Surface Concept Delayline DLD 8080 User manual

D

De

el

la

ay

yl

li

in

ne

e

D

De

et

te

ec

ct

to

or

r

D

DL

LD

D

8

80

08

80

0

Delayline Detector

DLD 8080

Manual

D

De

el

la

ay

yl

li

in

ne

e

D

De

et

te

ec

ct

to

or

r

D

DL

LD

D

8

80

08

80

0

2

D

De

el

la

ay

yl

li

in

ne

e

D

De

et

te

ec

ct

to

or

r

D

DL

LD

D

8

80

08

80

0

3

A

ll rights reserved. No part of this

manual may be reproduced without the

prior permission of Surface Concept

GmbH.

Surface Concept GmbH

Am Sägewerk 23a

55124 Mainz

Germany

Tel. ++49 6131 62760

Fax: ++49 6131 6271629

www.surface-concept.com,

Manual Version: 1.2

Date: 2010-05-10

D

De

el

la

ay

yl

li

in

ne

e

D

De

et

te

ec

ct

to

or

r

D

DL

LD

D

8

80

08

80

0

4

D

De

el

la

ay

yl

li

in

ne

e

D

De

et

te

ec

ct

to

or

r

D

DL

LD

D

8

80

08

80

0

5

1Table of Contents

1Table of Contents .................................................................................................................................................................................. 5

2Introduction.............................................................................................................................................................................................. 8

2.1 General Information................................................................................................................................................................... 8

2.2 Safety Instructions...................................................................................................................................................................... 8

2.3 General Overview of the System .......................................................................................................................................... 9

3Installation ............................................................................................................................................................................................. 10

3.1 Initial Inspection ........................................................................................................................................................................ 10

3.2 Installation ................................................................................................................................................................................... 11

3.2.1 Mounting the delayline detector.............................................................................................................................. 11

3.2.2 Detector Orientation .................................................................................................................................................... 11

3.2.3 Cabling and High Voltage............................................................................................................................................ 12

3.2.4 Recommended System Requirements................................................................................................................ 14

4USB 2.0 Driver Installation ............................................................................................................................................................ 15

5DLD - Principle of Operation .......................................................................................................................................................... 18

5.1 Basics of Delayline Detection.............................................................................................................................................. 18

5.2 Basic Operational Modes of the Delayline Detector ................................................................................................ 19

5.2.1 2D(x, y) Area Detection ............................................................................................................................................... 19

5.2.2 3D(x, y, t) time resolved imaging ............................................................................................................................. 19

5.3 Data Acquisition........................................................................................................................................................................ 20

5.4 Working with the DLD – Important details .................................................................................................................. 20

6Delayline Detector Layout .............................................................................................................................................................. 21

D

De

el

la

ay

yl

li

in

ne

e

D

De

et

te

ec

ct

to

or

r

D

DL

LD

D

8

80

08

80

0

6

6.1 Delayline Detector - Vacuum Wiring ............................................................................................................................... 21

6.2 Delayline Detector – Connection Ports ......................................................................................................................... 22

7Pulse Processing Electronics ....................................................................................................................................................... 24

7.1 Pulse Processing Electronics ACU 3.4.2...................................................................................................................... 24

7.1.1 Positions of the Discriminator Threshold Regulators ................................................................................... 25

8Time-to-Digital-Converter (TDC) ................................................................................................................................................... 26

8.1 Schematic Description of the USB2.0-TDC ................................................................................................................. 26

8.2 Basic Operation Modes of the GPX TDC Chip............................................................................................................. 27

8.2.1 I-Mode (USB2.0-TDC/ Double USB2.0-TDC ) ................................................................................................... 27

8.2.2 R-Mode (High Resolution/ Dual Channel/ Quad Channel USB2.0-TDC) ............................................. 27

8.2.3 G-Mode (High Resolution/ Dual Channel/ Quad Channel USB2.0-TDC) ............................................. 27

8.3 Layout of the Quad Channel USB2.0-TDC..................................................................................................................... 28

8.3.1 TDC Inputs (Stop + Start)........................................................................................................................................... 28

8.3.2 Trigger Synchronization IN/OUT ............................................................................................................................ 28

8.3.3 Line Input ........................................................................................................................................................................... 29

8.4 Interface (PC) and Software................................................................................................................................................ 29

9Dual HV Supply............................................................................................................................................................................. 30

9.1 Layout of Dual HV Supply & the HV filterbox................................................................................................................ 31

9.1.1 Line Input of Dual HV Supply ..................................................................................................................................... 32

