Surewerx PeakWorks SRL-73303-60 User manual

Self-Retracting

Lifelines

Certied to:

CSA Z259.2.2-17

Product Specic Name

SRL-73303-60 / V845643060

SRL-73303-96 / V845643096

READ CAREFULLY

BEFORE USE

Canada:

SureWerx, 49 Schooner St.,

Coquitlam, BC V3K 0B3 Made in Germany

ENGLISH

May 31, 2022

V845643060-V845643096 Manual

2

INTRODUCTION

This manual contains the Manufacturer’s Instructions as required by CSA Z259.2.2 It should be used as part of

the fall protection training program required by law. All PeakWorks® products are designed and engineered to

meet or exceed applicable CSA and ANSI standards along with labour ministry requirements.

WARNING: All persons using this equipment must read and understand all the instructions and

warnings contained in this manual. Failure to do so may result in serious injury or death. Do not use this

or any other fall protection equipment unless you have been properly trained.

FALL PROTECTION

It is the employer’s responsibility to provide fall protection and training for any worker deemed to be working

at height. In Canada, any worker that is more than 3 meters from the ground or first obstruction must have

fall protection.

SYSTEM COMPATIBILITY

PeakWorks equipment has been designed and approved for use only with PeakWorks connectors. Any

substitution of components may result in compatibility issues. Users should always ensure that the connectors

are properly selected and connected so as not to allow a load to be applied to the gate of the connector.

Failure to do so may result in serious injury or death. Do not use this or any other fall protection

equipment unless you have been properly trained.

TABLE OF FALL PROTECTION STANDARDS

Fall protection equipment is governed in Canada by the Canadian Standards Association (CSA).

Canadian Standards Association Fall Protection Standards:

CSAZ259.1 Safety Belts and Saddles for Work Positioning and Travel Restraint

CSA Z259.2.2 Self-Retracting Devices for Personal Fall-Arrest Systems

CSA Z259.2.3 Descent Control Devices

CSA Z259.2.4 Fall Arrester and Fixed Rigid Rails

CSA Z259.2.5 Fall Arrester and Vertical Lifelines

CSA Z259.10 Full Body Harness

CSA Z259.11 Energy Absorbers and Lanyards

CSA Z259.12 Connecting Components for Personal Fall Arrest Systems

CSA Z259.13 Flexible Horizontal Lifelines

CSA Z259.14 Fall Restrict Equipment for Wood Pole Climbing

CSA Z259.15 Anchorage Connectors

CSA Z259.16 Design of Active Fall Protection Systems

TRAINING

All workers and their employer must be trained in the correct use, care, and maintenance of this and any other

fall protection equipment used. It is the employer’s responsibility to provide proper fall protection training for

all workers using fall protection equipment. Both the worker and the employer must be aware of the correct

and incorrect applications and use of this equipment.

Failure to do so may result in serious injury or death. Do not use this or any other fall protection

equipment unless you have been properly trained.

3

RESCUE PLAN

A rescue plan is an integral and critical part of any fall protection plan and system. It is the responsibility of the

employer to have a rescue plan prepared by a competent person. All workers using any fall arrest system must

have a rescue plan prior to using the system.

REPAIR

Do not attempt to repair or alter this fall protection equipment. Repairs can only be performed by the

manufacturer or its authorized agents.

ELECTRICAL HAZARD

Due to the highly conductive nature of the materials used in the construction of this SRL, use extreme caution

when working near unprotected high voltage sources. If in doubt, ask!

SHARP EDGES, ABRASION & CUTTING

The wire rope or the webbing of the SRL should never be allowed to come in contact with sharp edges or

abrasive surfaces. Such contact could prevent the SRL from arresting a fall.

Failure to do so may result in serious injury or death.

SRL OVERVIEW

All PeakWorks’ SRLs have been designed and engineered to meet or exceed all applicable standards and

Ministry of Labour requirements. This PeakWorks Self-Retracting Lifeline is intended for use as a Fall Arrest

Block or Fall Recovery Block. It is not intended for use with work positioning, man-riding, goods lifting or

moving/lifting materials.

SRL SPECIFICATIONS

Description

Self-retracting devices (SRD) shall be classified as follows:

(a) Self-retracting lifeline (Class SRL):

A Class SRL device shall be suitable for applications where

i) it is anchored at an elevation which limits the free fall to the activation distance of the device; and

ii) the extracted lifeline cannot bear against an edge or surface during fall arrest.

