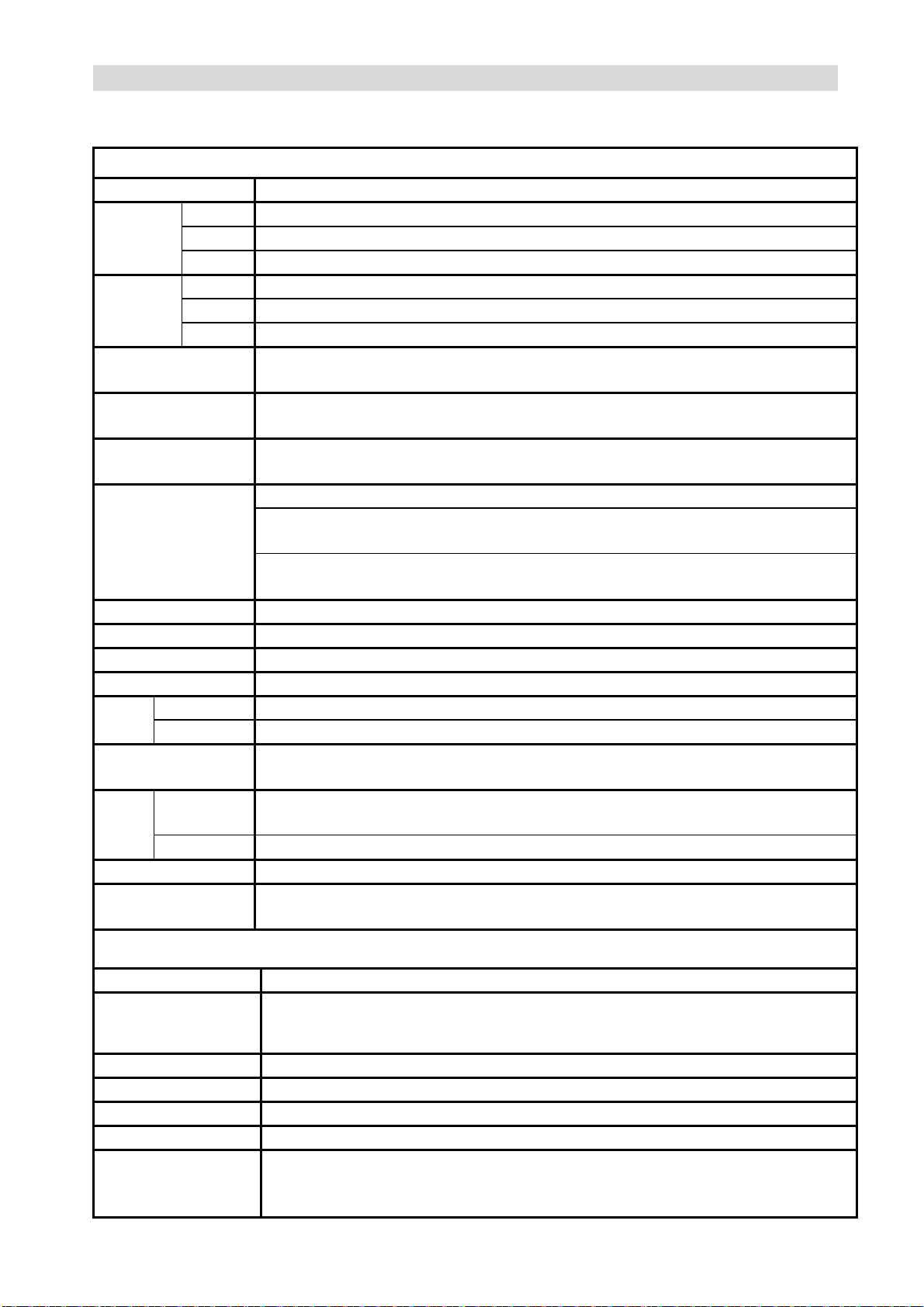

1.Specifications

1.1 Specifications

Main specifications:

CT-6110-POL (Non-reagent type free chlorine transmitter)

Measuring mode Residual(Free) Chlorine & pH / Temperature, Simultaneous display

Measuring

range

Free Cl20.00~3.00mg/l (Free Cl2corresponding range adjustable for graphical display)

pH -2.00~16.00pH

Temp 0.0~60.0C

Resolution

Free Cl20.01mg/l

pH 0.01pH

Temp 0.1C

pH compensation/

accuracy pH sensor auto compensation/ manual compensation/ OFF / ±0.01pH(±1 digit)

Temp. compensation/

accuracy NTC-30K(compensation range: 0~45C)/ ±0.2C (±1 digit)

Display Large LCM with sensitization sensor for auto/manual illumination function and

contract function

Display mode

Text mode: Numerical display

Chart mode: 3 mins real-time dynamic graph

(Free Cl2corresponding range adjustable)

Trace mode: Set up from 3 mins to 4 weeks duration of the measured value trend graph

(Free Cl2corresponding range adjustable)

Analog output Isolated DC 0/4~20mA corresponding to Free Cl2or pH, max. load 500

Voltage output DC ± 12V, 1W max. for PH-300T(Optional)

Logbook 50 event records

Serial interface Isolated RS-485(Modbus RTU or ASCII)

Setting Contact 240VAC, 0.5A Max. (recommended)

Activate Two individual Free Cl2or pH, Hi/Lo selectable, limited programmable

Clean/Auto Zero 240VAC, 0.5A Max. (recommended),

ON:0~99 min. 59 sec. OFF:0~999 hours 59 min.

Cl2

calibrati

on

Zero point Electrodeopencircuit

or apply activated charcoal filtered water (residual chlorine free water) / pure water

Span Sampling DPD measurement input calibration or standard buffer calibration

pH calibration Any, Tech & NIST buffer calibration

Diagnostic function Temperature sensor, zero-point & slope diagnosis, water/power outage,

logbook record or alarm symbol

Measurement system

Measuring principle Polarographic (No reagent needed for measurement)

Residual chlorine

electrode

2 in 1 rotating electrode (Working electrode: gold, Counter electrode: silver)

With relative slope index for electrode aging determination

Temperature probe NTC-30K

pH electrode Optional(No need for pH compensation when pH range within pH 6.5~7.5)

Cl2 electrode cleaning Ceramic beads auto cleaning

Motor protection Auto over heat protection

Water outage/

Electrode open

diagnosis

When water outage or electrode open, after auto diagnosis the motor auto shuts down