Surface Concept MCPD18 User manual

MCPD18 R104

1-channel MCP Detector

MCPD18

(Release 104)

Manual

1

MCPD18 R104

All rights reserved. No part of this manual

may be reproduced without the prior

permission of Surface Concept GmbH.

Surface Concept GmbH

Am Sägewerk 3a

551 4 Mainz

Germany

Tel. ++49 6131 6 7160

Fax: ++49 6131 6 716 9

www.surface-concept.com,

support@surface-concept.de

User manual for the

1-channel MCP Detector MCPD18

Release: 104

Manual Version: 1.0

Printed on: 10.10. 018

MCPD18 R104

1 Table of Contents

1 Table of Contents..............................................................................................................................................................................................3

Introduction..........................................................................................................................................................................................................4

.1 General Information.................................................................................................................................................................................4

. Safety Instructions...................................................................................................................................................................................4

.3 General Overview of the System.......................................................................................................................................................5

3 Installation.............................................................................................................................................................................................................6

3.1 Initial Inspection.........................................................................................................................................................................................6

3. Installation.....................................................................................................................................................................................................6

3. .1 Mounting the MCPD detector..................................................................................................................................................6

3. . Cabling and High Voltage............................................................................................................................................................7

4 Operation of the MCPD18...........................................................................................................................................................................8

4.1 Getting Started..........................................................................................................................................................................................8

4.1.1 “Start Up” Procedure....................................................................................................................................................................8

4.1. Dark Count Rate Measurement..............................................................................................................................................9

4.1.3 Standard Detector Measurement.........................................................................................................................................9

4. Standard Operation Procedure.....................................................................................................................................................10

4.3 Bake Out Procedure............................................................................................................................................................................10

5 MCP Detector Layout..................................................................................................................................................................................1

5.1 MCPD18 - Vacuum Wiring..............................................................................................................................................................1

6 Microchannel Plate.......................................................................................................................................................................................14

6.1 Specifications...........................................................................................................................................................................................14

6. Storage.......................................................................................................................................................................................................14

6.3 Handling......................................................................................................................................................................................................14

6.4 Operation...................................................................................................................................................................................................15

6.5 MCP Lifetime and Operation Voltage..........................................................................................................................................15

6.6 MCP Degase Procedure....................................................................................................................................................................18

6.7 Replacement............................................................................................................................................................................................18

7 Technical Data.................................................................................................................................................................................................19

8 List of Figure..................................................................................................................................................................................................... 0

3

MCPD18 R104

Introduction

.1 General Information

This manual is intended to assist users in the installation, operation and maintenance of Release 104 of the

1-channel MCP detector MCPD18.

It is divided into 8 chapters. The chapter “Introduction” contains a brief description of the Detector. The

chapter “Installation” refers to installation and cabling. Chapter “Operation of the MCPD18” describes the

operation of the detector. The final chapters contain amongst others technical details about the

microchannel plates and the MCP detector.

. Safety Instructions

Please read this manual carefully before performing any electrical or electronic

operations. Strictly follow the safety rules given within the manual.

The following symbols appear throughout the manual:

The “note symbol” marks text passages, which contain important information/ hints

about the operation of the detector. Follow these information to ensure a proper

functioning of the detector.

The “caution symbol” marks warnings, which are given to prevent an accidentally

damaging of the detector or the readout system. Do NOT ignore these warnings and

follow them strictly. Otherwise no guarantee is given for arose damages.

4

MCPD18 R104

.3 General Overview of the System

The Surface Concept MCPD18 R104 is a 1-channel MCP detector.

It consist of a chevron microchannel plate stack and a detector anode. MCP pulses are capacitively coupled

into the anode. The anode is a 50Ohm matched system and signal readout is realized ground close via a

coaxial cable and connector layout. The active detection area is 18mm.

5

MCPD18 R104

3 Installation

3.1 Initial Inspection

Visual inspection of the MCPD18 is required to ensure that no damage has occurred during shipping. Should

there be any signs of damage, please contact SURFACE CONCEPT immediately.

3. Installation

3. .1 Mounting the MCPD detector

The detector is packed under vacuum. Proceed as follows, to install it into your vacuum chamber:

Vent the package carefully.

Unpack the detector carefully.

Before installing the detector to your chamber, check the front side of the MCP stack for particles.