(b) Self-retracting lifeline with integral rescue capability (Class SRL-R):

A Class SRL-R device shall be a Class SRL device that is provided with an integral means for assisted rescue.

Note: Assisted rescue via raising or lowering the rescue subject.

SRL-R Performance Data

Maximum Arresting Force: 1,350 lbF (8 kN)

Average Arresting Force: 926 lbF (4.12 kN)

Capacity: 310 lbs (140 kg) including tools

Lifeline: Galvanised steel cable 0.21 in (5.5 mm)

Complies to: CSA Z259.2.2-17

D

A

N

G

E

R

DANGER

Working surface

30°

max.

4

SRL CAPACITY

PeakWorks SRLs are designed for use by a single person with a combined weight (clothing, tools, etc.) of

no more than 310 lbs. Make sure all of the components in your system are rated to a capacity appropriate

to your application.

SRL COMPATIBILITY

All PeakWorks’ SRLs come with a carabiner to connect to an anchor and a snap hook to connect to a full-body

harness. PeakWorks equipment has been designed and approved for use only with PeakWorks connectors. Any

substitution of components may result in compatibility issues. If you have any questions about component

compatibility, please contact PeakWorks.

Warning: Do not connect to this SRL with form hooks or any other large opening

SRL GENERAL OPERATION

The mechanism in this device is activated by centrifugal force acting on the brakes. This action is produced by

the inertia of a fall rapidly spinning the internal drum, which in turn causes the brakes to lock and arrest the fall.

Slow reeling of the line will not activate the brake. If the brake locks—due to a fall—the mechanism will reset if

the load is removed. In a fall arrest situation the mechanism will limit the force acting on the body to less than

8 kN. This device is designed to function vertically, at an angle of no more than 30º (see Figure 2).

Figure 2

Safety Factor

+ 3 ft (0,9 m)

FF

Fall Clearance

Self Retracting

Lifeline

Overhead

(per CSA Z259.2.2-17 )

