CONTENTS

Precautions for installation

1. Specifications..............................................................................................................................1

2. Assembly and installation

2.1 Transmitter installation..........................................................................................................2

2.2 Illustration of panel mounting................................................................................................2

2.3 Assembly of electrode and housing.......................................................................................3

2.3.1 Cable setup....................................................................................................................3

2.3.2 Assembly of immersive holder and junction box 8-09-5+PP-100A (Optional)...........3

2.3.3 Illustration of PP protective holder and L-shaped holder support base........................5

2.4 Illustration and description of the round junction box...........................................................6

2.5 Illustration and description of the square junction box..........................................................9

3. Wiring

3.1 Illustration of rear panel........................................................ ..............................................12

3.2 Descriptions of terminal function........................................................................................13

3.3 Wiring descriptions of transmitter............................................ ...........................................14

3.3.1 Illustration of electrical connection............................................................................14

3.3.2 Wiring of ATC probe and fixed temperature compensation.......................................15

3.4 Illustration of accessorial transmitter pH-300T (Optional)..................................................16

3.5 Connection of transmitter and accessorial transmitter pH-300T.........................................17

3.6 Wiring description of pH-300T............................................................................................18

3.7 Calibration steps after installation of pH-300T........................ ...........................................20

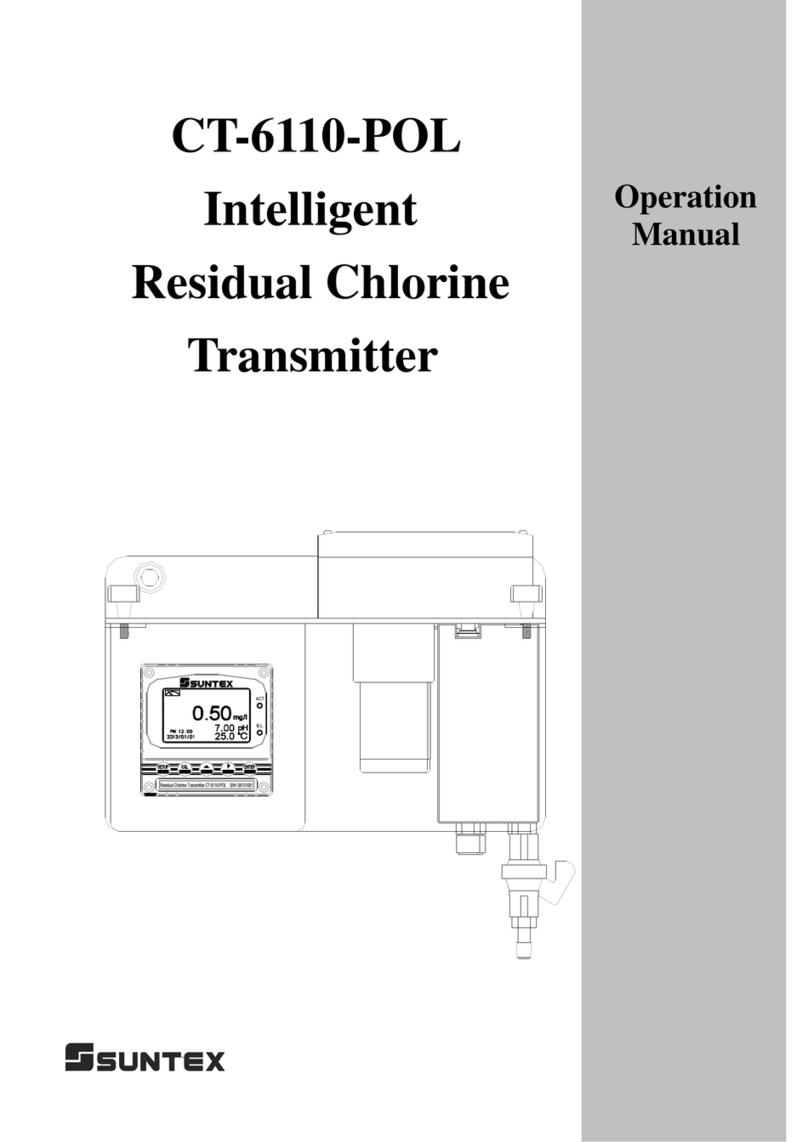

3.8 Illustration of online pH/ORP measurement system (Optional)..........................................21