The microchannel plates in front of the detector should be protected from exposure to

particle contamination. Particles that stick to the plate can be removed by using a

single-hair brush carefully and/or with dry nitrogen. Reading the instructions

“microchannel plates” in chapter 6 is strongly recommended.

6

MCPD18 R104

3. . Cabling and High Voltage

The general connection scheme of the detector is shown in Figure 1.

Figure 1: Connection scheme of the MCPD18 R104

The detector holds two SHV connectors (labeled

“

MCP-B” and “MCP-F”) for the high voltage supply

and one BNC connector (labeled “SIG”) for the signal output. “MCP-B” connects the high voltage part

of the detector anode and the back side of the MCP stack while “MCP-F” connects the front side of

the MCP stack.

Be sure that all voltages are settled to zero before connecting the high voltage cables to

the detector, otherwise serious damage to the detector can occur due to high voltage

sparks.

7

MCPD18 R104

4 Operation of the MCPD18

It is strongly advised to read the following sections completely before taking the detector to

operation and to strictly follow all given advices within it.

4.1 Getting Started

4.1.1 “Start Up” Procedure

Follow this procedure when taken the detector to operation the first time and after every venting.

Finish the complete cabling as described in chapter 3.

Be sure, that the vacuum pressure at the detector is remarkably below 1E-6mbar, otherwise the

microchannel plates might be damaged by a local discharging (in general: the lower the pressure, the

longer the lifetime of the MCPs).

Turn off all sources for electrons, ions, light or X-rays that might hit the detector.

Ion gauges and ion pump are both sources for electrons and ions. Ion pumps can also be

a source for X-rays. They can produce so many particles/ X-rays that the detector is in a

complete overload, even when they are not facing the detector directly. This will wear out

the MCPs very fast. Turn off ion pumps and ion gauges before turning on the high

voltage of the detector.

Turn on the high voltage carefully. The voltage increase should not exceed 400V per minute. A

schematic sketch on how to ramp the voltages during the “Start-Up” procedure is given Figure . The

starting operation voltage is specified in the specification sheet of the detector.

Watch the vacuum pressure while increasing the high voltage; turn the voltages back, if an unusual

increase is observed in the pressure (indicator for high voltage sparking).

High voltage sparks may seriously damage the detector anode or the MCPs. Observe the

chamber pressure carefully every time the high voltage is turned on. Switch off the high

voltage immediately in case of a temporary pressure rise by an order of magnitude or

more. This indicates high voltage sparking.

If sparking occurs, turn down the high voltage immediately and wait some time (up to 5

min.). Start the “Start-Up” procedure again with an increased ramp time. Turn off the

high voltage completely, stop the procedure and call SURFACE CONCEPT for further

assistance, if is it not possible to reach the operation voltage without sparking.

8

MCPD18 R104

Figure : Schematic sketch on voltage ramping during “Start-Up” procedure.

The detector starting operation voltage for “MCP-B” is given in the specification sheet.

Example: The “MPC-B” voltage is given in respect to the “MCP-F” voltage. A ramp time of 4min. should be used

to change the “MPC-B” voltage from 0V to a target voltage of exemplary +1600V.

4.1. Dark Count Rate Measurement

Check the detector output by means of any electronics and software or with an oscilloscope where

the input is terminated with 50Ohms.

The dark count rate without any source should be as given in the specification sheet.

4.1.3 Standard Detector Measurement

After finishing the dark count rate measurement with a satisfying result, you may now start carefully

with an electron or light source observing the detector output.

Turn off the high voltage before performing any changes of the cabling.

9

MCPD18 R104

4. Standard Operation Procedure

Follow this procedure for all later operation starts, when the detector has already been operated in vacuum

and has not been vented in between.

Finish the complete cabling as described in chapter 3.

Be sure, that the vacuum pressure at the detector is remarkably below 1E-6mbar, otherwise the

microchannel plates might be damaged by a local discharging (in general: the lower the pressure, the

longer the lifetime of the MCPs).

Turn off all sources for electrons, ions, light or X-rays that might hit the detector.

Turn up the high voltage carefully and stepwise within - 3minutes to the operation voltage. The

starting operation voltage is specified in the specification sheet of the detector.

Watch the vacuum pressure while increasing the high voltage; turn the voltages back, if an unusual

increase is observed in the pressure (indicator for high voltage sparking).