+ DD

+ Xh

+ Person

Fall Clearance Calculation

5

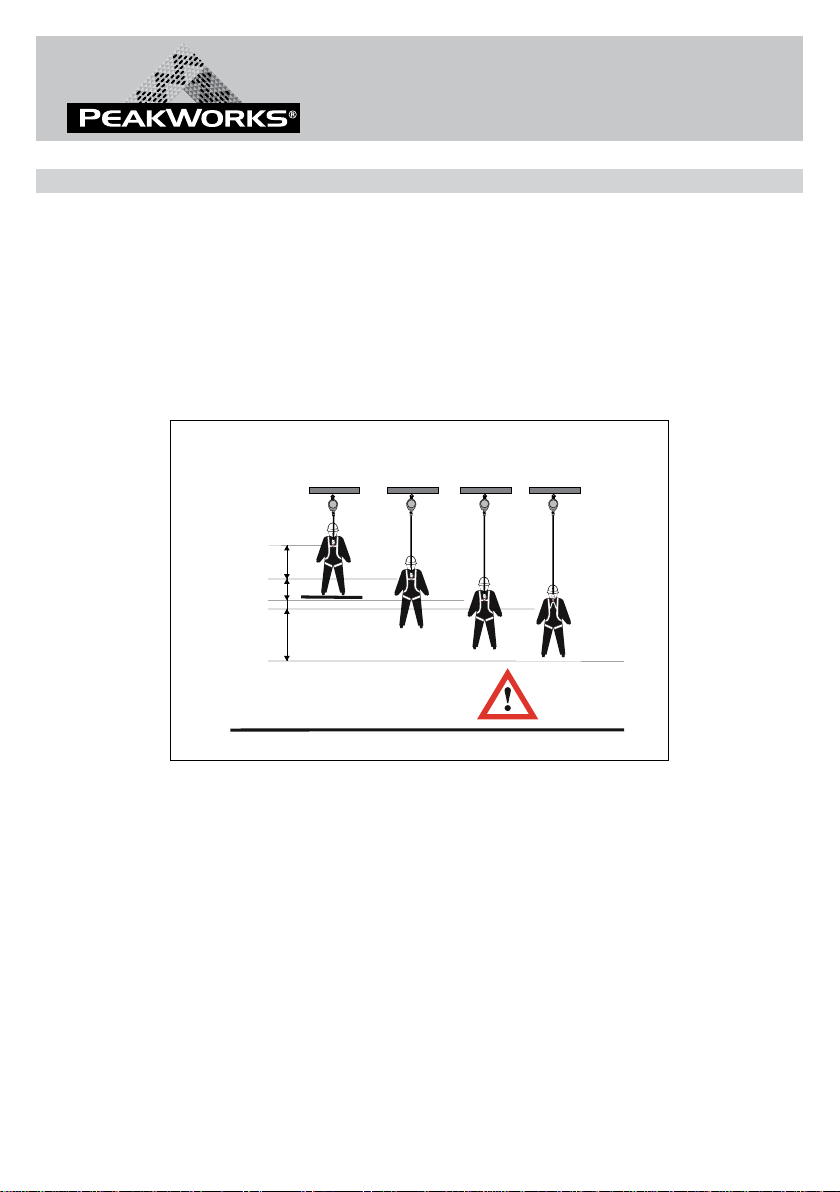

FALL CLEARANCE

Fall Clearance is the distance required to safely arrest the user’s fall. It is the distance from the anchorage to the

ground. A Fall Clearance Calculation must be done anytime this or any other fall protection equipment is used.

Step 1: Calculate Free Fall (FF)

Step 2: Determine how much the connecting device deploys (DD)

Step 3: Determine the stretch of the harness (Xh)

Step 4: Determine person height from feet to harness connecting device

Step 5: Add a safety factor (typically is 3 ft)

Step 6: Fall Clearance C = FF + DD + Xh + Person + SF

CSA Z259.2.2-17 Deployment Calculation:

Deployment is equal to [deployment factor, Dm] times [free-fall distance, h] for a maximum worker mass,

kg, or deployment based on the results of the dynamic performance testing specified in Clause 7.2, whichever

is greater.

When SRL-R is anchored overhead Maximum Deployment Distance:

SRL-73303-60 / V845643060 = 0.80 m (32 in)

SRL-73303-96 / V845643096 = 1.10 m (43 in)

EPORUE

597NE

Nk2.22

aciremAhtroN

3

4

max.

30°

EN 361

CSA

ANSI/

ASSE

1

5

STOP

2

6

INSTRUCTIONS FOR USE—HAZARD AREA

1. A PeakWorks SRL device with recovery mechanism in accordance with CSA Z259.2.2-17

SRL-R is an automatic fall arrest system, part of a fall protection PPE with integrated fall

restraint functions to serve as a fall arrest and recovery lifting device. In conjunction with a

safety harness, this SRL device provides safety for persons carrying out work with a risk of

falling (e.g., when moving in containers, vertical shafts, sewer systems). With the recovery

mechanism, the lifeline is wound up to lift the casualty in an emergency. This device may

only be used for the intended purpose.

2. The instructions for use are to be fully read and understood before use. Non-observance

of the instructions for use will put lives at risk ( 1). In case of a fall, prolonged suspension

of a person for more than 20 minutes must be avoided (risk of shock).

3. The recovery mechanism has only been approved for recovery purposes, not for lifting

and lowering other material.

4. Only safety harnesses in accordance with CSA Z259.10, ANSI Z359.11 and EN361 are

permitted for use with the fall arrest block with recovery mechanism (other harnesses are

not permitted) ( 2).

5. One device can only protect one person at a time but can be used successively by

several persons ( 3).

6. A rescue plan covering any rescue case that might occur during work must exist.

7. During the rescue operation, there must always be direct or indirect visual or

communicative contact with the person to be rescued.

8. A suitable attachment point of sufficient carrying capacity must be chosen (e.g.,

anchorage point in accordance with EN 795 (for North America 22,2 kN) in accordance

with CSA Z259.12 ( 4).

9. This device should be in a perpendicular position above the head of the person to be

rescued in order to prevent swinging ( 5). The suspension of the device must allow for

compensating deviations in cable/webbing length. When the device has been attached to

the anchorage point, attach the end of the connecting device (carabiner-type connector)

to the ring attachment point of the safety harness.

10. This recovery block with winding handle can only be used as part of a fall arrest system in

conjunction with the holders and support brackets of the PeakWorks anchor devices. The

instructions for use of the anchor devices and their components must be observed.

11. Before every use, check the readability of the product label. If the label is illegible, then

remove the SRL from service.

