Brief Instruction

Settings of measurement parameters (see chapter 7)

If you like to use security code of settings, the original code is 1111.

Settings of Calibration (see chapter 8)

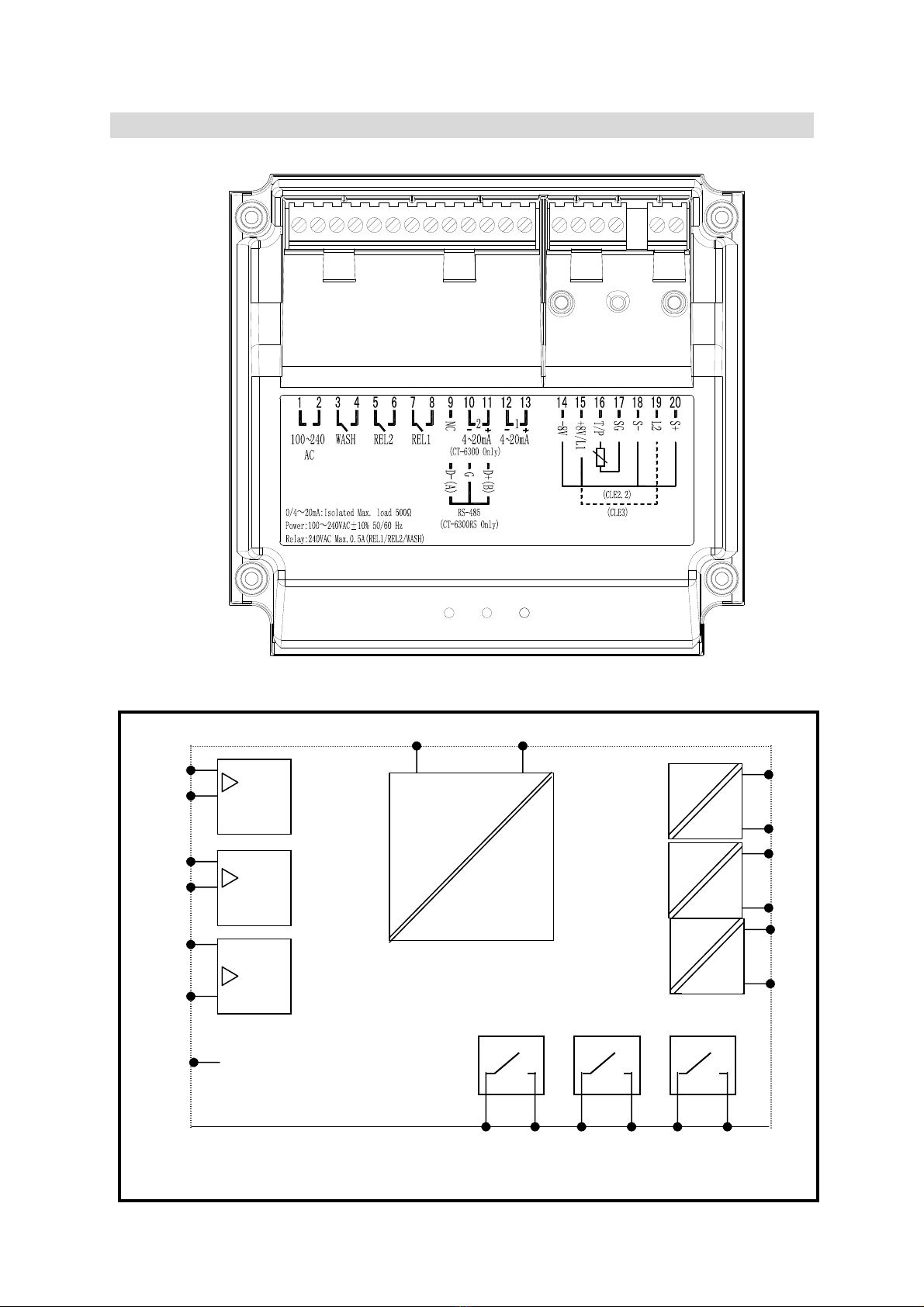

In the tP output function, please set analog output 2 with or

tem

erature

In the main measurement output function, please set analogoutputwith or

+

+

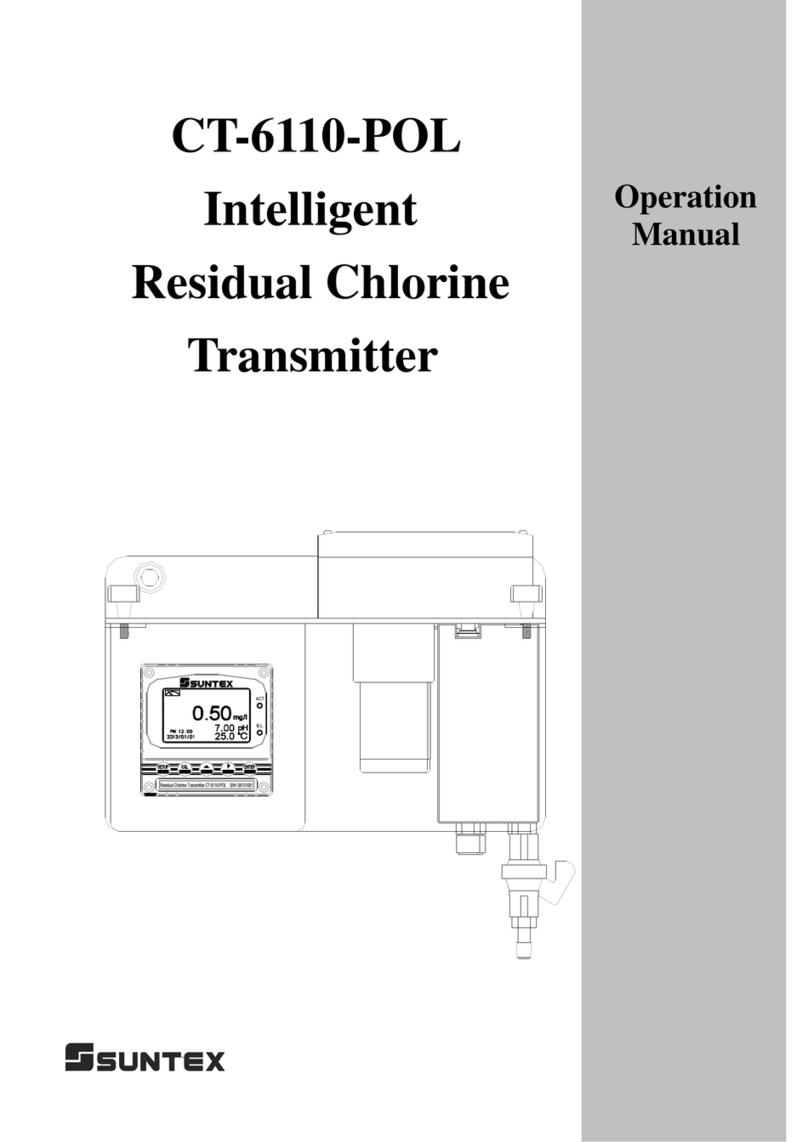

In measurement mode, pressing “Setup"and “Mode"simultaneously

allows you to access Set-up mode.

In the Code function, entering original code or user’s designated code allows you

to reset the code or shut down this function.

In the Configuration function, select Cl2or O3sensor according to the sensor’s model.

In the Temperature function, setup temperature or make temperature correction.

In the Relay 1 function, please select or to activate it or not.

In the Relay 2 function, please select or to activate it or not.

In the Clean function, please set wash time and stop duration.

In the Averaged measurement value function, please set measurement value

numbers for averaged measurement value to increase the stability of reading.

In the Back light function, please set brightness of display and sensitivity of

light-source sensor.

In measurement mode, pressing “Cal."and “Mode"simultaneously

allows you to access Calibration mode.

If you like to use security code of calibration, the original code is 1111.

In the Code function, entering original code or user’s designated code allows you to

reset the code or shut down this function.

In the Auto-return function, activate the auto-return to the measurement mode display if

not press any key in 3 minutes while in the setting mode or calibration mode. .