DESCRIPTION

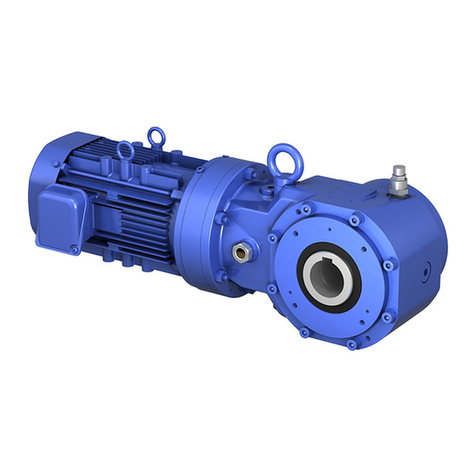

HANSEN M4 ACC GEAR UNITS

FOR AIR COOLED CONDENSER DRIVES

Coding

Type

1 : series P : Hansen M4

2 : V : vertical low speed shaft

3 : P : parallel shafts

4 : Size : DA-> FX

5 : number of stages: 2

Application

6:ACC:Air Cooled Condenser

Shaft arrangement

: high speed shaft extension : U : up

8 : low speed shaft extension : D : down

9 : low speed shaft type : N : normal solid shaft

Ratio

10 : nominal ratio of the gear unit

Drive package

11 : K: lantern drive package

Motor

12 : motor size and number of poles

Units are designed to comply with the standard CTI-111 specifications

for gear units.

The mechanical power ratings shown in the tables relate respectively to

input speeds of 1800, 1500, 1200, 1000, 900 and 50 RPM at the

high speed shaft. They are also valid for asynchronous speeds which

are max. 3% lower than the synchronous speeds.

Interpolation will yield power rating values for intermediate speeds. The

power rating for speeds lower than 50 RPM is based on the

continuous torque rating of that speed.

For input speeds exceeding 1800 RPM, please refer to us.

Basic components

Helical gears

Designed and rated in accordance with AGMA for maximum load

capacity, minimum losses and quiet operation.

All geared components are manufactured from alloy steel, gas

carburized, hardened and precision ground.

Low speed shafts

The low speed shafts are in solid version.

Length of the shaft extension according to customer's specification.

Bearings

Heavy duty roller bearings of the tapered, cylindrical or spherical roller

type.

Calculated in compliance with ISO and renowned bearing

manufacturers.

The low speed shaft bearings are selected to allow considerable thrust

loads. The nominal permissible thrust load F

xN

mentioned in the table,

page A41, is defined for a SFmin = 2, low speed shaft rotating

counter-clockwise and guarantees a calculated bearing life of 100000

hours.

Housings, lantern housings and covers

Made from grey pearlitic cast iron.

Machined on CNC machining centers.

Designed to ensure strength and rigidity.

Unused tapped holes are plugged.

Monobloc housing.

Systems

Lubrication

Lubricants: mineral oils are normally used. Lubricants should always

contain adequate EP-additives (refer to Service Manual).

Pump lubrication for the upper bearings is standard available.

The lubrication is guaranteed for input speeds down to 50 min

-1

(windmilling conditions).

The gear unit housing acts as a large oil sump.

Grease point with nipple according to DIN 1412 for grease lubri-

cation of the bearing at side of the low speed shaft end.

Checking of the oil level is done by means of the gear unit dipstick

(always in the plugged position).

Cooling

Heat generated in the gear unit due to losses, can be dissipated by:

natural cooling through the housing

additional fan cooling, shaft driven axial fan incorpo-

rated in the lantern housing

Free air entry at the suction side should always be

guaranteed

Thermal checks: refer to us.

Fill in "Request for quotation" on page A .

Sealing

Static: generalized use of sealing compound

inspection cover on the gear unit: re-usable flat seal

low speed shaft: drywell

Rotary: high speed shaft: standard : dust lip oil seal

option: regreasable labyrinth

low speed shaft: standard : double dust lip oil seal

option: regreasable labyrinth

The gear unit

1

P

2

V

3

P

4 5

2 U

6

A C C

7

U

8

D

9

N

10

11

K

12

A3