12. A visual inspection and functional test of this SRL must be performed before every use ( 6).

To do so, attach the fall arrest block to a suitable anchor point: Pull the cable, the ratchets

must lock audibly and the device must be locking. Firmly hold the cable and allow it to

retract into the fall arrest block in a controlled manner. If the cable is released, it may cause

injuries and damage by its quick and uncontrolled retraction into the housing. Check the

swivel hook for proper functioning (self-closing, lockable). Check the retractable connecting

device for proper condition. A recovery block with a damaged connecting element or

device (6a and 7), e.g., cable with a kink or broken/torn strand, must not be used and

removed from service.

5

6

6a

7

4

3

1

2

10

40 40

9

35–140 kg

110–310 lbs

7

8

9

10

11

12

13. A fall arrest block must be withdrawn from use if damaged, loaded by fall, or if its safe

condition is doubtful. It may only be used further and removed from service if tested and

released in writing by an expert from or trained by the manufacturer.

*Check connector to ensure that the indicator has not been released.

14. Fall arrest blocks must not be used for securing persons working above bulk goods or

similar substances in which people can sink ( 8).

15. As necessary, but at least every 12 months, fall arrest blocks with recovery mechanism must

be inspected by the manufacturer or by persons trained and authorized by the manufacturer

(9). This must be documented in the inspection logbook supplied with the product. The

effectiveness and durability of the fall arrest block depends on regular inspection.

16. Guidance and legislation in the country of use must be followed.

17. Maximum deployment for SRL-73303-60/V845643060 is 0.80 m/32 in and for

SRL-73303-96/V845643096 is 1.10 m/43 in.

18. The PeakWorks SRL with recovery mechanism can be used in a temperature range from

-40° F to +122° F (-40° C to +50° C) (10 ).

19. The rated load is 310 lbs (140 kg) and 1 person (maximum) ( 11 ).

20. Fall arrest blocks with recovery mechanisms must be protected from the effects of

welding flames and sparks, fire, acids, lye, solvents, and similar agents.

21. No modifications may be made on the device.

22. Note: Fall arrest blocks with recovery mechanism may only be used by persons who are

appropriately trained or otherwise skilled. Users must be free from health impairments

(alcohol, drug, medication, or cardiovascular problems).

23. The service life of the fall arrest block with recovery mechanism must be determined in the

yearly inspection; it is approximately 10 years depending on load stress.

24. After every use of the fall arrest block, the device must be inspected by an expert trained

by the manufacturer.

25. When this SRL is used, it must be ensured that the loaded lifeline does not pass

over edges ( 12 ).

8

FUNCTION DESCRIPTION FOR SELF-RETRACTING LIFELINES WITH

RESCUE LIFTING DEVICE THROUGH CRANK MECHANISM

Rescue Application:

Required Operations:

1. Open the sealed Velcro lock; see Figure 1.

2. Unfold the crank handle; see Figure 1.

3. Pull out the locking pin with pear handle (see

Figure 2), (Action 1), until the crank handle axis

(Action 2) pops out audibly and visibly (Figure 3).

4. Rotate the crank handle back and forth until the

gear has engaged. The locking pin jumps back

into its initial position (Action 3).

5. The “rescue function” of the device is established.

6. The casualty can now be cranked up and down.

Descending is only allowed to a maximum

distance of 2 m (6.56 ft.).

7. Note: Devices with rescue hoisting crank may

only be used with the corresponding holders

(holding plates) for PeakWorks fastening

facilities EN 795. After successfully using

the rescue hoisting device, the device must

always be checked by an expert trained by

the manufacturer.

Figures 1 and 3 show the PeakWorks self-retracting lifeline with crank position set to the “self-retracting lifeline” function.

Heben

up

soulève

subir

senken

down

descendre

bajar

46cCSA2460

Rescue function / fonction de sauvetage

1

3

2

Plombe im Rettungsfall entfernen.

To operate gearing mechanism, remove seal.

Ouvrir fermeture auto-agrippante plombee.

Kurbel nach oben ziehen, leicht drehen bis

Pull handle up, turn slightly until gear wheel

and trigger No. 2 snap in.

Tourner la bielle jusqu‘a ce que le

mecanisme s‘engage.

Pull gear trigger No. 2 out.

Tirer le boulon d‘arret avec la poignee plastique.

