1 Safety instructions

Table of contents

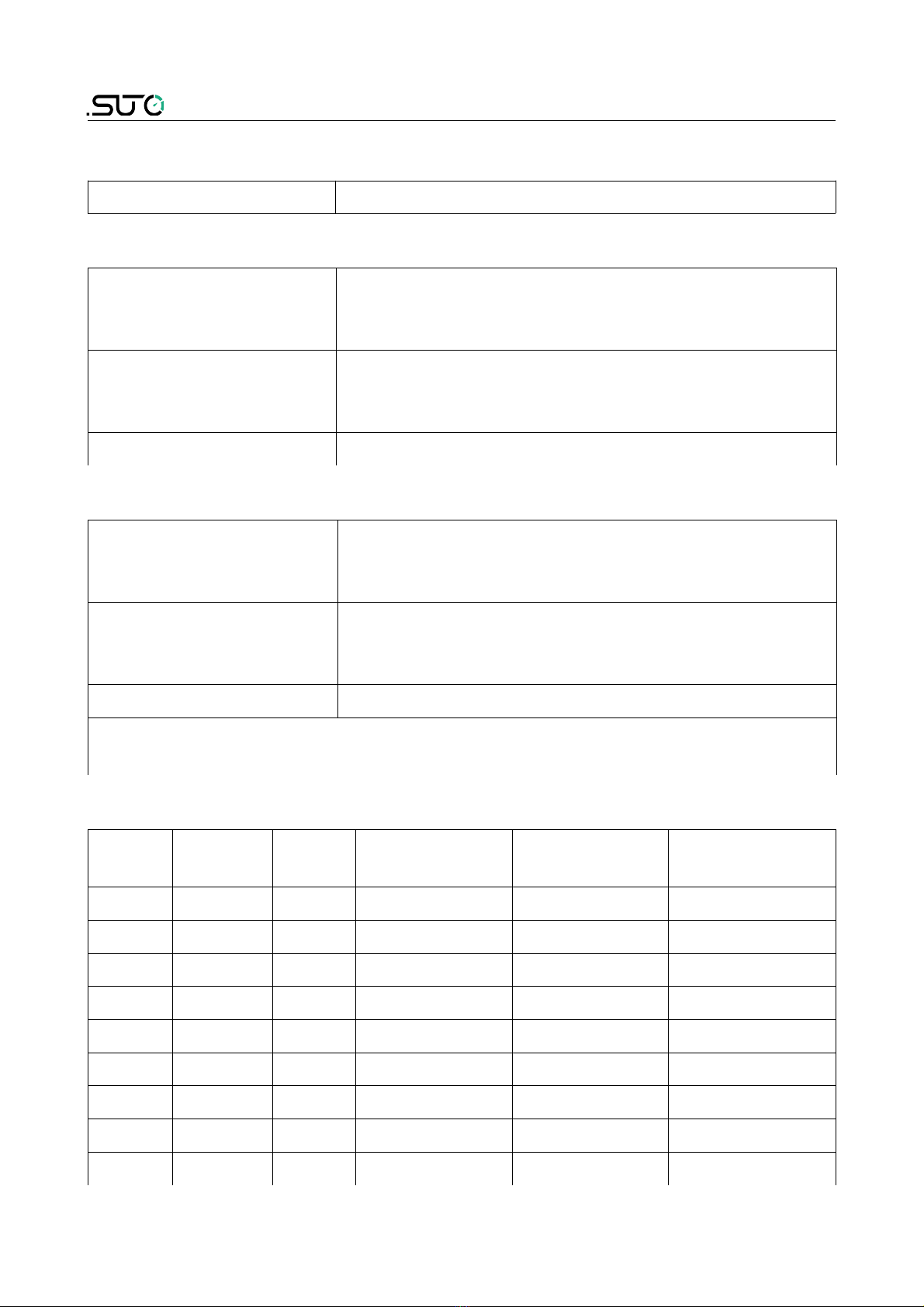

1 afety instructions........................................................................4

2 RF exposure information and statement..........................................7

3 Application..................................................................................8

4 Features......................................................................................8

5 Technical data..............................................................................9

5.1 General.................................................................................9

5.2 Electrical data......................................................................10

5.3 Output-signals......................................................................10

5.4 Accuracy .............................................................................10

5.5 Volumetric flow ranges..........................................................10

6 Dimensional drawing...................................................................12

7 Determining the installation point.................................................13

8 Reserving inlet and outlet sections................................................14

9 ensor installation .....................................................................16

9.1 Installation requirements.......................................................16

9.2 Installation procedure ...........................................................17

9.2.1 Calculating the installation depth...................................17

9.2.2 Installing the sensor.....................................................19

9.2.3 Removing the sensor....................................................20

9.3 Electrical connection..............................................................21

10 ensor signal outputs................................................................23

10.1 Analog output.....................................................................23

10.2 Pulse output.......................................................................23

10.2.1 Pulse connection diagram............................................25

10.3 Modbus output....................................................................26

11 ensor display (option)..............................................................27

11.1 tarting process..................................................................27

11.2 Configuration using the display.............................................28

12 ervice App 4C-F ..................................................................29

13 Calibration...............................................................................30

14 Maintenance.............................................................................30

15 Disposal or waste......................................................................30

16 Warranty.................................................................................30

17 Appendix A - Analogue output....................................................32

18 Appendix B - Modbus communication example..............................34

19 Appendix C - LRC and CRC calculation.........................................36

S401 3