CONTENTS

1INTRODUCTION .............................................................................................5

1.1 About this manual............................................................................................5

1.2 Updating ..........................................................................................................5

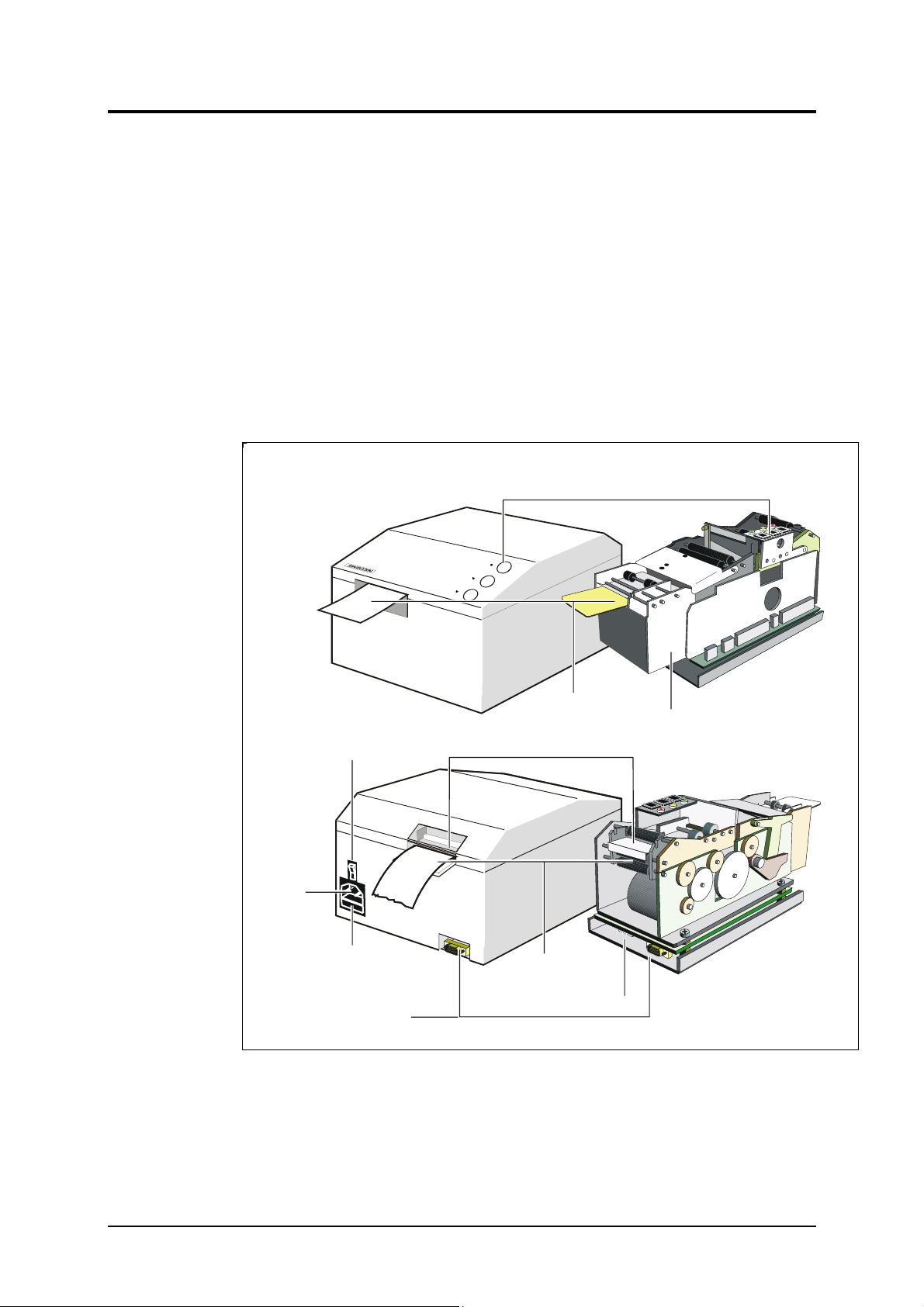

2PRODUCT PRESENTATION .........................................................................6

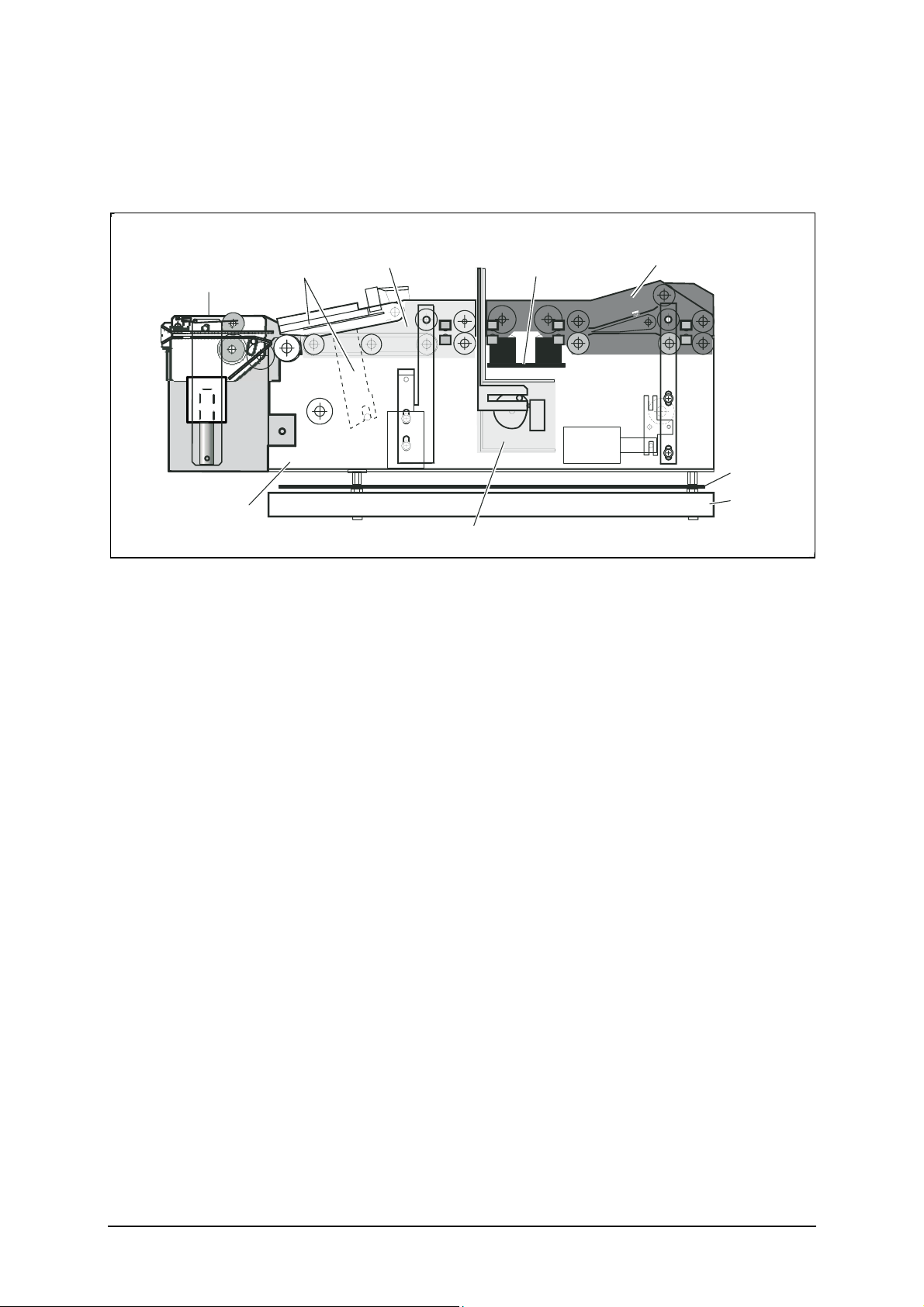

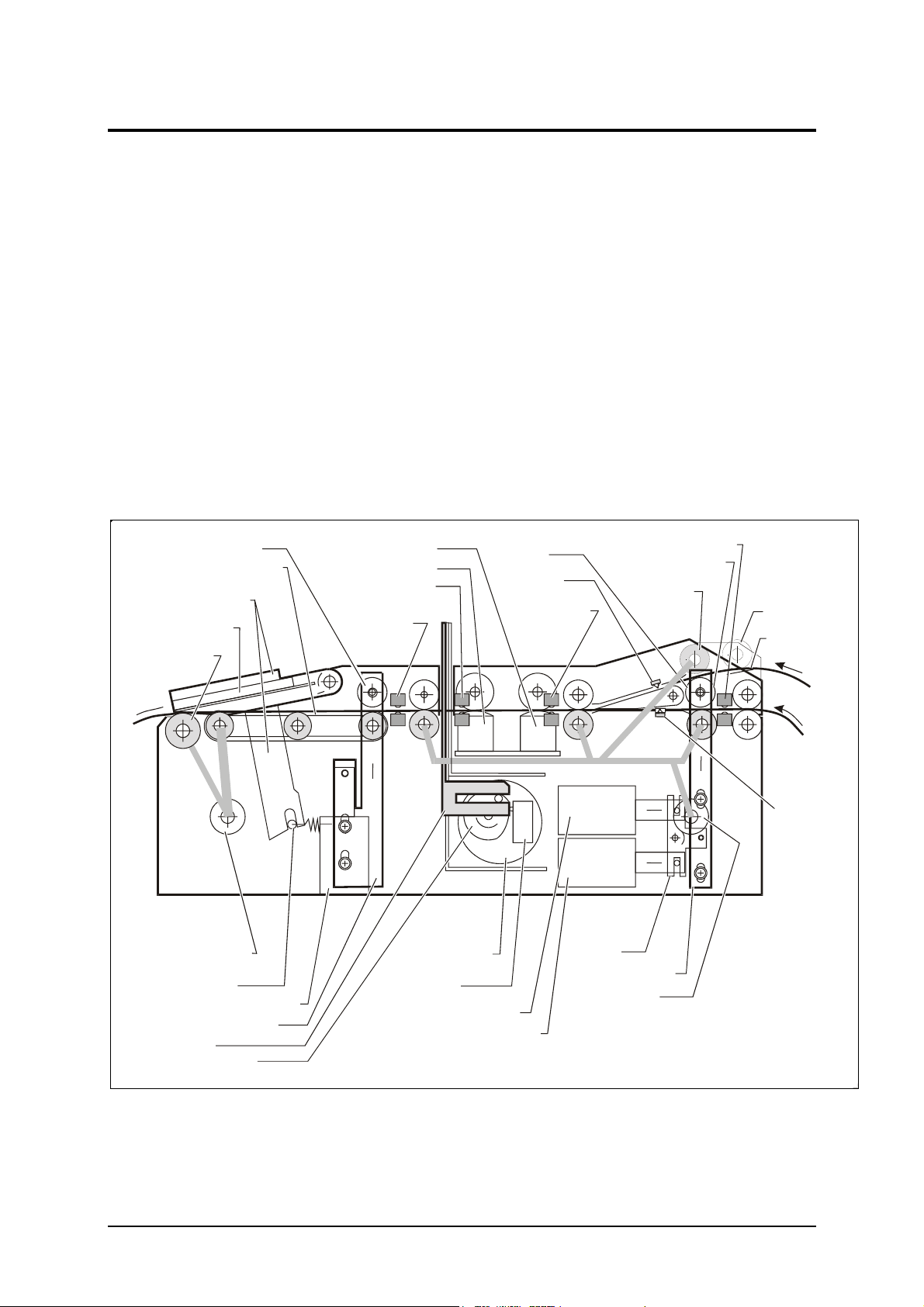

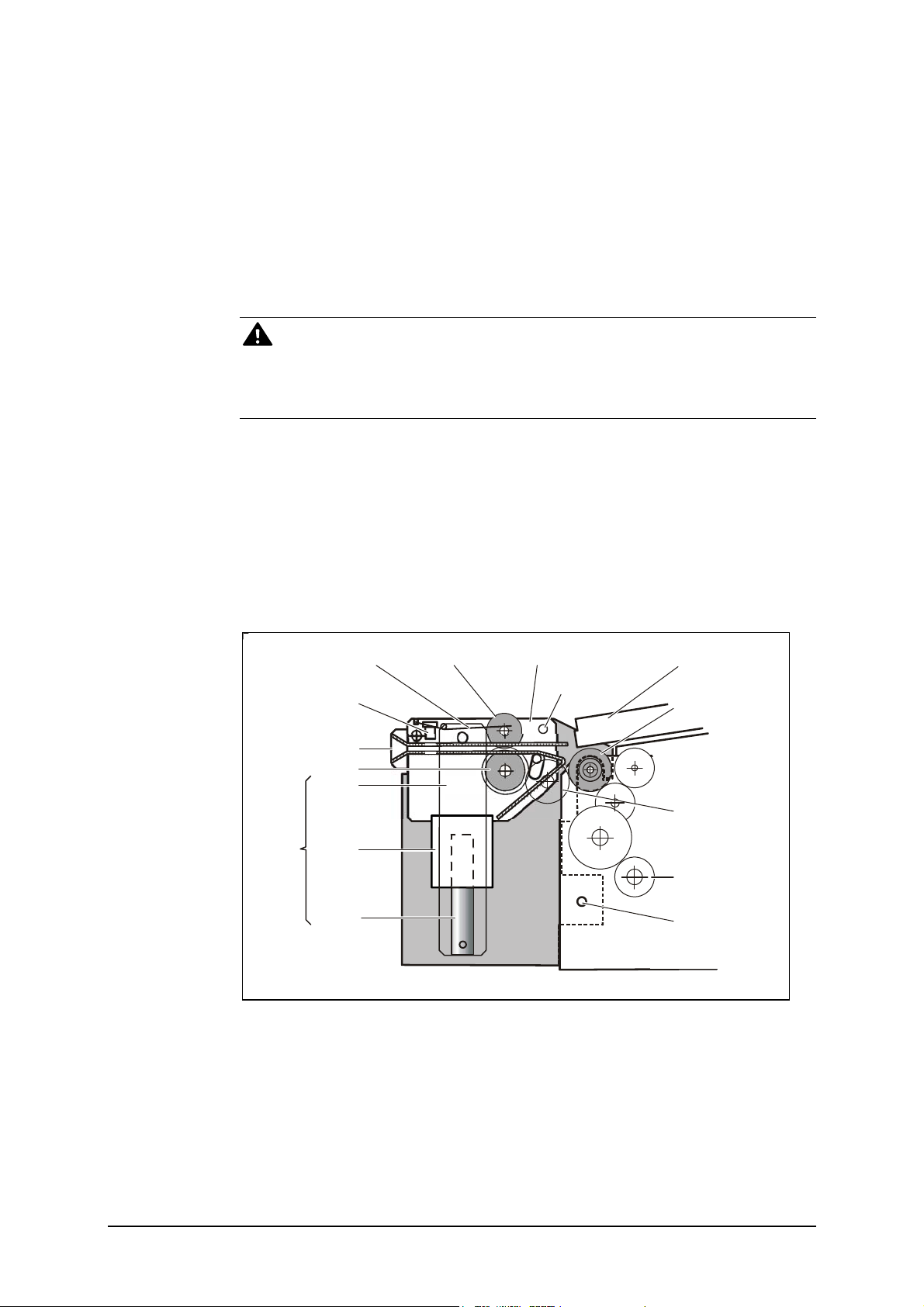

3FUNCTIONAL DESCRIPTION .......................................................................8

3.1 Standard TTPM2 model ..................................................................................8

3.2 Front Load 1, 2, and 3 .................................................................................. 10

3.3 TTPM2 with card dispenser.......................................................................... 16