462CSA9518

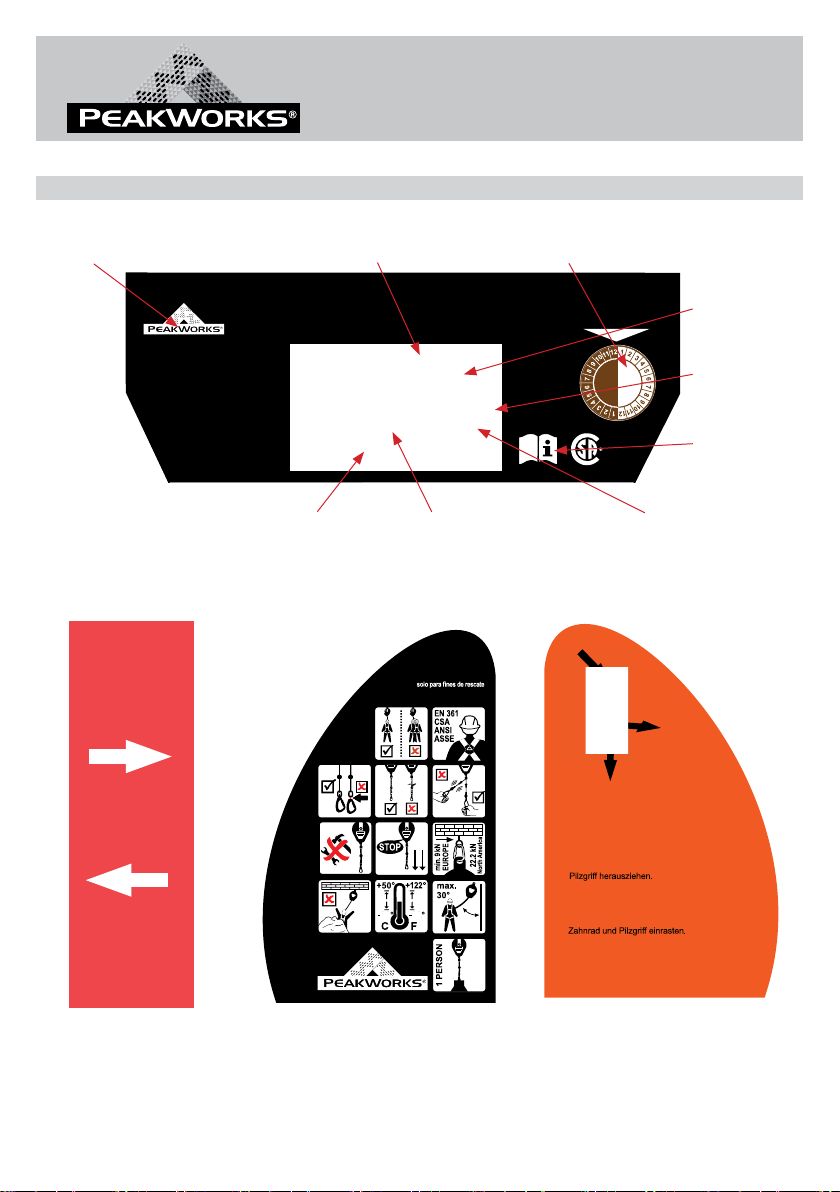

JET equipment and tools CSA type plates

HRA 12

HRA 18

HRA 33

461JET1218

Retractable type fall arrestor /

Les appareil antichute,

according to / selon

CSA Z259.2.2 -17 Class SRL-R

WARNING: This device

shall be removed from service when the visual load indicator is deployed.

Lifeline shall not contact edges or surfaces during fall arrest. Anchor above user’s dorsal D-Ring.

AVERTISSEMENT: Ce dispositif doit être retiré du service lorsque l’indicateur de chute du est activé. La

corde d’assurance ne doit pas entrer en contact avec des bords ou des surfaces lors de l’arret de chute.