9.2 Connection schemes for different operation modes............................................................................................... 32

10 Operation of the DLD................................................................................................................................................................... 36

10.1 Getting Started .................................................................................................................................................................... 36

10.2 Turning on the High Voltage........................................................................................................................................... 36

10.2.1 “Start-Up” Procedure (for new systems and for systems, after being vented)............................. 37

10.2.2 Standard Start Procedure.................................................................................................................................... 38

10.3 Bake Out Procedure .......................................................................................................................................................... 39

11 Microchannel Plate (MCP)........................................................................................................................................................ 40

11.1 Storage.................................................................................................................................................................................... 40

11.2 Handling .................................................................................................................................................................................. 40

D

De

el

la

ay

yl

li

in

ne

e

D

De

et

te

ec

ct

to

or

r

D

DL

LD

D

8

80

08

80

0

7

11.3 Operation................................................................................................................................................................................ 41

12 Technical Data .............................................................................................................................................................................. 42

13 List of Figure.................................................................................................................................................................................... 43

D

De

el

la

ay

yl

li

in

ne

e

D

De

et

te

ec

ct

to

or

r

D

DL

LD

D

8

80

08

80

0

8

2Introduction

2.1 General Information

This manual is intended to assist users in the installation, operation and maintenance of the Delayline

Detector DLD 8080. It is divided into 13 chapters. The chapter “Introduction” contains a brief description of

the DLD. The chapter “Installation” refers to installation and cabling. One chapter describes the USB driver

installation. Chapter “Principle of Operation” explains the theory of operation of the DLD. 3 chapters describe

the technical details of the detector readout package and chapter “Operation of the DLD” describes the

operation of the DLD. The final chapters contain amongst others, technical details about the microchannel

plates and the delayline detector in general.

2.2 Safety Instructions

Please read this manual carefully before performing any electrical or electronic operations and strictly

follow the safety rules given within this manual.

The following symbols appear throughout the manual:

The “note symbol” marks text passages, which contain important information/ hints

about the operation of the detector. Follow these information to ensure a proper

functioning of the detector.

The “caution symbol” marks warnings, which are given to prevent an accidentally

damaging of the detector or the readout system. Do NOT ignore these warnings and

follow them strictly. Otherwise no guarantee is given for arose damages.

The “high voltage symbol” marks warnings, given in conjunction with the description of

the operation/ use of high voltage supplies and/ or high voltage conducting parts.

Hazardous voltages are present, which can cause serious or fatal injuries. Therefore

only persons with the appropriate training are allowed to carry out the installation,

adjustment and repair work.

D

De

el

la

ay

yl

li

in

ne

e

D

De

et

te

ec

ct

to

or

r

D

DL

LD

D

8

80

08

80

0

9

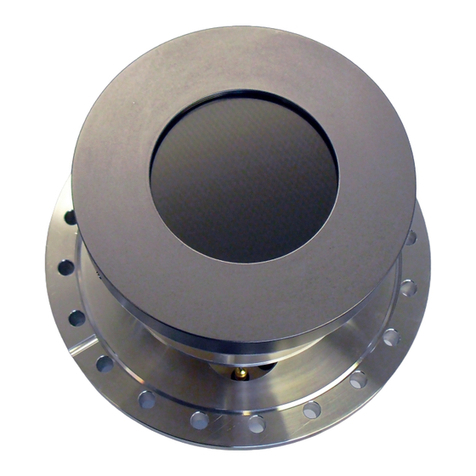

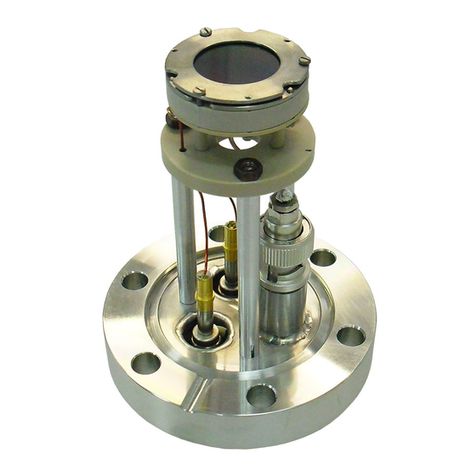

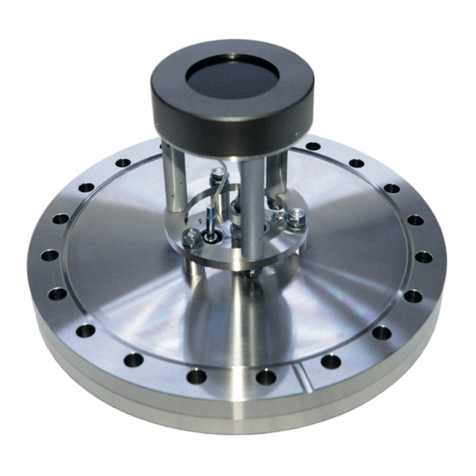

2.3 General Overview of the System

The Surface Concept delayline detectors are particularly developed for the needs of 1D(x), 2D(x,t), 2D(x,y) or