4. Configuration

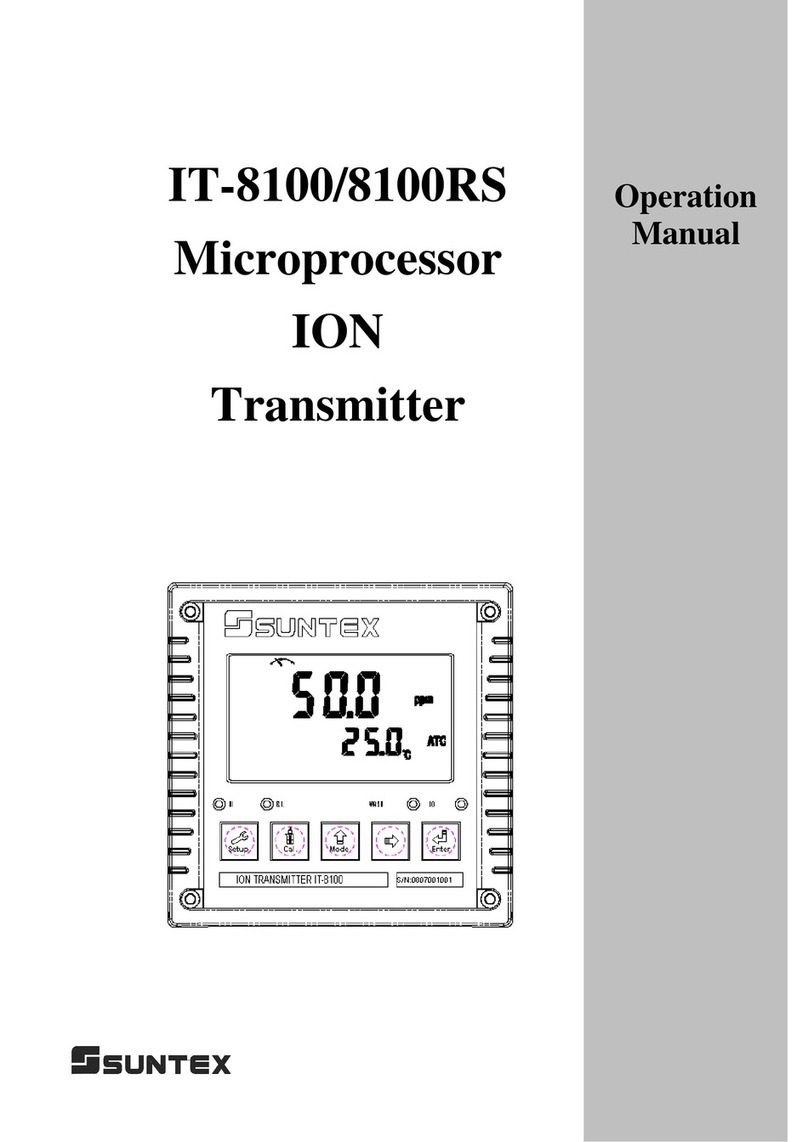

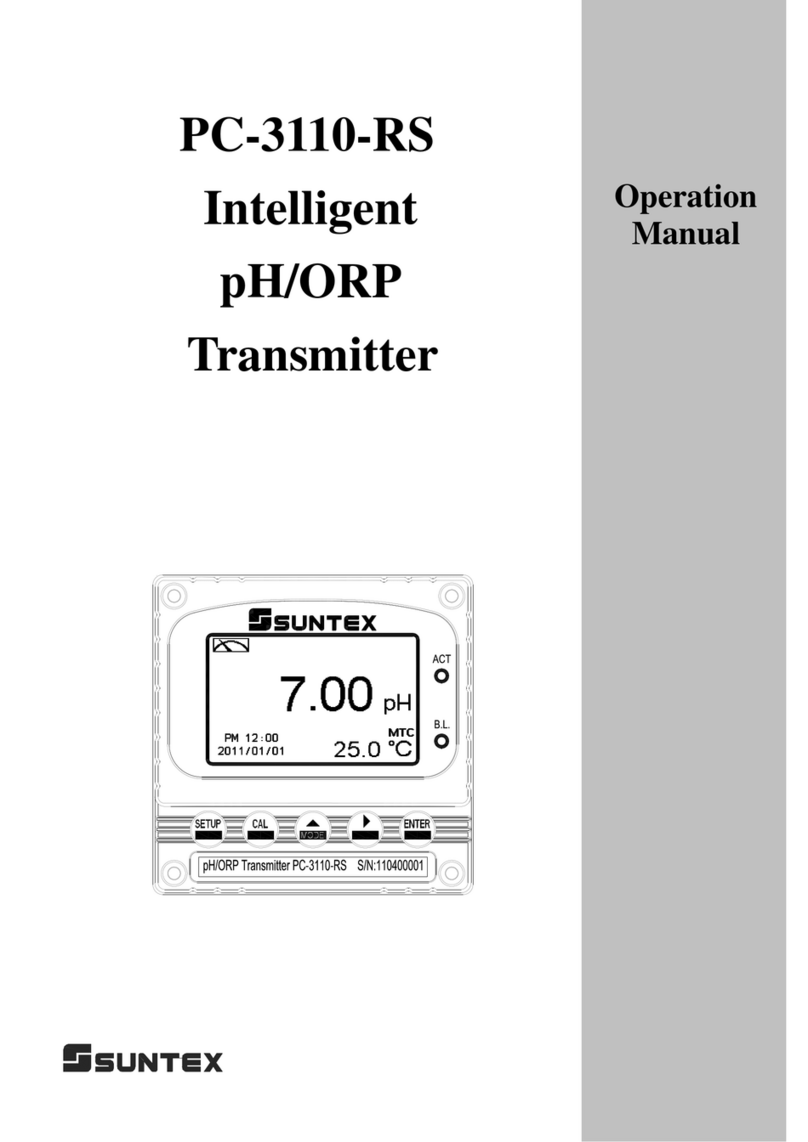

4.1 Illustration of front panel of PC-310A.................................................................................22

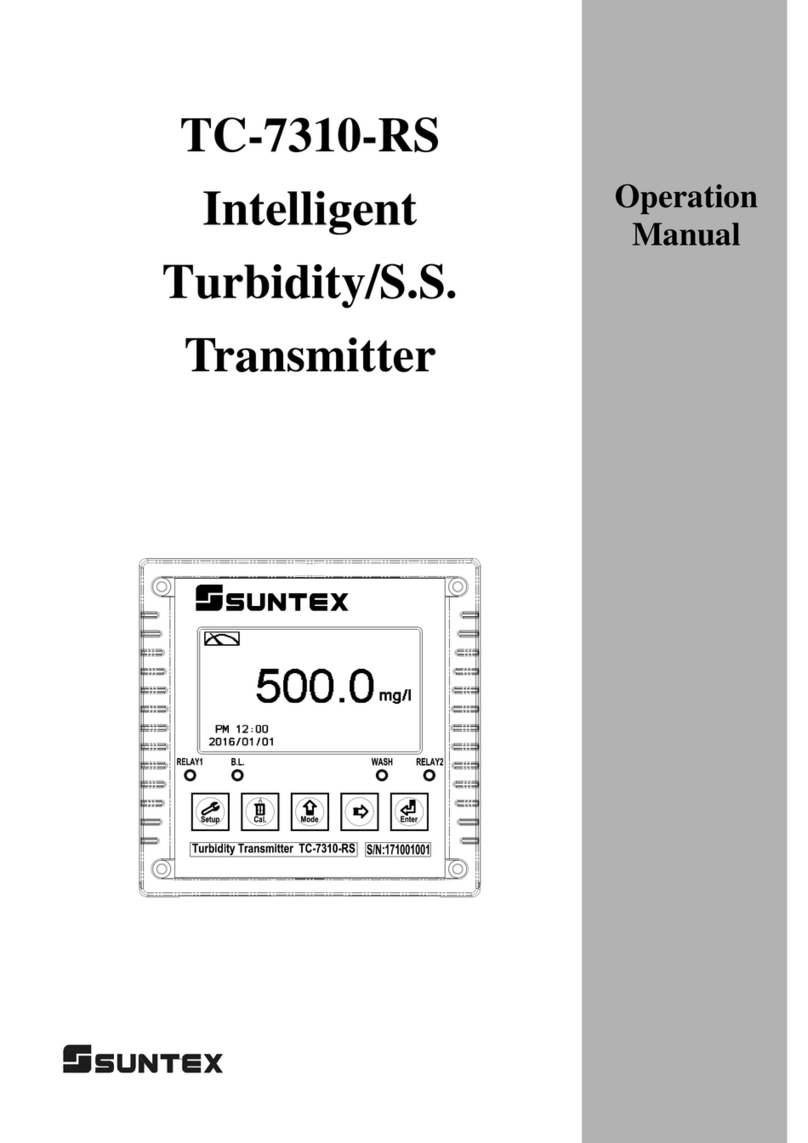

4.2 Illustration of front panel of PC-320A.................................................................................24

4.3 Block diagram of PC-300A.................................................................................................25

5. Calibration

5.1 Calibration of pH electrode..................................................................................................26

5.2 Inspection of ORP electrode................................................................................................27

6. Setting

6.1 RELAY control setup...........................................................................................................29

6.2 Analog output setting and RELAY test................................................................................30

7. Maintenance.............................................................................................................................32