High voltage sparks may seriously damage the detector anode or the MCPs. Observe the

chamber pressure carefully every time the high voltage is turned on. Switch off the high

voltage immediately in case of a temporary pressure rise by an order of magnitude or

more. This indicates high voltage sparking.

If sparking occurs, turn down the high voltage immediately and wait some time (up to

5min.). Start the “Start-Up” procedure again with an increased ramp time. Turn off the

high voltage completely, stop the procedure and call SURFACE CONCEPT for further

assistance, if is it not possible to reach the operation voltage without sparking.

Now you may start carefully with an electron source observing the detector output.

Turn off the high voltage before performing any changes of the cabling.

4.3 Bake Out Procedure

It is strongly advised to read the following sections completely before baking out the detector

and to strictly follow all given advises within it.

The maximum allowed temperature for the detector is 150°C. Do not exceed this

temperature.

Windows and feedthroughs should be wrapped with aluminum foil, to protect them from rapid

temperature changes.

The use of heating tapes and jackets is not recommended, due to danger of local overheating.

10

MCPD18 R104

Do not remove the blankets until the entire system has thoroughly cooled off.

Do not operate the detector before the temperature has returned to ambient conditions.

11

MCPD18 R104

5 MCP Detector Layout

5.1 MCPD18 - Vacuum Wiring

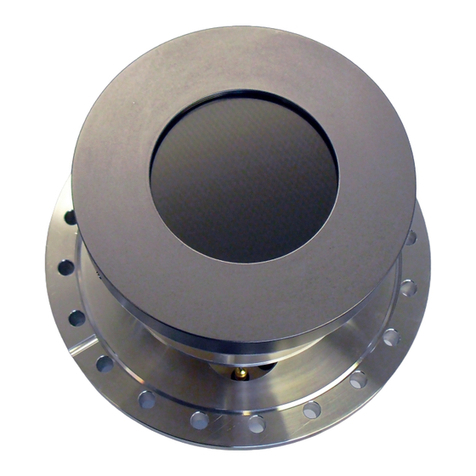

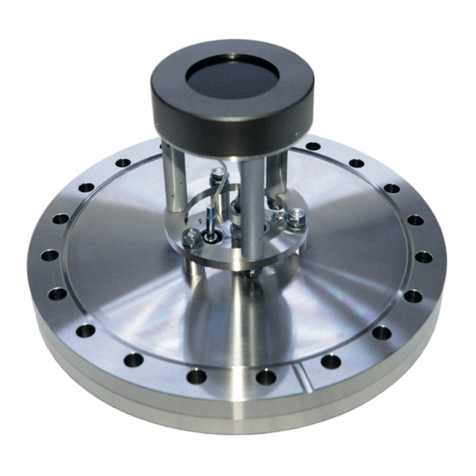

The MCP detector MCPD18 consist of a detection area, defined by the MCP holders and the detector anode.

The front side of the detector anode is on high voltage potential, while the signal readout is realized close to

ground potential (in respect to the high voltage of the MCPs). A pulse coupling layer is used to isolate the high

voltage from the ground potential within a “sandwich” layer system of the detector anode.

Figure 3: Layout of the HV connections and photos of the single detector elements.

The internal connection of the high voltage for MCPD18 R104 is given schematically in Figure 4.

1

MCPD18 R104

Figure 4: Internal connection of the high voltage potentials (schematic) for the R104.

The resistance between “MCP-F” and “MPC-B” (resistance of MCP stack and internal resistor)

should be in the range of 100 – 400 MΩ (the exact values are given in the specification sheet

of the detector). The resistance between “MCP-F” and “SIG” and“MPC-B” and “SIG” should be

unlimited.

13

MCPD18 R104

6 Microchannel Plate

6.1 Specifications

Please check the specification sheet of the MCPD for the exact MCP specification.

6. Storage

Because of their structure and the nature of the materials used in manufacture, care must be taken when

handling or operating MCPs. The following precautions are strongly recommended:

The most effective long-term storage environment for an MCP is an oil-free vacuum.

6.3 Handling

Shipping containers should be opened only under class 100 Laminar flow cleanroom conditions.

Personnel should always wear clean, talc-free, class 100 clean-room compatible, vinyl gloves when

handling MCPs. No physical object should come into contact with the active area of the wafer. The

MCP should be handled by its rims, there is no solid glass border! Use clean degassed tools

fabricated from stainless steel, Teflon™ or other ultra-high vacuum-compatible materials. Handling

MCPs should be limited to trained, experienced personnel.

