Table of contents

1. Safety instructions.......................................................................5

2. Application.................................................................................7

3. Features.....................................................................................7

4. Technical Data............................................................................8

4.1 General.................................................................................8

4.2 Electrical Data........................................................................8

4.3 Output-Signals.......................................................................8

4.4 Accuracy ..............................................................................9

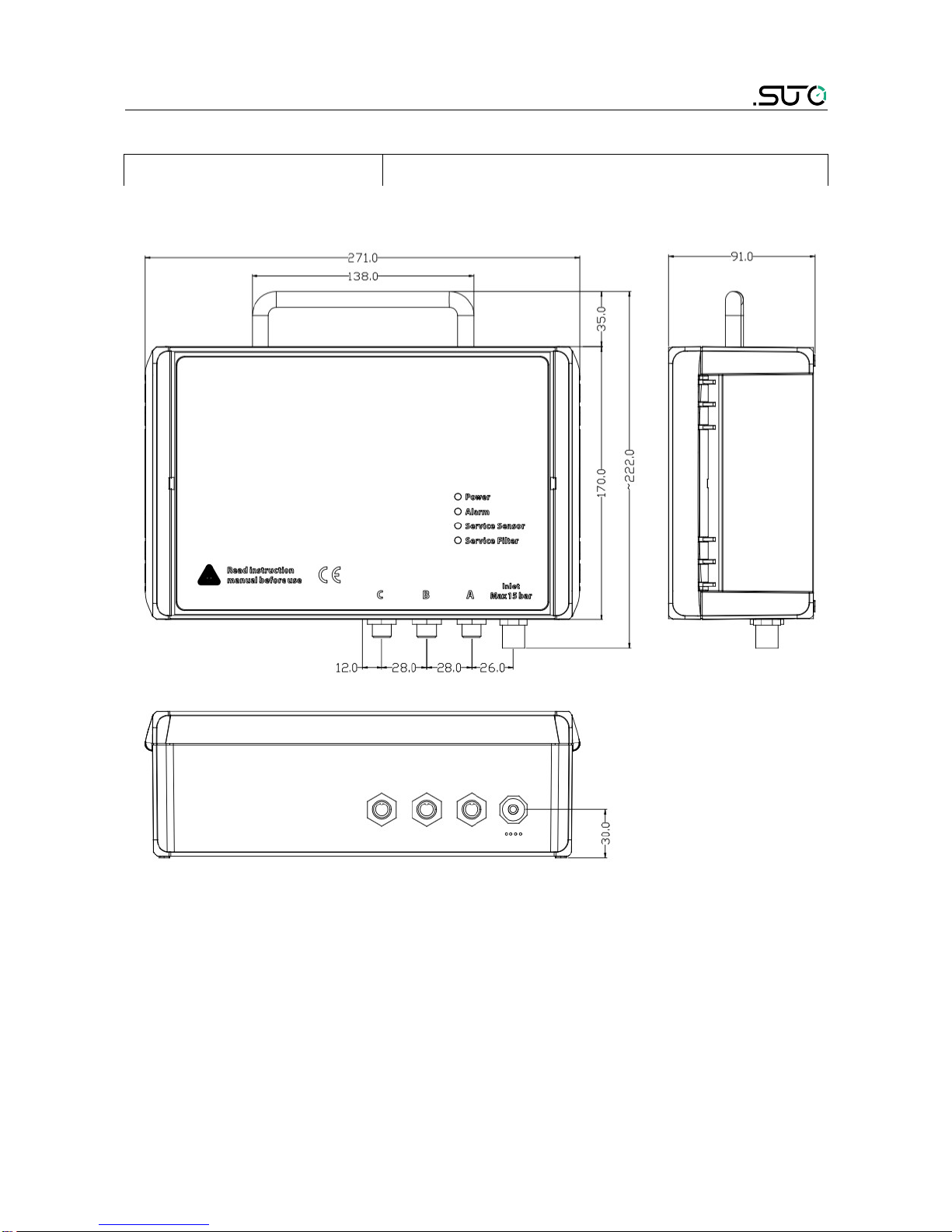

5. Dimensional drawing....................................................................9

6. Installation ..............................................................................10

6.1 Installation Requirements......................................................10

6.2 Wall mounting instructions ....................................................11

6.3 Installation Procedure............................................................12

6.4 Electrical connection ............................................................13

7. Configuration ...........................................................................14

7.1 Configuration without display ................................................15

7.2 Configuration with external display .........................................15

7.3 Configuration with internal display..........................................15

8. Operation with internal display ...................................................15

8.1 ser interface ......................................................................15

8.2 Main menu .........................................................................16

8.3 Description of display icons in status bar .................................17

8.4 Sensor settings ....................................................................17

8.4.1 Basic setting...................................................................18

8.4.2 Altitude settings .............................................................18

8.4.3 Analog output ................................................................18

8.4.4 Modbus settings..............................................................19

8.4.5 Alarm settings................................................................20

8.4.6 Status...........................................................................20

8.5. Logger................................................................................21

8.6 Files....................................................................................22

8.7 Service info .........................................................................22

8.8 System settings ...................................................................23

8.9 Communication ...................................................................23

9. LED indicators at front panel ......................................................24

9.1 S 120 error indications and display indications .........................24

10. Signal outputs.........................................................................25

10.1 Analog output ....................................................................25

10.2 Digital output ....................................................................25

10.3 Alarm output .....................................................................26

11. Optional extra accessories.........................................................27

S 120 3