3D(x,y,t) area and time detection of electrons, ions, x-ray and UV-light as well as for multi hit detection of high

rates with the 4-quadrant detector systems.

The DLD 8080 is mounted on a CF 150 vacuum flange with feed-throughs for high voltage supply and signal

transfer. It consists of a microchannel plate stack and two layers (x, y) of meander structured delaylines. The

image is sampled by the DLD readout electronics.

The 3D (x, y, t) detection bases on the measurement of time differences and time sums of signals, with a high

temporal resolution in one device. The count rate can reach up to 2.0 MHz in the commonly used 4-fold

coincidence measurement.

Typical applications are for example:

•imaging of parallel incident particle beams, particularly electrons

•spatially resolved time of flight spectroscopy in 2D/time resolved mode

•time referenced imaging of electrons excited by repetitive driven sources

and in energy analyzers:

•Fermi surface mapping, band mapping, photoelectron diffraction measurements, and similar angular

dispersion experiments in 2D mode

•XPS, UPS, ESCA and AES in virtual channel mode

•Stroboscopic experiments in 2D/time resolved mode

D

De

el

la

ay

yl

li

in

ne

e

D

De

et

te

ec

ct

to

or

r

D

DL

LD

D

8

80

08

80

0

10

3Installation

3.1 Initial Inspection

Visual inspection of the system is required to ensure that no damage has occurred during shipping. Should

there be any signs of damage, please contact SURFACE CONCEPT immediately. Please check the delivery

according to the packing list (see Table 1) for completeness.

1. Dual HV Supply

2. Quad Channel USB 2.0–TDC with USB2.0 cable

3. Delayline Detector DLD8080 under vacuum

4. HV filterbox

5. Pulse processing unit ACU 3.4.2

6. 2x SHV cables (5m),

7. 1x SHV cable (approx. 10 cm)

8. 1x SHV termination plug

9. 1x DLD readout cable (HDMI)

10. Documentation and Software (CD)

Table 1: Packing list for the Delayline Detector

Figure 1: Contents of delivery package

1 2

3

10

5

4

67

8

9

D

De

el

la

ay

yl

li

in

ne

e

D

De

et

te

ec

ct

to

or

r

D

DL

LD

D

8

80

08

80

0

11

3.2 Installation

3.2.1 Mounting the delayline detector

The detector is transported under vacuum. Vent the transport container carefully and release the M8

screws of the vacuum container and pull out the detector carefully.

Check the front side of the MCP stack for particles.

The microchannel plates in front of the detector should be protected from exposure to

particle contamination. Particles that stick to the plate can be removed by carefully using

a single-hair brush carefully and/or with dry nitrogen. Reading the instructions

“microchannel plates” in chapter 11 is strongly recommended.

Install the detector to your vacuum chamber.

The DLD needs a tube with a diameter of minimum 160 mm, to be installed to.

The max. outer diameter of the detector housing is 147mm. The housing is connected to

the MCP front potential. Due to isolation distances (detector housing potential can reach

more than 4000 V) the min. diameter of the tube, where the detector is installed to, must

be of at least 160mm.

Keep the transport container in case that the detector must be sent back for repair. It can also be used to

store the detector when not installed in a vacuum chamber.

The detector should be kept under vacuum all the time.

3.2.2 Detector Orientation

The black dot in Figure 2 marks the 0/0 position of the DLD image, which corresponds to the upper left

corner of the DLD image in the GUI software.

D

De

el

la

ay

yl

li

in

ne

e

D

De

et

te

ec

ct

to

or

r

D

DL

LD

D

8

80

08

80

0

12

Figure 2: 0/0 position of the DLD image (black dot).

3.2.3 Cabling and High Voltage

The general connection scheme of the delayline detector including its readout package is shown in Figure 3.

Figure 3: Connection scheme of the delayline detector and readout package.