3.4 Control board................................................................................................ 18

4MAINTENANCE ........................................................................................... 22

4.1 Preventive maintenance............................................................................... 22

4.2 Fault finding .................................................................................................. 24

4.3 Service checklist TTPM2 .............................................................................. 26

4.4 Parts removal and replacement ................................................................... 27

5ADJUSTMENTS........................................................................................... 33

5.1 Preparation ................................................................................................... 33

5.2 Ticket path adjustment ................................................................................. 34

5.3 Magnetic head pressure rollers adjustment ................................................. 37

5.4 Solenoids...................................................................................................... 38

5.5 Printers with front load.................................................................................. 40

5.6 Card dispenser ............................................................................................. 41

6REPLACEMENT PARTS............................................................................. 43

6.2 OEM version, final assembly........................................................................ 48

6.3 Card dispenser (CD200) version, final assembly......................................... 50

6.4 Basic module ................................................................................................ 52

6.5 Basic module, from autumn 2003................................................................. 60

6.6 Input module with one fanfold, and one single-ticket entry .......................... 64

6.7 Input module with two entries for fanfold ticket stock................................... 68

6.8 Presenter module, standard ......................................................................... 72

6.9 Presenter module, front load ........................................................................ 74

6.10 Printhead module assembly ......................................................................... 76

6.11 Cutter module ............................................................................................... 78

6.12 Front load 1 and 2 module ........................................................................... 80

6.13 Front load 3 module...................................................................................... 82

6.14 Card dispenser ............................................................................................. 84

September, 03 TTPM2 - Service Manual 3