Ancrer au-dessus de l’anneau en D dorsal du harnais de l‘utilisateur.

next inspection

prochaine révision

SureWerx, 49 Schooner St.,

Coquitlam, BC V3K 0B3

Peakworks.com +1 800-472-7685

For rescue purposes only

Label P/N 460JET1233

Orange = Pamtone 173 C

RAL White Aluminium

Label Process Black

Rot = Pantone 485 (Picogramm)

Material: Oracet 3951GHT-000

Untergrund: Aluminium

Layout date:

approved for print:

date: ____________________

signature: ____________________

08. Dezember 2021

Label Pantone 361

Cut Contour

Label P/N 460JET1233

461JET121846cCSA2460 462CSA9518

gk041-53

1 bl013-01 s

40 40

2

3

1

Part #/ Réf de pièce: SRL-73303-60

Lifeline length/longuer de cable: 18 m / 60 ft

Lifeline material/materiau de cable: Galvanized

Steel cable 4.8 mm / 0.1875" Diameter

Max. arrest force/arrêter de force: <8 kN / 1,350 lbF

Max. deployment/Déploiement max.: 0.80 m / 32 in

Serial Number: 1234567

Manufactured: 10/2021

2022

2023

Schilder_JET_HRA.pdf 1 5/12/22 8:52 AM

Rettungshubfunktion / Instruction /

Bedienungsanleitung

Schilder_JET_HRA.pdf 1 5/12/22 8:59 AM

Schilder_JET_HRA.pdf 1 5/12/22 9:01 AM

Schilder_JET_HRA.pdf 1 5/12/22 9:19 AM

Heben

up

soulève

subir

senken

down

descendre

bajar

46cCSA2460

Rescue function / fonction de sauvetage

1

3

2

Plombe im Rettungsfall entfernen.

To operate gearing mechanism, remove seal.

Ouvrir fermeture auto-agrippante plombee.

Kurbel nach oben ziehen, leicht drehen bis

Pull handle up, turn slightly until gear wheel

and trigger No. 2 snap in.

Tourner la bielle jusqu‘a ce que le

mecanisme s‘engage.

Pull gear trigger No. 2 out.

Tirer le boulon d‘arret avec la poignee plastique.

462CSA9518

JET equipment and tools CSA type plates

HRA 12

HRA 18

HRA 33

461JET1218

Retractable type fall arrestor /

Les appareil antichute,

according to / selon

CSA Z259.2.2 -17 Class SRL-R

WARNING: This device

shall be removed from service when the visual load indicator is deployed.

Lifeline shall not contact edges or surfaces during fall arrest. Anchor above user’s dorsal D-Ring.

AVERTISSEMENT: Ce dispositif doit être retiré du service lorsque l’indicateur de chute du est activé. La

corde d’assurance ne doit pas entrer en contact avec des bords ou des surfaces lors de l’arret de chute.

Ancrer au-dessus de l’anneau en D dorsal du harnais de l‘utilisateur.

next inspection

prochaine révision

SureWerx, 49 Schooner St.,

Coquitlam, BC V3K 0B3

Peakworks.com +1 800-472-7685

For rescue purposes only

Label P/N 460JET1233

Orange = Pamtone 173 C

RAL White Aluminium

Label Process Black

Rot = Pantone 485 (Picogramm)

Material: Oracet 3951GHT-000

Untergrund: Aluminium

Layout date:

approved for print:

date: ____________________

signature: ____________________

08. Dezember 2021

Label Pantone 361

Cut Contour

Label P/N 460JET1233

461JET121846cCSA2460 462CSA9518

gk041-53

1 bl013-01 s

40 40

2

3

1

Part #/ Réf de pièce: SRL-73303-60

Lifeline length/longuer de cable: 18 m / 60 ft

Lifeline material/materiau de cable: Galvanized

Steel cable 4.8 mm / 0.1875" Diameter

Max. arrest force/arrêter de force: <8 kN / 1,350 lbF

Max. deployment/Déploiement max.: 0.80 m / 32 in

Serial Number: 1234567

Manufactured: 10/2021

2022

2023

Schilder_JET_HRA.pdf 1 5/12/22 8:52 AM

Rettungshubfunktion / Instruction /

Bedienungsanleitung

Schilder_JET_HRA.pdf 1 5/12/22 8:59 AM

Schilder_JET_HRA.pdf 1 5/12/22 9:01 AM

Schilder_JET_HRA.pdf 1 5/12/22 9:19 AM

9

Product Number Next Revision

Consecutive

Serial Number

Date of

Manufacture

Read the

Instruction

Manual

Maximum

arrest force

Rope Length =

Max. Lifting

Height

Manufacturer

Maximum

deployment

LABELING OF THE FALL ARREST BLOCK WITH RECOVERY MECHANISM

For SRL: SRL-73303-60/V845643060, SRL-73303-96/V845643096

10

PRE-USE INSPECTION

If the Self-Retracting Lifeline is known to have arrested a fall, it must be removed from service immediately and

returned for inspection and servicing.

