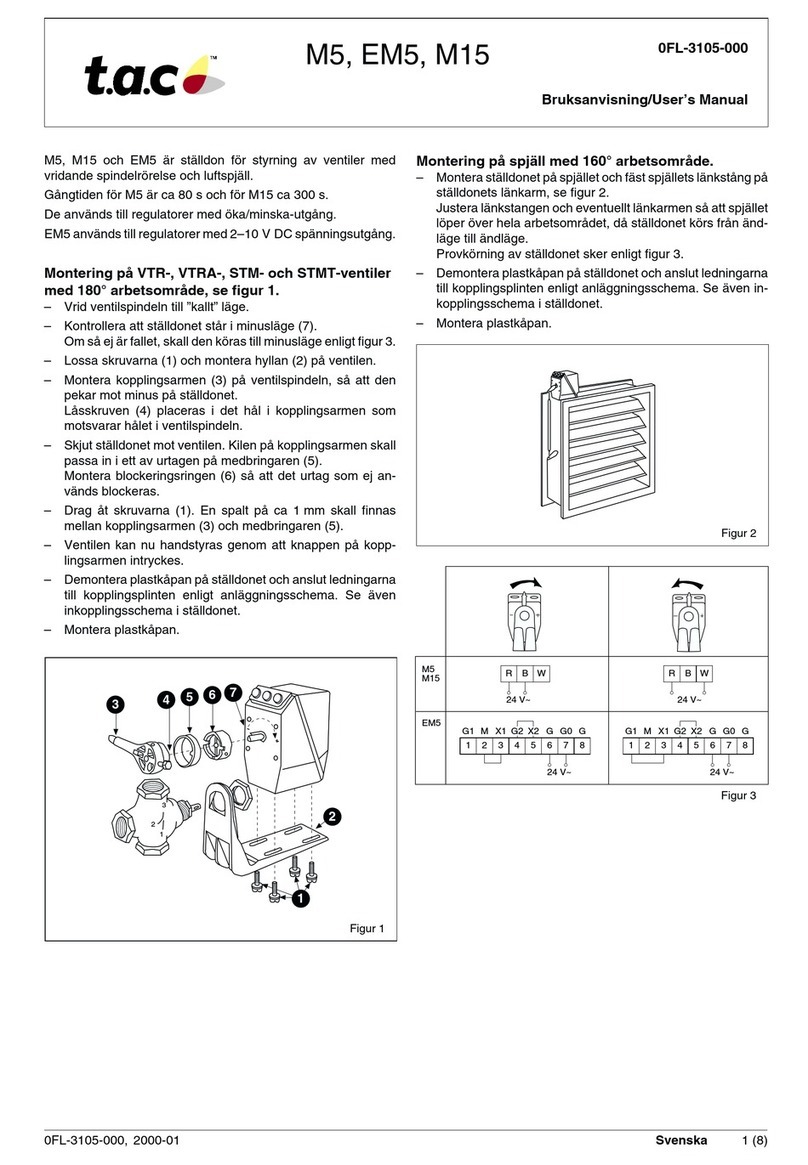

Figure 3-1: WSPC User Interface password

request

Figure 3-2: WSPC User Interface password

request

WSPC USER INTERFACE MANUAL SECTION 3

14

The program will open to the “Compressor Data

Display” with user level access. See Figure 3-4.

From the opening screen the user may navigate to all

other features of the program.

3.3 WINDOWS® BASIC

This section presents basic MS Windows® functions

that will be useful to using the WSPC program. The

active presentations of information on the computer

screen are referred to as “Displays.” At the top of

each display is a tab showing the display title. To

make a display active, click on the desired display

tab. See Figure 3-5. The active display allows the

user to see the data related to the tab title and to

perform functions on the display page.

Figure 3-3: User Option

Figure 3-4: WSPC Opening Window – Compressor Data Display

SECTION 3 WSPC USER INTERFACE MANUAL

15

Some screens allow for entry of values into fields on

the screen. To enter data into a field:

A. Click in the field to be modified.

B. Select the data currently contained in the field (if

any). Data in a field can be selected by double-

clicking on a character in a field. The entire data

field will be selected. Data can also be high-

lighted for editing by holding down the left mouse

button and dragging the cursor across the data in

the field.