•The pulse processing unit ACU can be connected directly to the DLD 4-fold SMB feed-through. The

metal pin gives the orientation. Fasten the ACU with the two clips on the housing.

•Use the DLD readout cable to connect the “Lines Out” socket on the front of the ACU with the “TDC

Input” socket at the rear panel of the USB2.0-TDC. To perform time measurements with respect to an

external clock, provide start pulses to the start input of the TDC. Use the BNC socket named “TTL

D

De

el

la

ay

yl

li

in

ne

e

D

De

et

te

ec

ct

to

or

r

D

DL

LD

D

8

80

08

80

0

13

Start” to apply standard TTL signals.

The start input of the TDC is not working with start signals of frequencies smaller 25 kHz and

larger than 7 MHz.

Larger start pulse frequencies must be divided down with an appropriate frequency divider (e.g.

divider with factor of 16 for 80 MHz start pulse frequency).

•There is a CF40 flange with 2 SHV feed-throughs for high voltage supply of the detector. The

connection of the feed-throughs is as follows:

MCP front (F) and detector anode (A)

The Dual HV Supply holds 6 SHV connectors labeled A, REF A, F, REF F, B+ and B-.

The connectors A and F must always be connected to the corresponding SHV feed-through of the DLD

with the HV filterbox in between.

Do not operate the DLD without the HV filterbox.

This will lead to a significant decrease in the image quality.

The operation voltage for the DLD (specified in the specification sheet) is always applied between A and

F. It is produced by the HV module “HV A”.

REF A and REF F are connected to A and F respectively. They allow connecting a reference potential to

the one or other side of the MCP stack. The DLD can be operated floating on a bias voltage (positive or

negative). The HV module “HV B” can be used to generate this bias voltage.

For the first tests the detector should be operated with the following HV connection:

•Connect the 2 SHV connectors A & F of the Dual HV Supply with the corresponding inputs of the

HV Filterbox.

•Connect the 2 SHV cables (named A & F) of the HV Filterbox to the corresponding SHV feed-

throughss on the CF 40.

•Terminate the REF F connector with the termination plug.

•The other three connectors won’t be used.

Further information about the cabling of the Dual HV Supply as well as about the detector operation

voltages can be found in chapter 9 and chapter 10.

A SHV termination plug is included in the delivery. In cases that no reference voltage is applied,

the termination plug must be used to ground the reference inputs. Otherwise the MCP stack is

not functioning as the reference potential is missing.

Be sure that all voltages are settled to zero before connecting the high voltage cables to

the detector, otherwise serious damage to the detector can occur due to high voltage

sparks.

•Connect the power cable to the main connector of the USB2.0-TDC and use the USB 2.0 cable to

connect the USB2.0-TDC to the PC. Switch on the TDC and follow the instructions for installing the

device driver if connected for the first time. If the device driver is already installed, the USB connection

is established automatically. Do not use PC front panel USB connectors; they are often restricted in

performance. For further details on driver installation please see chapter 4.

If the device driver is already installed, the USB connection is established automatically.

D

De

el

la

ay

yl

li

in

ne

e

D

De

et

te

ec

ct

to

or

r

D

DL

LD

D

8

80

08

80

0

14

Finish the complete cabling before the TDC is turned on and the GUI monitor software is

started. Also, close the software and turn off the TDC before performing any changes to

the cabling. This applies especially to the connection and disconnection of the start input

of the TDC. The start input of the TDC cannot handle pulses which are arriving in a time

interval of smaller than 150 ns, as they are produced by e.g. connecting to and

disconnecting from the start input respectively.

Don’t start the detector operation before you are familiar with the detailed descriptions

of chapter 5 within this manual.

3.2.4 Recommended System Requirements

Read-out of the USB2.0–TDC is done with a standard PC via USB2.0. For the PC the following system

requirements are highly recommended:

•Processor: 1.6 GHz

•RAM: 1GB

•Windows XP / Windows 2000

•USB 2.0 (no front panel connector)

•Monitor resolution: in Y min. 864 pixel (most critical), in X min. 1024 pixel

The use of USB2.0 for the readout of the TDC is highly recommended. In principle the readout of

the TDC is compatible to USB1.0, but the required data transfer rates are not reached. Do not

use PC front panel USB connectors; they are often restricted in performance.

D

De

el

la

ay

yl

li

in

ne

e

D

De

et

te

ec

ct

to

or

r

D

DL

LD

D

8

80

08

80

0

15

4USB 2.0 Driver Installation

•First, log on as Administrator. Close all applications on your PC. If you are using any anti-virus or

firewall software, close them (or disable them). Connect the USB cable to your Windows System with

USB2.0 enabled. Windows will find the new hardware, and the "Found New Hardware Wizard" will

launch. To continue, select “No, not this time” (not looking for windows updates) and ”click "Next>".