Before each use, check

(a) that the brake operates correctly

(b) that the SRL is securely anchored level with or above the user (NEVER below)

(c) that all components to be used in conjunction with this device are compatible and in good condition

(d) avoid anchoring the device in such a position that could result in a “pendulum/swing fall”

(this may occur if the device is positioned at > 30º from the vertical in relation to the end user).

Extend the wire rope/webbing fully (wearing suitable protective gloves) and inspect along its length

for damage, such as:

(a) broken or frayed wires/webbing

(b) soiling and/or corrosion

(c) kinks and twists in the wire/webbing

(d) inspect the swage/stitching for damage

(e) check the connector(s) being used as per the User Instructions supplied with the connector

(f) check that the Overload/Fall Indicator is not exposed.

Check the device housing for signs of mechanical deformation, cracks, or chemical contamination

and/or other defects.

Retract the wire rope/webbing slowly; during retraction, give the wire rope a sharp sudden tug in order

to activate the braking mechanism. This check should be carried out along the full length of the rope at

approximately 20% increments.

If any of the above criteria fails, then the device must be removed from service. In the event of any doubt,

consult a trained and competent person.

Warning: If this SRL or any fall protection device is known to have arrested a fall, it must be removed

from service immediately.

SERVICE AND MAINTENANCE

1. The lifeline shall only retract under load. On no account may the lifeline be fully pulled out and released

because the carabiner hook jolting against the device may cause the retraction spring to break.

2. For devices that are constantly exposed to the weather, it is recommended to grease the steel cable with

acid-free oils or Vaseline at regular intervals.

3. PeakWorks SRLs with recovery mechanism should be stored in dry, dust-, and oil-free condition in

a suitable container.

4. Components which have become wet during cleaning or use may only be dried naturally, not near

a fire or similar heat sources.