C. Type the new data into the field. Typing the new

data will replace the old data.

Typically an option can be chosen by pressing

“Enter” on the computer keyboard. Some options

present a dialog box that allow the user to confirm

the entries by clicking an “OK” button or cancel the

entries by clicking “Cancel.” A window can be

reduced, expanded, or closed by clicking on the

respective button located in the upper right corner of

the display:

3.4 CONNECTING THE PC TO

THE CONTROLLER

The standard connection of the PC Interface to the

WS Controller is via a specially designed RS-232

connector. This serial line connects to the computer’s

DB9 socket and runs directly to a custom designed

terminal located on the left side of the controller

cabinet. The PC may also be connected to the

controller by other means such as through RS-485

connections or remotely via modem or wireless

network.

3.5 CONNECTING /

DISCONNECTING THE WSPC

USER INTERFACE AND THE

WS CONTROLLER

After the communication lines are attached and the

WSPC software is running, the WSPC program can

be connected to the controller to begin receiving

machine operation data. Control data can also be

sent from the PC to the WS Controller to configure

the machine control parameters.

1. To establish connection between the WSPC

and the WS Controller click

(“Connect” button)

in the status bar. The box left of the Connect

button will appear bright green indicating the

connection is active. The software will

search for communication from the control-

ler, and fill the display with machine informa-

tion.

2. During normal connection, communication

activity will be shown on the bottom edge of

the WSPC screen, as shown in Figure 3-7.

The progress bar and block numbers simply

indicate that communications are occurring.

The WS Controller also provides led indica-

tors for communication near J13. Red indi-

cates a request was received from the PC,

Green indicates a message is being sent to

the PC.

Figure 3-5: User Interface display tab

Reduce Expand Close

Figure 3-6: User Option

WSPC USER INTERFACE MANUAL SECTION 3

16

3. If communication with the machine could not

be established, an error message will display

on the communication status line as depicted

in Figure 3-8. If this occurs, check the RS-

232 connection and other terminals for

proper connection.

4. To disconnect communication between the

WSPC and the controller, click on the “Con-

nect” button. The box left of the button will

change from bright green to dark, shaded

green, indicating that the WSPC is discon-

nected from the controller. The controller will

continue to operate according to the latest

set of parameters entered.

Figure 3-7: WSPC User Interface Display Screen

Figure 3-8: WSPC User Interface Display Screen

User Profile

Name

Communication

Status Indicator

Logging

Indicator

Menu Bar

Compressor

Status Bar

Connection

Button

Machine

Operation

Data and

Parameters

Title Bar

Figure 3-9: WSPC User Interface Display Screen

Display Tabs

SECTION 3 WSPC USER INTERFACE MANUAL

17

3.6 THE WSPC DISPLAY

SCREEN

The WSPC display screen consists of the title bar,

the pull-down menu bar, the compressor status bar,

display tabs, machine operation data display, and the

communication status bar. Refer to Figure 3-9. The

default screen is the Compressor Data display which

appears each time the WSPC software is opened.

Listed below are main elements of the screen display

that enable the user to access and view the machine

operation data, and modify the machine control

parameters.

Title Bar—Contains the name of the WSPC software

program.

"Menu Bar - Click to activate drop-down menus or

other screens to select WSPC configurations.

Section 5 provides additional details.

Connection Button—When activated, establishes

connection between the PC Interface and the WS

Controller unit.

Compressor Status Bar—Located on the left

margin of every display, the Compressor Status Bar

provides real-time data of the machine’s current

operation and condition. The Compressor Status Bar

is described in detail in Section 3.7.

Display Tabs—Allow for the selection of the desired

display. Section 4 provides a detailed description of

each display screen.

Machine Operation Data—Area where the machine

parameter data and operational information is

displayed.

Communication Status Indicator—Located at the

bottom of the display window, this line provides

communication status information.

User Profile Name—The name of the current user

profile is displayed. In Figure 3-9, the active profile is

named “Default User”.

Logging Indicator—This field will light when the PC

is recording data.