•Insert the CD-ROM, included in the delivery, into the PC's CD-ROM drive.

•Select "Install the software automatically (Recommended)" and Click "Next>".

D

De

el

la

ay

yl

li

in

ne

e

D

De

et

te

ec

ct

to

or

r

D

DL

LD

D

8

80

08

80

0

16

•Continue Installation although the Windows XP capability test failed.

•Enter the path where the driver is located (or Browse to it)

•The internal name of the USB2.0 TDC driver is “ceusb3.sys”, select it and press “Open”.

D

De

el

la

ay

yl

li

in

ne

e

D

De

et

te

ec

ct

to

or

r

D

DL

LD

D

8

80

08

80

0

17

•To continue, click "OK". The driver for the Surface Concept USB2.0 TDC will be installed.

•After a few seconds, a finishing dialog should appear as below. To finish, click "Finish".

After finishing the installation routine for the first time, it will start again. Go through the

routine again a second time completely. The driver installation will be complete only after the

second installation.

The driver has to be installed again, when the USB cable is connected to a different USB port on

the PC. In this case the driver installation should start automatically.

D

De

el

la

ay

yl

li

in

ne

e

D

De

et

te

ec

ct

to

or

r

D

DL

LD

D

8

80

08

80

0

18

5DLD - Principle of Operation

5.1 Basics of Delayline Detection

A delayline detector (DLD) consists of a microchannel plate array for pulse amplification and an in-vacuum

detection unit consisting of a meander structured delayline (DLD anode). Each hit position is encoded by a fast

data acquisition unit, which also may detect the hit time referenced to an external clock in repetitive

(stroboscopic) experiments.

Figure 4: Principle of the 3D (x, y, t) delayline operation

The DLD anode consists basically of two meander structured delaylines; one rotated by 90° with respect to

the other and both isolated from each other. The delaylines are positioned behind a microchannel plate stack,

which is required to amplify incoming electrons. The electron cloud from the MCP stack output is drawn to

D

De

el

la

ay

yl

li

in

ne

e

D

De

et

te

ec

ct

to

or

r

D

DL

LD

D

8

80

08

80

0

19

the DLD meander (positive potential difference between anode and back side of MCP stack) where it induces

electrical pulses in the delayline by capacitive coupling. The pulses are traveling to the both ends of the

meander within a time determined by the hitting position. The average time at both ends of the meander

relative to an external repetitive clock generates the time coordinate if required.

Delayline detectors are single counting devices; therefore the complete device works linearly even at

extremely low numbers of incoming electrons.

The detection principle limits the maximum detectable count rates at least due to the maximum delay of the

meanders. Currently, the main limitation is given by the appearance of multi-hit events, which can only be

resolved up to a certain degree. The maximum count rate in the fourfold coincidence measurement is right

now about a couple of million counts per second. The exact limit depends on the size of the active area of the

DLD.

5.2 Basic Operational Modes of the Delayline Detector

5.2.1 2D(x, y) Area Detection

The arrival times of pulses per event at the 4 ends of each DLD meander/ quadrant are subtracted in order

to determine a position in x and y (x: tx1-tx2; y: ty1-ty2). The TDC stop signals are grouped internally in pairs to

form the x- and y-coordinates. All DLD software adjustments are done by the end-user software according to

the user’s chosen parameters.

5.2.2 3D(x, y, t) time resolved imaging

The delayline detector may measure all events in temporal reference to an external clock. For this mode, the

user needs to start the USB2.0-TDC by an external clock, providing a low jitter LVTTL signal to the start input

of the TDC.

Time measurements are performed by summing up the arrival times of pulses at the end of the DLD

meanders, i.e. the same results which are used to determine positions for each event are summed. It is

possible to sum only tx1 and tx2 (tsumx) or ty1 and ty2 (tsumy). Because both sums should carry the same

temporal information of a time related experiment, the total sum t(DLD) of all four time measurements (tx1,

tx2, ty1, ty2) may be a good choice as well. The results of all these time sums correspond to t(sum) = t(offset)

+ n * (t(hit) – t(reference)), where (t(hit) – t(reference)) is the interesting time (e.g. ToF) in a given experiment,

n is the number of summed time results (2 or 4 results), and t(offset) is a device related constant, which

depends on cable lengths, electronics propagation times, experiments setup etc.. Therefore, it is possible to

completely determine position and time of each event from only 4 precise time measurements.

