Introduction

0705 TTPM3 Printer/Encoder–Technical Manual 3

CONTENTS

1

Introduction...................................................................................................................5

1.1

Document printing ...........................................................................................5

1.2

Magnetic encoding ..........................................................................................5

1.3

Document handling .........................................................................................5

2

Installation.....................................................................................................................6

2.1

Installing a desktop printer ..............................................................................7

2.2

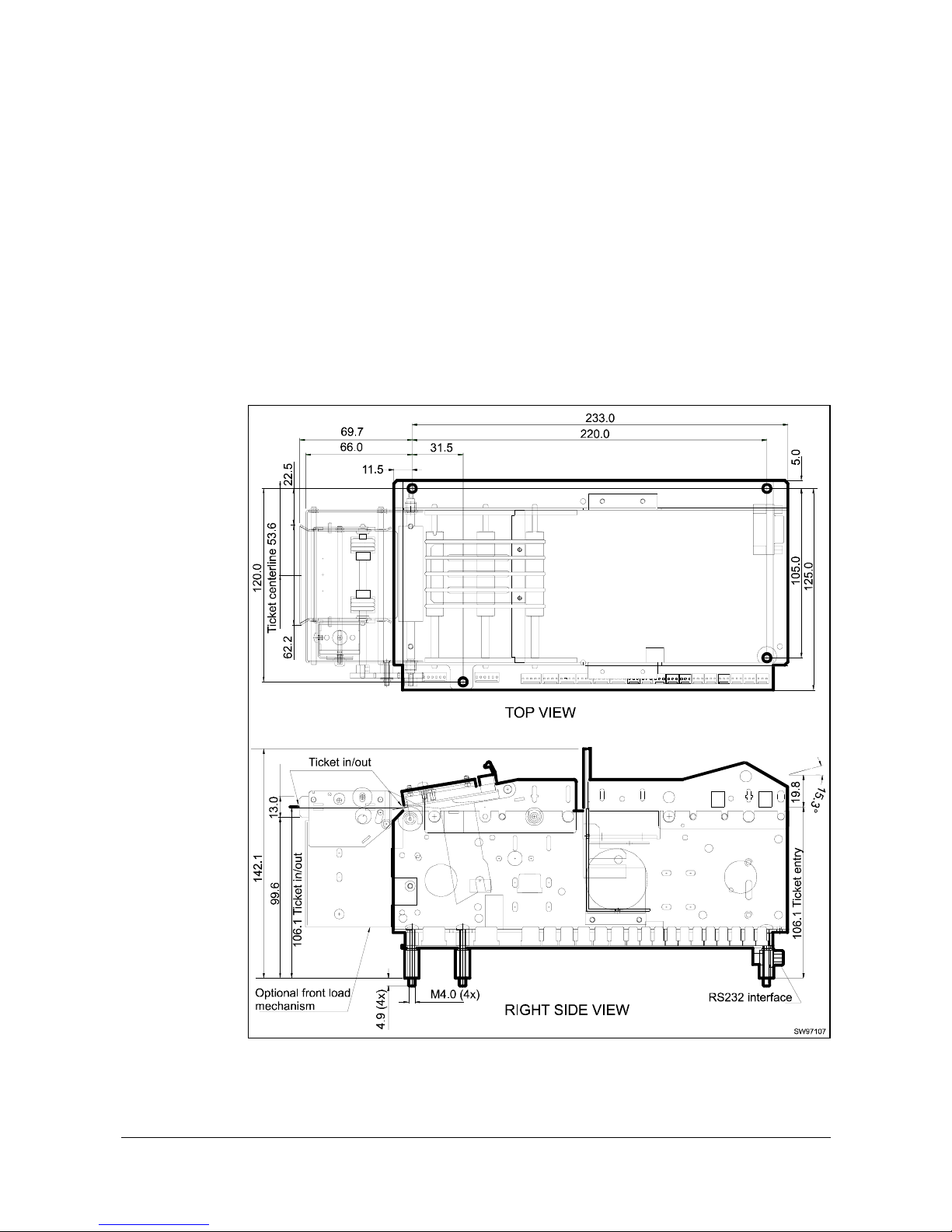

Installing an OEM printer mechanism ...........................................................10

3

Operation.....................................................................................................................12

3.1

Operator controls...........................................................................................12

3.2

Paper loading ................................................................................................12

3.3

Paper jam removal ........................................................................................14

3.4

Self test mode/ticket repeat mode.................................................................15

3.5

Error handling................................................................................................15

3.6

Single-ticket handling ....................................................................................16

4

Programming ..............................................................................................................20

4.1

Syntax............................................................................................................20

4.2

Initialization after power OFF ........................................................................20

4.3

Printing and encoding capability overview ....................................................21

4.4

How the commands are described................................................................24

4.5

Summary of commands ................................................................................25

4.6

Command Reference ....................................................................................27

5

Ticket Examples..........................................................................................................52

Text attributes..........................................................................................................55

6

Default parameter settings ........................................................................................56

6.1

How the parameters are described...............................................................56

6.2

Summary of parameter settings ....................................................................57

6.3

Parameter Reference....................................................................................59

7

Error codes and Status reporting .............................................................................65

7.1

Status ............................................................................................................65

7.2

Security additions..........................................................................................65

7.3

Errors.............................................................................................................66

7.4

Extended acknowledgement .........................................................................67

8

Maintenance ................................................................................................................68

8.1

Fault finding...................................................................................................68

8.2

Cleaning the print head .................................................................................69