3.7 COMPRESSOR STATUS BAR

The Compressor Status Bar, which is located left of

the main window, displays real-time data regarding

the status of the compressor. The status bar is

constantly displayed whenever the WSPC software

is connected to the controller. This feature allows the

user to quickly view the status of the compressor

operation regardless of which display screen is

active. Information presented in the status bar

includes the compressor operating mode, operating

state, compressor temperature, sump pressure, and

discharge pressure. See Figure 3-9.

The Compressor Status Bar can be displayed as a

stand alone compressor operation monitor as shown

in Figure 3-10. The full display window can be hidden

leaving only the status bar information appearing on

the screen. This feature allows the user to continue

monitoring the compressor operation while

performing other tasks on the PC.

To reduce the display to show only the status bar:

1. Place the cursor on the right border of the

WSPC display window.

2. Press and hold the left mouse button.

3. “Drag” the display border to the left until it

stops. The compressor data window will be

hidden leaving the status bar in the display.

4. To return to the full screen presentation, click

on the expand window icon in the upper

right corner of the display.

5. To return again to the status bar only view,

click on the reduce window icon in the upper

right corner of the display.

WSPC USER INTERFACE MANUAL SECTION 3

18

3.8 FILE MENU

The File Menu contains options that allow the user to

configure and set preferences that control how the

program functions. See Figure 3-10 From the “File”

menu, the user can choose three options:

Profiles—Allows the user to create and edit profiles.

A profile will contain settings that configure the

WSPC program according to the operator or group’s

preferences. The features of the Profiles menu

option are described in Section 5 of this manual.

Login—Presents the Login box which allows the

user to choose a profile from a list of available User

profiles. See Figure 3-12.

Exit—Closes the WSPC User Interface program.

Exiting the software does not affect the compressor

or controller operation.

Communication

Operating Mode

Communication

Operating State

Communication

Temperature

Measurement

Sump Pressure

Measurement

Communication

Pressure

Discharge

Figure 3-10: Compressor Status Bar (Reduced)

File Menu

Figure 3-11: File Menu Options

SECTION 3 WSPC USER INTERFACE MANUAL

19

3.9 REPORT

This menu Item will request a folder location and file

name in which to file a comprehensive service report.

See Figure 3-13

3.10 COM PORT

This provides a dialog to select the communications

port of the PC on which the program is running. This

is typically COM1, but your PC may be equipped with

additional ports. See Figure 3-15

3.11 ABOUT

This provides information about the WSPC program.

See Figure 3-14

Figure 3-12: Login Screen A

Figure 3-13: Report Dialog

Figure 3-14: About Information Box

WSPC USER INTERFACE MANUAL SECTION 3

20

Figure 3-15: Com Port Dialog

Other manuals for WSPC

1

Table of contents

Other Sullair Controllers manuals

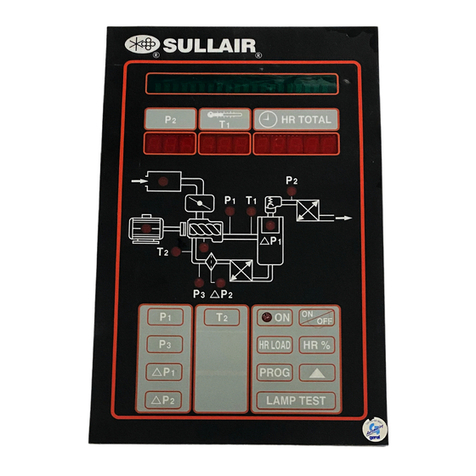

Sullair

Sullair ShopTek User manual

Sullair

Sullair SUPERVISOR CONTROLLER Series User manual

Sullair

Sullair SUPERVISOR CONTROLLER User manual

Sullair

Sullair SUPERVISOR CONTROLLER User manual

Sullair

Sullair Supervisor II User manual

Sullair

Sullair EC2000 User manual

Sullair

Sullair 02250160-842 User manual

Sullair

Sullair SUPERVISOR I User manual

Sullair

Sullair Supervisor IE User manual

Sullair

Sullair SUPERVISOR CONTROLLER User manual