MCPs without solid glass border should be handled very carefully with great care taken to contact

the outer edges of the plate only.

The MCP should be protected from exposure to particle contamination. Particles which become

affixed to the plate can be removed by using a very pure and low pressure air flow such as from a

clean rubber bellows.

The MCP should be mounted only in fixtures designed for this purpose. Careful note should be taken

of electrical potentials involved.

14

MCPD18 R104

Voltages must not be applied to the device while at atmospheric pressure. The pressure

should be 1E-6mbar or lower at the microchannel plate before applying voltage.

Otherwise, damaging ion feedback or electrical breakdown will occur.

6.4 Operation

A dry-pumped or well-trapped/diffusion-pumped operating environment is desirable. A poor vacuum

environment will most likely shorten MCP life or change MCP operating characteristics.

A pressure of 1E-6mbar or better is preferred. Higher pressure can result in high background noise

or even to damaging due to ion feedback or to an electrical breakdown.

Apply voltages as defined in chapter 4. If fluctuations appear, damage or contamination should be

suspected and the voltage should be turned off. The assembly should then be inspected before

proceeding.

Voltage across single MCPs should not exceed the maximum voltage given in P and in the

specification sheet of the detector. Higher potentials may result in irreversible damage.

MCPs can be degraded by exposure to various types of hydrocarbon materials which raise the work

function of the surface, causing gain degradation.

Operation at higher temperatures (> 50 °C) will cause gain degradation.

MCPs may degas for quite a while during operation. The pressure increase also depends on the

number of initial particles given to the MCP (e.g. pressure increase from 5E-10mbar up to 1E-8mbar

for a new chevron MCP stack). A degas procedure for MCPs is described in chapter 6.6.

6.5 MCP Lifetime and Operation Voltage

The lifetime of the MCPs is determined by the MCPs gain degradation over time, whereas the gain

degradation is a function of the extracted output charge. Therefore the lifetime of the MCPs strongly depends

on the count rate applied to the detector over time.

The typical gain degradation of a MCP is shown in Figure 5 as a function of extracted output charge in terms

of coulombs per square centimeter.

15

MCPD18 R104

Figure 5: Typical gain degradation of MCPs as function of the extracted output charge

After an initial burn-in period, in which the detector gain changes as a result of electron induced chemical

allocation together with degassing residual gas molecules from the inside of the channels, the MCP

performance is very stable over a large amount of extracted output charge. The MCP gain is also a function of

the detectors operation voltage. Therefore gain degradation can always be compensated by increasing the

detector voltage.

Detector delivery will still happen with the MCPs operating within the burn-in period, although the detector has

been operated for some longer time with highest count rates during the test phase, Therefore gain

degradation will be still significant in the first year of operation (or even longer, depending on applied count

rates) and becomes obvious by a decline of the detector performance. Therefore it will become necessary to

increase the operation voltage from time to time. Voltage increase should always be made in small steps

(typically 50 V). There is a recommended maximum operation voltage, to which the detector voltage can be

increased to compensate gain degradation over time. This voltage is given in the specification sheet of each

detector.

A typical behavior of the detector voltage increase over time to compensate gain degradation is given

schematically in Figure 6.

Figure 6: Schematic plot of increasing the operation voltage to compensate gain degradation over time

as function of the extracted charge (all values are only exemplary).

16

MCPD18 R104

It is not unusual that the operation voltage must be increased several times especially in the

first year of operation.

Typically, the final operation voltage at the end of the burn-in period will be close to the recommended

maximum operation voltage. An increase of the operation voltage above the recommended maximum

operation voltage is in principal possible and allowed, as long as there is no significant increase in the dark

count rate, bright spots at the detection area and/or appearance of high voltage sparking.

The operation voltage can be increased even above the recommended maximum operation

voltage. A safe and reliable operation will still be possible as long as there is no increase in

the dark count rate and/ or no appearance of high voltage sparking.

It can be sufficient to estimate the correct operation voltage by monitoring the detector results, when

increasing the voltage to compensate the gain degradation. The exact operation voltage can always be

determined by measuring a so called MCP curve. The MCP curve plots the detected count rate as a function

of the operation voltage. Do as follows to measure an MCP curve:

Start the detector operation with a homogeneous illumination (as good as possible).

Use an appropriate device to measure the count rate output of the detector.

