Table of contents

1. Safety instructions.......................................................................5

2. Application.................................................................................7

3. Features.....................................................................................8

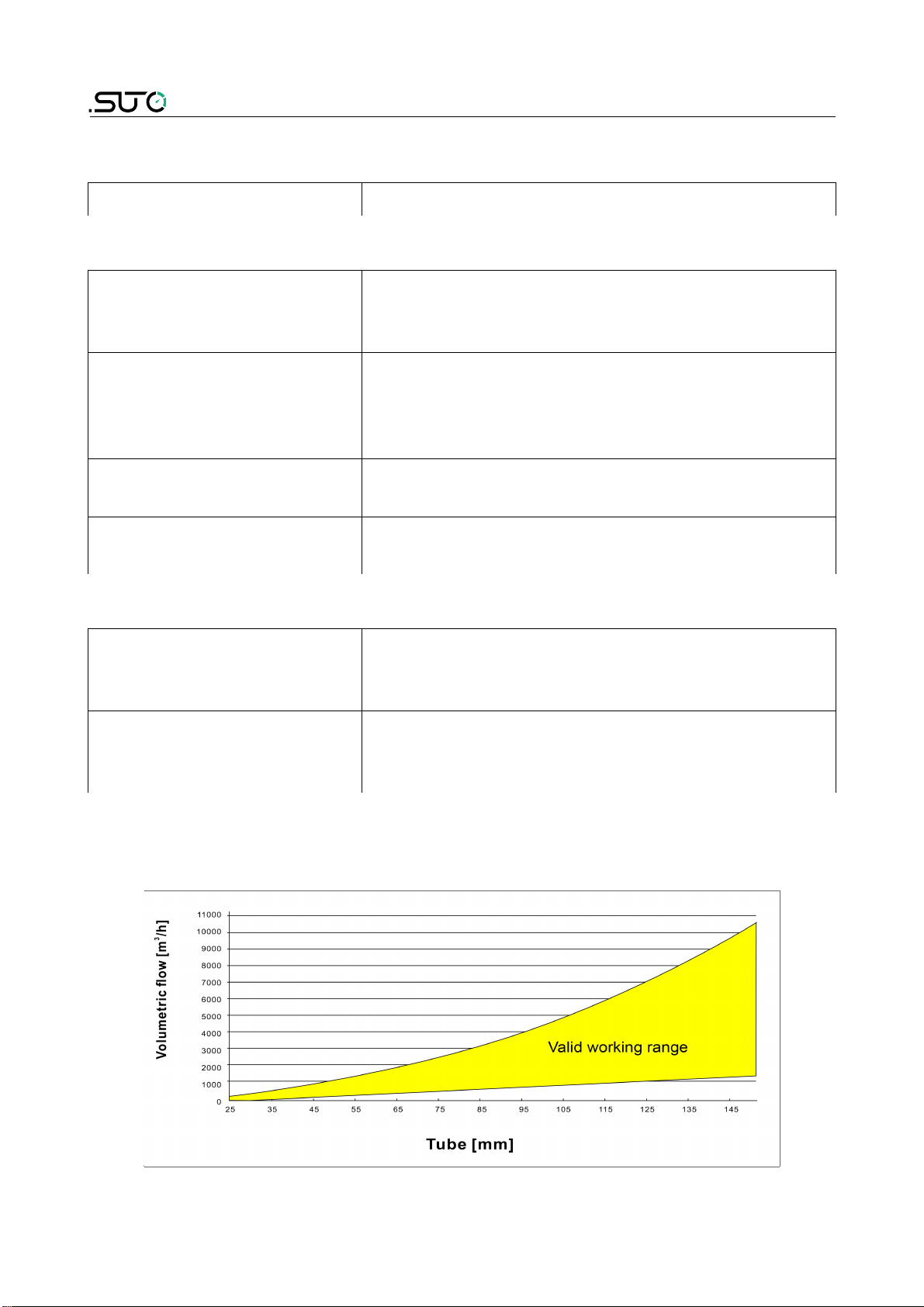

4. Technical Data............................................................................9

4.1 General.................................................................................9

4.2 Electrical Data......................................................................10

4.3 Output-Signals.....................................................................10

4.4 Accuracy .............................................................................10

5. Dimensional drawing..................................................................12

6. Installation...............................................................................13

6.1 Installation Requirements......................................................13

6.2 Determination of the installation point.....................................13

6.2.1 Inlet and outlet sections....................................................................14

6.2.2 Insertion angles...............................................................................15

6.3 Calculating the insertion depth...............................................16

6.3.1 Centre installation............................................................................16

6.3.2 Non-centre installation......................................................................17

6.4 Installation of the sensor ......................................................18

6.5 Performing the zero flow calibration........................................19

6.5.1 Prerequisites...................................................................................19

6.5.2 sing the service App S4C-FS............................................................19

6.5.3 sing the local display......................................................................21

6.6 Removing the sensor.............................................................21

6.7 Making electrical connection...................................................22

7. Configuration............................................................................23

7.1 Description of sensor settings.................................................23

7.1.1 Flow settings...................................................................................23

7.1.2 nit settings....................................................................................24

7.1.3 Reference conditions.........................................................................24

7.1.4 Factory settings...............................................................................24

7.1.5 Output settings................................................................................24

7.1.6 Language setting.............................................................................24

7.2 Configuration using the service App S4C-FS.............................25

7.3 Configuration using the optional sensor display.........................26

7.3.1 Starting process...............................................................................26

7.3.2 About the home page.......................................................................26

7.3.3 Configuration instructions..................................................................27

8. Sensor signal outputs.................................................................28

8.1 Analog output......................................................................28

8.2 Pulse output.........................................................................28

8.3 Pulse Connection Diagram......................................................30

8.4 Modbus output ....................................................................30

8.5 M-Bus output ......................................................................31

S430 3