11

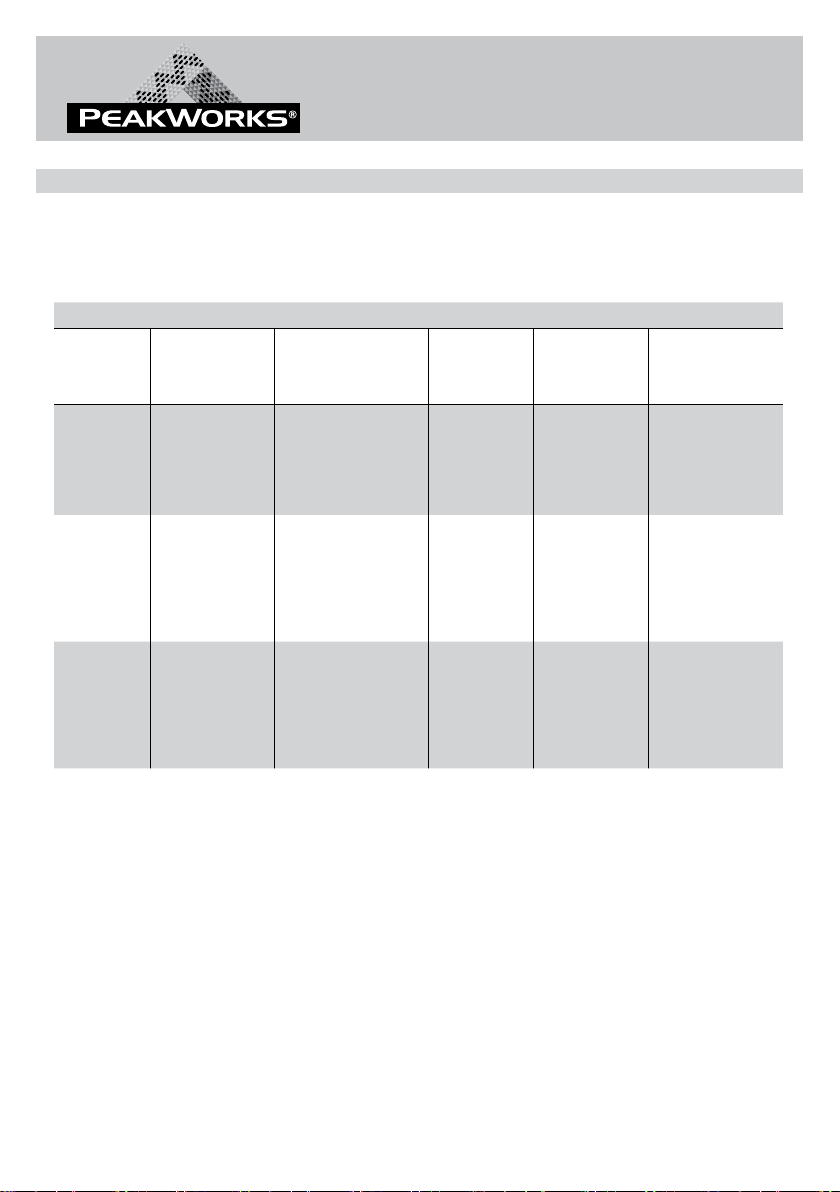

INSPECTION

This equipment and any other fall protection equipment used in conjunction with it should be inspected by the

worker every time it is used. This equipment must be inspected annually by a competent person. A competent

person is defined by OSHA: “By way of training and/or experience, a competent person is knowledgeable of

applicable standards, is capable of identifying workplace hazards relating to the specific operation and has the

authority to correct them”. Details of how to inspect this equipment are discussed later in the manual.

Inspection Requirements for Self-Retracting Devices

Type of use Application

examples

Example of

conditions of use

Worker

inspection

frequency

Competent

person

inspection

frequency

Product

revalidation

frequency

Infrequent

to light

Rescue and

confined

space, factory

maintenance

Good storage

conditions, indoor

or infrequent

outdoor use, room

temperature, clean

environments

Before

each use

Annually At least every

5 years, but

not more

than intervals

required by the

manufacturer

Moderate

to heavy

Transportation,

residential

construction,

utilities,

warehouse

Fair storage

conditions, indoor

and extended

outdoor use, all

temperatures,

clean or dusty

environments

Before

each use

Semi-annually

to annually

At least every

2 years but

not more

than intervals

required by the

manufacturer

Severe to

continuous

Commercial

construction,

oil and gas,

mining, foundry

Harsh storage

conditions,

prolonged or

continuous

outdoor use, all

temperatures, dirty

environments

Before

each use

Quarterly to

semi-annually

At least annually

but not more

than intervals

required by the

manufacturer

Notes:

1. Failure of a worker to perform a “before each use” inspection or failure of an inspection by a worker shall

initiate the requirements for inspection by a competent person.

2. Failure of a competent person to perform inspections as specified in this table, or failure of an inspection

by the competent person shall initiate product revalidation or disposal.

3. Determination of the type of use category shall be determined by a competent person.

4. An SRD that is considered non-repairable, or not designed for disassembly such that internal inspection is

not possible without rendering it unserviceable, is not subject to revalidation inspection. These SRDs shall

have service life and other inspection requirements as provided by the manufacturer’s instructions.

12

INSPECTION LOG

Inspection

Date Results

Corrective

Action

Maintenance

Performed

Inspection

Conducted By

1

2

3

4

5

6

7

8

9

10

13

NOTES

Canada:

SureWerx, 49 Schooner St.,

Coquitlam, BC V3K 0B3 Made in Germany

This manual suits for next models

3

Other Surewerx Safety Equipment manuals

Popular Safety Equipment manuals by other brands

Lanex

Lanex PB-20 instruction manual

SKYLOTEC

SKYLOTEC ANCHOR ROPES Instructions for use

Besto

Besto Buoyancy Aid 50N Instructions for use

TEUFELBERGER

TEUFELBERGER NODUS Manufacturer's information and instructions for use

Troy Lee Designs

Troy Lee Designs Tbone Product owners manual

Innova

Innova Xtirpa Instruction and safety manual

bolle SAFETY

bolle SAFETY B810 quick start guide

SHENZHEN FANHAI SANJIANG ELECTRONICS

SHENZHEN FANHAI SANJIANG ELECTRONICS A9060T instruction manual

Hiltron security

Hiltron security POWER8E Installation and use manual

Salewa

Salewa MTN SPIKE user manual

Hatco

Hatco B-950P installation guide

Sitec

Sitec TX MATIC operating manual