Decrease the operation voltage until the count rate of the detector is reduced to zero.

Increase the operation voltage in steps of 50V until far above the last operation voltage (please

respect the recommended maximum operation voltage) or until the detector shows significant

artifacts. Measure the count rate for each voltage step.

Plot the measured count rate as a function of the operation voltage. This is the MCP curve. It should

show a change in the slope of the rising curve, which indicates the beginning of the area of operation.

The new value for the operation voltage should be a bit above the position of the change in the slope.

Figure 7 shows an example of a MCP curve with the specified operation voltage. The MCP curve for specifying

the starting operation voltage for a detector can always be found in the specification sheet.

Figure 7: Example of MCP curve (for illustration only).

The life time of MCPs can be very large, due to the high stability of the operation performance over a large

amount of extracted output charges after the burn-in period. The main reason for an often much shorter

17

MCPD18 R104

operation time of the MCPs is an inhomogeneous irradiation of the MCPs. This is connected to a locally

(strong) different gain degradation, which results in an inhomogeneous detector response. Locally different

gains can still be compensated by increasing the operation voltage, but very often the increasing voltage step

must be much larger to reach again a homogeneous detector response.

Gain degradation also depends strongly on the environment in which the MCPs are being operated. Care

should be taken to prevent exposure to high concentrations of hydrocarbons and halogens. Also prevent MCP

operation at higher temperatures (> 50°C, e.g. respect an appropriate cooling phase after bake out).

Strong inhomogeneous irradiation of the MCPs lead to strong locally different gain

degradation and to an inhomogeneous detector response, which is the main reason for a

shortened operation time of the MCPs.

6.6 MCP Degase Procedure

The effect of MCP outgasing can be reduced by running a degas procedure. To do so the detector must be

operated at a high count rate of several Mcps for a time period of about 8 hours.

It is really important that the detector is irradiated homogeneously over the complete

active area. Otherwise the MCPs will degenerate at various positions differently, which

will lead to an inhomogeneous flat field of the detector.

Operate the detector continuously. During the degas procedure the pressure increase should reduce

significantly to an acceptable pressure range. Then switch to the final application. The pressure increase for a

smaller count rate should now be much smaller. Unfortunately the degas procedure must be started anew

(to a certain extend) after each venting of the detector.

6.7 Replacement

Contact your provider before performing a replacement.

Please contact your provider before performing any MCP replacement. We will provide you with a detailed

step by step description.

Please take care to note the orientation of the MCPs. The channels in the MCPs include a certain angle

against the surface normal to the plate and the MCPs must be mounted in a chevron configuration. All

parts of the detector, especially the MCPs should be handled with great care. The MCP surfaces are very

sensitive and should never be touched or scratched.

18

MCPD18 R104

7 Technical Data

MCPD18 R104:

Active area: 18mm

Operation voltage at detector: see specification sheet

Voltage at MCP front: see specification sheet

HV connections: SHV connectors (MCP front, MCP back)

Connections for signal: 1 BNC connector (50Ohm matched coaxial signal)

Max. bake-out temperature: 150°C

Vacuum pressure range for operation: < 1E-6mbar

19

MCPD18 R104

8 List of Figure

Figure 1: Connection scheme of the MCPD18 R104..........................................................................................................................7

Figure : Schematic sketch on voltage ramping during “Start-Up” procedure.......................................................................9

Figure 3: Layout of the HV connections and photos of the single detector elements.....................................................1

Figure 4: Internal connection of the high voltage potentials (schematic) for the R104.................................................13

Figure 5: Typical gain degradation of MCPs as function of the extracted output charge..............................................16

Figure 6: Schematic plot of increasing the operation voltage to compensate gain degradation over time as

function of the extracted charge (all values are only exemplary)................................................................................................16

Figure 7: Example of MCP curve (for illustration only)......................................................................................................................17

0

Table of contents

Other Surface Concept Security Sensor manuals

Surface Concept

Surface Concept HVPS User manual

Surface Concept

Surface Concept CEM 4230 User manual

Surface Concept

Surface Concept DLD6060-8S User manual

Surface Concept

Surface Concept Delayline DLD 8080 User manual

Surface Concept

Surface Concept DLD4040 User manual

Surface Concept

Surface Concept MCPD40 User manual

Surface Concept

Surface Concept MCPD25 User manual

Surface Concept

Surface Concept Delayline DLD 8080 User manual