The software may group all measured time sums in plain 1D time histograms, which are valid for the chosen

region of interest (ROI). The time bin size for each readout channel x1, x2, y1 and y2 is 82ps in the I-mode

(see chapter 8.2). The channel width in the 1D histogram is 41ps for the tsumx and tsumy histograms and

20.5ps for the total t(DLD) histogram.

The time bin size for the readout channels in the R-mode (see chapter 8.2) is 27ps and the channel width in

the 1D histogram is 13.5ps for the tsumx and tsumy histograms and 6.75ps for the total t(DLD) histogram.

Due to the calculation of the tsums and t(DLD), the time axis is expanded virtually (simplified expression). The

t(DLD) signature can be used in order to setup the regions of interest in time for measurements of time

resolved images, the software is able to sample 3D histograms as image stacks in time, where each image

corresponds to one time bin of the total time histogram.

D

De

el

la

ay

yl

li

in

ne

e

D

De

et

te

ec

ct

to

or

r

D

DL

LD

D

8

80

08

80

0

20

5.3 Data Acquisition

Each readout line of the detector anode is connected to a fast amplifier followed by a constant fraction

discriminator (CFD) for pulse shaping. They are encapsulated inside the pulse processing electronics (ACU =

Amplifier-CFD-Unit or AU = Amplifier-Unit). The main function of the CFD is digital pulse discrimination, ideally

without any time-walk even at varying pulse heights. A time-to-digital converter (TDC) behind these chains

serves as stop-watch for arrival time measurements. The measurement results, in terms of differences and

sums are fed into the PC via a USB 2.0 interface and are completed to 2D images (with or without time

stamps) by the histogram module of the data acquisition DLL. Data processing and presentation on the PC is

realized with the GUI software. See the corresponding software manuals for detailed information on the

software package.

5.4 Working with the DLD – Important details

The DLD is a counting system that works in a laterally resolving sense by detecting four pulses from the four

ends of the delayline meanders in a fourfold coincidence. It only works correctly within a certain range of the

supply voltage. The MCP voltage has to exceed an operation threshold for the detector otherwise the pulse

detection is not possible. This is due to the induced pulses on the delayline which have to reach a certain

amplitude to be detected by the electronics, independent on the intensity of the electron source (e.g. mercury

lamp). On the other hand, if the MCP voltage and/or the intensity of the electron source are too high, the

detector overloads and again pulse detection is not possible. Saturation effects of the MCPs limit the amount

of electrons provided by single pulses. An intensity increase of the electron source leads to an increased

number of hits on the MCP. The current per bunch and therefore the amplitude of the pulses decreases.

There are two kinds of overloads: local and global. A local overload (locally high intensity on the MCP) leads to

no count rate within this local area and to an absolute “black spot” in the images. An intensity too high and

homogeneously distributed over the whole MCP first leads to diffuse images and with further increasing

intensity to randomly distributed artificial structures up to no count rate at all (global overload). The

explanation for the effects for a local overload is a pulse amplitude that is too low to be detected by the

electronics. The explanation for the global overload effects is mainly the loss of the fourfold coincidence

condition of an incoming event and a fitting fourfold coincidence of random pulses, respectively. High intensity

on the MCPs always leads to a significant pressure increase. Therefore an observed pressure increase can

always be taken as an indicator for an overload of the detector, when problems with the functionality of the

DLD occur.

It is easy to mistake an overload for no signal at all. To distinguish between these two, check the

pressure. A pressure increase indicates an overload.

The DLD has been calibrated for an optimized MCP voltage and it is strongly advised to use this optimized

voltage value for operation. It is given in the specification sheet. A change of the MCP voltage can lead to

artifacts within the images. The MCP voltage should only be increased to compensate a decrease in

amplification of the MCP stack do to wearing-out.

Other manuals for Delayline DLD 8080

1

Table of contents

Other Surface Concept Security Sensor manuals

Surface Concept

Surface Concept MCPD25 User manual

Surface Concept

Surface Concept DLD6060-8S User manual

Surface Concept

Surface Concept HVPS User manual

Surface Concept

Surface Concept CEM 4230 User manual

Surface Concept

Surface Concept Delayline DLD 8080 User manual

Surface Concept

Surface Concept MCPD18 User manual

Surface Concept

Surface Concept DLD4040 User manual

Surface Concept

Surface Concept MCPD40 User manual