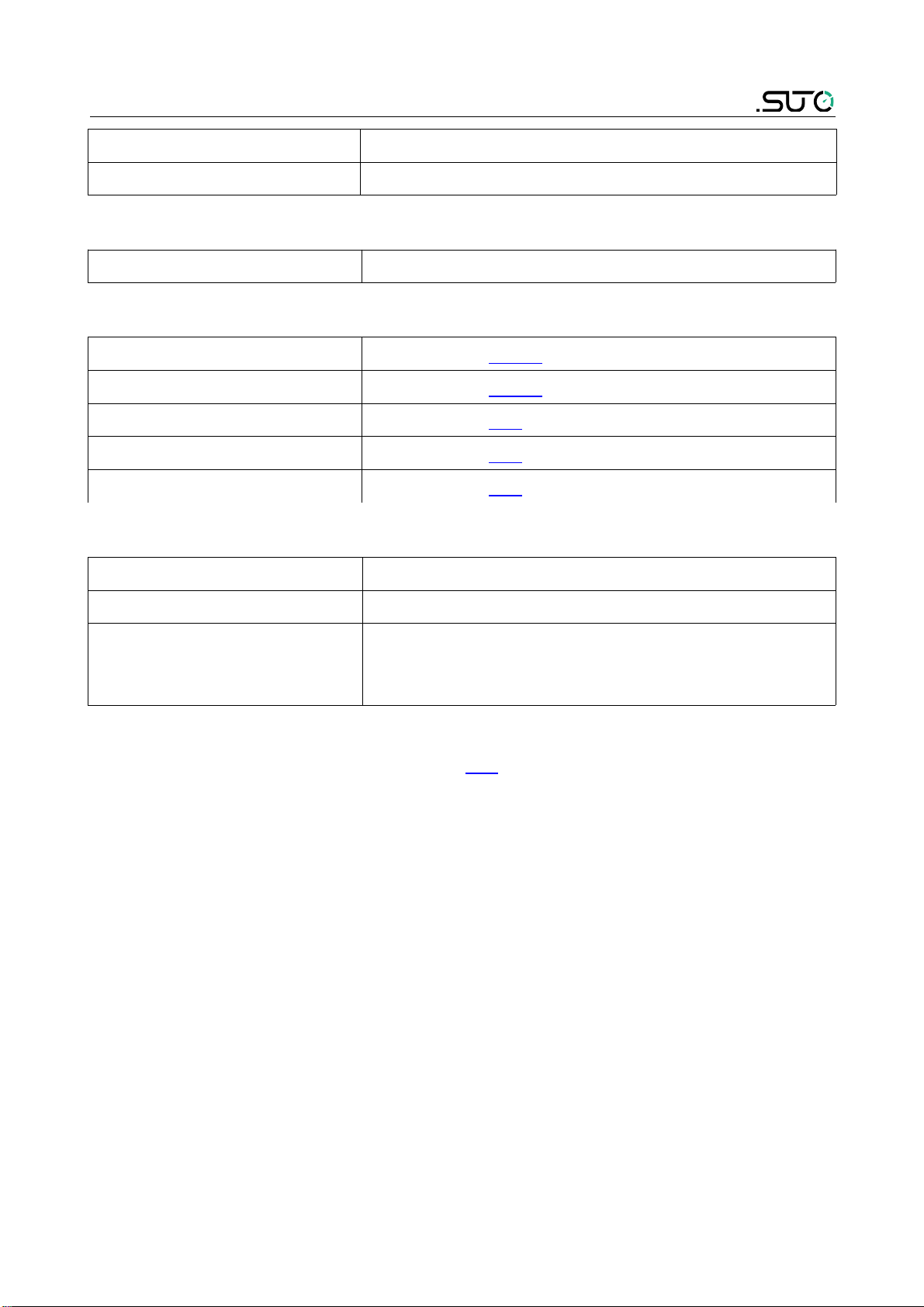

Table of Contents

1 Safety instructions......................................................................4

2 Registered trademarks.................................................................6

3 Application.................................................................................7

4 Features....................................................................................7

5 Technical data.............................................................................8

5.1 General................................................................................8

5.2 Electrical data.......................................................................9

5.3 Output signals......................................................................9

5.4 Accuracy .............................................................................9

5.5 Flow ranges..........................................................................9

6 Dimensional drawing..................................................................11

7 Determining the installation point................................................12

7.1 Inlet and outlet sections.......................................................13

8 Installation ..............................................................................15

8.1 Installation requirements......................................................15

8.2 Installation procedure .........................................................16

8.2.1 Determining the insertion depth of the sensor...................16

8.2.2 Installing the sensor......................................................17

8.2.3 Removing the sensor......................................................18

8.3 Electrical connection............................................................18

8.3.1 Connection diagram.......................................................19

8.3.2 Pin assignment..............................................................19

9 Signal outputs..........................................................................21

9.1 Analog and pulse outputs ....................................................21

9.1.1 Analog output...............................................................21

9.1.2 Pulse output..................................................................21

9.2 HART output ......................................................................23

9.3 Modbus output ...................................................................23

9.4 M-Bus output .....................................................................25

10 Configuration..........................................................................25

11 Optional accessories................................................................27

11.1 Sensor display...................................................................27

11.2 Service kit........................................................................27

12 Calibration..............................................................................28

13 Maintenance...........................................................................28

14 Disposal or waste....................................................................28

15 Appendi - Modbus communication e ample...............................29

S450 3